In today’s era of rapid development in global medical and health undertakings, a stable, safe, and efficient oxygen supply has become the “lifeline” for the normal operation of medical institutions. From the golden 4 minutes of emergency rescue to long-term oxygen therapy for patients with chronic respiratory diseases, and from the operating rooms of large Grade-A tertiary hospitals to primary clinics in remote areas, the quality of oxygen and the continuity of supply are directly related to medical quality and patients’ lives. As an industry leader with over 20 years of experience in Pressure Swing Adsorption (PSA) oxygen generation technology, Jiangsu Minnuo Group, relying on its in-depth understanding of medical scenarios and technological innovation capabilities, has provided nearly 3,000 customized oxygen supply solutions to medical institutions in more than 50 countries and regions around the world. This article will comprehensively analyze how PSA oxygen generators reshape the modern medical oxygen supply system from the perspectives of technical principles, international standards, application scenarios, cost advantages, and future trends.

I. Decoding PSA Oxygen Generation Technology: The “Air-to-Oxygen” Magic in Medical Oxygen Supply

1.1 Core Principle: Efficient Nitrogen-Oxygen Separation at Room Temperature

The Pressure Swing Adsorption (PSA) oxygen generation technology is a gas separation technology developed in the 1970s. Its core advantage lies in its ability to use air as a raw material and achieve efficient oxygen extraction through physical adsorption principles. The medical PSA oxygen generators of Jiangsu Minnuo Group adopt high-performance lithium-based molecular sieves as adsorbents. This special material has a strong selective adsorption capacity for nitrogen. Under pressurized conditions, the molecular sieves preferentially adsorb impurity gases such as nitrogen and carbon dioxide in the air, allowing oxygen to pass through the adsorption tower. When the system is depressurized, the nitrogen adsorbed by the molecular sieves is quickly desorbed and discharged, restoring the adsorption capacity.

Through the alternating pressurized adsorption and depressurized desorption of two adsorption towers, the equipment can continuously produce medical oxygen with a stable oxygen concentration of 93% ± 3%. This indicator fully complies with the “Oxygen 93 Percent” standard of the United States Pharmacopeia (USP) and the minimum concentration requirement of 94% in the European Union. The entire process requires no chemical additives and no high or low-temperature environment, truly realizing a green oxygen generation mode of “on-demand production, turning air into oxygen”.

1.2 Technological Upgrades: The Core Competitiveness of Minnuo Group

As a senior engineer of PSA oxygen generators, I have always believed that technological innovation is the core of a product’s vitality. Jiangsu Minnuo Group has achieved three major breakthroughs based on traditional PSA technology:

First, the molecular sieve composite bed technology: We use a composite filling structure of imported carbon molecular sieves and lithium-based molecular sieves. The adsorption capacity is increased by 20% compared with the industry average, and the service life is extended to more than 8 years. This design enables the equipment to maintain an adsorption efficiency of over 92% even in complex environments with high humidity and high dust, making it particularly suitable for medical institutions in tropical regions and areas with severe industrial pollution.

Second, the intelligent control system: Equipped with PLC intelligent control system, it can real-time monitor 12 key parameters such as oxygen concentration, pressure, and flow rate. When the oxygen concentration is lower than 90% or the pressure fluctuation exceeds ±0.02MPa, the system will immediately trigger an audible and visual alarm and automatically switch to the backup oxygen source. Through the Internet of Things module, the equipment also supports remote monitoring and fault early warning. Engineers can complete parameter debugging and fault diagnosis from thousands of miles away, achieving an operational reliability of 99.9%.

