I. Core Demands for Nitrogen Generation Technology in the Food Industry

Throughout the entire food production chain—from raw material storage to final product packaging—there are persistent threats such as oxidative deterioration and microbial growth. According to industry statistics, 15%–20% of global food loss each year is due to oxidation and mold. Nitrogen, as an inert protective gas, can displace oxygen and create an anaerobic environment to preserve freshness and quality, making it a key technical solution to these issues. The core requirements for nitrogen generators in the food industry can be summarized in three aspects:

Controllable Purity: Nitrogen purity must range from 99.5% to 99.9999%, tailored to specific food characteristics.

Stable Supply: Continuous 24-hour production lines require uninterrupted nitrogen output.

Safety and Compliance: Systems must meet strict food-grade safety and regulatory standards.

II. Mainstream Nitrogen Generation Technologies and Their Suitability for the Food Industry

(1) PSA (Pressure Swing Adsorption) Technology

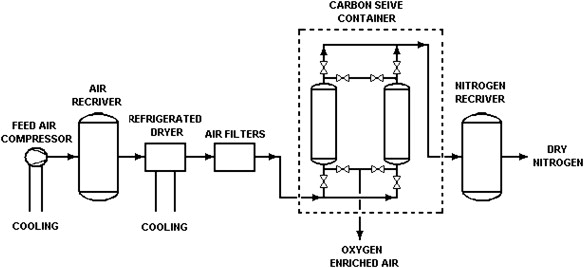

Currently, the most widely used method in the food industry is PSA technology. Its core principle lies in the selective adsorption difference between oxygen and nitrogen by carbon molecular sieves. Through cyclical “pressurized adsorption and depressurized desorption,” oxygen is removed, and nitrogen is separated. The process involves three main steps:

Air Preparation: Oil-free air compressors compress air, followed by refrigerated dryers to remove moisture and oil, yielding clean compressed air.

Gas Separation: The compressed air enters the adsorption towers where, under high pressure, the carbon molecular sieve preferentially adsorbs oxygen, allowing nitrogen to be collected as the product gas.

Regeneration Cycle: Once the sieve reaches saturation, the system automatically switches to a second tower while the first depressurizes and desorbs oxygen for regeneration.

Advantages of PSA in the food industry include:

Flexible purity control: Easily adjustable to meet various purity demands (e.g., 99.5% for baked goods to 99.999% for milk powder).

Quick startup: Reaches rated purity within 10–15 minutes, ideal for intermittent operations.

Low operational cost: Operating costs are about 30% of bottled nitrogen. One brewery reported a 40%–75% reduction in nitrogen expenses within two years, recovering initial investment.

(2) Other Nitrogen Generation Technologies

Membrane Separation Technology:

Utilizes the permeability difference across hollow fiber membranes. Compact and easy to maintain, suitable for small-scale operations with low flow demands. However, purity typically maxes at ≤99.9%, limiting its use in high-purity applications.

Cryogenic Air Separation:

Produces ultra-high-purity nitrogen but involves high capital investment and long startup times (several hours), making it viable only for large-scale operations producing over 10,000 tons/year. It is rarely applied in small to medium enterprises.

III. Typical Applications of Nitrogen Generators in the Food Industry

(1) Packaging Preservation for Solid Foods

Baked & Puff Snacks:

Baked goods like bread and cakes are susceptible to starch retrogradation and mold due to oxygen. PSA nitrogen generators used for nitrogen flushing can extend shelf life by 2–3 days while maintaining softness. For puffed snacks like chips, where oxygen must be reduced below 1%, nitrogen prevents fat oxidation and acts as a cushion to prevent breakage. One snack manufacturer reported a 30% increase in crispness retention.

Nuts & Dried Goods:

Nuts (e.g., peanuts, walnuts) contain unsaturated fats that oxidize easily. Modified Atmosphere Packaging (MAP) using 99.8% nitrogen can extend shelf life from 3 to 12 months without chemical preservatives. Nestlé’s Dubai milk powder plant installed 8 Nitro Swing nitrogen generators supplying 250 m³/h, preventing oxidation and clumping.

(2) Protection During Liquid Food Processing

Alcoholic Beverages & Soft Drinks:

In winemaking, nitrogen blankets prevent oxidation during fermentation. In beer bottling, nitrogen back-pressure minimizes CO₂ loss and stabilizes foam. A juice plant implemented nitrogen purging to reduce residual oxygen to below 0.5%, improving Vitamin C retention by 25%.

Edible Oil Storage:

Oils are prone to rancidity during storage. Introducing nitrogen into oil tanks maintains a micro-positive pressure (0.1–0.3 bar), reducing acid value increase by 60% and extending shelf life up to 18 months.

