Against the backdrop of rapid global industrial transformation, liquid nitrogen is becoming increasingly important, especially in emerging markets such as Brazil, where it is becoming a key resource for a number of core industries. From food cold chain, biomedical to high-end manufacturing, liquid nitrogen is not only a means of cryogenic treatment, but also a hidden driving force for industrial modernization. In this article, we will focus on the role of liquid nitrogen in Brazil, analyze its industrial distribution, cost challenges and supply chain issues, and help readers fully grasp the real status and future direction of the Brazilian liquid nitrogen market.

So, in what areas is liquid nitrogen widely used in Brazil? Liquid nitrogen plays an indispensable role in agricultural preservation, medical refrigeration, scientific research and industrial processing. At the same time, Brazil faces many bottlenecks in obtaining and stabilizing the supply of liquid nitrogen due to long logistical distances, unbalanced infrastructure and limited refrigeration resources. Especially for small and medium-sized enterprises (SMEs), the uncertainty in the price of liquid nitrogen and the uncontrollable supply cycle have a serious impact on their business expansion and cost forecasting.

With these questions in mind, this article will take a chapter-by-chapter look at: who uses liquid nitrogen? Why is it expensive? Where is the difficulty? Is it worth building your own system? If you are in the agriculture, healthcare or manufacturing industry and are facing a dilemma with your nitrogen source usage, what follows may provide a more certain path to a solution.

1. What Is Liquid Nitrogen and Why It Matters

1.1 Understanding Liquid Nitrogen: Composition and Physical Traits

Liquid nitrogen is nitrogen in a liquid state at an extremely low temperature of -196°C. At this point, it becomes a colorless, odorless, non-flammable cryogenic fluid, with inert properties that make it suitable for sensitive applications.

Unlike other refrigerants, liquid nitrogen does not pose a risk of explosion or contamination. It is non-toxic and evaporates into nitrogen gas—a harmless component of the atmosphere—making it one of the safest substances in cryogenic technology.

However, due to its ultra-low temperature, storage must be handled with care:

Only Dewar flasks, vacuum-insulated tanks, or special cryogenic vessels can contain it safely.

Improper containers can cause severe frostbite, material embrittlement, or pressure buildup.

1.2 Why Liquid Nitrogen Matters: Key Benefits & Practical Impact

1.2.1 Ultra-Fast Freezing and Preservation

Liquid nitrogen enables rapid freezing, which is critical in:

Medical field: Preserving organs, blood, and vaccines.

Food industry: Flash-freezing fruits, seafood, and ready-to-eat meals without altering texture or flavor.

Agriculture: Long-term storage of seeds, embryos, and genetic samples.

✅ In Brazil, rapid freezing is essential due to the tropical climate, helping prevent spoilage in rural regions far from processing hubs.

1.2.2 Compact Storage of Large Volumes of Gas

One liter of liquid nitrogen expands to about 700 liters of nitrogen gas. This allows:

Efficient storage without needing heavy gas cylinders.

On-demand vaporization for industries that need dry nitrogen gas but lack space or infrastructure.

This is especially helpful for remote agricultural facilities, field hospitals, and research stations across Brazil where refilling gas cylinders regularly is logistically complex and expensive.

1.2.3 Precision Under Extreme Conditions

Liquid nitrogen plays a unique role in high-tech applications:

Medical cryosurgery: Safely destroys abnormal tissues (e.g., warts, tumors) without cutting.

Electronics and metalwork: Used to shrink-fit metal parts or reduce thermal noise during tests.

Scientific research: Enables ultra-low temperature physics experiments and superconductivity trials.

In Brazil’s industrial zones, this enables more cost-efficient prototyping and material treatment without expensive imports.

1.3 Key Insight: Why Self-Production Matters

Due to Brazil’s vast territory, inconsistent cold chain infrastructure, and rising import costs, relying on externally sourced liquid nitrogen is both expensive and unsustainable. Owning an on-site liquid nitrogen generator becomes a cost-saving and scalable solution, especially for:

Mid-to-large medical centers

Agricultural biotech firms

Cryo-storage providers

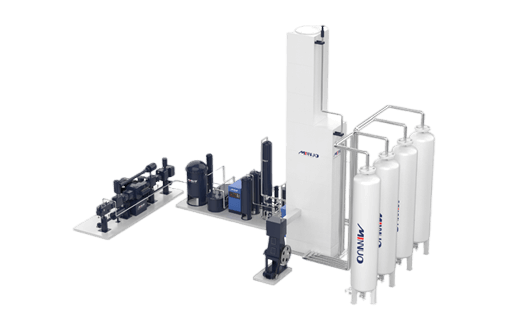

By choosing MINNUO’s liquid nitrogen generators, companies gain:

Autonomy in supply

Reduced long-term cost

Potential to become local suppliers for smaller clients

2. Top 5 Industries in Brazil Using Liquid Nitrogen

Liquid Nitrogen is not only a “freezing tool” in Brazil’s top 5 industries, it is also an important safeguard to improve process precision, reduce operational risks and extend product life cycle. The following is an exploration of the underlying logic behind these industries, taking into account their actual pain points.

