Nitrogen generation is about purity and cost. Oxygen generation is about life and safety.

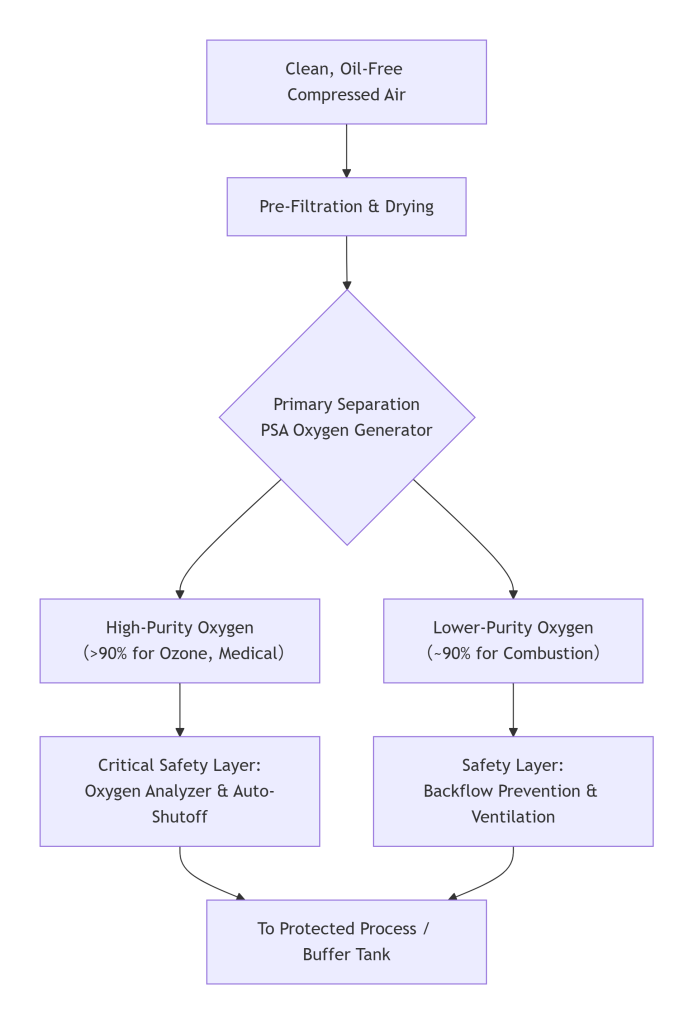

Whether it’s for medical gas backup, ozone production for water treatment, or enhancing combustion in a furnace, an on-site oxygen generator represents a paradigm shift in supply—from delivered cylinders to autonomous production. But this shift comes with a non-negotiable dual mandate: the system must be intrinsically safe while delivering uncompromising efficiency and purity.

Fail in safety, and you risk catastrophic fire. Compromise on efficiency, and your operational costs spiral. This guide delves into the engineering principles that meet this dual mandate, moving beyond sales specs to the critical implementation details that define a truly reliable oxygen supply.

I. The Foremost Priority: Designing for Inherent Oxygen Safety

Oxygen doesn’t burn; it dramatically accelerates combustion. At concentrations above 23.5%, materials behave differently. Safety isn’t an add-on; it must be designed in from the molecular level up.

- The Oil-Free Imperative: Hydrocarbons and pressurized oxygen are a deadly combination. A true medical-grade or industrial oxygen generator must be fed by a 100% oil-free air compressor (Class 0). Any trace of oil in the air stream can accumulate in the sieve beds, creating a potent fuel source.

- Material Compatibility: Every component in contact with enriched oxygen—valves, piping, vessels—must be made of oxygen-compatible materials (typically stainless steel 316L or copper alloys). These materials resist ignition and burning in an oxygen-rich environment. Standard carbon steel or incompatible seals are a severe hazard.

- Contamination Control: The system design must prevent backflow and include inlet filters rated for oil and particulate removal. The adsorption towers and piping should be designed to be cleanable and inspectable.

II. The Efficiency Challenge: PSA Oxygen vs. PSA Nitrogen

While both use Pressure Swing Adsorption, separating oxygen (O₂) from air is a different game than separating nitrogen (N₂).

- The Adsorbent Difference: Oxygen generators use a Nitrogen-Selective Sieve (typically a specialized zeolite). It adsorbs nitrogen, allowing oxygen to pass through. This sieve is often more sensitive to moisture and CO₂ than carbon molecular sieves used for nitrogen.

- The Purity-Pressure Trade-Off: For a given sieve and cycle design, oxygen purity is inversely related to recovery rate. Pushing for 95%+ purity for medical or ozone use requires more precise control and often results in lower oxygen recovery (higher specific energy consumption) compared to a 90% purity industrial unit.

