In 2025, global sourcing will no longer be a standardized process of “compare prices – place an order – wait for delivery”. In the face of fast-changing geopolitical situations and frequently adjusted trade policies, the enterprise procurement chain is undergoing a profound restructuring. From tariff barriers to logistics bottlenecks, from technical standards to regulatory compliance, every variable may become a key factor affecting delivery, budget and even project success or failure.

Especially in the field of industrial and medical key equipment, such as oxygen systems, European and American companies are facing not only higher equipment prices, but also comprehensive challenges related to on-time delivery, smooth customs clearance, production compliance and long-term stable operation. You may be thinking: Will equipment purchases be interrupted due to policy? How to choose the brands and solutions that you can trust in the midst of the turbulence?

This article will focus on “how to build supply chain resilience against trade wars and policy uncertainties” as the core, analyze the real problems faced by oxygen systems in the current procurement environment and the evolution of risk trends, and combined with MINNUO’s practical experience, to provide practical solution strategies and procurement advice, to help you control the project at the source, to help you control the project at the source, to help you control the project at the source, to help you control the project at the source. This will help you to control project risks from the source, and ensure delivery stability and long-term investment returns.

1.Market Pressures in 2025: What’s Affecting Oxygen System Costs?

Oxygen equipment purchasing in 2025 is not just about “price increases” – it is about structural cost reorganization and systemic uncertainty. Especially in steel, electronic control, shipping and certification, customers are generally facing five major pressure sources:

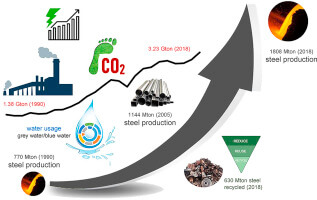

1.1 Raw material prices continue to rise, compression of systematic cost space

Stainless steel, aluminum, carbon steel and other key materials prices generally increased by more than 15%, the biggest impact is the following links:

PSA/VPSA system adsorption tower, tanks, support frames and so on, a large number of stainless steel structural components need to be used

Carbon steel pressure vessels used in high-pressure systems are difficult to replace due to welding standards and plate quality.

Restrictions on imported raw materials for certain components have led to a “passive price increase” in the domestic supply chain.

Response: Priority is given to evaluating domestic material substitution programs, especially for industrial gas systems that require high structural strength but have relatively flexible standards.

1.2 Restricted supply chain of electronic components, double risks of delivery and cost

In 2025, key electronic components such as PLC motherboards, industrial touch panels, servo drives, solenoid valves and other key components still rely on imports from high-tariff countries such as Japan, Germany, and the U.S. The impact is as follows:

Extension of the regular delivery period to 10~14 weeks

Frequent fluctuations in prices, unable to lock in the offer of the long-term project

Increased policy uncertainty of the risk of embargoes or export control Uncertainty

Suggestion: In cooperation with MINNUO, you can choose Chinese and Korean brands as an alternative (e.g. Inovance Huichuan/ LS), which can control the delivery time to less than 6 weeks and reduce the risk of export policy in sensitive areas.

