In the purchase of oxygen concentrator, many users often only focus on the oxygen concentration, noise level, duration and other intuitive parameters, however, to determine whether these properties can be durable and stable output, not the appearance of the function, but the internal two core components: molecular sieve and compressor. This article will focus on these two technical core, systematic analysis of its principle, type and matching relationship, to help users understand the essence of oxygen concentrator quality from the source.

So, why is the oxygen concentrator “good or bad”, depends on the molecular sieve and compressor? The molecular sieve determines whether it can stably separate high concentration of oxygen, and the compressor provides the power needed to maintain the adsorption cycle. These two are like “brain and heart”, one is indispensable, improper matching will directly affect the output concentration, equipment life and even oxygen safety.

Whether an oxygen concentrator can output high concentration of oxygen stably for a long time, and whether it runs quietly and durably is determined by the performance and matching degree of its two components. This article will systematically analyze the technical principle, type selection and matching relationship between the two, to help users grasp the core of oxygen concentrator quality from the source.

Ⅰ.A brief description of the working principle of oxygen generator

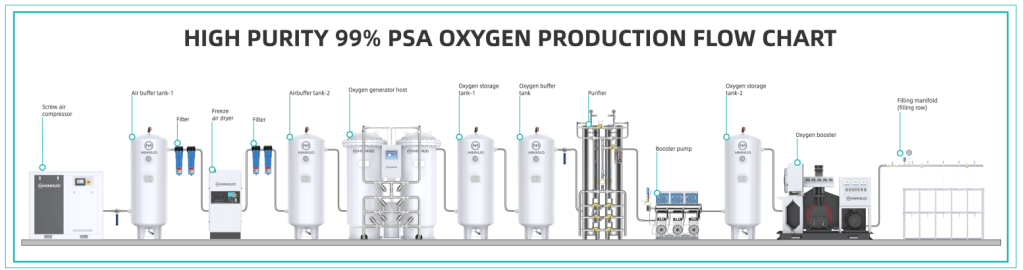

The vast majority of modern household and medical oxygen generators use PSA (Pressure Swing Adsorption) technology. This is a kind of advanced separation technology based on the physical adsorption and desorption behavior of gas molecules, which can realize efficient oxygen purification under normal temperature and pressure, avoiding the disadvantages of high energy consumption and large volume of traditional low-temperature separation equipment.

The core workflow of PSA can be divided into four stages:

1. Air Filtration and Compression

The indoor air first undergoes primary purification treatment such as coarse filtration and dust removal, and then enters into the compressor system to be pressurized, so as to have sufficient pressure (usually at 0.3~0.5MPa) to drive the subsequent adsorption process. The key to this stage is the stable output of the compressor and the continuous supply of gas, which is the “power source” of the whole system.

2.Adsorption stage (molecular sieves in action)

The compressed air is fed into an adsorption tower filled with high performance molecular sieves. In this process, the molecular sieve will preferentially adsorb nitrogen molecules and release oxygen molecules, which are smaller and diffuse faster. The choice of molecular sieve and filling process directly determines the stability of oxygen concentration and separation efficiency.

3.Oxygen-enriched release and output

When the adsorption is completed, the unadsorbed oxygen is released through the gas-conducting channel to the oxygen storage tank or outlet port, and is output in the form of high-purity oxygen-enriched oxygen for the user’s use. At this stage, the control valve in the system automatically adjusts the output cadence according to the flow regulator setting to ensure that the oxygen concentration is always maintained in the desired zone (e.g. 93±3%).

4.Desorption and regeneration (molecular sieve recovery)

The adsorption tower will automatically switch to the “desorption mode” after adsorption saturation, and the nitrogen molecules adsorbed in the molecular sieve will be released by lowering the internal air pressure to complete the regeneration cycle. The regeneration cycle is completed by lowering the internal air pressure to release the adsorbed nitrogen molecules from the molecular sieve. The process is usually automatic, and pairs of adsorption towers are operated alternately to achieve a continuous and stable supply of oxygen.

