Nitrogen generators are widely used in many industries that require nitrogen to perform daily operations. These industries range from food processing plants and pharmaceutical companies to electronics, thermal processing, and many other applications. However, for users who rely on bottled liquid nitrogen, rising costs, transportation, and safety concerns in storage have long plagued them. On-site liquid nitrogen generators can end traditional liquid nitrogen supply methods, using them to produce liquid nitrogen at one-third the cost of transporting it. They have gained wide acceptance in the market for their reliability and economy.

But when your business decides to invest in a liquid nitrogen generator, what’s the first step? Liquid nitrogen generators come in various sizes and models, and choosing the suitable unit is critical. In addition to considering cost, this article will provide six details to help you choose the right liquid nitrogen generator.

What is your application?

Generally, your industry and your application determine the required liquid nitrogen purity. In industrial production, the liquid nitrogen generator uses compressed liquid air fractionation to obtain liquid nitrogen, which can be used as a deep refrigerant. Due to its chemical inertness, it can directly contact biological tissues and freeze immediately without destroying physical activity. It can be used for:

- Quickly freezing and transporting food or making ice products;

- Research low-temperature physics;

- Demonstrate a low-temperature state in science education. Objects that are soft at room temperature will be as brittle as glass when soaked in liquid nitrogen;

- Provide the temperature required for high-temperature superconductors to exhibit superconductivity.

- It can be used as a refrigerant to rapidly freeze biological tissues to prevent them from being destroyed.

- They are used for industrial nitrogen fertilizer production.

- Chemical detection.

Purity requirements

Some applications require a higher degree of purity than others. For example, for industries such as food packaging, it is essential to keep the final product as oxygen-free as possible.

Generally, purity greater than 99% is sufficient for experimental or freezing purposes. Liquid nitrogen generators typically use two technologies to generate nitrogen on-site: membrane technology and variable pressure adsorption (PSA) technology. Membrane nitrogen generators are usually used for applications requiring a purity of less than 99.5%. Conversely, PSA nitrogen generators are more commonly used in applications requiring purity levels greater than 99.5%.

PSA (Pressure Swing Adsorption) technology

- Produces nitrogen gas with 99.999% purity,

- High flow rate

- Cost-effective.

- Instability at high flow rates, relatively noisy, and requires a change of consumables.

Membrane separation technology

- The simple and reliable separation process

- No noise pollution

- Small floor space, and no need to replace consumables.

- The flow rate is lower, the purity is not high, and the price is a bit higher.

Assess your level of usage

Proper consideration of the liquid nitrogen production requirements needed for your application will help you make an informed decision. If you purchase a nitrogen generator that is too large for your specific requirements, it could cost you money you don’t need to spend. Conversely, if your usage is within the capacity of your nitrogen system, then you may experience problems and slowdowns in your production line.

Also, in the following table, I will list some examples of customer applications for different sizes of liquid nitrogen generators.

| Small (0.4L/h – 5L/h) | Nuclear magnetic resonance spectroscopyNuclear magnetic resonance spectroscopy is mainly used to determine the structure of small molecules of organic compounds and biological macromolecules in solution. It has various applications in chemistry, biology, physics, materials, pharmacy, and medicine. The superconducting magnets are immersed in liquid helium, the outer layer of which is liquid nitrogen. The liquid helium is used to maintain the superconductivity of the interest to provide the required magnetic field environment. In contrast, liquid nitrogen is used to add a “thermal barrier” between the liquid helium and the external environment to reduce the evaporation of the liquid helium. |

| Medium-sized (10L/h-100L/h) | Superconductor TechnologyThe unique properties of superconductors have led to their widespread application. Using liquid nitrogen instead of liquid helium as a superconducting refrigerant to obtain superconductors has led to the general application of superconductivity skills.Electronic component manufacturing and testingLiquid nitrogen is a faster and more helpful method for shielding and testing electronic components and circuit boards.Low-temperature ball milling technologyLiquid nitrogen gas is fed continuously into a planetary ball mill equipped with an insulated cover for confusion, fine grinding, and new product development in a low-temperature environment.Green cutting processing technology |

| Large (100L/h-2000L/h) | Liquid Nitrogen Drip InjectionLiquid nitrogen drip injection is widely used in producing beverages, edible oils, and pharmaceuticals.The produced pure nitrogen is liquefied directly into liquid nitrogen and then drip-injected into beverages or edible oils.Many beverage manufacturers have adopted nitrogen or a mixture of nitrogen and C02 instead of the traditional C02 to aerate and package beverages. The nitrogen-filled, highly carbonated beverages cause fewer problems than those filled with C02 only; filling a small amount of liquid nitrogen in non-filled beverage cans can remove the oxygen in the top space of each can, thus extending the storage period of perishable products. |