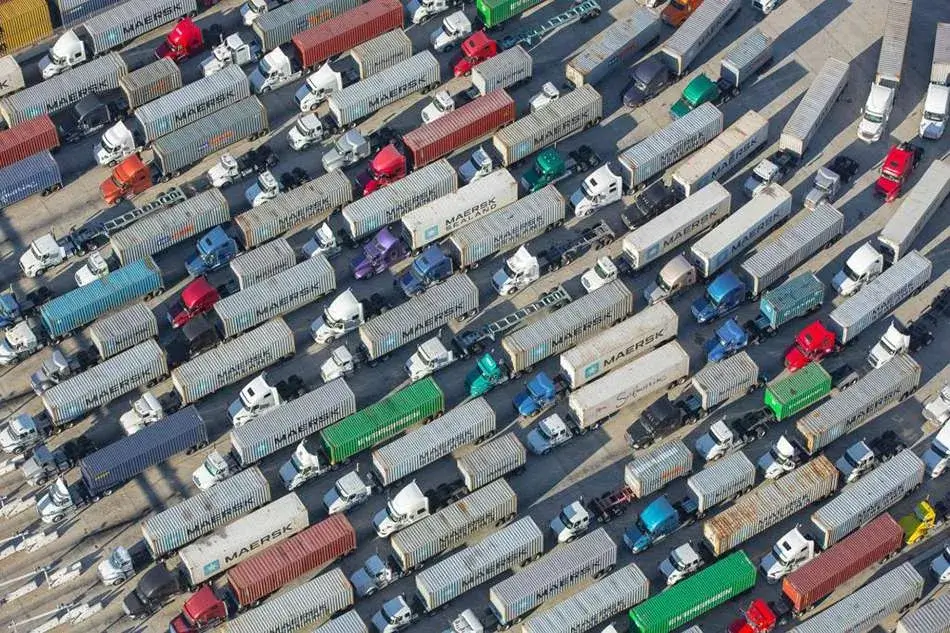

1.3 Poor logistics channel: port congestion + non-compliance of documents = double the cost

Congestion increases in major ports such as the U.S. East, U.S. West, Rotterdam, etc. Once there is a “missing document / HS classification error”, customs clearance delay will lead to the following problems:

daily storage costs

delay in the installation of the project plan, the cost of construction

government subsidies or equipment filing failures. Failure to file

Suggestion: Choose a manufacturer that supports DDP delivery, such as MINNUO, to lock in the responsibility of freight and customs clearance, and reduce trade risks. We also provide complete Customs Classification Proposal + Certificate of Origin + Export Declaration Template.

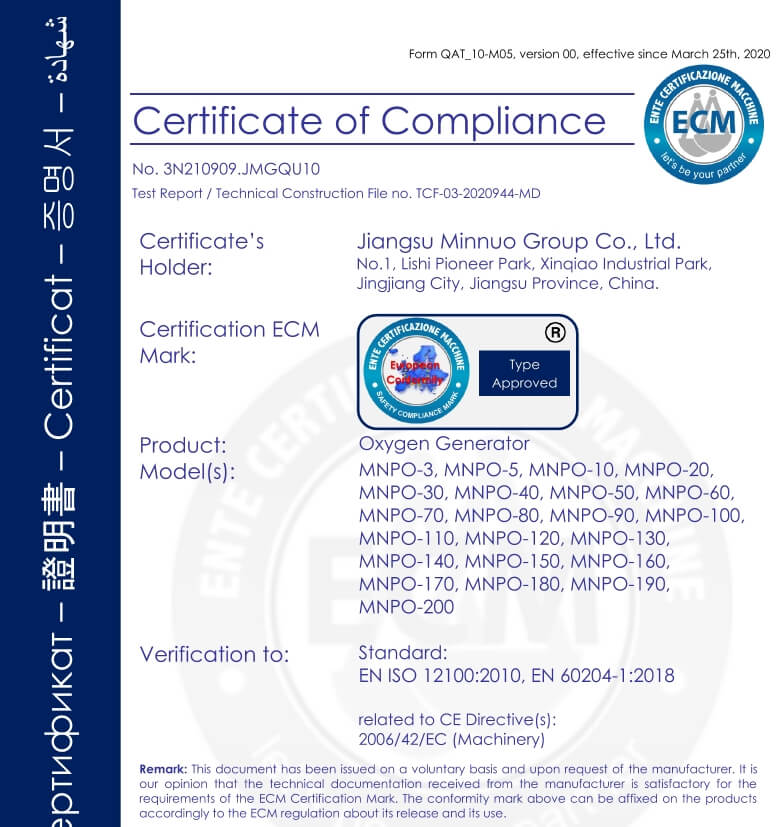

1.4 Multiple Compliance Thresholds: Loss of Access if Equipment is not Certified

CE, PED, ASME, ISO13485 and other certifications are not just “standards”, they are mandatory conditions that determine whether the equipment can be accepted by healthcare systems, environmental protection agencies, or government programs. It is a mandatory condition for acceptance by medical systems, environmental organizations, or government programs.

