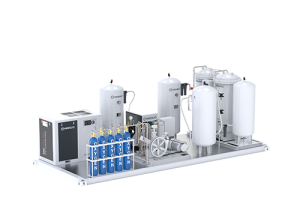

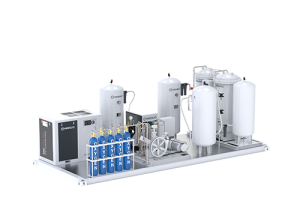

Oxygen Filling Station

Minnuo produces and offers a complete set of oxygen filling stations, that can fill 10-100 cylinders per day. up to 99% Pure Oxygen

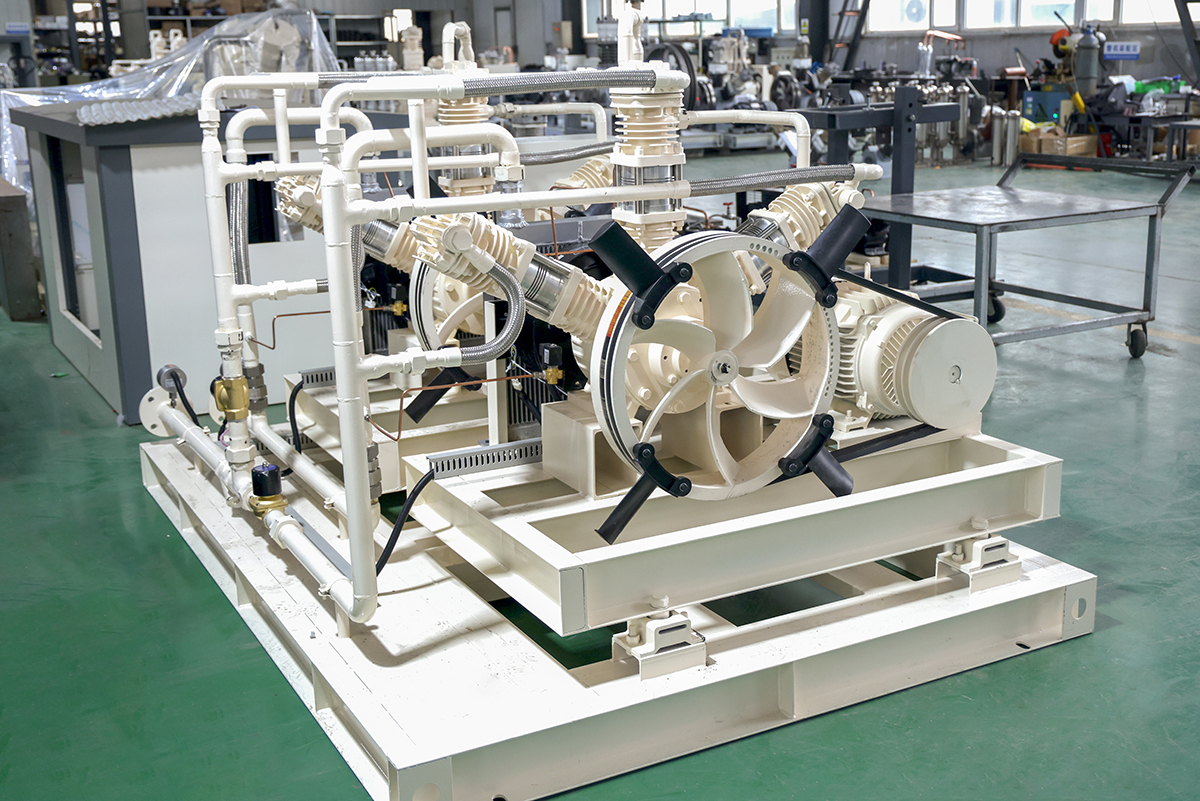

All oil-free compressors do not need to add lubricating oil. The discharged gas does not contain oil or oil vapor, and does not pollute the end products of users. It is an environmentally-friendly and energy-saving product. when used as a general power source, it is more convenient to use than oil-based compressors with low maintenance costs. as the simple stand most ideal equipment to provide high-quality oil-free compressed gas, it saves complicated oil filtering and processing equipment saving a lot of equipment expenses and maintenance costs.

This series of compressors is widely used in air-separation oxygen plant, oxygen circulation system, medical oxygen supply center, industrial combustion cutting and other oxygen industries.

It is completely oil-free. The operating noise is silent, less than 75 dB, and it can

work silently in the medical station area. It operates at a low speed and has a long

service life.

| Model | Intake pressure.barg | Exhaust pressure.barg | Exhaust volume NM3/h | Power.KW |

| MN-10/5-20 | 5 | 20 | 10 | 2.2 |

| MN-30/4-10 | 4 | 10 | 30 | 3 |

| MN-50/3-12 | 3 | 12 | 50 | 5.5 |

| MN-70/4-15 | 4 | 15 | 70 | 7.5 |

| MN-80/4-15 | 4 | 15 | 80 | 11 |

| Model | Intake pressure.barg | Exhaust pressure.barg | Exhaust volume NM3/h | Power.KW |

| GMN-70/4-150 | 3-4 | 150 | 70 | 22 |

| GMN-80/4-150 | 3-4 | 150 | 80 | 30 |

| GMN-90/4-150 | 3-4 | 150 | 90 | 30 |

| GMN-100/4-150 | 3-4 | 150 | 100 | 30 |

| GMN-120/4-120 | 3-4 | 150 | 120 | 370 |

1.The whole compression system has no thin oil lubrication, avoiding the possibility of contact between oil and high pressure and high purity oxygen, ensuring the safety of the machine.

2.The whole system has no lubrication and oil-distribution system. The machine structure is simple, easy to control, and easy to operate.

3.The whole system is oil-free, so the oxygen of the compressed medium is pollution-free, and the oxygen purity of the compressor inlet and outlet is the same.

4.Four-stage compression, water-cooling and stainless steel water cooler are adopted to ensure a good cooling effect of the compressor and effectively extend the service life of key wearing parts. The intake port is equipped with a device for low-intake pressure control and the exhaust end is equipped with an exhaust device. High pressure protection for each stage, high exhaust temperature protection, safety valve and temperature display. If the temperature is too high or overpressure, the system will alarm and stop, ensuring safe operation. There is a forklift at the bottom of the compressor, which can be easily moved. A construction site.

5.Our standard high-pressure oxygen compressor has passed the EU CE certification to meet the requirements of the EU market.

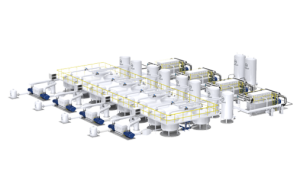

Minnuo produces and offers a complete set of oxygen filling stations, that can fill 10-100 cylinders per day. up to 99% Pure Oxygen

As a designer and manufacturer of the Cryogenic Oxygen Plant, provide cost-effective energy-efficient, and reliable production of oxygen gas, liquid oxygen

China PSA Oxygen generator manufacturer at Good Price, O₂ Capacity: 1~1000Nm3/hr, O₂ Purity: 93%±3%, can customize up to 99%

VPSA Oxygen plant special molecular sieve adsorbs impurities , desorbed under vacuum to produce high purity oxygen (90-95%).

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168