In oil and gas exploration, development, and production, as well as in underground coal mines and various surface industries where nitrogen is needed as a protective gas to prevent flaring, Minnuo designs and supplies high – quality membrane nitrogen generator solutions for mobile on – site nitrogen generation. It can meet the requirements of many workplaces with special and flexible conditions, such as dispersed sites, field operations with high climate change, humidity, poor road conditions, and insufficient water.

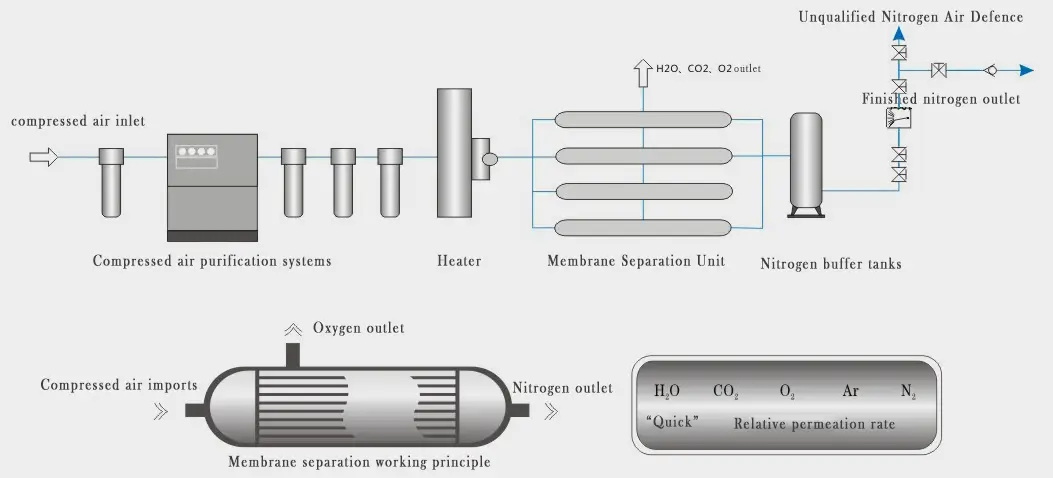

Minnuo Membrane separation oxygen Units. Using membrane separation technology, clean and dry compressed air enters one or more membrane modules, where the gas components with faster permeation rates (e.g. H20, H2, O2, etc.) are enriched on the low-pressure permeation side by preferentially passing through the membrane wall, while the gas components with relatively slow permeation rates (e.g. N2, etc.) are enriched on the high-pressure stagnation side, thus obtaining the required purity of nitrogen gas.

1.The compressed air from the air compressor enters the air buffer tank and then enters the multi-stage filter, including the activated carbon filter, which removes particles, oil and water from the air.

2.The clean air enters the membrane for oxygen and nitrogen separation. Generally speaking, the imported filters can remove the particles in the air to <0.01um and oil to <0.01ppm, which can fully meet the requirements of the membrane for air quality.

3.Stable quality suction dryers and cold dryers can treat the water in compressed air to the dew point of -20 to -60℃.

4.There is temperature heating and control in the middle of the filter to ansure that the membrane works under optimal conditions.

5.Constant temperature, clean air then enters the membrane for separation, qualified product gas goes to the next process, unqualified product gas is automatically discharged

For obtaining nitrogen,there are usually three options: liquid nitrogen,bottled nitrogen,and nitrogen generators, liquid nitrogen and bottle nitrogen use high cost, frequent replacement, autonomy and safety are poor, the use of the phenomenon of possible gas breakage, on-site air separation nitrogen can be a good solution to the above problems, box type nitrogen generator to meet the standard production, the user is easy to select, suitable for the use of gas is not a small amount of occasions, is becoming the trend to replace the bottled nitrogen.

Scope of application

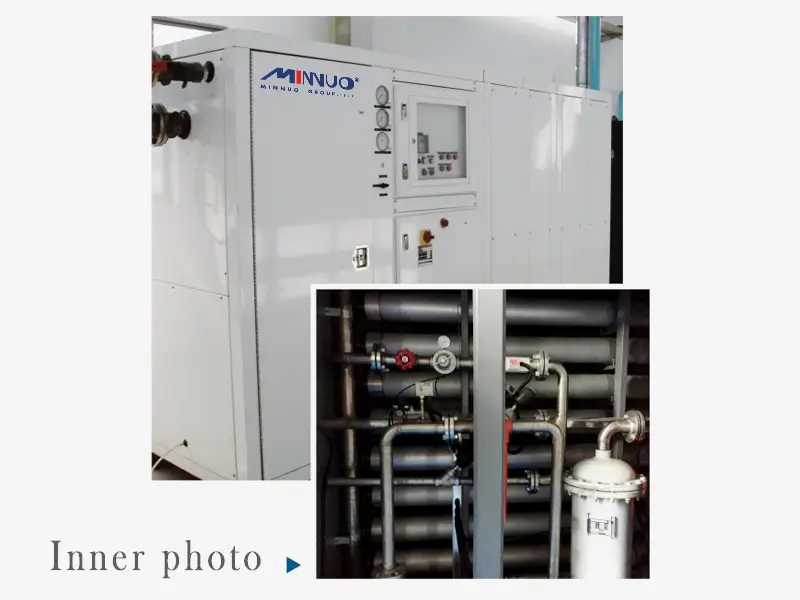

Suitable for use in environments with high requirements for size, floor space and noise free operation (e.g. laboratories, ship cabins, gymnasiums, food and beverage plants, electronics plants, etc.) and where the nitrogen flow requirements are small and can be flexibly relocated.

Simplified start-up and commissioning make our nitrogen membrane generators incredibly easy to deploy. Integrated air manifold connections ensure seamless operations, with low-maintenance design guaranteeing minimal downtime.

Ensure continuous operations with a dependable nitrogen supply. Our advanced membrane technology offers low energy consumption, securing your operations while reducing your total cost of ownership.

Designed to withstand extreme temperatures, high dust levels, and humidity, our nitrogen membrane generators guarantee consistent performance even in the harshest conditions.

On-site nitrogen generation cuts transport costs and reduces CO₂ emissions. Thanks to energy-efficient membrane technology, operational costs are minimized while sustainability is enhanced.

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168