MINNUO, as China’s top cryogenic liquid nitrogen plant manufacturer, we have three large – scale liquid nitrogen plants and 36 years of experience. We can provide professional cryogenic air separation of oxygen, nitrogen, argon, krypton, xenon, neon, helium and other rare gases into a complete set of equipment

A cryogenic liquid nitrogen plant is not only used to produce nitrogen but also liquid nitrogen. For processes requiring larger amounts of liquid nitrogen, we are the leading manufacturer of air – separation plants in China. We provide safe, reliable, advanced and intelligent gas solutions free of charge.

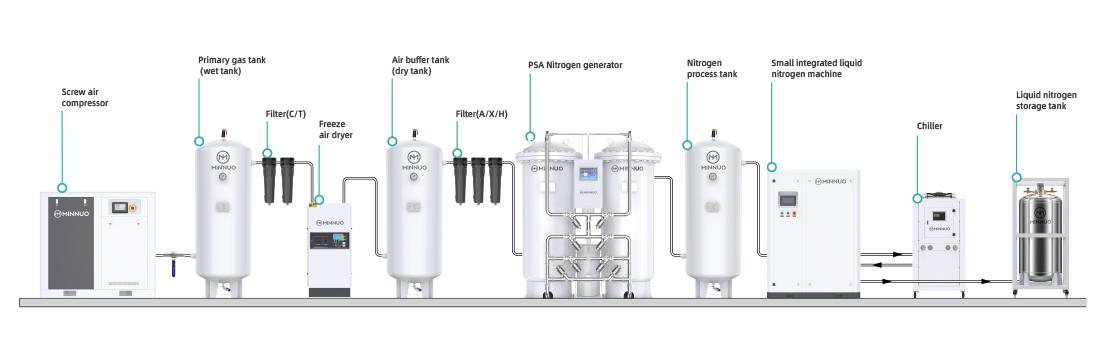

There are many ways to produce nitrogen in industry, such as PSA nitrogen, membrane nitrogen, cryogenic air separation nitrogen, etc. Cryogenic air separation is also one of the longest-used nitrogen production methods. It takes air as raw material, after compression and purification, and then uses heat exchange to liquefy the air into liquid air. Liquid air is mainly a mixture of liquid oxygen and liquid nitrogen, utilizing the different boiling points of liquid oxygen and liquid nitrogen, and obtaining nitrogen by separating them through the distillation of liquid air. Nitrogen is cooled into liquid nitrogen by cryogenic liquid and then filled to form finished liquid nitrogen.

The principle of deep freezing method is based on the different boiling points of each component of the gas mixture, and the method of separating them at low temperature by partial condensation or liquefaction distillation process. Among the methods of oxygen and nitrogen production such as deep freezing, chemical, electrolysis, adsorption and thin film permeation, the deep freezing method is the most economical, the most adaptable and the most widely used.

MINNUO, as oxygen and nitrogen plant manufacturer and supplier for 36 years, has rich experience in liquid nitrogen plants and systems. We have three factories with more than four hundred employees specializing in the production of liquid nitrogen plants and liquid nitrogen cryogenic tanks, and we can provide our customers with all kinds of liquid nitrogen generators and storage equipment, and we can also handle the demand for nitrogen production from all regions of the world.

| Model | MNON-50 | MNON-100 | MNON-200 | MNON-400 | MNON-500 | MNON-1000 | MNON-2000 |

| Type | Tower | ||||||

| Liquid Nitrogen Production | 50L/H | 100L/H | 200L/H | 400L/H | 500L/H | 1000L/H | 2000L/H |

| Oxygen Purity | ≥99.5% | ||||||

| Nitrogen Purity | ≥99.995% | ||||||

| Voltage frequency | 380VAC 3P 50Hz/220VAC 1P 50Hz | ||||||

| Ambient temperature requirements | 0-30℃,Ground level, good ventilation | ||||||

| Infrastructure | Infrastructure required | ||||||

| Note | For non-standard voltage and frequency, altitude >1000m, purity >99%, custom-made | ||||||

If you have additional production specifications and purity requirements, you can contact our equipment engineers for professional answers and one-on-one customized solutions with the opportunity to receive discounted pricing!

We have two series of cryogenic nitrogen plants to meet the different specification of product nitrogen</p >

The low-temperature characteristics of liquid nitrogen make it play an important role in the above fields. With the advancement of technology and the growth of market demand, the application scenarios of liquid nitrogen may be further expanded, and it is also an opportunity to choose suitable cryogenic liquid nitrogen equipment in time.

| Ancillary units | Unit |

| 1.Centrifugal air compressors | 1Set |

| 2.Air pre-cooling systems | 1Set |

| 3.Purification systems | 1Set |

| 4.Pressurised turbine expansion units | 1Set |

| 5.Fractionator systems | 1Set |

| 6.Liquid storage systems | 1Set |

| 7.Instrumentation and control systems | 1Set |

| 8.Electronic control systems | 1Set |

Purification system with a built-in filter, and featuring parallel blow-off and purifier regeneration. A high-efficiency electric heater is used to ensure the complete regeneration of the molecular sieve.

German centrifugal air compressor, high efficiency, low consumption, stable and reliable operation

Siemens electronic control systems, fully automatic production systems, digital control systems

Fractionating column heating, cooling, buildup and purification. Easy to operate, made of aluminum alloy or stainless steel for added strength and reduced torsion of the pipes. The cold box construction ensures overall strength and resistance to vibration and wind. Sealed gas protection and safety devices are provided during operation.

Turbine expander with gas bearings, simple, reliable, easy to operate and highly efficient The expander cold box is set up separately for easy maintenance

German refrigeration compressor, set water separator, automatic drain, regular water removal

Contact us and you will receive a free customized gas solution

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168