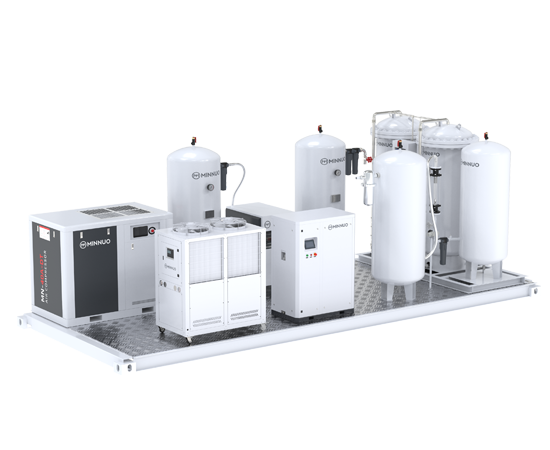

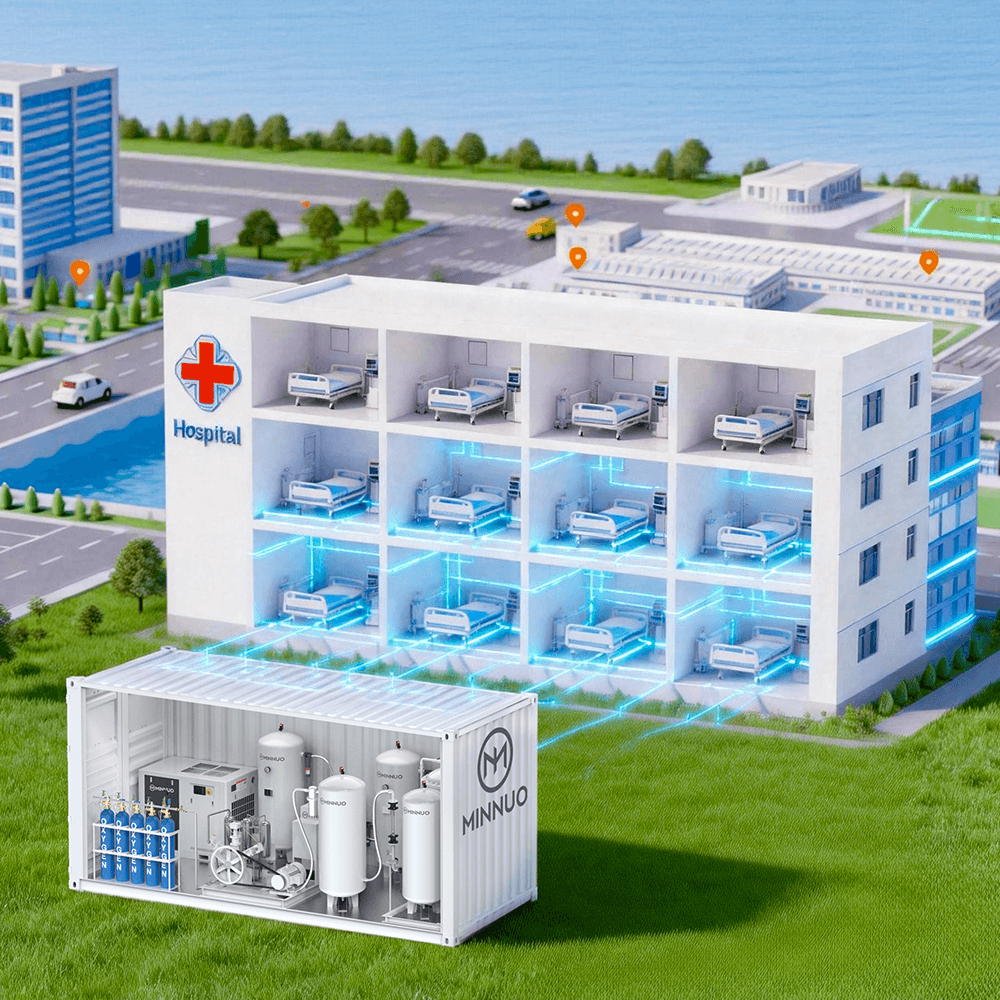

1. For hospital beds: 2-3LPM per bed can be used, for example, 100 beds is 300LPM (300*60=18000L/hour=18Nm3/hour), it is recommended to use 20Nm3/hour equipment, which is our MNPO-20/93 equipment.