Especially in the following scenarios:

Medical-grade oxygen supply system (ICU, operating room)

State grid/government green energy projects (environmental certification + financial filing)

High-risk industries (chemical, pharmaceutical, energy)

Suggestion: ask for the original certification documents 1~2 months in advance, MINNUO provides electronic preview version + customs compliance list for all export projects, supporting official filing purposes.

1.5 High-tariff countries focus on imported parts, the BOM structure determines the final cost

Steel (China’s exports were added), valve parts (Japan/Germany), electronic control (U.S., Japan and South Korea) a number of materials are listed as high tariffs, which directly leads to the overall BOM cost increase of 12~25%.

Some enterprises were forced to replace the whole package or return the goods because they failed to evaluate the BOM substitutability in time.

Suggestions:

Prioritize the review of “price fluctuation-sensitive parts” in the BOM

Select equipment systems with “flexible structural design”

Use the substitution BOM strategy template provided by MINNUO to estimate the substitution rate of parts and the impact of finished product certification in advance.

2.The Strategic Role of BOM Flexibility

Flexible BOM, not just a technical issue, but the “bottom line” for controlling equipment procurement risks in 2025.

What is “Flexible BOM”?

A BOM (Bill of Materials) is a list of parts that make up a piece of equipment. The traditional fixed BOM, which relies on a single brand or standard parts of a specific origin, has the advantage of uniformity and standardization; however, this model is now becoming a “source of contagion” for project risks.

The so-called “flexible BOM” refers to the core functions and certification compliance under the premise of ensuring:

Support multi-brand / multi-origin component replacement (e.g. PLC can be flexibly selected from Siemens, OMRON, Huichuan)

With alternative material options (e.g. carbon steel instead of imported high-end stainless steel)

Allow regional differences in the optimization of BOM structure (e.g. the Middle East is important to the thermostat). For example, the Middle East focuses on thermostats, while the EU focuses on CE marking packages)

Why is BOM flexibility the bottom line for equipment procurement in 2025?

In the context of high tariffs, fluctuating raw material prices, and rising international certification thresholds, an inflexible BOM means:

Once the price of a component skyrockets (e.g., aluminum case or high-end diaphragm), the overall equipment cost is uncontrollable

Once the key component fails to clear customs, the whole machine will be stranded or unable to be installed

Once some of the parts are delayed in the delivery schedule (e.g., U.S.-made PLCs, Japanese compressors), the overall project will be delayed

The advantages of a flexible BOM include

✅ Avoid high-risk source countries (e.g. U.S., Japan, Germany)

✅ Dynamically balance price and delivery

✅ Adjust parts grade and supply channel for certification requirements

✅ Support multiple configuration plans to cope with the differences in subsidies, tax rates, customs clearance and other scenarios

Oxygen generation system core components affected list

Pressure vessels (carbon steel/stainless steel)

For example, gas tanks, adsorption towers, if imported 304 stainless steel, the price and customs clearance are extremely sensitive; MINNUO can provide domestic 304/316 alternative + PED certification.

Molecular sieve module (adsorber)

involves high temperature area/high humidity environment application, material selection affects the performance stability; partly domestic reinforced structure can be used to replace high-end American components.

Electronic control system (PLC / touch screen)

such as Siemens, Omron and other brands are limited by export policies or tariff changes, MINNUO supports multi-brand docking, control protocol compatible with Modbus/TCP/IP, etc..

Pneumatic Valves / Compressors / Vacuum Pumps

Such components are often high in price and long in delivery, flexible BOM can be realized through Korean / Chinese brands to replace the function and control the budget.

