For years, the nitrogen generation industry has sold on a single, seductive metric: final purity percentage. 99.5%, 99.9%, 99.999% — these numbers dominate spec sheets and sales conversations.

But here’s the uncomfortable truth familiar to every seasoned plant engineer: a spec sheet purity number is meaningless if it isn’t stable over time. You can have a generator rated for 99.9%, yet your laser welds show oxidation, your packaged foods spoil faster, or your chemical yields vary batch-to-batch. The problem isn’t the purity you achieve at peak performance; it’s the instability you experience in the real world of dynamic factory operation.

This is the Stability Illusion. This guide moves beyond the spec sheet to dissect the real-world factors that create unstable nitrogen, and provides a concrete framework—a Stability Protocol—to achieve the reliability your process truly demands.

I. Purity vs. Stability – Defining the Real Goal

- Purity (The Number): A point-in-time measurement of nitrogen concentration, typically taken under controlled, ideal conditions.

- Stability (The Requirement): The ability to maintain a consistent purity level despite fluctuations in feed air, ambient conditions, and, most critically, variable downstream demand.

Think of it like water pressure: you don’t just want high pressure; you want consistent pressure, so your shower doesn’t scalding or freezing every time someone flushes a toilet. Your sensitive manufacturing processes are even more demanding.

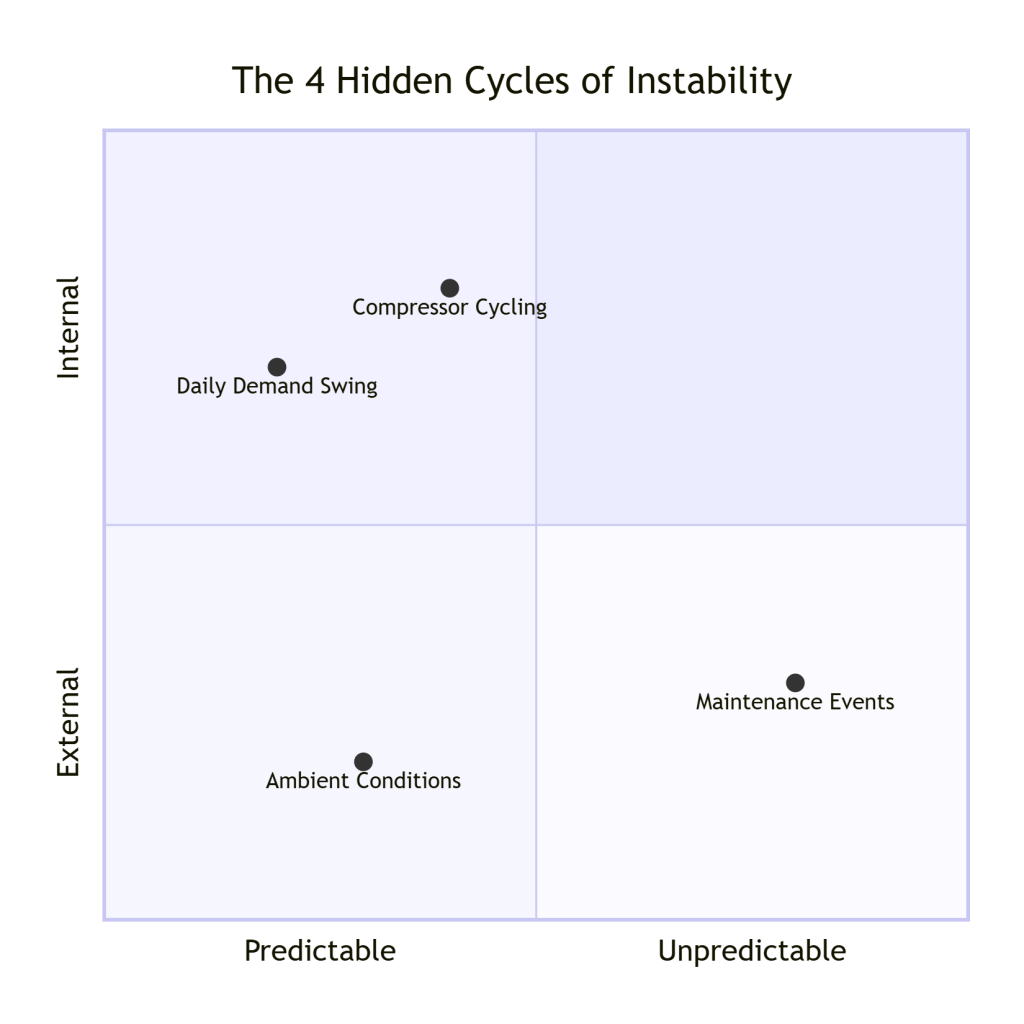

II. The 4 Hidden Cycles That Sabotage Stability

Instability rarely comes from the nitrogen generator itself failing. It emerges from the interaction between your generator and the hidden, rhythmic cycles of your plant.

1. The Daily Demand Swing (The Predictable Internal Cycle)

- The Cycle: Morning startup surges, lunchtime lulls, and end-of-shift shutdowns.

- The Impact: PSA and membrane generators are sensitive to flow changes. A sudden drop in demand can cause purity to spike briefly before controls adjust, while a surge can overwhelm the separation capacity, causing a dip.

- The Illusion: Checks done during steady-state midday operation miss these transient events.

2. The Compressor Cycling Effect (The Predictable External Cycle)

- The Cycle: Your air compressor’s load/unload or variable speed drive (VSD) cycles.

- The Impact: Even small fluctuations in feed air pressure and temperature directly alter the separation efficiency of membranes and the adsorption kinetics in PSA systems. This creates a low-frequency “pulse” of instability synchronized with your compressor.

- The Illusion: You blame the nitrogen generator, but the root cause is upstream.

3. The Ambient Condition Rollercoaster (The Unpredictable External Cycle)

