Minnuo group, 36 years a leading manufacturer of PSA nitrogen plants, provides high – purity 95% – 99.9995% molecular sieve with 10 – year warranty, and offers 20- year warranty for main valve equipment.

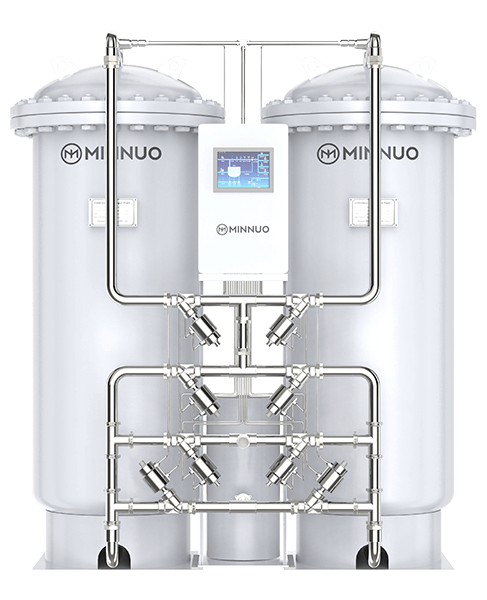

PSA’s full name is Pressure Swing Adsorption. PSA is a new gas – separation technology. Its principle is to utilize the differences in the “adsorption” performance of molecular sieves for different gas molecules to separate the components in a gas mixture. Taking air as the raw material, it uses a high – efficiency and highly – selective solid adsorbent to selectively adsorb oxygen (usually oxygen is more preferentially adsorbed by the molecular sieve compared to nitrogen in PSA for nitrogen production) and thus separate nitrogen and oxygen in the air.

Modular PSA nitrogen generators are equipped with patented technology that allows for the production of a steady stream of gaseous nitrogen directly on site. This compact system is particularly suited to low-flow, high-purity applications that have traditionally been reliant on high-pressure gas cylinders or dewars of nitrogen. With modular PSA nitrogen generators, the inconvenience of handling gas cylinders and liquid dewars is eliminated, as nitrogen is generated continuously and reliably at your location with only a compressed air supply needed.

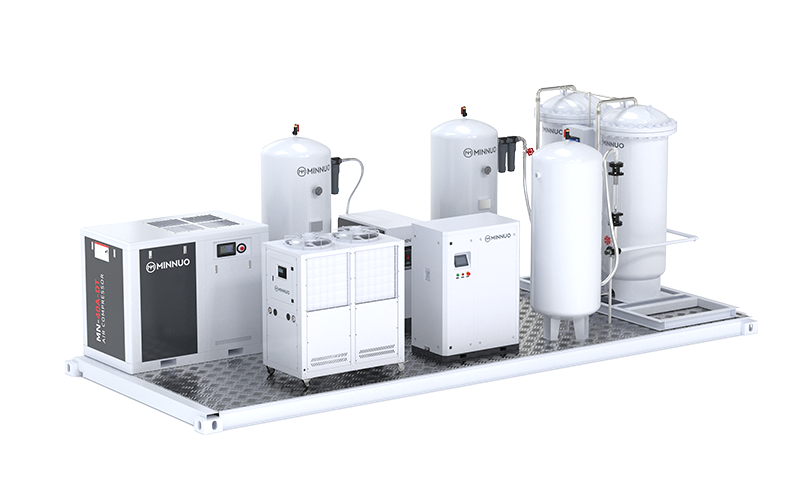

Skids are a compact and cost-effective solution for producing nitrogen on-site. They are a complete set of devices that can be controlled and managed by skilled workers, without requiring substantial installation costs. Skids are designed to be “plug and play,” meaning they can be easily and quickly set up according to the provided directions. A skid typically includes a compressor with a dryer, filters, a nitrogen pressure vessel, and a nitrogen generator, but it can be customized to meet your specific requirements. With a skid, you’ll have everything you need to produce nitrogen on-site according to your exact specifications.

