In stainless steel production workshops, the moment a high-temperature burned steel billet comes into contact with air, its surface will quickly oxidize and form mottled rust without effective protection. This not only affects the product’s finish but also significantly reduces the material’s mechanical properties. As the core source of inert protective gas, nitrogen runs through the entire industrial chain of stainless steel smelting, rolling, heat treatment, welding, and other links. Its purity, stability, and supply cost directly determine the production efficiency of enterprises. Jiangsu Minnuo Group has specialized in PSA pressure swing adsorption nitrogen generation technology for more than ten years, breaking the limitations of traditional nitrogen supply models with customized solutions and becoming a core partner for stainless steel enterprises to improve quality and efficiency.

I. The “Nitrogen Necessity” in Stainless Steel Production: Full-Process Protection from Smelting to Finished Products

Stainless steel has corrosion resistance due to its alloying elements such as chromium and nickel, but these elements are prone to react with oxygen in the air during high-temperature processing, forming oxide scales or causing component segregation. As an “invisible protective layer,” nitrogen plays an irreplaceable role in various key processes.

In the smelting process, AOD refining furnaces need to be injected with nitrogen for decarburization and chromium preservation. At this time, the nitrogen purity must reach more than 99.5%. By precisely adjusting the flow rate and pressure, it can not only quickly reduce the carbon content of the molten steel but also avoid the oxidative loss of chromium elements. Data from a large stainless steel enterprise shows that the refining process protected by qualified nitrogen can increase the chromium recovery rate by 3-5 percentage points and reduce the cost per ton of steel by nearly 100 yuan.

Rolling and heat treatment are key processes determining the surface quality of stainless steel. During bright annealing of cold-rolled stainless steel plates, it must be carried out in a nitrogen-protective atmosphere. The purity must be ≥99.9% to effectively prevent surface oxidation and discoloration, ensuring the finished product presents a mirror-like luster. For gas nitriding treatment of high-end stainless steel molds, the nitrogen purity is even required to reach 99.999%, and the moisture dew point must be strictly controlled at ≤-60℃; otherwise, the uniformity of the nitrided layer will be affected, leading to insufficient mold hardness. Jiangsu Minnuo PSA nitrogen generator can achieve precise control of purity from 99.5% to 99.999% according to process requirements, fully covering the heat treatment requirements of the entire stainless steel series.

In the welding process, the protective effect of nitrogen is directly related to the weld strength. When welding stainless steel pipes, not only the front side needs a nitrogen-argon mixed shielding gas (nitrogen accounts for 20%-50%), but also the back side needs to be purged with nitrogen to replace air, reducing the oxygen content to below 0.5% to prevent the formation of Cr₂O₃ oxide scales on the inner wall, which may cause corrosion hazards. The multi-point gas distribution system supporting Minnuo nitrogen generator can realize simultaneous gas supply for multiple stations, with pressure fluctuation controlled within ±0.02MPa, ensuring the weld qualification rate is stably above 99%.

II. The Dilemma of Traditional Nitrogen Supply: Dual Anxiety of Cost and Quality for Stainless Steel Enterprises

For a long time, most stainless steel enterprises have relied on liquid nitrogen or high-pressure steel cylinders for nitrogen supply. This model has gradually exposed many shortcomings in actual production, becoming a bottleneck restricting the development of the industry.

The hidden costs of liquid nitrogen supply are often overlooked. The price of purchased liquid nitrogen is about 1.7-2.0 yuan/Nm³, and transportation costs and storage losses must be borne—even for storage tanks with the best thermal insulation performance, the daily natural evaporation loss is 0.1%-0.5%. A stainless steel enterprise with an annual output of 50,000 tons has a daily nitrogen consumption of 300Nm³, and the annual expenditure on liquid nitrogen exceeds 2 million yuan. More critically, there is the issue of supply stability: transportation disruptions due to extreme weather and insufficient production capacity of suppliers occur from time to time. Once the nitrogen supply is interrupted, all stainless steel workpieces in the annealing furnace will be scrapped, with a single loss of up to hundreds of thousands of yuan.

High-pressure steel cylinders have dual hazards of safety and efficiency. Steel cylinders need to be replaced frequently, which not only occupies a lot of labor but also increases the difficulty of workshop safety management due to their high-pressure characteristics. Moreover, the nitrogen purity in steel cylinders fluctuates greatly, often leading to “blossoming” defects on the stainless steel surface due to excessive impurities, with a rework rate of more than 15%. A stainless steel product factory once had to rework a batch of stainless steel pipes for export medical devices due to excessive oxygen content in the nitrogen from steel cylinders, resulting in a direct loss of more than 800,000 yuan and the loss of important orders.