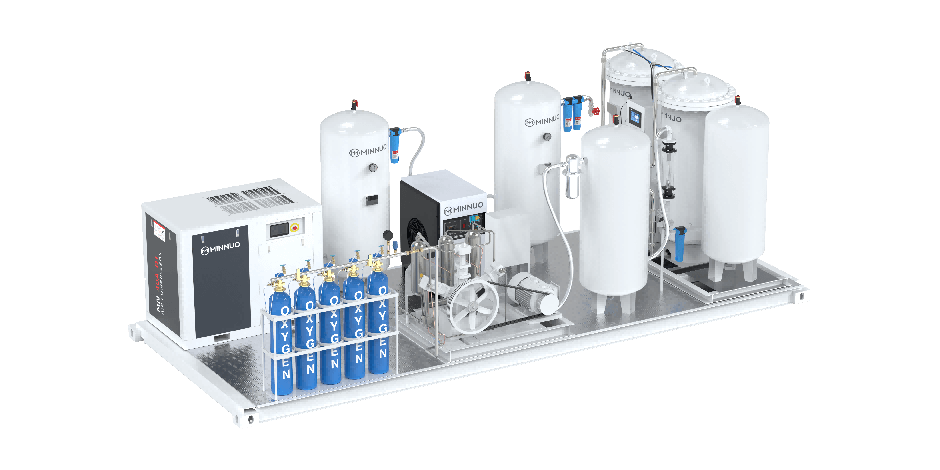

Third, the modular integrated design: To meet the needs of medical institutions of different scales, we integrate core components such as the oxygen generation host, air compressor, filter, and air storage tank into standardized modules. The small module covers an area of only 1.5 square meters and can meet the needs of primary clinics with fewer than 60 beds. The large-scale unit can achieve an oxygen production capacity of 5,000 Nm³ per hour through multi-module parallel connection, suitable for large hospitals with 1,000 beds. This design not only shortens the installation cycle to 15 days but also facilitates capacity expansion and upgrading according to the growth of oxygen consumption in the later stage.

II. Endorsement by International Standards: The Safety Pass for Medical-grade Products

The core attribute of medical equipment is safety, and international standard certification is the best endorsement of safety performance. The PSA oxygen generators of Jiangsu Minnuo Group have fully passed the mainstream global medical equipment certification systems, providing reliable quality assurance for foreign customers.

2.1 Adaptation to Mainstream Global Standards

Different countries and regions have strict regulatory requirements for medical oxygen generation equipment. Minnuo’s products have achieved full coverage of major international standards:

- U.S. Market: Obtained FDA Class II medical device certification. Among them, large-scale central oxygen supply systems are produced in accordance with cGMP pharmaceutical machinery standards. The produced oxygen meets the requirements of the USP30 Pharmacopeia and can be used in core medical scenarios such as operating rooms and ICUs.

- EU Market: Obtained CE certification (Class IIa medical device), meeting the requirements of the 93/42/EEC Medical Device Directive, and can circulate freely in 27 member states including Germany and France.

- Emerging Markets: Compliant with the medical oxygen equipment standards recommended by the WHO, and has obtained regional certifications such as India’s CDSCO and Brazil’s ANVISA, adapting to the medical regulatory systems of developing countries.

In addition, all products have passed the ISO 13485 Medical Device Quality Management System Certification. From raw material procurement to finished product delivery, they undergo 38 quality inspection procedures. Among them, the oxygen purity inspection adopts an imported laser gas analyzer with an accuracy of 0.1% level.

2.2 Multiple Guarantees for Safety Performance

In clinical applications, safety is always the top priority. The PSA oxygen generators of Jiangsu Minnuo have built a comprehensive safety protection system from the initial design stage:

- Low-pressure operation protection: The system operating pressure is controlled at 1-6 kg/cm², which is much lower than the high-pressure risk of 150 kg/cm² of cylinder oxygen, fundamentally avoiding the risk of explosion.

- Multi-stage purification system: Adopting a four-stage purification process of “primary filtration + intermediate filtration + activated carbon filtration + ultraviolet sterilization”, ensuring that the moisture content in the produced oxygen is ≤ 0.07 g/m³, the CO concentration is ≤ 0.01% (V/V), and the dust particle concentration is ≤ 0.3 μm, fully complying with GMP certification standards.

- Full-cycle safety monitoring: Equipped with multiple safety components such as an online oxygen concentration monitor, pressure safety valve, and high-temperature protection device. The equipment operation data is stored in real-time for traceability, meeting the compliance requirements of medical institutions.

Clinical studies in the United Kingdom, Canada, and other countries have confirmed that the 93% medical oxygen produced by PSA oxygen generators has no difference in clinical efficacy from traditional cylinder oxygen and liquid oxygen, and can be safely used in all medical scenarios such as emergency rescue, surgery, and respiratory support.

III. Full-Scenario Coverage: Oxygen Supply Solutions from Core Departments to Primary Medical Care

The diversity of medical scenarios determines the differentiation of oxygen supply needs. Jiangsu Minnuo Group has created a full-range of PSA oxygen generation solutions based on the characteristics of different medical scenarios.