Our nitrogen generator container systems are specifically designed and constructed to be compatible with ISO steel containers or similar structures, ensuring secure and effortless transportation. At Minnuogroup, we construct the entire nitrogen generator within a 10-foot, 20-foot, or 40-foot container that can be conveniently transported by truck. Once the nitrogen container unit arrives at the customer’s facility, all that is needed is to connect the electrical system on site to initiate nitrogen production.Our product line is specially engineered for medium and high flow rates, with a significantly smaller footprint compared to traditional systems.

Pressure swing adsorption(PSA) is a process that uses high pressure to attract gases to solid surfaces. As pressure increases, gas is adsorbed and when it decreases, the adsorbed gas is released. PSA can separate gases based on their attraction to different solid surfaces. For example, if air is passed through an adsorbent bed of Carbon Molecular Sieve (CMS) under pressure, oxygen will be attracted more strongly than nitrogen, so oxygen will stay in the bed and nitrogen will come out. The bed can be regenerated by reducing pressure and releasing the adsorbed oxygen for another cycle of producing high purity nitrogen. Two adsorbent vessels can be used for near-continuous production and energy savings through pressure equalization, where gas leaving one vessel depressurizes the second vessel. This is a common industrial practice.

PLC

Process Flowmeter ,Core components imported from Japan

Molecular Sieve from JALOX ,CMS

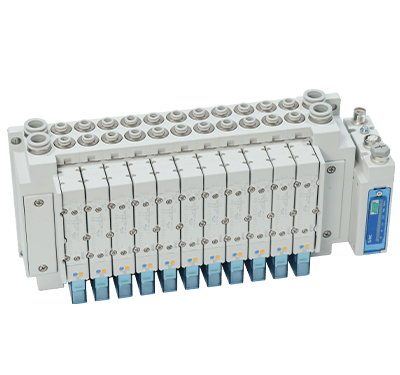

Germany pneumatic valves

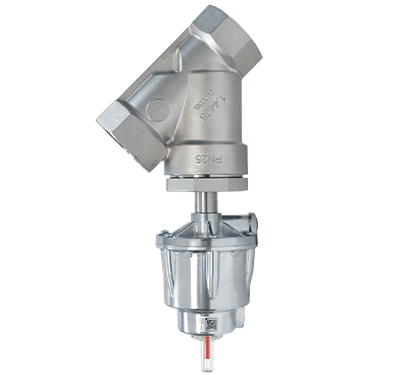

Pilot operated solenoid valve

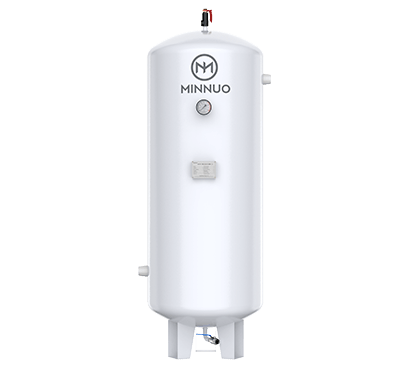

ASME standard air tank

1.Choose the right nitrogen concentration

Incorrectly selected concentration can significantly increase the price by several times. A difference of 0.05% in concentration can double the cost of the system.

2.Calculate station performance

Considering all consumer parameters, calculate the total amount of nitrogen consumed. Pay attention to the units of measurement, the flow must be normalized, Nm³/h at a pressure of 1 bar and a temperature of 20°C.

3.Consider the operating conditions

All parameters of the station are specified under standard operating conditions of 20°C. If the temperature rises above 38℃,it willaffect the air compressor, so be sure to keep the use of the site ventilation heat

4.Choose a compressor with a margin of 10%

For the correct operation of the system, many factors must be taken into account: the nature of consumption, the number of peak loads, additional losses of compressed air, the volume of receivers, and much more.

5.How Much Cost?

Start a small 20m³ PSA N2 generator price is $12000. We promise a good price with top quality.

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168