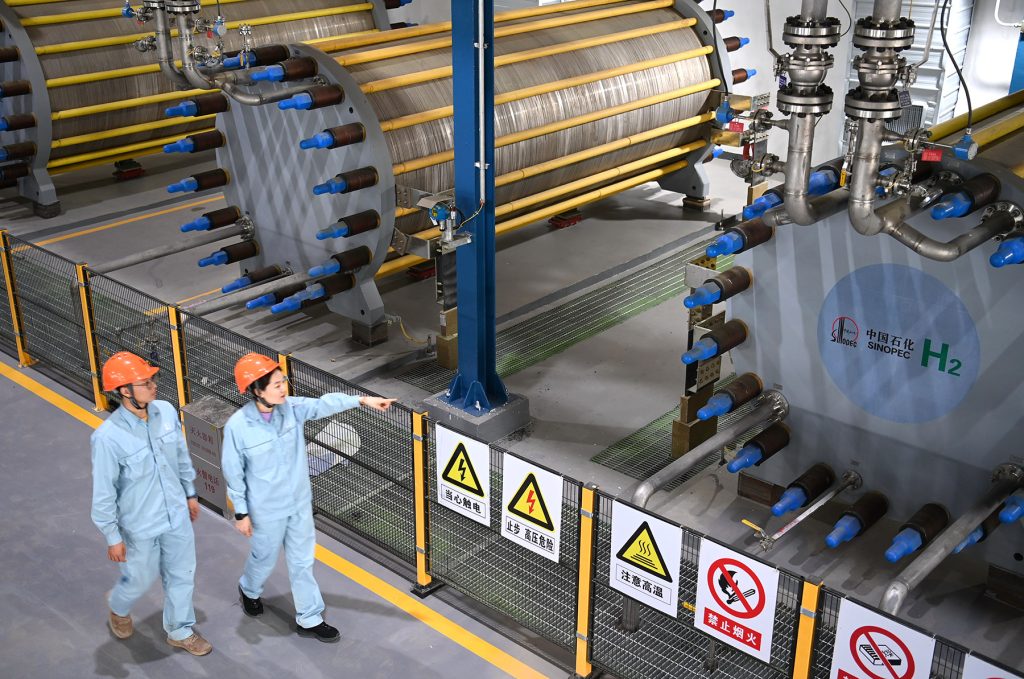

In the field of industrial production, electrolyzers serve as core equipment for numerous critical processes (such as chlor-alkali chemical industry, non-ferrous metal smelting, etc.). Their operational stability directly determines production efficiency, product quality, and operational safety. However, during operation, electrolyzers face pain points including difficult pressure control and process interference caused by impurity residues. As a professional gas equipment supplier, the company provides an efficient and reliable solution for the pressurization and flushing of industrial electrolyzers with its independently developed nitrogen generators, becoming an important partner to help enterprises reduce costs and increase efficiency.

I. Nitrogen Generator: A “Customized Gas Source” Adapting to Electrolyzer Process Requirements

As an inert gas, nitrogen features stable chemical properties and does not react with raw materials and products in electrolyzers, making it an ideal gas source for electrolyzer pressurization and flushing. Compared with the traditional mode of purchasing nitrogen externally, this nitrogen generator boasts core advantages of “on-demand gas production, adjustable purity, and stable supply”. It can accurately output nitrogen with a purity of 95%-99.999% according to the process parameters of electrolyzers in different industries (such as ion-exchange membrane electrolyzers in the chlor-alkali industry and electrolytic refining tanks in the metallurgical industry), ensuring the stability of the electrolyzer process from the source.

Whether for intermittent electrolysis operations in small and medium-sized factories or continuous production in large enterprises, this nitrogen generator can be flexibly adapted through modular design. It avoids the problem of gas source interruption caused by transportation delays and storage losses of externally purchased nitrogen, providing “all-weather” gas source guarantee for the continuous operation of electrolyzers.

II. Application in Electrolyzer Pressurization: Stabilizing Pressure and Protecting Core Components

During the operation of electrolyzers, especially ion-exchange membrane electrolyzers, there are strict requirements for the pressure of the cathode chamber. Excessively high pressure may lead to damage of the ion membrane, while excessively low pressure may allow air or chlorine from the anode chamber to penetrate into the cathode chamber, forming a flammable and explosive mixture and triggering safety risks. The nitrogen generator provides precise guarantee for electrolyzer pressurization through the following methods:

1. Closed-Loop Pressure Control for “Zero Fluctuation” Operation

Equipped with high-precision pressure sensors and an intelligent control system, the generator can real-time monitor pressure changes inside the electrolyzer and automatically adjust nitrogen output according to process requirements. For example, in chlor-alkali production, when the pressure of the electrolyzer’s cathode chamber drops due to fluctuations in hydrogen production, the generator can respond within 0.5 seconds to supplement nitrogen to the set pressure (usually 0.02-0.05MPa), avoiding pressure fluctuations from impacting the ion membrane and extending the service life of the ion membrane.

2. Inert Protection to Eliminate Safety Hazards

Compared with pressurization using compressed air, the high-purity nitrogen output by this equipment can completely isolate oxygen, preventing the mixture of hydrogen and oxygen in the cathode chamber from reaching the explosive limit. Meanwhile, the inert nature of nitrogen can avoid oxidative corrosion of metal components inside the electrolyzer due to contact with oxygen, reducing equipment maintenance costs. According to customer feedback, the annual equipment maintenance cost can be reduced by 20%-30%.