3.1 Application in Core Scenarios of Large Hospitals

In large general hospitals, operating rooms, ICUs, and emergency rooms are the scenarios with the most urgent oxygen demand and the highest requirements. Taking a Grade-A tertiary hospital with 1,000 beds as an example, its daily oxygen consumption can reach 10,500 m³. The large-scale PSA oxygen generation system of Minnuo Group can perfectly meet such needs:

Application in operating rooms: It provides a stable oxygen source for laparoscopic surgery, coronary artery bypass surgery, etc. Through pressure closed-loop control technology, the oxygen supply pressure fluctuation is controlled within ±0.02MPa, ensuring the accurate operation of equipment such as anesthetic machines and ventilators. A university-affiliated hospital in Germany has adopted our 3 parallel oxygen generation systems, which can simultaneously meet the continuous oxygen supply of 8 operating rooms. The oxygen concentration is stable at 94%-95%, and it has been operating safely for 2,400 days without failure.

ICU intensive care: To meet the long-term oxygen therapy needs of patients with respiratory failure such as COPD and pulmonary fibrosis, the equipment can achieve stepless flow adjustment of 0-10 L/min. When used with a humidifier, it can effectively improve the comfort of the patient’s respiratory tract. The system is equipped with a 4 m³ air storage tank, which can ensure 30 minutes of emergency oxygen supply even during equipment maintenance, building a safety barrier for critically ill patients.

Emergency rescue: The oxygen consumption in the emergency room fluctuates greatly. The response time of Minnuo’s PSA oxygen generator is ≤ 3 seconds, which can automatically increase the oxygen production efficiency during the peak period of emergency rescue. With the automatic switching console of the backup oxygen source, it realizes the seamless switching between the main and backup oxygen sources, ensuring the oxygen demand for the rescue of patients with acute diseases such as myocardial infarction and stroke.

3.2 Adaptable Solutions for Primary Medical Institutions

In primary medical scenarios such as township health centers, community clinics, and nursing homes, low oxygen consumption, limited budgets, and insufficient professional maintenance personnel are common pain points. The small modular PSA oxygen generators of Jiangsu Minnuo just solve these problems:

This type of equipment has a power of only 1.35 KW, and the power consumption per 1 m³ of oxygen produced is about 0.8 kWh, so the operating cost is much lower than that of cylinder oxygen. Taking a township health center that uses 60 cylinders of oxygen per month as an example, after adopting Minnuo’s MOGFZS Type I oxygen generator, the monthly oxygen cost can be saved by more than 30%. The equipment is equipped with a simple split-type oxygen inhalation terminal, which does not require professional pipeline engineering for installation and can operate by plugging in the power supply. Daily maintenance only requires regular replacement of the air filter, which greatly reduces the use threshold of primary medical institutions.

In the rural clinic project in Rwanda, Africa, our portable PSA oxygen generators have played an important role. This equipment weighs only 100 KG and can be transported by motorcycle. It is equipped with a solar power supply module, which solves the problem of no stable power supply in remote areas and has provided oxygen therapy services for more than 2,000 patients with respiratory diseases in the local area.

3.3 Customization for Special Medical Scenarios

In addition to conventional medical scenarios, Jiangsu Minnuo has also developed customized solutions for special needs:

Plateau medical support: In plateau areas with an altitude of more than 4,000 meters, the oxygen content in the air is only 60% of that in plain areas, and the efficiency of traditional oxygen generation equipment is greatly reduced. Our plateau-type PSA oxygen generators can stably produce oxygen with a concentration of more than 90% in an environment with an altitude of 5,000 meters by optimizing the molecular sieve adsorption cycle and compressor power. They have been widely used in border posts and mountaineering rescue stations in the Himalayas.

Emergency medical rescue: For disaster scenarios such as earthquakes and floods, we have developed container-type mobile oxygen generation stations, which can be quickly deployed by trucks or helicopters. This mobile station is equipped with an independent power supply system and an oxygen storage tank. A single unit can meet the emergency oxygen supply needs of 50 people. In the 2023 Turkey earthquake rescue, Minnuo’s mobile oxygen generation station provided a stable oxygen source for the temporary hospital for 72 consecutive hours.