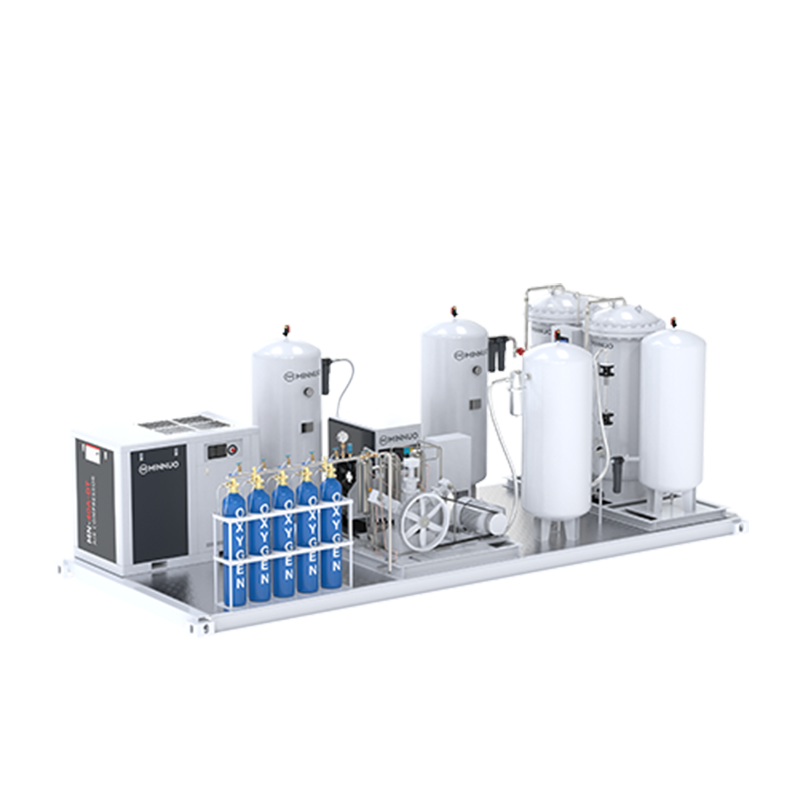

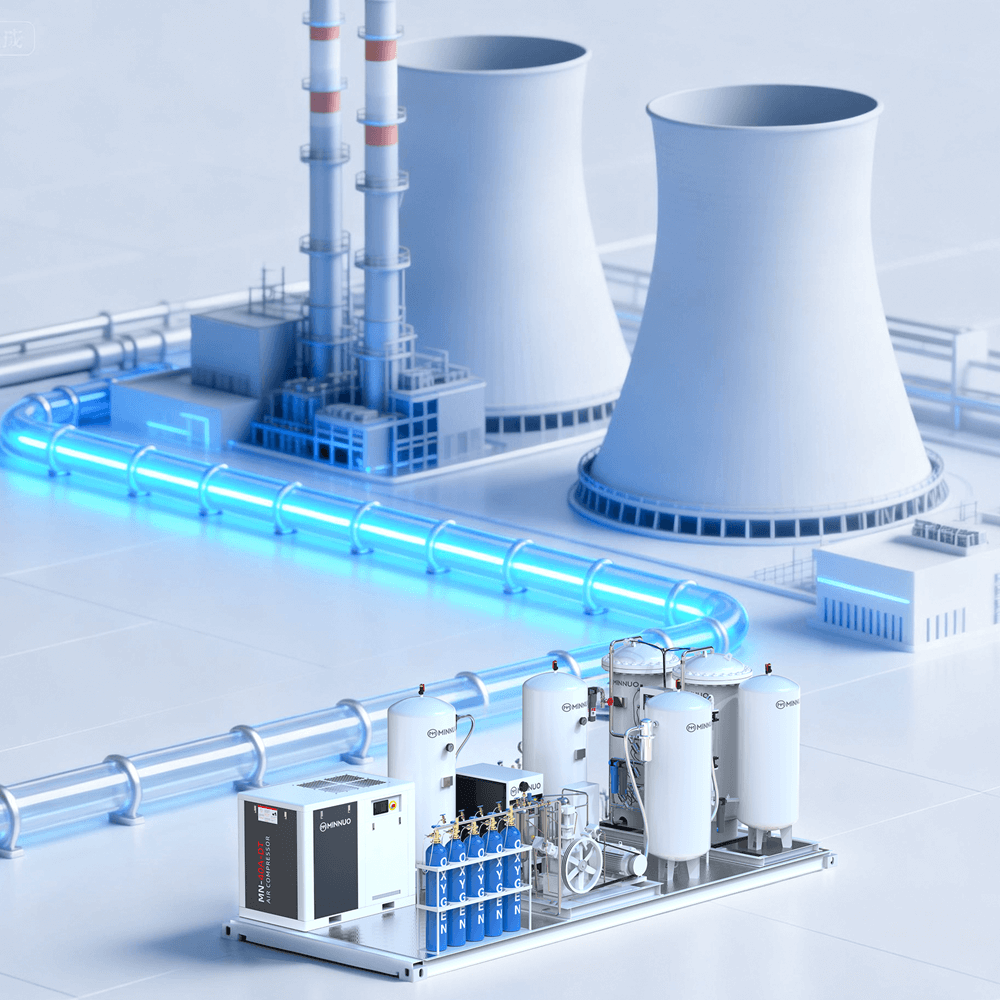

2. For filling oxygen bottles: the volume of oxygen stored in each oxygen bottle is water volume * filling pressure, for example: 100 bottles of 40L oxygen bottles are filled every day, and the filling pressure is 150 bar, so each bottle is about 6 cubic meters of oxygen, 100 bottles is 600 cubic meters, according to the calculation of 24 hours a day, 25Nm3/hour equipment is needed.

sales2:+86 17506119168

sales2:+86 17506119168