The core contradiction of the traditional nitrogen supply model is the inability to balance quality stability and cost controllability. As the stainless steel industry enters a stage of high-quality development and puts forward higher requirements for the accuracy and continuity of nitrogen supply, on-site nitrogen generation has become an inevitable choice.

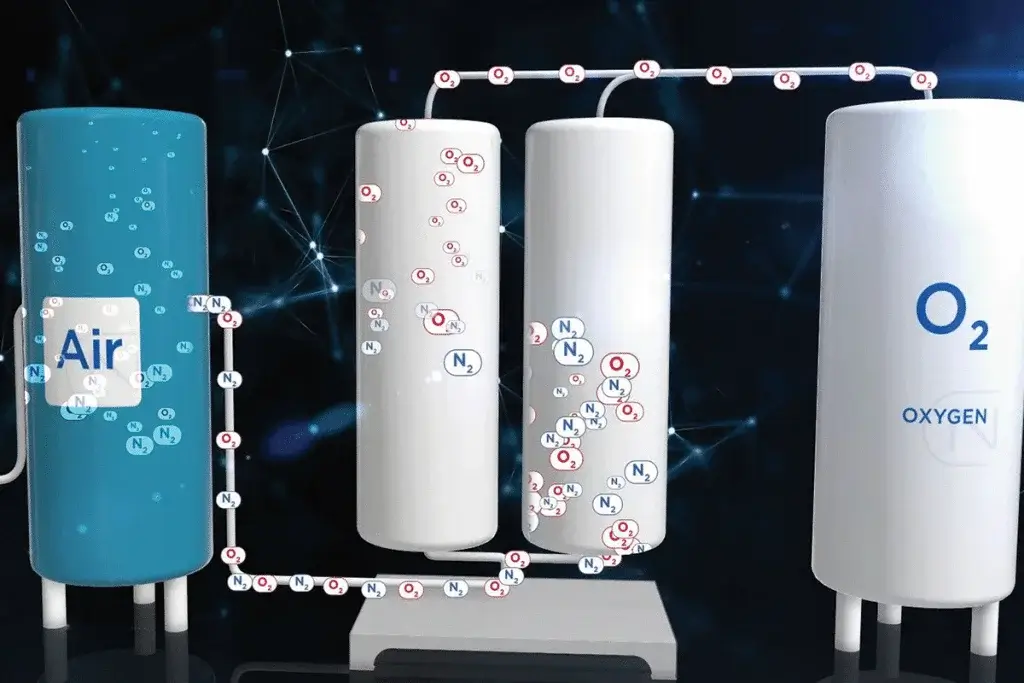

III. Minnuo PSA Nitrogen Generator: The Core Technical Solution to Solve Industry Pain Points

As a leading enterprise in the field of PSA nitrogen generation, Jiangsu Minnuo Group has created special nitrogen generation equipment suitable for the stainless steel industry relying on independently developed “high-efficiency carbon molecular sieve adsorption system” and “intelligent control system,” fundamentally solving the problems of traditional nitrogen supply.

The core advantage of the equipment lies in precise adaptability. Minnuo’s engineering team will customize solutions according to the enterprise’s production capacity and process type: for the welding and ordinary annealing needs of small and medium-sized stainless steel product factories, it launches economical equipment with a gas production capacity of 10-50Nm³/h, with purity stable at 99.5%-99.9% and initial investment of only 100,000-300,000 yuan; for large stainless steel smelting enterprises, it provides large-scale units with a gas production capacity of more than 200Nm³/h, which can realize 99.999% ultra-high purity nitrogen supply. The supporting adsorption dryer makes the nitrogen dew point as low as -70℃, meeting the requirements of precision nitriding processes. All core components of the equipment are made of 304/316L stainless steel, which is corrosion-resistant and oxidation-resistant, and the service life of the equipment is extended by more than 30% compared with the industry average.

The reduction in operating costs is particularly significant. The energy consumption of Minnuo PSA nitrogen generator is only 0.2-0.4kWh/Nm³. Calculated at the industrial electricity price of 0.7 yuan/kWh, the nitrogen generation cost is about 0.14-0.28 yuan/Nm³, which is only 1/10-1/5 of the liquid nitrogen cost. The aforementioned stainless steel enterprise with an annual output of 50,000 tons reduced its annual gas cost to less than 300,000 yuan after switching to Minnuo nitrogen generator, with an investment payback period of only 8-12 months. In addition, the equipment adopts twin-tower alternating adsorption technology, which can produce gas within 3-5 minutes after startup and operate continuously for 24 hours without interruption, completely eliminating the risk of supply interruption.

