Cryogenic Oxygen Plant

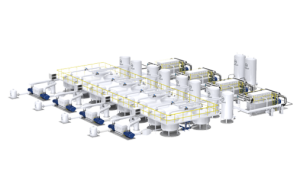

As a designer and manufacturer of the Cryogenic Oxygen Plant, provide cost-effective energy-efficient, and reliable production of oxygen gas, liquid oxygen

MINNUO offers oxygen generators with customizable cylinder filling plants (CFPs) that produce medical-grade oxygen up to 93±3% purity. Our equipment adheres to applicable codes like ASME, ANSI, NEMA, and CE and can meet CRN and CSA standards. The CFPs provide on-demand oxygen 24x7x365 for medical and industrial needs, and can be tailored to specific requirements.

Minnuo Group is a professional manufacturer of oxygen & nitrogen generators, with over 22 years of experience in the industry. Our products are known for their quality and reliability, and are used by businesses and individuals all around the world. We’re dedicated to providing our customers with the best possible products and service, and always put our customers first.

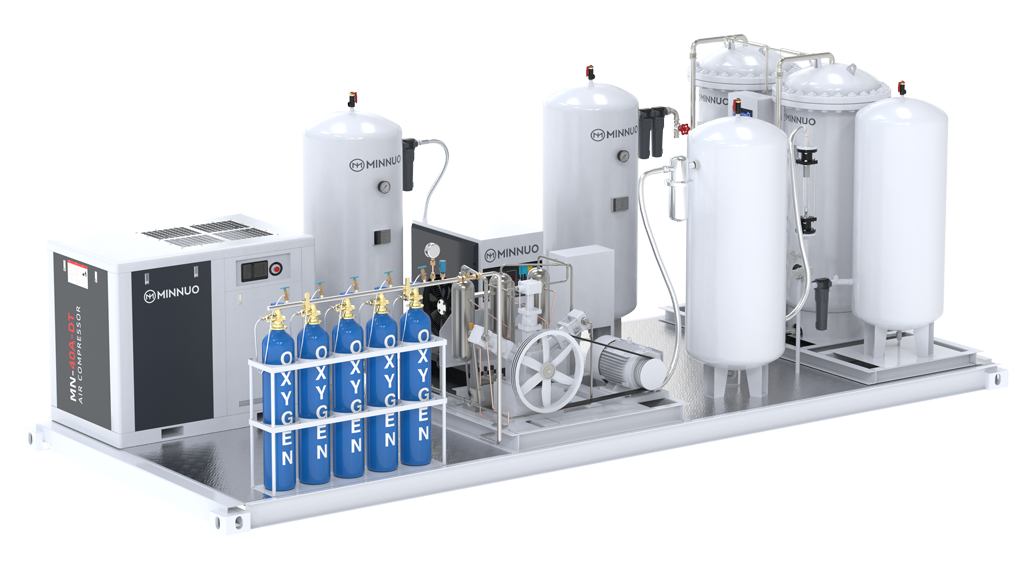

MINNUO Group is a leading manufacturer of PSA, VPSA, Cryogenic air separation technology, and specialized oxygen production solutions in China.We produce a complete set of oxygen cylinder filling system, which can fill 8-100 oxygen cylinders per day. Complete equipment includes air compressor, air dryer, oxygen generator, oxygen compressor and cylinder filling row. The oxygen compressor pressurizes the oxygen to 2,200 psig (15,169 kPa or 151.6 barg) that can fill 10 cylinders at a time. These cylinder filling machines operate automatically and fill 93% oxygen. For special applications, an optional high-purity module can be added to the device to increase the oxygen concentration to 99% .

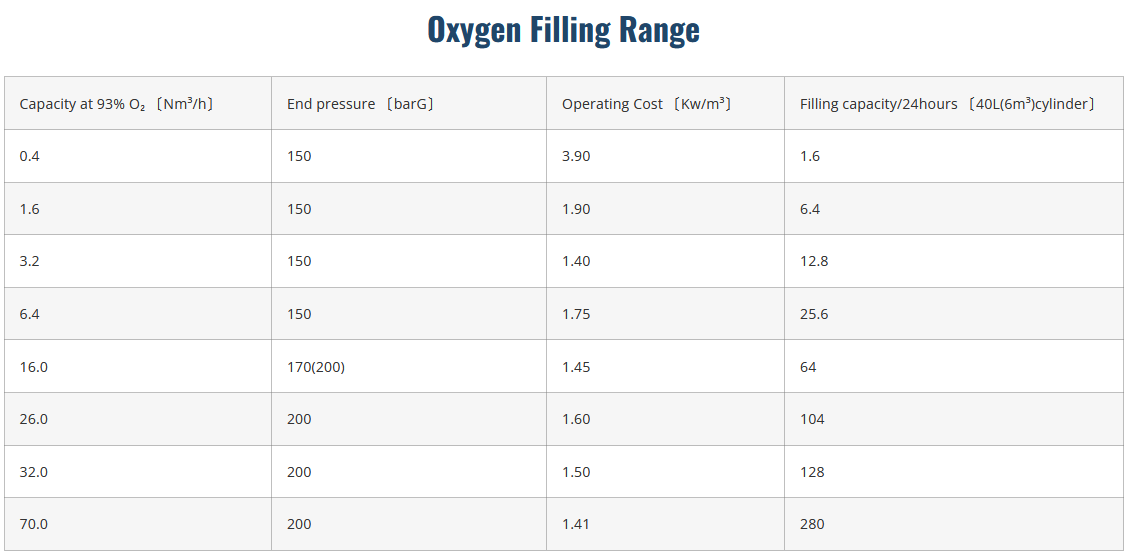

MINNUO offers a full range of high pressure oxygen cylinder filling system of filling 10 to 100pcs medical oxygen cylinders per day at pressure from 150 to 200 bar.