Home medical scenarios: The portable home-use PSA oxygen generator weighs only 5 KG, with a noise level of ≤ 45 decibels. It is equipped with a rechargeable lithium battery and has a battery life of up to 8 hours. The equipment supports real-time display of oxygen concentration and flow adjustment, which is particularly suitable for long-term home oxygen therapy for COPD patients and the elderly. It has passed FDA certification and entered the U.S. home medical market.

IV. Cost Revolution: The Economy of Medical Oxygen Supply under the BOO Model

For medical institutions, the economy of the oxygen supply system directly affects the operating costs. Jiangsu Minnuo Group has innovatively adopted the BOO (Build – Own – Operate) model, combining the cost advantages of PSA oxygen generation technology to provide medical institutions with a long-term cost optimization plan.

4.1 Cost Comparison with Traditional Oxygen Supply Methods

Traditional medical oxygen supply mainly adopts two methods: liquid oxygen and cylinder oxygen, which have obvious cost disadvantages compared with PSA oxygen generators. Taking a hospital with 1,000 beds as an example, we conducted a comparative analysis based on the actual operation data of Hubei Jingzhou Traditional Chinese Medicine Hospital:

Traditional liquid oxygen plan: The average monthly oxygen consumption is 10,500 m³, the purchase unit price of liquid oxygen is 1,000 yuan/m³ (converted to gaseous oxygen of 5 yuan/m³). Adding labor handling fees, equipment maintenance fees, fire management fees, etc., the comprehensive cost reaches 6.3 yuan/m³. The total oxygen cost in 12 years is about 8.12 million yuan.

PSA oxygen generator BOO model plan: The hospital does not need to bear the equipment purchase cost, and only needs to pay the oxygen usage fee of 6.78 yuan/m³ and the electricity fee of 0.56 yuan/m³. The comprehensive cost in the first 9 years is 5.9 yuan/m³. After 9 years, there is no need to pay the oxygen usage fee, and only a small amount of maintenance fees and electricity fees are borne. The total oxygen cost in 12 years is about 6.85 million yuan, which is 1.27 million yuan less than the liquid oxygen plan, and the cost is reduced by 15.6%.

For small primary medical institutions, the cost advantage is more significant. After a community health service center adopted Minnuo’s small PSA oxygen generator, the monthly oxygen cost decreased from 4,800 yuan for cylinder oxygen to 2,100 yuan, saving 32,400 yuan in cost annually, and the investment payback period is only 14 months.

4.2 Core Value of the BOO Model

The BOO model is a cooperative model tailored by Minnuo Group for medical institutions. Its core lies in that the manufacturer undertakes all responsibilities for equipment investment, construction, and operation, and the hospital only needs to “pay on demand and pay after use”. The specific advantages are reflected in three aspects:

Zero initial investment: Medical institutions do not need to invest millions of yuan in equipment procurement, which greatly reduces financial pressure. They can use more funds for the upgrading of medical equipment and the training of medical staff.

Controllable fixed costs: The oxygen usage fee adopts a fixed unit price model, which is not affected by the fluctuation of market liquid oxygen prices, facilitating the hospital’s cost budget management. If the oxygen produced by the equipment does not meet the standards, the hospital can refuse to pay, protecting its own rights and interests.

Full-cycle service guarantee: Jiangsu Minnuo Group is responsible for the lifelong maintenance, consumable replacement, and technological upgrading of the equipment. It has 28 professional after-sales teams and promises a service standard of 2-hour response and on-site service within 24 hours. In a hospital project in Southeast Asia, our engineers quickly solved the problem of abnormal equipment pressure through remote diagnosis, avoiding the risk of oxygen supply interruption.

4.3 Hidden Cost Savings in Long-term Operation

In addition to the direct oxygen cost, PSA oxygen generators can also save a lot of hidden costs for medical institutions:

- Safety cost savings: Low-pressure operation avoids the storage risk of high-pressure gas cylinders, and there is no need to invest in special fire-fighting facilities and safety training costs.

- Labor cost savings: The equipment realizes unattended automatic operation, eliminating the need for special personnel to be responsible for cylinder handling and equipment monitoring, which can save the cost of 2-3 full-time personnel.

- Environmental protection cost savings: Using air as raw material, it has zero emissions and zero pollution, conforming to the global “dual carbon” goal, and avoiding the risk of carbon emission fines during the transportation of liquid oxygen.

The oxygen concentration is stably maintained above 92% in the desert environment. The successful implementation of this project has proved the strong adaptability of Minnuo’s PSA oxygen generators to extreme environments.