- The Cycle: Day/night temperature swings, seasonal humidity changes.

- The Impact: For PSA systems, warmer, more humid inlet air reduces the capacity of desiccant pre-dryers and carbon molecular sieves. For membrane systems, temperature directly affects permeability. A 10°C rise can drop membrane output purity by a measurable percentage.

- The Illusion: A gradual, seasonal decline in performance is mistaken for “catalyst aging” or “normal wear.”

4. The Maintenance & Human Activity Cycle (The Unpredictable Internal Cycle)

- The Cycle: Draining of air system condensate, filter changes, or a technician connecting/disconnecting an air hose.

- The Impact: These events cause sudden pressure drops or introduce bursts of contamination (oil, water) that can temporarily poison adsorbents or membranes, creating a “step-change” drop in purity that may slowly recover—or not.

- The Illusion: The purity drop is attributed to “bad luck” or a faulty component, not linked to the maintenance log.

III. The 5-Point Stability Protocol

To combat these cycles, you need a system-level protocol. Here is a actionable framework:

Point 1: Source Stabilization

- Action: Install a dedicated, properly sized receiver tank immediately before your nitrogen generator’s inlet. This is non-negotiable. It decouples the generator from compressor cycles and demand surges.

- Rule of Thumb: Tank volume (in gallons) should be at least 1-2 times the generator’s rated flow in SCFM.

Point 2: Intelligent Buffering

- Action: Install a polishing buffer tank after the nitrogen generator, but before your critical process line.

- Why: This tank absorbs the generator’s own minor output fluctuations (e.g., from PSA valve switching) and provides a crucial reservoir for sudden process demands.

Point 3: Trend-Based Monitoring

- Action: Stop relying on purity alarms with a fixed threshold (e.g., alarm at <99.5%). Implement trend monitoring.

- How: Use your analyzer’s data-logging function. Watch for the slope of the purity line. A gradual downward trend over days is an early warning of adsorbent aging or membrane fouling. A cyclical pattern points to a hidden cycle (see Part 2).

Point 4: Controlled Demand Management

- Action: Audit your point-of-use applications. Identify and eliminate non-essential or intermittent nitrogen uses (e.g., cooling, cabinet purging with high flow) from your high-purity loop.

- Goal: Flatten the demand curve as much as possible. Consider a separate, lower-purity loop for non-critical applications.

Point 5: Proactive Environmental Guarding

- Action: For PSA systems, monitor the dew point of your feed air religiously. For membrane systems, monitor inlet air temperature. Install simple gauges or data loggers. Set preventive maintenance for pre-filters and dryers based on actual data, not just a calendar.

