On offshore platforms and FPSOs, nitrogen is far more than a utility gas; it is a critical safety barrier for process integrity, explosion prevention, and production continuity.

The following is an objective and transparent analysis of Membrane Nitrogen Generator design requirements, tailored for Project Managers and Procurement Decision-Makers. We will explore how to balance harsh environment adaptability, spatial constraints, and Total Cost of Ownership (TCO) to help mitigate decision risks and calculate real ROI. This content is based on industry standards (e.g., API, DNV) and years of field engineering experience.

1. What is an Offshore Membrane Nitrogen System?

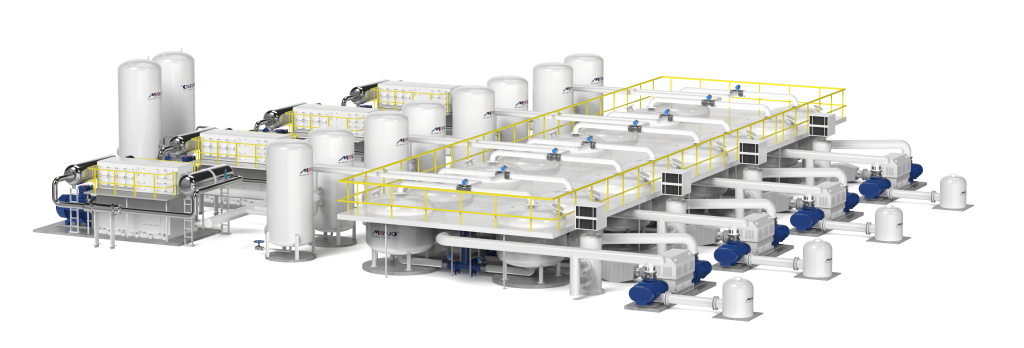

Core Definition: An offshore membrane nitrogen system uses Hollow Fiber Membrane technology to separate oxygen and water vapor from compressed air based on differential permeation rates, generating high-purity nitrogen on-site.

For offshore applications, it is not merely a gas separation device but a skid-mounted system integrated to Marine Grade standards. Unlike onshore systems, the design core focuses on “compactness” and “extreme environmental resilience.”

2. Key Design Requirements: Environmental Adaptability & Safety

Offshore environments demand that designs go far beyond standard industrial grades:

A. Hazardous Area Classification

Due to the presence of flammable gases, electrical and instrumentation design is paramount.

- Zone 1 & Zone 2 Certification: All electrical components (PLCs, solenoid valves, sensors) must comply with ATEX or IECEx standards.

- Enclosure Protection: Control panels typically require Ex d (Flameproof) or Ex p (Pressurized) protection.

B. Corrosion Control & Material Selection

High salt spray and humidity require maximum corrosion resistance.

- Piping & Valves: Must be SS316L stainless steel; carbon steel or standard copper alloys are strictly prohibited.

- Coating Standards: Structural steel skids must meet NORSOK M-501 System 1 or equivalent marine heavy-duty anti-corrosion standards.

- Ingress Protection: Electrical cabinets must be at least IP66.

C. Classification Society Certification

Depending on the project location, systems usually require Third-Party certification or Type Approval from bodies such as:

- DNV (Det Norske Veritas)

- ABS (American Bureau of Shipping)

- BV (Bureau Veritas)

3. Performance & Process Parameters

Design requirements depend on the nitrogen purity, flow rate, and pressure dew point required by the specific process. These parameters directly impact CAPEX (number of membrane modules) and OPEX (compressed air consumption):

- Nitrogen Purity: * 95% – 99.9% (Typical range).

- Note: 95% is used for general purging; 97–99% for chemical blanketing; 99.9% for sensitive instrumentation or completion fluids. Higher purity increases the Air/N2 Ratio, leading to higher energy consumption.

- Outlet Pressure: Typically 7 – 12 bar (g). High-pressure injection (e.g., 300 bar) requires a downstream booster.

- Pressure Dew Point (PDP): Must be lower than the minimum ambient temperature, usually designed for -40°C to -60°C to prevent line freezing.

4. Mechanical & Structural Design: Space Optimization

Deck space and weight capacity on offshore platforms are extremely expensive.

- Compact Skid-Mounted Design: Vertical layouts are preferred over horizontal ones to minimize the footprint.

- Vibration Resistance: Membrane modules and piping must have specialized anti-vibration supports to handle platform resonance and sea-state-induced swaying.

- Lifting Frame: Skids must comply with DNV 2.7-1 or DNV 2.7-3 lifting standards, equipped with certified pad eyes.

- Maintenance Access: Despite the compact footprint, space (usually 600-800mm on at least one side) must be reserved for filter element and membrane tube replacement.

5. The Core Protective Barrier: Air Pre-treatment

Expert Tip: 90% of membrane system failures stem from improper pre-treatment. Membrane fibers are extremely sensitive to oil; once contaminated, separation efficiency drops irreversibly.

Standard Pre-treatment Sequence:

- Water Separator: Removes bulk liquid water.

- Multi-stage Coalescing Filters: * Stage 1: Removes particles > 1 micron.

- Stage 2: Removes oil aerosols > 0.01 micron.

- Activated Carbon Tower: Adsorbs oil vapors, ensuring residual oil < 0.003 mg/m³.

- Dust Filter: Catches activated carbon fines.

- Process Heater: Vital for offshore use. It heats air to the optimal temperature (40-50°C) to ensure no liquid water enters the membrane and maintains peak permeation efficiency.

6. Technical Comparison: Why Membrane?

| Dimension | Membrane | PSA (Pressure Swing Adsorption) | Liquid N2 / Cylinders |

|---|---|---|---|

| Moving Parts | Minimal (Valves only) | Many (Switching valves) | None (But requires logistics) |

| Vibration Resistance | Excellent | Weak (Adsorbent may powder) | Moderate |

| Footprint | Smallest | Medium | Large (Tank storage needed) |

| Maintenance | Low (Filter changes) | Medium (Valves, Molecular Sieve) | High (Logistics are costly) |

| Start-up Speed | Fast (Minutes) | Slow (Pressure cycling) | Instant |

| Dew Point Control | Excellent (Built-in) | Good | Excellent |

Conclusion: For offshore applications requiring purity up to 99.9%, Membrane technology is usually the highest ROI choice due to its lack of moving parts, vibration resistance, and compact size.

7. FAQ

Q1: What is the typical lifespan of a membrane in offshore conditions?

A: With proper pre-treatment (regular filter changes), high-quality membrane modules typically last 8 to 10 years. Failure is usually a gradual decline in flow rather than a sudden breakdown.

Q2: Can the system be installed on an open deck?

A: Yes, but it must be rated IP66. A rain/sun shield is highly recommended to prevent membrane overheating from direct sunlight or heavy rain ingress into electrical components.

Q3: How does inlet temperature affect performance?

A: As temperature rises, nitrogen production increases, but purity decreases (or more air is required). Heater control is therefore critical for maintaining stable output despite the large day-to-night temperature swings at sea.

Conclusion

Designing an offshore membrane nitrogen system is about more than choosing a model—it is an exercise in safety, corrosion resistance, and spatial efficiency. Overlooking a DNV detail or a pre-treatment step can lead to astronomical downtime costs.

If you are planning a new offshore project or upgrading an existing nitrogen package, I recommend starting with a Site Condition Audit, specifically to verify the actual quality of your compressed air source and available pressure.

sales2:+86 17506119168

sales2:+86 17506119168