V. Future Trends: Development Direction of Intelligence and Greenization

As a senior engineer, I have always paid attention to the development frontier of PSA oxygen generation technology. Combining the changes in global medical needs and the trend of technological innovation, the future medical PSA oxygen generators will show three major development directions:

5.1 Higher Purity and Lower Energy Consumption

With the development of medical technology, some high-end medical scenarios have higher requirements for oxygen purity. Jiangsu Minnuo Group has launched the research and development of 99% high-purity PSA oxygen generation technology. Through new molecular sieve materials and multi-tower adsorption processes, the oxygen purity can be increased to more than 99%, adapting to high-end scenarios such as biological vaccine production and precision medicine.

In terms of energy consumption optimization, we use variable-frequency compressors and waste heat recovery technology to reduce the energy consumption per unit oxygen generation from 0.8 kWh/m³ to 0.6 kWh/m³, further reducing the operating costs of medical institutions and responding to the global call for low-carbon medical care.

5.2 In-depth Integration of Smart Healthcare

PSA oxygen generators are upgrading from a single oxygen supply device to a smart medical terminal. The fifth-generation product being developed by Minnuo Group will integrate AI diagnosis functions. By analyzing the patient’s oxygen therapy data, it can automatically adjust the oxygen supply parameters and generate personalized treatment suggestions. The equipment will also seamlessly connect with the hospital’s HIS system to realize the automatic filing of oxygen therapy data and medical insurance settlement, improving the hospital’s management efficiency.

In the field of telemedicine, portable PSA oxygen generators will be equipped with 5G modules to support medical staff in remotely monitoring the patient’s oxygen therapy effect, which is particularly suitable for the home management of patients with chronic diseases. This function has been piloted and promoted in the European home medical market.

5.3 Upgrade of Scenario-based Solutions

In response to the detailed needs of different medical scenarios, Minnuo Group will launch more customized solutions: in the pediatric scenario, develop a low-flow precision oxygen supply model to avoid the stimulation of high-flow oxygen on children’s respiratory tracts; in infectious disease hospitals, launch negative-pressure isolation oxygen generators to prevent cross-infection during oxygen delivery; in home medical scenarios, realize the linkage between the equipment and wearable devices such as smart bracelets, real-time monitor the patient’s blood oxygen saturation, and automatically adjust the oxygen supply.

VI. Minnuo’s Commitment: A Reliable Partner for Global Medical Oxygen Supply

Since its establishment, Jiangsu Minnuo Group has always taken “guarding the breath of life” as its mission and won the trust of global customers with technological innovation and high-quality services. For foreign customers, we make three core commitments:

6.1 Commitment to Technical Compliance

All exported products comply with the medical equipment standards of the target market and provide complete certification documents and technical materials. According to the voltage, climate, and other environmental characteristics of different countries, personalized equipment debugging is carried out to ensure the stable operation of the equipment in the local environment.

6.2 Commitment to Service Guarantee

Seven global service centers have been established, and localized service teams have been set up in Southeast Asia, Africa, and Europe to realize rapid response to equipment installation, commissioning, and maintenance. It provides “1-year free maintenance + lifelong technical support” services, and conducts regular equipment inspections and performance optimizations.

6.3 Commitment to Flexible Cooperation

In addition to the BOO model, it also provides various cooperation methods such as equipment sales, financial leasing, and technology authorization to meet the needs of different medical institutions. For emergency medical projects, a green channel can be activated to realize global delivery of equipment within 72 hours.

Conclusion: Guarding Global Medical Respiration with Technological Innovation

From technological breakthroughs in the laboratory to wide application in clinical practice, PSA oxygen generators have completely changed the pattern of traditional medical oxygen supply. As a senior engineer of Jiangsu Minnuo Group, I deeply understand that each oxygen generator bears the responsibility of guarding life. In future development, we will continue to deepen technological innovation, optimize the service system, and provide safer, more efficient, and more economical oxygen supply solutions for global medical institutions, becoming a reliable partner in the global medical and health industry.

Whether you are an equipment manager of a large general hospital or an operation manager of a primary clinic, Jiangsu Minnuo Group can tailor a suitable PSA oxygen generation solution for you. Welcome to contact our global service team to obtain exclusive oxygen supply scheme design and technical consultation services.

sales2:+86 17506119168

sales2:+86 17506119168