IV. Industry Spotlight: Stability Challenges in Critical Sectors

The cost of instability is measured in failed products and lost revenue. Here’s how the Purity Illusion manifests in high-stakes industries:

- Electronics Manufacturing & SMD Reflow Ovens: For nitrogen stability in electronics packaging, even minor, transient oxygen ingress during reflow can lead to solder balling, tombstoning, and reduced joint strength. The 5-Point Protocol, especially Intelligent Buffering (Point 2) and Trend-Based Monitoring (Point 3), is critical to prevent these defects.

- Pharmaceuticals & Aseptic Packaging: Under GMP standards for nitrogen purity control, data integrity is paramount. A purity dip during a vial capping operation is not just a process deviation; it’s a potential batch failure. Implementing the Stability Protocol provides the documented, controlled environment required for audit trails and quality assurance.

- Additive Manufacturing (3D Metal Printing): Inert atmosphere stability is crucial to prevent powder oxidation and ensure part integrity. The Hidden Cycles, particularly from Ambient Conditions and Compressor Cycling, can introduce variability that affects mechanical properties from one build job to the next.

Frequently Asked Questions

Q: Our pharmaceutical packaging line requires 99.9% nitrogen. We pass QC checks, but still see occasional spoilage. Could instability be the cause?

A: Absolutely. QC checks are point-in-time snapshots. GMP compliance for nitrogen requires continuous monitoring and control. The spoilage likely occurs during transient events missed by sampling—like a morning startup surge or a compressor cycle. Implementing Trend-Based Monitoring (Point 3) is essential to identify and eliminate these risk windows.

Q: We have a PSA nitrogen generator, and purity is gradually declining. The supplier says it’s “normal aging,” but it’s only been 3 years. What’s wrong?

A: This is a classic sign of potential carbon molecular sieve contamination or degradation, often misdiagnosed as simple aging. The root cause is usually inadequate air preparation, allowing oil vapor or moisture to poison the sieve. Before accepting an expensive sieve change, rigorously audit your pre-filtration and drying system as part of Proactive Environmental Guarding (Point 5). A true “stability” approach fixes the root cause, not just the symptom.

Q: Our membrane nitrogen generator’s purity drops significantly on hot days. Why does temperature affect it so much, and how can we control it?

A: Membrane separation is intrinsically temperature-sensitive. Higher inlet air temperature increases the permeability of all gases, reducing the system’s selectivity (its ability to separate oxygen from nitrogen). This is a direct membrane generator temperature control challenge. Solutions include: 1) Ensuring your air compressor’s aftercooler is functioning optimally, 2) Installing a refrigerated air dryer to actively control inlet air temperature, and 3) Discussing with your supplier if your membrane is correctly rated for your peak summer ambient conditions.

Q: For laser cutting stainless steel, how critical is nitrogen stability compared to just high purity?

A: For laser cutting, stability is often more critical than the absolute purity number. A stable 99.5% nitrogen flow will produce clean, oxide-free cuts consistently. An unstable flow fluctuating between 99.9% and 99.0% will cause variations in cut edge quality, color, and burr formation along the length of the cut. The hidden demand cycles in your workshop are likely the culprit. Focus on Source Stabilization (Point 1) and Controlled Demand Management (Point 4).

Conclusion: From Illusion to Engineered Reality

True nitrogen reliability is not a product you buy; it’s a system you engineer and manage. Moving beyond the Purity Illusion means shifting your focus from a static number on an analyzer to the dynamic behavior of an integrated system: air prep, generation, storage, distribution, and use.

It requires asking not just “What is the purity?”, but “How does it behave over a week, a season, a maintenance cycle?” When you manage for stability, you achieve not only better product quality but also predictable maintenance, longer component life, and lower energy costs.

At MINNUO, we engineer our gas generation systems with this holistic stability in mind. But more importantly, we partner with engineers and plant managers to implement the thinking behind this Stability Protocol. Because the most reliable system is one that is thoroughly understood, meticulously monitored, and proactively managed. Let’s build systems that are not just pure, but predictably and reliably so.

sales2:+86 17506119168

sales2:+86 17506119168