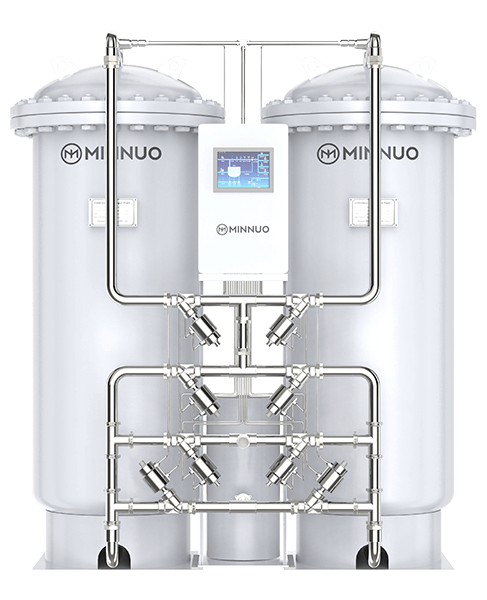

PLC

Process oxygen anlyzer ,Core components imported from Japan

Molecular Sieve from JALOX, UOP

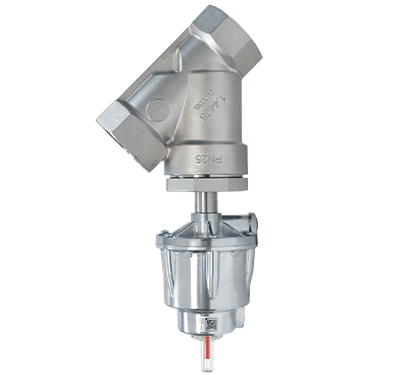

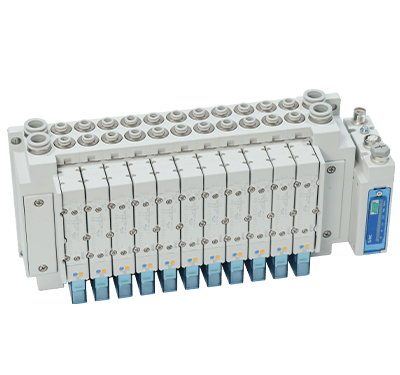

Germany pneumatic valves

Pilot operated solenoid valve

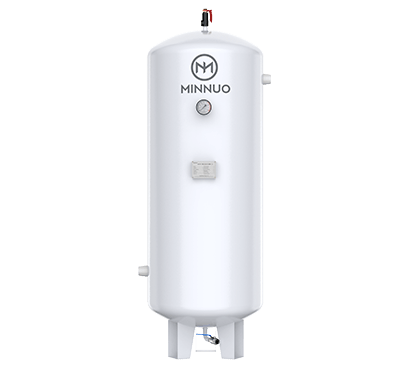

ASME and PED standard air tank

1. Calculate how many cubic meters of oxygen per hour are required?

There are two types of production of oxygen

eg, 40L/200bar oxygen cylinder, 40*200=8000L, about 8m³ of oxygen capacity, then multiply, e.g., filling 100 cylinders/day.100*8=800 m³ of oxygen /day. the oxygen plant working 20 hours, 800/20= 40, then 40 m³ oxygen machine is your required.

2、Tell us the altitude of your local area

Normal altitude below 1KM. Higher altitudes require additional compressors.

3、Determine your local voltage and frequency

The voltage in Australia is 240V and the frequency is 50HZ.

The voltage in Belgium, France is 230V and the frequency is 50HZ.

If you want to know how to maintain the equipment, please contact our technical service department on engineer@minnuogas.com

Our technical service team will give you all support and all necessary information.

Return of investment (ROI) is calculated as 1-2 years. There are many local factors to consider, such as electricity bills, labor, etc.. If you wish to receive a ROI for your project, please contact us on engineer@minnuogas.com.

Installation time depends on the complexity of the equipment supplied. It can take from 2 days to a week.The start-up also includes a basic training of the operators on site.

The startup steps are determined by the type of system you have – only Nitrogen/Oxygen generator, stand alone, skid mounted or containerized. For the filling station, The start-up steps are very easy, you can refer to the operation manual sent to you with the equipment system. If you encounter any problems, Our service team is here to support you anytime (24/7/365).

To increase your capacity, you can use a large Oxygen Plant or add another Oxygen Plant. Please contact us on engineer@minnuogas.com for more details.

As a designer and manufacturer of the Cryogenic Oxygen Plant, provide cost-effective energy-efficient, and reliable production of oxygen gas, liquid oxygen

China PSA Oxygen generator manufacturer at Good Price, O₂ Capacity: 1~1000Nm3/hr, O₂ Purity: 93%±3%, can customize up to 99%

VPSA Oxygen plant special molecular sieve adsorbs impurities , desorbed under vacuum to produce high purity oxygen (90-95%).

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168