Ⅱ. Molecular sieve technology in detail: the key to determine the oxygen concentration

The role of molecular sieve

Molecular sieve is a kind of adsorption material with regular microporous structure, usually made of zeolite-like compounds, with highly selective adsorption characteristics. In the oxygen generator, it mainly utilizes the mechanism of “molecular size difference” and “physical adsorption selectivity” to sieve the gases in the air: nitrogen molecules are preferentially adsorbed, while oxygen molecules are able to penetrate the molecular sieve and be exported.

The adsorption efficiency, cycle stability and regeneration capacity of molecular sieve directly affect whether the output oxygen concentration can be maintained at 93%±3% of the medical grade standard for a long time, especially for medical or plateau use scenarios, its performance is crucial.

Comparison of common molecular sieve types

| Molecular sieve type | Adsorption capacity | Regeneration performance | Lifespan | Applicable products |

| Ordinary industrial molecular sieve | Adsorption speed is slow | Regeneration is poor | Easy to be pulverized, short lifespan | Mostly used in low-end models |

| High-performance medical-grade molecular sieve | Adsorption speed is fast | Can be regenerated again and again | Long lifespan (>3 years) | Mid-end and high-end home/medical oxygen concentrators |

High-quality brands:

France CECA: high adsorption capacity, strong resistance to chalking, good stability;

Japan TOSOH: strong suitability, excellent particle uniformity;

UOP: suitable for high-flow, high-purity continuous oxygen equipment.

The medical grade molecular sieves produced by these brands not only have high adsorption efficiency, but also have better pressure resistance and thermal stability, which are suitable for application in medical environments or plateau environments that require all-weather operation.

Although the molecular sieve is invisible and intangible, it is one of the core devices that determine the “usefulness” of the oxygen concentrator. Choosing high quality molecular sieve is not only related to whether the oxygen concentration is up to standard, but also determines whether the whole machine is durable, safe and energy-saving. For users who pursue medical grade standard or long time stable output, it is more critical to look at the molecular sieve than the panel.

Ⅲ.The compressor technology in detail: to determine the stability of operation and life expectancy

The Role of Compressor

In the oxygen generator system, the role of compressor is to pressurize the inhaled air and send it to the molecular sieve adsorption tower. Only to reach the set working pressure, the molecular sieve can adsorb nitrogen and release oxygen normally. Therefore, the compressor is not only the “power core” of the oxygen generator, its performance also directly affects:

Whether the oxygen flow is stable

Whether the adsorption efficiency is up to the standard

Whether the equipment can be operated continuously for a long time

Noise control and service life of the whole machine

It can be said that the molecular sieve determines the oxygen concentration, and the compressor determines the “ability to produce oxygen continuously” and the “ability to produce oxygen continuously” and “ability to produce oxygen continuously”.

Mainstream compressor structure and type

1. Oil vs. oil-free compressor

| Type | Characteristics and Comparison | Scope of application |

| Oil-type | Lubricating oil is required, high power, but not environmentally friendly, frequent maintenance, | Industrial oxygen production, large-scale equipment |

| Oil-free type | No lubrication, low noise, simple structure, green and environmentally friendly | Oxygen concentrators for domestic and medical use |

✅ Oxygen concentrators for domestic and medical use are generally used oil-free compressors, which are more suitable for high-frequency and long-time operation due to their easy maintenance, low noise, no oil pollution. It is more suitable for high frequency and long time running.

2. Single vs Double Cylinder Compressors

| Type | Feature & Comparison | Applicable Scenarios |

| Single Cylinder | Simple structure, low price, but limited exhaust capacity | Light load household equipment |

| Double Cylinder | Double cylinder structure has stronger output, smoother work, and better load resistance | Medical grade oxygen generator, 5L or above models |

✅ It is recommended to choose a double-cylinder compressor for high-flow oxygen demand (e.g., 5-10L/min), which can ensure the stable supply of air when the load increases.