(3) Fresh Food Preservation and Processing

Meat & Seafood:

Fresh pork oxidizes and discolors in oxygen. MAP using 80% nitrogen and 20% CO₂ inhibits Pseudomonas growth, extending freshness from 3 to 7 days. During thawing, nitrogen flushing prevents surface browning, improving visual appeal.

Fruits & Vegetables:

Perishables like strawberries and spinach benefit from gas mixtures with 70–80% nitrogen to suppress respiration and delay ripening. One produce base reduced spoilage rates from 20% to 8%.

(4) Safety Measures in Food Production

In the processing of powders like flour and cocoa, dust mixed with air can form explosive atmospheres. Nitrogen inerting reduces oxygen concentration below 12%, eliminating explosion risks. This inerting method has become a mandatory safety standard in powder food plants.

IV. Food-Grade Nitrogen Generator Selection and System Design

(1) Key Parameters for Equipment Selection

Purity Requirements:

Vary across food types, requiring accurate matching.

Flow Rate Calculation:

Should consider production speed and packaging specs.

Example: A chip packaging line processes 60 bags/min, with each bag needing 20ml nitrogen.

Hourly nitrogen need:

60 × 60 × 20ml × 1.2 (safety factor) = 86.4L/h = 0.0864 m³/h.

Pressure Matching:

Packaging machines typically require 0.2–0.8 MPa; storage tanks need 0.1–0.3 bar. Systems must include proper pressure regulation.

(2) Key System Configuration Considerations

Air Purification:

Food-grade systems must include triple filtration and refrigerated dryers, ensuring oil content ≤ 0.01 ppm and dew point ≤ -40°C to avoid food contamination.

Purity Monitoring:

Online oxygen analyzers should be installed for real-time purity monitoring. The system must trigger alarms and switch to backup sources if purity drops below set thresholds.

Smart Control Systems:

PLC-based systems automatically switch towers, control purity via closed-loop feedback, and support remote monitoring and diagnostics, minimizing manual maintenance.

(3) Economic Comparison

On-site nitrogen generation is significantly more cost-effective than bottled gas.

Example: A nut processing plant with annual output of 1,000 tons uses ~50 m³/day nitrogen.

PSA nitrogen generator: Initial investment ~¥150,000; annual operating cost ~¥30,000.

Bottled nitrogen (40L/bottle @ ¥15): Annual cost ~¥168,000.

ROI: Payback period of ~14 months.

V. Safety Operation and Maintenance Standards for Food-Grade Nitrogen Generators

(1) Risk Management

Nitrogen’s inert nature can lead to asphyxiation. Work areas must be equipped with oxygen detectors (alarm threshold: 19.5%) and mechanical ventilation (≥10 air changes/hour). Before maintenance, ensure nitrogen purging is complete and oxygen levels restored to 20.9%. Workers must use self-contained breathing apparatus (SCBA) when entering confined spaces.

(2) Routine Maintenance

Filter Replacement:

Air filters every 2,000 hours; carbon molecular sieves every 5–8 years depending on purity degradation.

Pressure Checks:

Weekly inspections of tower pressure curves to detect valve leaks or sieve blockages.

Dryer Maintenance:

Drain condensate monthly; check dew point quarterly to ensure dry and clean air supply.

VI. Development Trends of Nitrogen Generators in the Food Industry

(1) Intelligent Technology Upgrades

Modern nitrogen generators integrate IoT technologies for remote monitoring and automatic regulation. A newly launched smart system adjusts output based on packaging machine load, achieving 15%–20% energy savings.

(2) Low-Carbon and Energy Efficiency

New models with optimized tower structures and advanced carbon molecular sieves reduce energy consumption by 30%. Variable-frequency generators further lower standby power by adjusting compressor speed to real-time demand.

(3) Modular and Customized Design

For small-scale producers, mobile nitrogen generators (e.g., DS-NM3 model: 3 m³/h flow, only 10W power, <1㎡ footprint) can flexibly serve multiple production lines. Large enterprises may adopt multi-tower systems with stepless control over flow and purity.

(4) Green Integration

Next-generation systems combining nitrogen generation with carbon capture can utilize the oxygen-rich byproduct for fruit ripening, achieving energy cascade utilization in line with the food industry’s green development goals.

VII. Conclusion

As a key solution for food preservation and safe production, nitrogen generators play a pivotal role in improving quality and efficiency in the food industry. From the widespread adoption of PSA technology to the emergence of intelligent systems, nitrogen generation is advancing toward greater efficiency, safety, and sustainability. For food enterprises, proper equipment selection and maintenance can reduce product loss, extend shelf life, and enhance brand competitiveness. With the ongoing shift toward greener, smarter food processing, nitrogen technology will play an increasingly important role in preservation innovation and production safety—ultimately delivering fresher, safer food products to consumers.

sales2:+86 17506119168

sales2:+86 17506119168