Comparative case study: fixed BOM vs. flexible alternative cost difference

| Project Dimensions | Fixed BOM program (German configuration) | Flexible BOM program (MINNUO) |

| Pressure Vessels | 316L imported from Germany, price increase +16% | China 304 + internal polishing treatment, cost reduction of 12% |

| PLC Controls | Siemens S7-1200 | Sinkawa/Omron/compatible PLC |

| Solenoid Valves | SMC from Japan, full import clearance slow | China Baoshuo + Korea KCC replacement |

| Project Lifecycle | 90~120 days | Controlled at 45~60 days |

| Overall Percentage Cost Savings | – | Cost reduction of approximately 10~18 |

3.How MINNUO Helps Buyers Build Supply Chain Resilience

3.1 Modularization of alternatives: proactive response to price fluctuations and tariff changes

In the current environment of “tariffs + price shocks”, fixed standard sourcing solutions have become a source of risk. All MINNUO equipment supports modularized BOM alternatives, which allow customers to switch flexibly according to budget, delivery, and certification requirements:

Compressor: support fast switching between Chinese brand, Korean brand and Japanese original

Valve and pneumatic control: support domestic Baoshuo and imported SMC according to the tariff rate allocation

Shell material: support 304/316L stainless steel and high-strength carbon steel alternative strategy, significantly reduce the cost and complexity of customs clearance

Practical tip: We provide “Multi-country tariff + logistics risk assessment table” for customers to compare the delivery efficiency of alternative modules.

3.2 Certification Coverage: Quadruple certifications come standard by default to avoid customs clearance obstacles

MINNUO export equipment standards are accompanied by the following certification information:

CE (European Union Common Compliance Standard)

PED (European Union Pressure Equipment Directive)

ASME (American Pressure Vessel Standard)

ISO13485 (Quality System Standard for Medical Devices)

These certifications cover different scenarios of industrial-grade and medical-grade to meet the requirements for procurement in hospitals, wastewater treatment plants, biofuel projects, and other industries. These certifications cover both industrial and medical applications, and meet the qualification requirements for hospitals, wastewater treatment plants, and biofuel projects. We can also provide:

EAC (Eurasian Economic Union)

TSSA (Ontario Pressure System, Canada)

COI + Chamber of Origin Dual Certification

Practical Tips: We support electronic pre-qualification, paper version with goods and third-party endorsement to ensure the smooth establishment of the project.

3.3 DDP Delivery Guarantee: One price all-inclusive to lock the delivery date and budget

Under the current environment of international shipping turbulence + port clearance complexity, MINNUO provides one-stop delivery covering tariffs/customs clearance/freight:

Clarify the terms of the DDP to lock the delivery price

Assist customers in designating the port of delivery and transit routes (to avoid transshipment and tax increase)

Provide the declaration of the HS Code compliance analysis, to reduce the probability of misjudgement and deductions

Case reference: After a French customer adopted DDP program, the overall delivery time was shortened by 17 days compared with traditional FOB, and the project was delivered ahead of schedule.

3.4 Pre-configuration of energy saving module: support customers to control operation cost and reach ESG target

With the reduction of IRA subsidy and the tightening of carbon tax in Europe, the energy efficiency of the equipment directly affects the operation burden in the later stage of the project. MINNUO equips each set of equipment with the following standard features:

Low-energy VPSA system: ≤0.45kWh/Nm³ operation cost

PID regulation + tail gas recovery function

Inverter control and night energy saving operation mode

These features help customers to control OPEX expenditure. These functions help customers to control OPEX expenditure and reduce dependence on external subsidies.

Customer feedback: A glass factory in the Netherlands reduced electricity consumption by 12% per ton of product through our optimized energy efficiency module, saving nearly €34,000 per year.

3.5 Multi-language remote operation and maintenance support: guarantee stable operation after the equipment is put online.

For customers in Europe and North America, the tight manpower for on-site commissioning is the biggest pain point for project startup. MINNUO provides a complete remote support system:

Multi-language touch screen interface (English, German, French), German, French)

Control system compatible with Modbus, TCP/IP, SCADA mainstream platforms

Remote OTA debugging, fault location, parameter optimization

Provide customer operation manuals + video training + operation and maintenance manuals

Practical tips: we have long-term cooperation in Europe and the United States, technical service providers, according to the needs of the spare parts to provide support for the localization of inventory.