2.1 Medical & Cryogenics

Core applications: tissue sample preservation, vaccine logistics, frozen embryo management

In the Brazilian healthcare system, liquid nitrogen is bringing about far-reaching changes in the following scenarios:

Vaccine and biological samples transportation across state lines: to solve the challenges of cold chain caused by the difference in climate between the north and the south, liquid nitrogen can maintain the temperature of -196°C, which is suitable for the unstable region of the vaccine cold chain. The cold chain for vaccines is unstable.

Expanded use of cryotherapy: Liquid nitrogen cryopreservation, for example, for removing skin lesions, is gradually becoming more common in public hospitals, reducing the trauma of traditional treatments.

Assisted reproduction safety: Brazil’s assisted reproduction market is growing rapidly, and liquid nitrogen is used to freeze embryos and sperm, which significantly improves the success rate of preservation and the probability of pregnancy.

✅ Liquid Nitrogen technology allows cold chain transportation without relying on expensive compression refrigeration equipment, improving the resilience of the healthcare system.

2.2 Food Processing & Preservation

Core applications: meat freezing, MAP air-conditioning preservation, cold chain breakpoint protection

Food safety has been the focus of public opinion in Brazil’s agricultural powerhouse, and liquid nitrogen empowers the following key links:

Instant quick-freezing and locking of freshness: the use of liquid nitrogen spray freezing of chicken, beef, seafood, etc., to solve the problem of slow speed and quality decline of traditional mechanical freezing. Liquid nitrogen can help to solve the problems of slow freezing speed and declining quality of traditional mechanical freezing.

High-end MAP packaging (gas-conditioned packaging) synergistic application: liquid nitrogen is used for oxygen drainage and nitrogen filling to enhance the shelf life, especially for export-type chilled products.

Emergency program for broken chain: In case of sudden power failure or cold chain failure, liquid nitrogen can be used as a temporary cold source to reduce the cargo loss rate.

✅ Liquid nitrogen freezing shelf life is up to 95% or more, suitable for large-scale export processing factories and retailers’ transit warehouses.

2.3 Agriculture & Livestock

Core applications: semen freezing, sample preservation, animal breeding support

Liquid nitrogen is becoming a bridge between scientific research and practice in livestock breeding upgrading and disease research:

Frozen bovine, sheep and swine semen: to improve the conception success rate and standardize the seed source across the country, and to reduce the pressure of regional transportation of breeding cattle.

Epidemic sample preservation: In animal disease outbreak monitoring, liquid nitrogen can preserve tissue samples and serum to ensure accurate testing.

Frozen embryo export: with the transportation of liquid nitrogen tanks, Brazilian high-quality breeding cattle embryos have been exported to Argentina, Chile and other countries.

✅ Liquid nitrogen helps livestock genetic improvement programs to land, and strengthens Brazil’s voice in the South American breeding market.

2.4 Industrial Manufacturing

Core applications: precision metal treatment, parts cleaning, heat treatment cooling

The Brazilian manufacturing industry’s requirements for parts stability and machining accuracy are rising, and liquid nitrogen is breaking through the boundaries of the traditional process:

Deep-cooling heat treatment: applied to aerospace parts, mold steel, high-strength bearings, etc., to improve the wear resistance and stability of the material.

Stainless steel de-stressing treatment: prevent deformation after welding, enhance life span, suitable for export-oriented mechanical product manufacturers.

Precision Cleaning: Liquid nitrogen can replace the traditional solvent cleaning method, no corrosion and no residue on sensitive equipment such as semiconductors and circuit boards.

✅ Cost reduction and efficiency, liquid nitrogen-assisted process often reduces product defective rate by more than 20%.

2.5 Education and Scientific Research

Core applications: deep-cooling experiments, materials performance research, engineering limit testing

In university labs and national research institutes, liquid nitrogen is a key tool for breaking through experimental limits:

Chemical low-temperature reaction carrier: promoting research breakthroughs in high-temperature superconducting materials, nanostructures and so on.

Engineering fatigue testing: testing the properties of metals or composites at very low temperatures, simulating extreme conditions such as Antarctica and the deep sea.

Liquid nitrogen supply chain for scientific research: some universities and corporate laboratories are building small liquid nitrogen sites to realize low-cost and stable supply.

✅ The frequency of liquid nitrogen scientific research use has risen significantly, reflecting its strategic position in the field of new materials research.