- The Heat of Adsorption: Adsorbing nitrogen releases heat. In high-throughput systems, managing this thermal swing is crucial for maintaining consistent purity and sieve life. Poor thermal design leads to unstable output.

III. The Application Dictates the Specification

There is no “one-size-fits-all” oxygen generator. The end use defines the critical parameters:

- Medical Oxygen (93% ±3%): The standard is rigid. The system must have continuous purity monitoring with automatic diversion to vent if purity falls outside spec. Redundancy (dual PSA units) is common. Documentation for regulatory compliance (like ISO 13485) is as important as the hardware.

- Ozone Production (90-95% Purity): Purity directly correlates with ozone yield. Efficiency is key. These systems often run continuously at high load. Feed air dew point is critical, as moisture poisons the sieve and reduces output.

- Combustion Enhancement / Oxidization (25-90% Purity): Requirements vary widely. A furnace might only need 25-30% O₂ enrichment, allowing for simpler, higher-recovery designs. Corrosion resistance in the exhaust gas stream becomes a secondary design factor.

IV. The 5-Point Pre-Purchase Audit for Your Oxygen Project

Before selecting a system, answer these questions thoroughly:

- Air Source: Is your compressed air supply guaranteed Class 0 oil-free? What is its worst-case dew point?

- Purity & Flow Profile: What is your exact required purity and flow rate over time? Is demand steady or cyclical?

- Safety Certifications: Does the proposed system have material compatibility certificates for oxygen service? Is the control system designed with fail-safe oxygen safety logic (e.g., high-purity purge, automatic shutdowns)?

- Total Cost of Ownership: Calculate beyond the capex. Include the cost of sieve replacement (every 5-10 years), energy consumption at your intended load, and planned maintenance.

- Vendor Expertise: Does the provider have a proven track record in your specific application (medical, ozone, industrial)? Can they provide detailed process and instrumentation diagrams (P&IDs) that reflect safety in design?

Frequently Asked Questions

Q: What is the main difference between an industrial oxygen generator and a medical oxygen generator?

A: While the core PSA technology is similar, medical oxygen generators are built as life-support devices. They require stricter certifications (like ISO 13485), redundant safety systems (e.g., dual oxygen analyzers with automatic shutdown), and must deliver oxygen consistently at 93% ± 3% purity as per pharmacopoeia standards. Industrial units prioritize efficiency and cost for applications like ozone production or combustion, where purity can vary within a wider band.

Q: Why is oil-free air so critical for an oxygen generator? What happens if there is oil contamination?

A: Hydrocarbons (oil) and high-concentration oxygen under pressure create a severe fire and explosion hazard. Even trace oil can accumulate on the molecular sieve, dramatically increasing the risk of auto-ignition. This is why a Class 0 oil-free compressor is non-negotiable. Contamination also degrades sieve performance, leading to rapid purity loss.

Q: We need oxygen for ozone generation. What purity level is typically required, and what are the key specs to look for?

A: Ozone generators typically require feed oxygen at 90% to 95% purity. Higher purity directly increases ozone yield and system efficiency. Key specs include: 1) Guaranteed outlet purity under your specific operating conditions, 2) Dew point of the feed air (must be very low, e.g., -40°C or better, to protect the sieve), and 3) Specific energy consumption (kWh/Nm³ of O₂), which determines your long-term operating cost.

Q: How often does the molecular sieve in an oxygen generator need to be replaced, and what are the signs it’s failing?

A: Sieve life depends on air quality and operating hours, but typically ranges from 5 to 10 years. Signs of failure include: 1) Inability to reach target purity even with adjusted cycles, 2) Increased cycle frequency for the same output, and 3) A gradual, consistent decline in oxygen purity over months. Regular purity logging is the best way to monitor sieve health.

Q: Can we use an oxygen generator as a backup for cylinder supply in a hospital?

A: Yes, PSA oxygen generators are an excellent primary or backup source for hospitals. They provide onsite, continuous supply, eliminating logistics risks. The system must be medically certified, include a buffer tank for instantaneous demand, and have a fallback mechanism (like cylinder banks) that activates automatically if the generator fails or purifies below the required threshold.

Conclusion: Beyond the Generator – A System of Trust

Selecting an oxygen generator is not a commodity purchase. It is the establishment of a lifecycle partnership with a provider who understands that their equipment is the heart of a safety-critical process.

The most reliable systems are born from a philosophy where safety and efficiency are not traded off, but engineered in tandem. It requires a deep understanding of adsorption science, mechanical design for hazardous service, and the operational realities of your plant.

At MINNUO, we approach oxygen generation with this holistic discipline. From specifying the upstream air source to ensuring every wetted component meets the strictest oxygen service standards, our focus is on delivering more than just gas—it’s about delivering unwavering reliability and safety for your most critical applications. In the world of oxygen, there is no room for compromise.

sales2:+86 17506119168

sales2:+86 17506119168