The defining operational challenge for nitrogen-dependent plants is shifting. It’s no longer just about maintaining purity or managing energy costs—though these remain critical. The emerging imperative is eliminating the business risk of unplanned downtime.

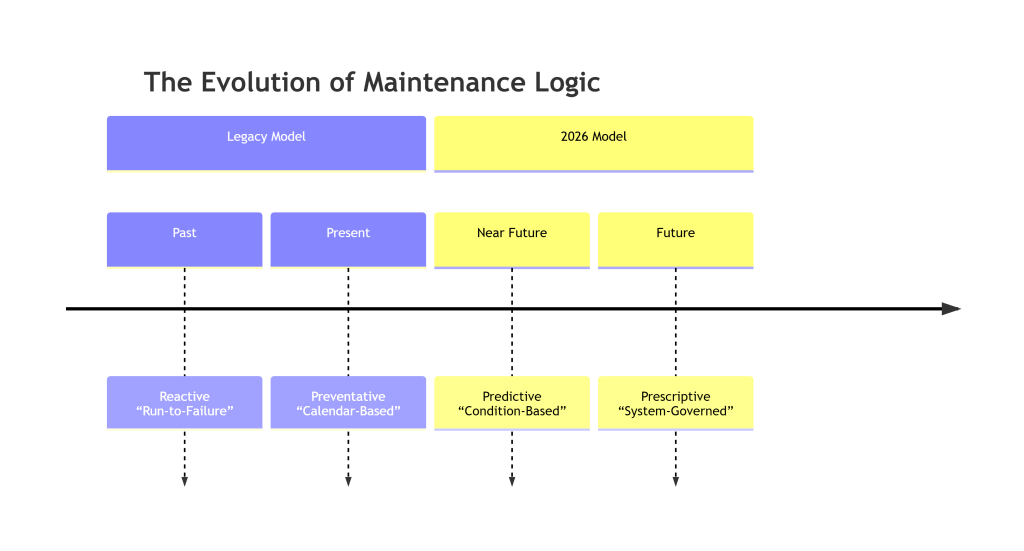

For decades, the solution has been the preventative maintenance (PM) calendar: change the filters every X hours, inspect the valves every Y months, replace the sieve every Z years. This calendar-based logic is about to become obsolete.

Why? Because it treats all equipment and operating hours as equal. It cannot see the unique wear profile of your machine in your environment. By 2026, leading operations will have moved beyond this blunt instrument to a state of Predictive Readiness: a condition where your system itself signals its health, allowing you to intervene with precision, maximising uptime and minimising cost.

This isn’t about buying expensive IoT kits. It’s about a new way of listening to your existing system. Here’s how to build it.

I. The Limits of the Calendar: Why Time is a Poor Proxy for Health

Your maintenance calendar operates on two assumptions:

- Failure is time-based. (It’s not; it’s stress and cycle-based).

- All operating hours are identical. (They’re not; running at 100% load in summer is not the same as 40% load in winter).

The result? You often perform maintenance too early (wasting money and component life) or too late (risking failure). True efficiency lies in the perfect, need-based timing of intervention.

II. The 2026 Standard: From Scheduled to Signal-Driven

Predictive Readiness flips the logic. Instead of asking “Has enough time passed?”, you ask “Is the system showing signs of needing attention?”. This requires monitoring weak signals—subtle, early deviations from a healthy baseline—long before they become hard failures.

III. The 5 Weak Signals of a Nitrogen System (Your New “Alarms”)

Learn to monitor these five parameters for trends, not just thresholds.

1. The Purity Trend Slope

- The Signal: A gradual, consistent downward drift in purity (e.g., losing 0.1% per week), even within specification.

- What It Predicts: Progressive adsorbent degradation in PSA systems or membrane aging/fouling. It’s the system whispering “My separation efficiency is declining.”

- 2026 Action: Log purity data and perform a simple linear regression. A negative slope triggers a root-cause investigation, not an alarm.

2. The Specific Energy Creep

- The Signal: A steady increase in kWh consumed per Nm³ of nitrogen produced, calculated weekly.

- What It Predicts: Growing internal resistance—clogging filters, fouled heat exchangers, deteriorating valve seals, or compressor inefficiency. It’s the system saying “I’m working harder to do the same job.”

- 2026 Action: Make this KPI the heart of your efficiency dashboard. A 5% sustained creep is a more urgent call to action than a calendar date.

3. The Cycle-Time Drift (For PSA Systems)

- The Signal: The adsorption/purge cycle time slowly elongates to maintain purity.

- What It Predicts: Loss of adsorbent capacity. The control system is compensating by giving the sieve more time to adsorb, a clear sign of exhaustion or contamination.

- 2026 Action: Monitor the cycle time setpoint from the controller’s data log. A drift beyond 10% of its original setting is a critical weak signal.

4. The Correlation Breakdown

- The Signal: A long-standing relationship between two parameters changes. Example: inlet air temperature and outlet pressure used to correlate tightly; now they don’t.

- What It Predicts: A fundamental shift in system dynamics—a developing leak, a failing sensor, or a control valve sticking. It’s a sign that the system’s “personality” is changing.

- 2026 Action: Periodically review simple X-Y scatter plots of key parameters. Look for the visual “cloud” of data points suddenly shifting shape.

5. The Audio-Visual “Fingerprint” Change

- The Signal: A change in the normal sound profile or vibration pattern you’ve grown accustomed to.

- What It Predicts: Mechanical issues—bearing wear, loose components, imbalanced fans, or internal turbulence.

- 2026 Action: Use a smartphone app for basic spectrum analysis or simply keep a dated audio log. The human ear, trained on a baseline, is a powerful sensor. A new, consistent hum or click is a signal.

IV. Your Practical Roadmap to Predictive Readiness (No Major Capex Needed)

You don’t need to overhaul your plant. Start with this 4-phase approach:

Phase 1: Baseline Capture (Next 30 Days)

For each of the 5 signals above, establish a “golden week” baseline during normal, stable operation. Document it. This is your system’s health fingerprint.

Phase 2: Low-Cost Monitoring (Months 2-3)

Leverage Existing Data: Configure your purity analyzer, flow meter, and power meter to output trend data.

Add One Thing: Install a low-cost multi-channel data logger to capture pressure and temperature trends at key points.

Phase 3: Define Actionable Thresholds (Month 4)

Set sensible trend-based triggers, not failure alarms. Example: “If Specific Energy Creep exceeds 5% for two consecutive weeks, initiate Phase 2 diagnostic checklist.”

Phase 4: Integrate into Workflow (Ongoing)

Make reviewing these trend charts a 10-minute item in your weekly operations meeting. The goal is cultural: to start making decisions based on system signals, not the calendar.

V. Conclusion: Building the 2026-Ready Operation Today

The shift to Predictive Readiness is not a technology purchase; it’s a philosophical and operational upgrade. It’s about treating your nitrogen generation system not as a utility to be maintained, but as a vital organ whose continuous health is critical to the business.

By 2026, this will be the standard for competitive, reliable manufacturing. The early adopters building this capability today will enjoy a decisive advantage: uninterrupted production, optimised maintenance spend, and total confidence in their gas supply.

At MINNUO, we design reliability into every component. But true operational resilience is co-created with forward-thinking partners. We are committed to providing not just the hardware for the future, but the insights and partnership to help you build the predictive readiness that turns a capital asset into a strategic, worry-free advantage. The future of maintenance isn’t on the calendar. It’s in the data your system is already giving you.

sales2:+86 17506119168

sales2:+86 17506119168