Selecting the right dewars

We call a liquid nitrogen storage tank a dewar and use it to store and release liquid gas safely. A liquid nitrogen storage tank is an essential partner for a liquid nitrogen generator. The capacity of the Dewar depends on how many days of production you want to set aside for backup. For example, if your facility has a production rate of 10L/H, you will get about 240L of liquid nitrogen in two days. If you want to set aside two days of production, then one 500L Dewar may be sufficient for your needs.

Choosing the material of the Dewar is also a task. Storage tanks come in different materials, mainly stainless steel and carbon steel. Using tanks made of stainless steel is recommended because they are more durable. Carbon steel tanks are painted with a layer of glue inside, so peeling may occur over time, affecting the quality of the gas.

You can ask the supplier personnel to recommend one to you.

Cool your air compressor in the right way

The air compressor provides clean compressed air for the separation unit of the nitrogen generator. The amount of compressed air required for nitrogen production equipment with 99.9% purity is generally six times the amount of nitrogen produced by the equipment. The amount of compressed air necessary for nitrogen production equipment with 99.99% purity is eight times the amount of nitrogen produced by nitrogen production equipment. Therefore, the air compressor is crucial. Air compressors generate a lot of heat during production, and we generally use air or water cooling to keep them running well. You will see the advantages and disadvantages of these two methods below.

| Advantages | Disadvantages | |

| Water-cooled | Excellent heat dissipation effect and high reliability.Primarily used in medium and large air compressors. | Complex structure.Water consumption. |

| Air-cooled | As long as air is present around your equipment, independent of environmental factors. | Easy to contaminate the equipment.Poor heat dissipation effect, mainly used for small air compressors. |

In the industry, we usually use water-cooled air compressors when the liquid nitrogen production exceeds 5L/H.

Are you in a high-altitude area?

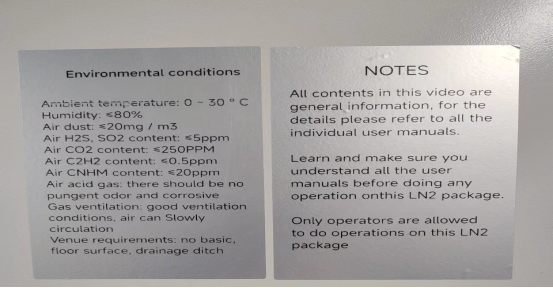

Altitude, atmospheric pressure, ambient temperature, and humidity greatly influence the air compressor’s exhaust pressure and air volume. The larger size and ambient temperature will also reduce the nitrogen production efficiency of the nitrogen generator. You must provide data such as ambient temperature, humidity, altitude, atmospheric pressure, air pollutants, and their content to the supplier before purchasing for the seller’s reference when designing.

When shopping for a nitrogen generator, you can outline and prepare these details so that our technical experts can help you make the right choice. If you have special requirements or if the environmental conditions deviate from the design, we can make a targeted design to meet the criteria based on the data provided by the user.

Plant conditions

Space requirements

To ensure the smooth operation of your liquid nitrogen generator, you need to have enough space for it in your facility. Figuring out how much nitrogen you need will help you determine how much space you need. The table below will provide a reference for some of this data. It will help you decide what type of system is best for your site and ensure that it will meet your production needs.

| Size | Small (0.4L/h – 5L/h) | Medium-sized (10L/h-100L/h) | Large (100L/h-2000L/h) |

| Required space | 5-15㎡ | 30-300㎡ | Infrastructure needed |

Power conditions: operating voltage and frequency

Before you start production, you must configure the power supply strictly according to the voltage and frequency indicated on the nameplate of the liquid nitrogen generator. Suppose you provide the voltage and frequency configuration outside the standard voltage and frequency range. In that case, you will need to provide your technician with the technology for a targeted design.

Conclusion

When investing in a liquid nitrogen generator for your business, you need to outline and prepare these details above so that the supplier’s technical experts can help you make the right choice. Fortunately, our technical experts will evaluate your operational processes and analyze your nitrogen needs. Our goal is to provide you with a high-quality nitrogen product today and meet your long-term needs, Contact our engineers if you need to.

sales2:+86 17506119168

sales2:+86 17506119168