A stable, high-purity nitrogen supply is the lifeblood of countless processes, from food packaging and electronics manufacturing to laser cutting and chemical inerting. When your nitrogen generator’s output purity begins to drop or fluctuate, it’s not just an equipment issue—it’s a direct threat to product quality, yield, and operational continuity.

Conventional troubleshooting often focuses on quick fixes, which can be costly and temporary. This guide provides a systematic, engineering-focused framework to diagnose the root cause of purity degradation in Pressure Swing Adsorption (PSA) and Membrane Nitrogen Generators, offering solutions that deliver lasting reliability.

Step 1: Gathering Evidence Like a Forensic Engineer

Before touching any settings, become an observer. Accurate data points are crucial for correct diagnosis. Note the following:

- The Purity Trend: Is the drop sudden, gradual, or cyclical? A graph from your analyzer is the most valuable clue.

- Associated Parameters: Simultaneously record inlet pressure and temperature, outlet pressure, and (for PSA) the exhaust flow/pressure during regeneration.

- Environmental & Upstream Changes: Have there been changes in compressor oil, new painting operations nearby, or significant shifts in ambient temperature/humidity?

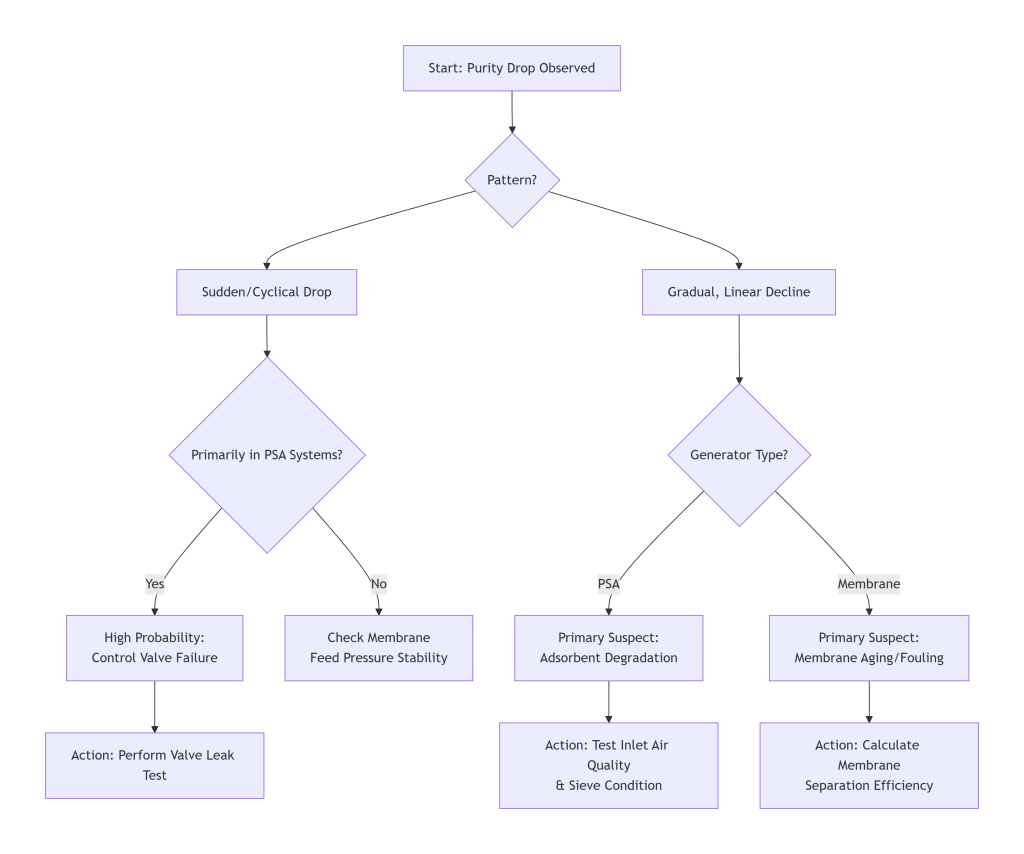

Step 2: The Diagnostic Decision Tree

Use the evidence from Step 1 to follow this logic path:

Step 3: Deep Dive into Root Causes & Corrective Actions

For PSA Nitrogen Generators:

- Root Cause A: Adsorbent (Carbon Molecular Sieve) Degradation.

