If you see units like Nm³, m³, Nm³/h, NL/min or SCFM in gas equipment datasheets and feel confused, this page gives you a quick, practical explanation and conversion method.

In the production, trade, and engineering applications of gas equipment, distinguishing between standard cubic meters (Nm³) and actual cubic meters (m³) is crucial. This article will explain the core differences between the two, conversion methods, and engineering application scenarios to help you accurately select equipment and optimize your processes.

Nm³ represents the volume of gas measured under standard conditions (0°C, 101.325 kPa), suitable for global comparisons and trade settlements, whereas m³ refers to the actual volume of gas under real working conditions, reflecting on-site flow. The two can be converted using the ideal gas equation based on temperature and pressure to ensure data consistency across different environments.

1. Basic Definitions: Core Differences Between Nm³ and m³

What is Nm³? Nm³ Meaning and Full Form

- Definition: The volume of gas measured under standard conditions (0°C, 101.325 kPa), internationally recognized as Nm³.

- Purpose: Eliminates the effects of temperature and pressure fluctuations to enable global flow data comparability. For example, the actual displacement (m³) of the same compressor varies significantly across regions, but when converted to Nm³, it is consistent.

- Application Scenarios: Trade settlements, environmental monitoring, equipment performance calibration (e.g., compressor and fan flow parameters).

Actual Cubic Meter (m³)

- Definition: The volume of gas under actual working conditions, directly reflecting the instantaneous flow of the equipment at specific temperatures and pressures.

- Purpose: Used for on-site operational monitoring, such as pipeline design and real-time flow control.

- Limitations: Non-standardized, highly influenced by environmental factors, and cannot be directly compared across regions or equipment.

2. Core Difference: Why Distinguish Between Nm³ and m³?

| Dimension | Nm³ | m³ |

| Reference Conditions | 0°C, 1 atm (Internationally recognized) | Actual temperature and pressure |

| Data Comparability | Global standard, suitable for trade and equipment benchmarking | Reflects local working conditions, not directly comparable |

| Engineering Applications | Equipment selection, contract calibration | On-site operation, pipeline design |

| Industry Standards | ISO 80000 – 3 (Space and Time Units Standard) | No unified benchmark, must specify working conditions |

Example: When a customer purchases a MINNUO compressor, using m³/h as a reference will result in inflated flow readings in high-altitude areas (low pressure), leading to incorrect selection. Using Nm³/h ensures consistent performance globally.

3. Conversion Methods Between Nm³ and m³

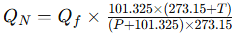

Ideal Gas Equation Method (Precise Conversion)

Based on the formula P₁V₁/T₁ = P₂V₂/T₂, this method is suitable for high-precision scenarios such as trade settlements:

Standard State Flow (Nm³/h):

Working Flow (m³/h):

Parameters: P is the working pressure (kPa), T is the working temperature (°C).

Quick Estimation Method (Simplified Formula)

When temperature differences are negligible, standard flow ≈ working flow × (working pressure bar + 1), suitable for quick daily operations estimation.

4. Key Issues in Engineering Applications

Industry Differences in Standard Conditions

Some countries use 15°C or 15.6°C (60℉) as the contract temperature, while China uses 20°C (SY/T6143 standard) for natural gas, and 0°C or 20°C is often used for coal gas.

Recommendation: Equipment parameters should clearly state the “standard conditions” definition to avoid ambiguity.

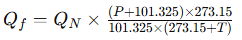

Calculation of Mass Flow

By combining molar mass and the gas equation, volume flow can be further converted to mass:

Application Scenario: Chemical reaction ratios, energy consumption measurement.

5. MINNUO Solutions: Global Standardized Service

- Dual Calibration of Equipment Parameters: Provides both Nm³/h and m³/h flow data to cater to different regional customer needs.

- Intelligent Temperature and Pressure Compensation: Built-in sensors adjust working conditions in real time, outputting standardized flow (e.g., MFC controller technology).

- Customized Standards: Defines “standard conditions” based on the industry specifications of the customer’s country (e.g., ISO 80000 – 3, API standards).

6. Frequently Asked Questions (FAQ)

Q1: Why do different manufacturers define Nm³ at different temperatures?

- Historical reasons: Early SI units were not fully standardized, and some manufacturers continue to use the 20°C standard (e.g., the Chinese compressor industry).

- Solution: Suppliers should clearly specify the temperature and pressure reference, or unify the standards through contractual negotiation.

Q2: How should flow units be selected?

- Trade and Equipment Benchmarking: Use Nm³ as the priority.

- Process Flow Control: Use m³, ensuring temperature and pressure are monitored concurrently.

7. Conclusion

Understanding and accurately applying the conversion between Nm³ and m³ is essential when selecting and using gas equipment. By deeply understanding standard and actual working conditions, you can avoid equipment selection errors due to data inconsistencies and ensure accuracy in cross-regional applications. MINNUO‘s global standardized solutions will help you achieve precise control in different working conditions, ensuring excellent performance for your equipment in any environment.

sales2:+86 17506119168

sales2:+86 17506119168