3. Energy-Saving Design to Reduce Operational Costs

Adopting Pressure Swing Adsorption (PSA) technology, the nitrogen generator has energy consumption only 1/3 of that of traditional cryogenic nitrogen generators, and no wastewater or waste gas emissions during gas production. Taking a unit with a processing capacity of 50Nm³/h as an example, compared with purchasing liquid nitrogen externally (calculated at the market average price of 1.2 yuan/Nm³), it can save approximately 432,000 yuan in gas source costs annually, with an investment payback period of only 1.5-2 years, bringing significant economic benefits to enterprises.

III. Application in Electrolyzer Flushing: Efficient Impurity Removal and Guaranteed Process Purity

After electrolyzer shutdown for maintenance or component replacement, electrolyte, metal impurities, or air are likely to remain inside the tank. If not completely removed, restarting the electrolyzer will lead to a decrease in product purity (such as reduced caustic soda purity in the chlor-alkali industry) and even damage electrolytic components. The nitrogen generator efficiently solves this pain point through the “inert flushing + cyclic purification” mode:

1. Flushing Principle: Replacing Impurities Without Dead Ends

The dry nitrogen (dew point ≤ -40℃) output by the generator can be introduced from the top or side of the electrolyzer through a dedicated spray gun or pipeline system. Utilizing the characteristic that nitrogen density is slightly less than that of air, it “pushes out” residual impurities such as air and electrolyte vapor inside the tank, realizing the replacement of the internal atmosphere of the tank. At the same time, the dry nature of nitrogen can avoid corrosion of the electrolyzer’s inner wall caused by residual moisture, making it particularly suitable for electrolytic processes sensitive to humidity (such as lithium battery material electrolysis).

2. Operational Process: Simple, Efficient, and Adaptable to Industrial Scenarios

The flushing operation process of this nitrogen generator has been standardized, with specific steps as follows:

① Pretreatment: Close the inlet and outlet valves of the electrolyzer, connect the dedicated flushing pipeline of the generator, and check the tightness;

② Nitrogen Flushing: Start the equipment, adjust the nitrogen flow rate (usually 2-3 times the electrolyzer volume per hour), and continue flushing for 30-60 minutes. During this period, monitor the oxygen concentration inside the tank with a gas detector until the oxygen content is ≤ 0.5%;

③ Cyclic Purification: For electrolyzers with complex structures, the circulation loop of the generator can be activated to recover and purify the mixed gas inside the tank for flushing again, reducing nitrogen loss (nitrogen consumption can be reduced by 15%-20%);

④ Acceptance: After flushing, detect the impurity content inside the tank, and proceed to the next production step only after confirming that it meets the process requirements.

3. Comparison with Traditional Flushing: Significant Advantages and Improved Process Level

Compared with traditional water flushing or compressed air flushing, this flushing solution has three core advantages:

- No Secondary Pollution: Nitrogen does not react with substances inside the tank and is dry without moisture, avoiding electrolyte dilution and equipment rust caused by water flushing;

- Higher Efficiency: Nitrogen replacement is fast, which can shorten the restart time of the electrolyzer after maintenance by 2-4 hours and improve equipment utilization;

- Safe and Controllable: Full-process inert atmosphere protection eliminates the risk of mixing oxygen (possibly introduced during compressed air flushing) with flammable substances inside the tank.

IV. Core Advantages: Technology Empowerment and Service Support

As an enterprise deeply engaged in the gas equipment field for many years, this nitrogen generator has become the preferred choice for industrial electrolyzer applications due to its comprehensive advantages in technology, products, and services:

1. Technological Leadership: Customized Adaptation to Different Processes

The company has a professional R&D team that can customize nitrogen generator solutions according to parameters such as the type of customer’s electrolyzer (such as plate electrolyzer, tubular electrolyzer), production capacity, and process pressure. For example, for electronic-grade electrolytic processes requiring high purity, a nitrogen generator with 99.999% purity can be provided; for large-scale continuous production, a multi-unit parallel system can be designed to ensure uninterrupted gas supply.

2. Reliable Products: Stable Operation and Low Failure Rate

Core components of the nitrogen generator (such as adsorption towers, molecular sieves, solenoid valves) are made of high-quality imported materials and delivered after strict testing. The continuous operation failure rate of the equipment is less than 0.5%. Meanwhile, it is equipped with a remote monitoring system, allowing customers to real-time check the operating parameters (purity, pressure, flow rate) via mobile phones or computers. When an abnormality occurs, the system automatically alarms and notifies the operation and maintenance team, reducing downtime.

3. Comprehensive Services: Whole-Life Cycle Support

The company provides customers with full-process services including “pre-sales consultation – scheme design – installation and commissioning – operation and maintenance training – after-sales repair”:

Pre-sales: Free on-site survey to optimize the scheme according to the customer’s production status;

Installation: Professional team conducts on-site installation to ensure seamless connection between the equipment and the electrolyzer system;

After-sales: Offers 1-year free warranty and lifelong maintenance, with 24-hour response to repair needs and on-site service within 48 hours in remote areas.

V. Summary and Outlook: Choose Jiangsu Minnuo to Start a New Chapter of Efficient Electrolyzer Production

Against the background of the intelligent and green transformation of industrial production, electrolyzers, as core equipment, have higher requirements for the stability, purity, and economy of the gas source. With the advantages of “on-demand gas production, precise control, energy saving, and consumption reduction”, this nitrogen generator not only solves the core pain points of electrolyzer pressurization and flushing but also helps enterprises achieve the production goals of “safety, efficiency, and low cost”.

In the future, the company will continue to deepen nitrogen generation technology, launch smarter and more energy-saving products, and provide customized solutions for electrolyzer processes in more industries. Choosing Jiangsu Minnuo means choosing stable gas source guarantee, professional technical support, and worry-free whole-life cycle services, making your electrolyzer production more efficient, safer, and more economical!

sales2:+86 17506119168

sales2:+86 17506119168