The intelligent operation and maintenance system further enhances the equipment value. Minnuo PSA nitrogen generator is equipped with a PLC control system and on-line monitoring module as standard, which can display parameters such as purity, flow rate, and pressure in real time. When the purity fluctuation exceeds ±0.1%, it will automatically alarm and adjust. Through the 4G remote monitoring function, Minnuo engineers can realize remote diagnosis and maintenance, controlling the equipment failure rate below 0.5%. A customer feedback that the equipment has only undergone regular filter replacement in the three years of operation, and the maintenance cost is less than 3% of the equipment investment.

IV. Case Witnesses Strength: The Practical Results of Minnuo Nitrogen Generator

In the production workshop of a precision stainless steel strip enterprise in Jiangsu, two Minnuo PSA nitrogen generators are running stably. The enterprise previously used liquid nitrogen for nitrogen supply, and the unstable purity led to frequent surface color difference problems of the strip after annealing, with a customer complaint rate of up to 8%. After introducing Minnuo’s customized system in 2023, according to the needs of its 20 bright annealing furnaces, two sets of nitrogen generation units with a gas production capacity of 150Nm³/h were configured, with purity stable at 99.95% and dew point controlled at -65℃.

Since the equipment has been in operation for more than a year, the surface oxidation defect rate of the strip has dropped from 5% to 0.3%, the number of customer complaints has decreased by 90%, and the processing profit per ton of strip has increased by 120 yuan. Financial data shows that the annual gas cost has dropped from 1.8 million yuan to 220,000 yuan, and the rework cost has been saved by about 1.5 million yuan. The person in charge of the enterprise said: “Minnuo nitrogen generator not only solved our quality pain points but also brought tangible cost advantages, making us more competitive in the high-end stainless steel strip market.”

Another case comes from a stainless steel pipe manufacturing enterprise in Zhejiang. The enterprise mainly produces food-grade stainless steel pipes and has strict requirements for welding quality. After adopting the back purging nitrogen system supporting Minnuo PSA nitrogen generator, the formation rate of weld oxide scales is almost zero, and the pass rate of pipe corrosion resistance test has increased from 85% to 100%. With stable product quality, the enterprise has successfully entered the nuclear power engineering supply chain, and the order volume has increased by 40% year-on-year.

V. More Than Equipment: Minnuo’s Full-Cycle Service Guarantee

Jiangsu Minnuo Group deeply understands that the production continuity of stainless steel enterprises is crucial, so it has established a full-cycle service system covering “consultation – design – installation – operation and maintenance.” In the early stage of the project, the engineering team will conduct in-depth on-site surveys of the workshop and issue personalized solutions combined with process drawings and production capacity planning; during the installation stage, modular construction is adopted to minimize the impact on production, and the installation cycle of conventional projects does not exceed 7 days; during the operation and maintenance stage, 2-hour quick response and 24-hour on-site service are provided, and equipment health files are established to conduct regular on-site inspections and performance optimization.

In response to the high-temperature and high-humidity production environment of the stainless steel industry, Minnuo also launched a “five-year extended warranty service,” covering the replacement of core components and system upgrades, relieving enterprises of worries. At present, Minnuo PSA nitrogen generators have served more than 300 stainless steel enterprises nationwide, with an equipment stable operation rate of 99.8% and a customer repurchase rate of over 60%.

Conclusion: Nitrogen Empowers the High-Quality Development of the Stainless Steel Industry

As a basic material for high-end manufacturing, the quality upgrading of stainless steel is inseparable from the innovation of core production factors. With technological innovation as the engine, Jiangsu Minnuo Group uses PSA nitrogen generators to break the constraints of traditional nitrogen supply models, providing stainless steel enterprises with nitrogen solutions featuring “controllable quality, optimized costs, and stable supply.”

Under the strategic guidance of “Made in China 2025,” the stainless steel industry is accelerating its transformation towards high-end and refined development. Minnuo Group will continue to specialize in PSA nitrogen generation technology, continuously optimize equipment performance and service systems, and work with stainless steel enterprises across the country to escort quality upgrading with high-quality nitrogen and jointly write a new chapter in the high-quality development of China’s stainless steel industry.

sales2:+86 17506119168

sales2:+86 17506119168