3. How Brazil’s geography complicates liquid nitrogen distribution

3.1 Vast terrain + tropical climate → increased transportation complexity

Brazil’s vast size and year-round high temperatures and high evaporation pose a serious challenge to cryogenic logistics. Liquid Nitrogen (LIN) requires a constant low temperature environment and specialized vacuum insulated containers. In a country where town centers are hundreds or even thousands of kilometers apart, it is virtually impossible to transport goods over long distances without advanced cold chain infrastructure to avoid evaporation.

Challenge: Tropical climate accelerates evaporation of LIN.

Implications: Need for high-cost Dewar’s bottles or ISO canisters, frequent refilling, and technical training at each node.

3.2 Uneven development → unstable supply chain

While urban areas such as São Paulo or Rio de Janeiro can ensure consistent delivery of LIN, many remote areas in the Amazon, Northeast and Midwest lack infrastructure and supplier networks. The poor quality of roads, scarcity of local distributors and lack of technical services lead to delays and even severe shortages.

In key industries such as veterinary clinics, artificial insemination centers or regional laboratories, “supply cuts” are not uncommon, often resulting in costly emergency airlifts or service suspensions.

3.3 High Transportation Costs + Distribution Dependence → High End-User Prices

Inland transportation in Brazil is predominantly by road, and roads in remote areas are often unpaved or poorly maintained. Combined with the rising price of diesel fuel, transportation costs for cryogenic materials can account for more than 40% of the final price of a LIN in some regions.

Even in large cities, the cost of LIN fluctuates due to centralized production over long distances. Most suppliers only offer bulk distribution to fixed hubs, which creates difficulties for users with irregular or urgent needs.

✅ Strategic solution: Decentralized production with on-site LIN generators

Many advanced users in the agricultural, pharmaceutical and industrial testing sectors are no longer relying on unstable supply chains and are turning to in-house liquid nitrogen production systems. By installing LIN generators:

users avoid heat loss and delivery delays.

Long-term costs are significantly reduced after the initial capital outlay.

Can be supplied to other local companies, creating a new revenue stream or ecosystem.

Example: A poultry farm in the province of Goiás installed MINNUO’s integrated LIN generator. Within six months, they reduced their nitrogen-related logistics costs by 55% and began selling excess LIN to neighboring clinics.

4. Why Relying on Liquid Nitrogen Supply Is No Longer Sustainable

As the application of liquid nitrogen becomes more and more widespread in healthcare, food, agriculture, livestock and industry, many companies are beginning to reflect on the question of whether long-term reliance on traditional liquid nitrogen supply systems is really sustainable. Here is an in-depth analysis from three levels:

❌ Escalating Risks: Challenges Facing the Traditional Liquid Nitrogen Supply Chain

High Transportation Costs: Brazil is a vast country and liquid nitrogen needs to be transported by cryogenic tanker trucks, which pushes up the cost of the transportation radius, and may not be able to cover the remote areas.

Frequent fluctuations in supply and demand: once the upstream gas source is tense or there are problems in transportation (e.g. strikes, road conditions, fuel fluctuations), downstream customers are often faced with “temporary supply cuts”, which affects normal production.

Relying on bottled liquid nitrogen poses safety risks: Repeated replacement of cylinders or frequent transportation of liquid nitrogen storage tanks increases operational difficulties and personnel safety risks, especially in medical, agricultural and animal husbandry scenarios.

Shifting Trends: From “Passive Purchasing” to “Active Nitrogen Generation”

Many local Brazilian companies are turning to on-site nitrogen generation solutions, where nitrogen is obtained directly through membrane separation or PSA technology, stored and used on-demand. Many local Brazilian companies are turning to On-site Nitrogen Generation to obtain nitrogen directly through membrane separation or PSA technology, store it and use it on demand.

In-house systems not only eliminate transportation and price fluctuations, but also provide the flexibility to control the flow and purity of nitrogen for different applications (e.g., food grade, industrial grade).

Some small and medium-sized food processing plants and bovine embryo freezing laboratories in Brazil have begun to use compact nitrogen generation equipment to replace liquid nitrogen storage and transportation modes.

✅ Cost control and long-term benefits at the same time

Shortened payback cycle: at the current average market price of liquid nitrogen in Brazil, self-built nitrogen systems can generally pay for themselves in 18-30 months, saving 20%-40% of operating expenses in the long run.

Strong adaptability of energy structure: low electricity prices or solar energy resources in some areas can further reduce the operating costs of nitrogen production.

Ready-to-use, environmental protection and carbon reduction: Reduce the loss of liquid nitrogen volatilization in the transportation process, taking into account the carbon emission control and sustainable development goals.

