MINNUO, a leading on – site PSA nitrogen generator manufacturer and supplier in China, has 36 years of experience in the PSA nitrogen generator system and equipment. Having served more than 2,000 nitrogen generator equipment, we can provide molecular sieves with a purity of up to 99.9995%. The molecular sieves come with a 10 – year warranty, and the main valve equipment has a 20 – year warranty.

PSA’s full name is Pressure Swing Adsorption. PSA is a new gas – separation technology. Its principle is to utilize the differences in the “adsorption” performance of molecular sieves for different gas molecules to separate the components in a gas mixture. Taking air as the raw material, it uses a high – efficiency and highly – selective solid adsorbent to selectively adsorb oxygen (usually oxygen is more preferentially adsorbed by the molecular sieve compared to nitrogen in PSA for nitrogen production) and thus separate nitrogen and oxygen in the air.

PSA nitrogen gas generator takes clean compressed air as raw material and carbon molecular sieve as the adsorbent, and utilizes the principle of variable pressure adsorption to obtain nitrogen at room temperature. According to the difference in the adsorption amount of oxygen and nitrogen in the air on the surface of carbon molecular sieve and the diffusion rate of oxygen and nitrogen in the carbon molecular sieve, the opening and closing of the programmable controller controls the programmed valves, realizing the process of adsorption under pressure and desorption under reduced pressure, completing the separation of oxygen and nitrogen, and obtaining the nitrogen with the required purity.

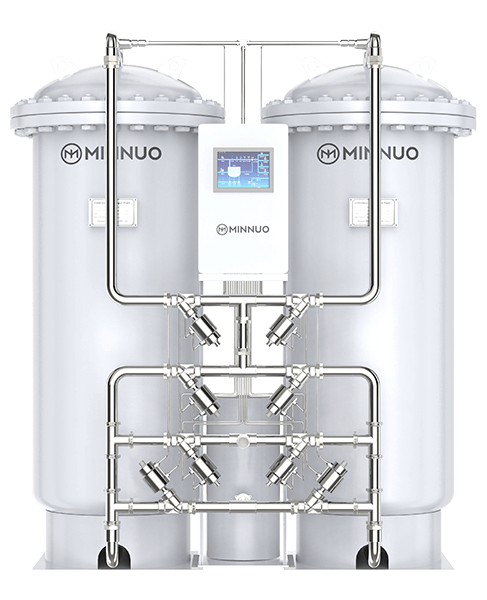

Nitrogen generator is based on the principle of variable pressure adsorption, using high quality carbon molecular sieve as adsorbent, and extracting nitrogen from air as raw material under certain pressure. The purified and dried compressed air is adsorbed under pressure and desorbed under reduced pressure in the adsorber. Due to the aerodynamic effect, the diffusion rate of oxygen in the micropores of the carbon molecular sieve is much larger than that of nitrogen, and oxygen is preferentially adsorbed by the carbon molecular sieve, while nitrogen is enriched in the gas phase to form finished nitrogen. Then after depressurization to atmospheric pressure, the adsorbent desorbs the adsorbed oxygen and other impurities to realize regeneration. Generally, two adsorption towers are set up in the system, one tower adsorbs nitrogen, the other tower desorbs and regenerates, and the opening and closing of the pneumatic valve is controlled by PLC program controller, so that the two towers circulate alternately to realize the purpose of continuous production of high-quality nitrogen.

PSA on-site nitrogen generator has the features of simple process, high degree of automation, fast gas production (15-30 minutes), low energy consumption, product purity can be adjusted according to user’s needs in a wide range, easy operation and maintenance, low operation cost, and strong adaptability of the device, etc. Therefore, it is quite competitive among the nitrogen generating equipments below 1,000Nm3/h, which is more and more welcomed by the medium-sized and small-sized nitrogen users, and the PSA nitrogen generator has become the preferred choice of medium-sized and small-sized nitrogen users.

MINNUO as a professional on-site nitrogen generator manufacturer and supplier, we have been specializing in the production of gas separation and purification technology for 36 years, with rich experience and cases, we not only sell PSA nitrogen generator, but we also have membrane nitrogen generator, cryogenic liquid nitrogen generator and the whole system equipment. We have our own professional factory and foreign trade sales team, we can provide the most professional analysis and offer low price, hurry to contact us!

Cost & energy saving

Safety Guarantee

Reliability

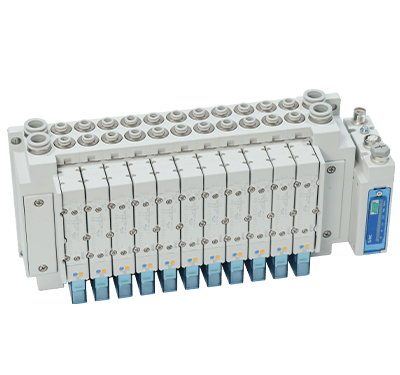

PLC Panel

Process Flowmeter ,Core components imported from Japan

Molecular Sieve from JALOX ,CMS

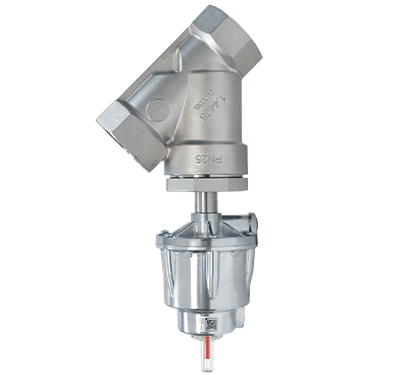

Germany pneumatic valves

Pilot operated solenoid valve

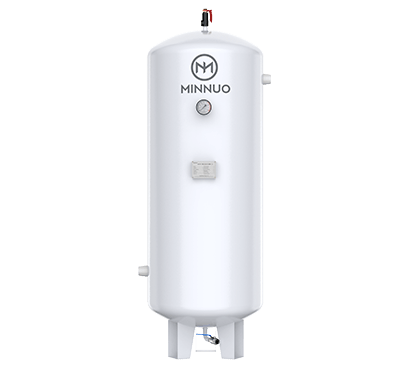

ASME standard air tank

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168