3. Scroll compressor (rarely seen in civilian oxygen generator)

Scroll compressor replaces piston movement with its rotary structure, running almost no vibration, very low noise, very high efficiency, widely used in high-end industrial equipment or deep cooling air separation system. Its cost is high and it is not suitable for home portable oxygen equipment.

✅ Summary of recommendations

When selecting an oxygen concentrator, in addition to focusing on “oxygen concentration” and “flow rate”, you should also pay attention to:

whether the type of compressor is a high-efficiency oil-free type;

whether it adopts a double-cylinder low-noise design;

whether it provides compressor warranty and technical support services;

whether it is Whether the compressor brand or technical parameters (such as displacement, power, operating life) are indicated.

The compressor is the “heart” of the oxygen generator, which determines whether the equipment runs for a long time, runs steadily and quietly. Choosing the right compressor is a key step to ensure the efficient operation of the equipment, reduce the cost of use and extend the life of the equipment. Especially for highland, hospital, chronic disease oxygen therapy and other scenes, the compressor performance difference of one point, the use of experience difference of ten points.

Ⅳ. The molecular sieve and compressor matching relationship

In the core system of oxygen generator, molecular sieve and compressor are like a pair of left and right hands, one is indispensable, and must work in coordination. A lot of equipment surface parameters are excellent, but the measured effect is not ideal, often in the two match. Understanding the interaction between the two is a key step in judging the quality of equipment.

❓ Why is a good compressor with poor molecular sieve useless?

Even if the compressor provides sufficient compressed air, if it is paired with low-end molecular sieve with poor adsorption efficiency, loose particle structure or weak regeneration capacity:

Nitrogen can not be fully adsorbed, resulting in the purity of oxygen can never reach the standard of medical grade (≥ 93%);

Rapid saturation of the molecular sieve, fluctuations in efficiency, resulting in a continuous decline in oxygen concentration;

The overall system is “powerful”, but not “powerful”; The overall system is “powerful”, but not ‘powerful’, but not “powerful”. Although the overall system is “powerful”, it fails to “output results”, which is manifested in unstable oxygen flow, low purity, and frequent switching of the machine, which increases energy consumption and system wear and tear.

❓ Why change the large molecular sieve, oxygen production is not ideal?

Some users try to replace the higher level of molecular sieve (such as CECA, UOP), hoping to improve the oxygen concentration, but found that the performance of the equipment is not significantly improved, or even worse.

The problem often lies in: insufficient compressor airflow or insufficient air supply pressure. If the compressor can not provide the molecular sieve to start adsorption of the minimum working pressure required (usually at 0.3 ~ 0.5MPa), then even if the molecular sieve is more advanced, it is also “no gas can be sucked”, completely unable to play the adsorption advantage.

Similar to the installation of a high-performance engine, but only half throttle, the performance can not be released;

in high altitude, humidity or continuous operation of the scene is more obvious, the lack of compression will lead to the system “can not be compressed, running”.

Professional advice

When buying an oxygen concentrator, do not only look at the “oxygen concentration” and “flow rate” parameters, but should pay attention to whether the compressor and molecular sieve configuration is clearly labeled, such as brand, model, specification matching;

Prefer models designed by the same brand system integration, such as the MINNUO series products. Prefer those models designed by the same brand system integration, such as MINNUO series products, the compressor and molecular sieve for two-way fit, overall optimization.

Oxygen generator is not a “half” equipment. The molecular sieve and compressor must realize “efficient synergy” to ensure stable oxygen concentration, durable equipment, quiet operation and reasonable energy consumption. If the match is good, the equipment will be reliable; if the match is wrong, even the high parameters will be an illusion.