- The Problem: Sieves can be poisoned by oil aerosols, condensed water, or excessive CO2 from inadequate air prep. They also naturally age and abrade, losing capacity.

- The Evidence: Gradual purity decline, often coupled with increased exhaust flow to maintain purity.

- The Action:

- Test Inlet Air: Verify the output quality of your pre-filters (oil content, dew point).

- Inspect the Sieve: A simple visual check can reveal caking or oil sheen. Advanced users can measure bed weight or perform a pressure-hold test.

- The Solution: If contamination is confirmed, replacement is necessary. The long-term fix is upgrading pre-filtration—consider coalescing filters plus desiccant or catalytic air dryers for critical applications.

- Root Cause B: Valve Failure (The Most Common Culprit for Cyclical Drops).

- The Problem: Solenoid valves, pneumatic actuators, or seal rings wear out. A leaking outlet valve or a sluggish regeneration valve causes cross-contamination and poor bed purging.

- The Evidence: Purity drops that coincide with the switching cycle, audible hissing, or erratic pressure gauges.

- The Action:

- Isolate and Test: Use a “vessel isolation pressure decay test” during maintenance. Pressurize an adsorption tower and monitor for pressure drop with all valves closed.

- Listen and Feel: Ultrasonic leak detectors can pinpoint internal leaks.

- The Solution: Rebuild or replace faulty valve assemblies. Implement a preventive maintenance schedule for valve inspection.

For Membrane Nitrogen Generators:

- Root Cause: Membrane Fiber Fouling or Aging.

- The Problem: Membranes are highly sensitive. Oil vapor permanently coats fibers. Liquid water blocks pores. Over years, plasticizers slowly age the polymer.

- The Evidence: Gradual purity decline. To maintain purity, you must reduce product flow or increase feed air pressure.

- The Action:

- Calculate Efficiency: Measure feed and product flows and purities. A drop in Nitrogen Recovery Efficiency signals membrane issues.

- Verify Air Quality: This is paramount. Ensure inlet air is Class 1 (oil-free) and has a dew point at least 10°C below ambient temperature.

- The Solution: There is no cleaning process. Protecting the membrane with impeccable inlet air is the only solution. If failed, the membrane bundle must be replaced.

Step 4: System Optimization for Long-Term Health

After solving the immediate problem, optimize for resilience and efficiency:

- Implement Predictive Monitoring: Move beyond a simple purity alarm. Use data loggers to track purity trends and feed pressure. A gradual negative trend is an early warning.

- Audit Your Air Treatment System: Your nitrogen generator is only as good as the air you feed it. Regularly service pre-filters and dryers. Consider installing continuous oil vapor monitors.

- Review Operating Parameters: Ensure the unit is running at its designed capacity. Consistently operating at 120% of rated flow will accelerate wear and degrade purity.

Frequently Asked Questions

- Q: Our purity is okay, but the dew point has risen suddenly. Why?

- A: This almost always points to a failure in the compressed air drying system upstream of your nitrogen generator. Check your refrigerated or desiccant dryer immediately.

- Q: Can I just increase the exhaust flow or pressure to regain purity?

- A: This is a temporary, costly workaround. It masks the real problem, increases air consumption, accelerates component wear, and will eventually stop working. Diagnose and fix the root cause.

- Q: How long do carbon molecular sieves or membranes typically last?

- A: With perfect inlet air, CMS can last 7-15 years, and membranes 5-10 years. Poor air quality can reduce this lifespan to 1-3 years. There is no substitute for proper filtration.

Conclusion: From Reactive Fixes to Proactive Management

A drop in nitrogen purity is a symptom, not the disease. By adopting a systematic, evidence-based approach to diagnosis—focusing on air quality, valve integrity, and adsorbent/membrane health—you can implement solutions that restore and sustain performance for the long term.

Building a reliable nitrogen supply requires viewing the system holistically: from the air compressor intake to the final filter on the nitrogen line. This proactive mindset minimizes unplanned downtime and protects your critical processes.

For over three decades, the team at MINNUO has specialized in providing not just high-performance gas generation equipment, but also the technical depth and support to ensure your entire system operates with unwavering reliability. We believe in empowering users with knowledge, because understanding your equipment is the first step toward optimizing it.

sales2:+86 17506119168

sales2:+86 17506119168