Practical Suggestions for Enterprises

For high-frequency nitrogen enterprises, it is recommended to evaluate whether to switch from the following dimensions:

Monthly liquid nitrogen usage > 5000L;

The distance between the place of use and the supply station is more than 100km;

There are clear requirements on the purity and stability of the nitrogen gas (e.g., medical-grade, refrigeration-grade);

There are energy-saving and emission reduction targets in the annual budget.

5.A Smarter Way Forward: Produce Your Own Liquid Nitrogen

As the cost of nitrogen continues to rise, more companies are turning to self-built liquid nitrogen systems to get rid of their dependence on external supply. MINNUO provides efficient, safe and energy-saving liquid nitrogen solutions to bring you a truly controllable future:

✔ On-demand production, zero transportation cost

Nitrogen is produced and liquefied on-site through the integrated equipment, no need for transportation, storage and replenishment, so it can be truly “ready to use and ready to produce”.

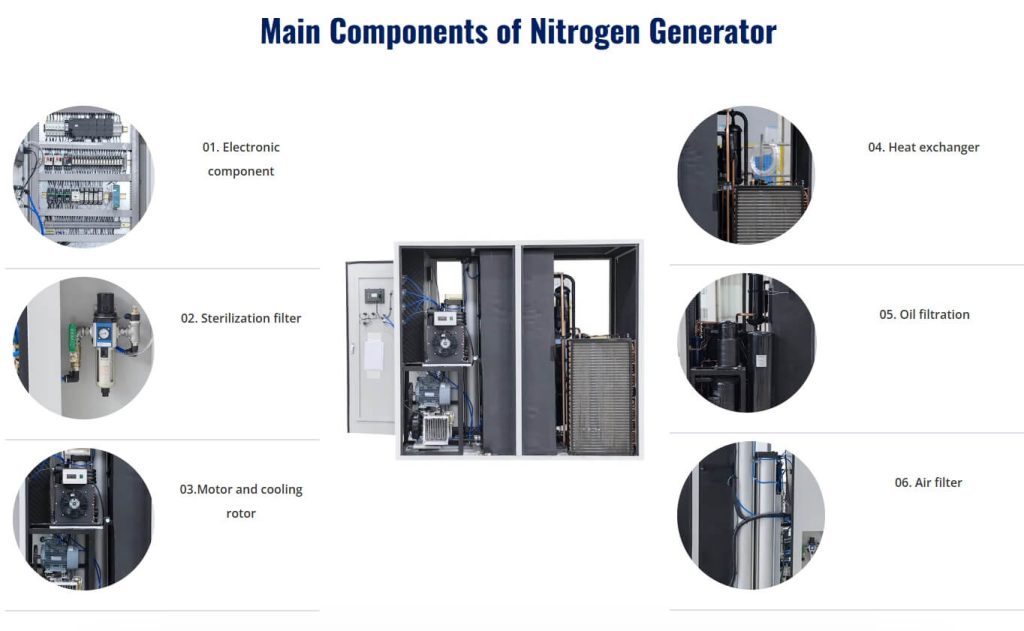

✔ Energy-saving operation, intelligent management

The equipment adopts advanced energy-saving compression technology, with PLC control system, realizing 24-hour stable operation and remote monitoring, reducing labor cost.

✔ High purity output, adapting to a variety of industries

can stably output ≥99.9% purity of liquid nitrogen, which is widely used in high standard scenarios such as medical storage samples, experimental analysis, electronic cooling, food quick-freezing and so on.

✔ Fast cost recovery, 3-18 months can pay back

Compared with the traditional purchase mode, the equipment investment recovery cycle is short, and can save more than 60% of nitrogen cost in the long term.

✔ Cope with the risk, from “wait” to “control”

Say goodbye to the situation of passive waiting due to the interruption of logistics and price increase of liquid nitrogen, and build an independent and stable nitrogen source system for enterprises, which is a strategic choice.

Conclusion

The demand for liquid nitrogen in Brazil continues to grow, with industrial upgrading, agricultural cold chain, medical research and other sectors driving this trend. However, high purchasing costs and limited distribution networks have left many companies in a situation of “high demand but no control”.

That’s why building your own liquid nitrogen system is becoming a newly recognized strategic path. It is not only a means of cost control, but also a key step in controlling the stability of the nitrogen source.

In this market context, the choice of integrated equipment with efficient nitrogen production, automatic liquefaction and remote monitoring capabilities will help enterprises to get rid of dependence and seize the first opportunity.

If you’re facing an unstable supply of liquid nitrogen, uncontrollable prices and limited growth, perhaps it’s time to consider a more proactive solution.

MINNUO liquid nitrogen systems can help you move from “passive waiting” to “self-sufficient control”.

sales2:+86 17506119168

sales2:+86 17506119168