4.Real Case Example

How Food Industry Customers Avoid Equipment Delivery Risks and Save Costs through Flexible BOM and Export Compliance

Customer Background

Country: Belgium

Industry: Food Processing Enterprises

Application Scenario: Encapsulation and Ozone Sterilization with High Oxygen Concentration is required for yogurt filling process to ensure that microbial inhibition standard meets the European Union’s food export regulations.

Technical requirements:

Oxygen flow rate ≥ 40Nm³/h

Continuous operation ≥ 20h/day

Oxygen purity ≥ 93%±3%

CE + PED + food-grade piping adaptability

Problems encountered

Supplier’s delivery time is not controllable

A local brand in Belgium quoted a price up to 1.5 times the equipment purchase budget, and the lead time required was 120 days

Critical control systems and modules had to be shipped from the headquarters in Germany and faced port congestion and customs delays. Port congestion and customs delays

Costs exceeded the original upper limit

Stainless steel material prices increased by 18%

EU electronic control parts (e.g. Siemens PLC) increased by more than 12% per piece, and the whole BOM lost its cost-effectiveness

The policy window is approaching

If the project fails to complete the initial delivery by the end of June, the project will not be able to apply for the Belgian government’s “Local Energy and Carbon Reduction Fund” rebate policy in 2025 “

MINNUO Solution

In order to help customers avoid the risk of delays and cost overruns, MINNUO team provides a complete set of ”tariff optimization + export compliance + module substitution” solution path:

1. Alternative solution

Pressure vessel: domestic food-grade 304 stainless steel, through the neutral salt spray test certification. Neutral salt spray test certification

Control system: replace the original design of German Siemens PLC with China-Korea co-branded PLC (with CE + EMC + IP65 protection certification)

Structural components: compressor / adsorbent tower switch to China’s domestic A-grade manufacturers, with food hygiene standard seals

2. Compliance delivery

Randomly provided with a full set of Belgian/EU version of CE + PED + ISO13485 trilingual certification Certification

Complete “Declaration of Origin”, “Declaration of Matching Materials for Customs Clearance” and “Declaration of Substitution of BOM Documents”

DDP Delivery terms: MINNUO assumes full responsibility for tariffs + port clearance + transportation

3. Project tempo control

Delivery period: production lock-order → assembly completion → sea transportation to the port, the whole process is controlled within 28 days

Installation period: the equipment adopts a modular preassembled structure, and after arrival, it only needs to be connected to the inlet and outlet ports and power supply, and on-line testing can be completed in 3 days

Final results

| Project Indicators | MINNUO Achievements |

| Delivery Cycle | 31 days from order to installation |

| Cost Control | About 18% saving on the budget of the original European solution |

| Policy Compliance | Successfully obtained a funding subsidy of €47,000 from the local energy agency |

| Oxygen System Operation | Fluctuation control ≤ ±0.3% without a single shutdown in the whole year |

| Follow-up Evaluation | Included in the 2026 supplier recommendation list of the customer’s headquarters |

Conclusion

In this uncertain 2025, the global trade situation fluctuates frequently, with abrupt policy changes, escalating logistics costs, and tight supply of key components …… Procurement of Oxygen Systems is no longer a simple technology selection, but a systematic project covering compliance, cost, delivery and stable operations.

However, an uncertain market does not mean that uncertain risks must be taken. You can still find a path to stability in the midst of turbulence through more forward-thinking supply chain design and higher-dimensional sourcing strategies.

This is exactly what MINNUO specializes in: with 30 years of experience in gas equipment manufacturing, MINNUO offers flexible BOM solutions, CE/PED/ASME/ISO13485 certification support, DDP terms and conditions, remote commissioning and multi-language technical services, helping you to build a “buy-now, stabilize-now” supply system. supply system.

sales2:+86 17506119168

sales2:+86 17506119168