Ⅴ.How to choose and buy the oxygen concentrator equipped with high-quality core components

When choosing an oxygen concentrator, many users tend to fall into the misunderstanding of “only looking at the oxygen concentration”, “pursuing high flow rate”, “focusing on the appearance of the function”, while ignoring the two core elements that really affect the performance of oxygen production – molecular sieve and compressor. Molecular sieve and compressor are the core elements that really affect the performance of oxygen generation. They not only determine the actual effect of the equipment, but also affect the service life, operational stability and maintenance costs.

The following are practical suggestions for general-purpose home users, medical purchasers or cross-border traders.

Recommendations for general-purpose users: three checks and one question

✅ 1. Check whether the brand and model of molecular sieve and compressor are clearly indicated

Quality manufacturers will clearly indicate the brand of molecular sieve (e.g., CECA, UOP) and the parameters of the compressor (e.g., power, flow rate);

If the product is only labeled with vague parameters such as “oxygen concentration”, “operating time”, etc., but not with any other parameters, then it is not recommended to purchase a new compressor for this purpose. If the product is only labeled with vague parameters such as “oxygen concentration” and “running time” without mentioning the core components, it is recommended to choose with caution.

✅ 2. Check whether it supports molecular sieve replacement or compressor maintenance.

As a consumable, molecular sieve has a limited adsorption life, so you should choose a model that supports original replacement service.

Is the compressor closed? Is it maintainable? Is there a technical response window? This determines the cost and stability of the equipment for the next 3~5 years.

✅ 3. Check whether there are protection mechanisms such as concentration monitoring, abnormality alarm, overheating protection, etc.

A good oxygen concentrator is not only strong in performance, but also should be guaranteed in safety and intelligent control;

Is the oxygen concentration displayed in real time? Is there a low concentration/high temperature alarm function? This reflects whether the equipment is designed to consider the stability of the user’s long-term use.

❓ A question: Is there any certification and after-sales protection?

Has it passed ISO 13485, CE, FDA and other international standards certification?

Does it provide 1~3 years warranty for core components? Does it support OEM/ODM service for export market?

✅ MINNUO Product Recommendation

As a brand focusing on gas equipment manufacturing and exporting, MINNUO always adheres to the high standard configuration in the core system of oxygen concentrator, bringing customers solutions with high performance, stability and customization ability:Supports long-term oxygen output of 93±3%, which is suitable for both home and medical treatment.

Self-developed high-efficiency oil-free compressor:No lubricant, low noise design, smooth operation, suitable for family night or hospital ward quiet environment;Exhaust efficiency is stable, to ensure that the plateau, high humidity areas can also be sustained oxygen supply.

All series are equipped with concentration monitoring and intelligent control system:real-time display of oxygen concentration;automatic alarms for over-pressure, over-temperature and low concentration;many models support App remote management function.

Diversified customized services:support molecular sieve and compressor separate replacement;OEM , language menu customization, voltage/frequency international standard conversion services;provide one-stop supporting services for global agents, e-commerce platforms, and medical engineering projects.

A good oxygen concentrator is not only “oxygen concentration up to standard”, but also in the core components “reasonable”, “stable and long-lasting”, ‘service’, “service”. “Service to the point” on the effort. Especially for long-term use, special environment (such as plateau / high temperature) or export trade users, from the source to choose the core components of high-quality products, is the most cost-effective investment.

Conclusion

Molecular sieve and compressor are the “soul double core” of an oxygen generator, which determines the oxygen production capacity, service life and safety performance. They are not only the combination of materials and power, but also a set of matching science and technical stability of the system engineering. Users in the purchase of oxygen concentrator, not only to see the surface parameters, should pay more attention to its “heart” and “brain” is excellent and reliable.

If you are looking for an oxygen generator with stable performance and reliable operation, the series of products provided by MINNUO will be a trustworthy choice. From molecular sieve process to compression system optimization, from home healthcare to clinical oxygen therapy, MINNUO always creates efficient, safe and intelligent oxygen solutions with global standards.

sales2:+86 17506119168

sales2:+86 17506119168