For many industrial applications, 99.9% nitrogen purity is more than adequate. It’s a reliable workhorse for inerting, packaging, and pneumatic systems. But in the worlds of semiconductor fabrication, advanced laser cutting, pharmaceutical synthesis, and cutting-edge research, that last 0.1% of impurities (1,000 ppm) is an ocean of contamination that can ruin processes, destroy products, and invalidate experiments.

The leap from 99.9% to 99.999% (10 ppm impurities) or even 99.9995% (5 ppm) is not a linear progression. It is a fundamental shift in system design philosophy. You cannot simply “turn up” a standard PSA generator. Achieving and maintaining such purity requires re-engineering the entire chain—from the air intake to the final point-of-use valve—to eliminate contamination at a molecular level. This guide explores the specialized engineering behind these ultra-high purity (UHP) gas systems.

I. The Adversary: Understanding the “Last 0.1%”

In a 99.9% N₂ stream, the 0.1% impurity is primarily oxygen and argon, with trace water and CO₂. To reach 99.999%, you must remove 99% of the remaining impurities. The challenges are multiplicative:

- Exponential Difficulty: Removing the last few ppm is vastly harder than the first 99.9%. Adsorption isotherms flatten, and contamination from system components becomes the dominant source.

- The “System” as the Source: At this level, impurities no longer primarily come from the feed air; they leach, desorb, and permeate from the system’s own pipes, valves, and vessels.

II. The Five Pillars of an Ultra-High Purity System

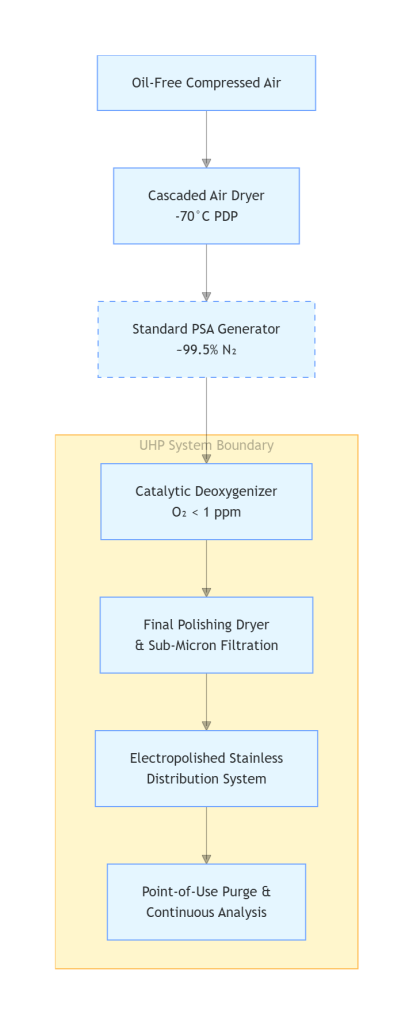

Building a system for 99.999% nitrogen requires addressing five critical pillars beyond a standard PSA unit.

1. Ultra-Clean Feed Air Preparation

- Standard Approach: Refrigerant or desiccant dryer to ~-40°C dew point.

- UHP Requirement: A cascaded drying system, often combining a refrigerant dryer with a heated blower desiccant dryer to achieve a consistent -70°C dew point or lower. This brutally suppresses water vapour, which competes for adsorption sites and is a primary impurity.

2. Multi-Stage Purification: The “Polish” After Generation

A standard PSA output of 99.5-99.9% is just the starting point.

- Oxygen Removal: A downstream catalytic deoxygenizer is essential. It uses a catalyst (often palladium-based) to chemically bind residual O₂ with a small stream of added hydrogen, forming water vapour, which is then removed by subsequent drying. This can reduce O₂ to < 1 ppm.

- Final Drying & Filtration: The gas then passes through a final ultra-low dew point desiccant tower and a 0.01 micron (or smaller) particulate filter to catch any catalyst or desiccant fines.

III. The Infrastructure: Where Purity is Preserved or Lost

The “plumbing” is not plumbing; it is the containment vessel for your ultra-pure asset.

- Material Science: Electropolished 316L stainless steel (EP SS) is the standard. Electropolishing removes surface micro-roughness where impurities can lodge, creating a smooth, passive surface that minimizes adsorption and outgassing.

- Joining Technology: Orbital welding creates seamless, smooth joints. For necessary connections, high-integrity double-ferrule tube fittings are used instead of threaded connections, which can harbor contaminants and create particulates.

- Dead-Leg Elimination: System design must aim for zero dead volume. Stagnant areas allow gas to sit, equilibrate with pipe walls, and become a source of contamination when flow resumes.

IV. Validation & Continuous Assurance

You cannot manage what you do not measure. In UHP systems, measurement is continuous and critical.

- Analytical Instrumentation: Continuous trace oxygen analyzers (ppb level) and dew point meters are installed post-purification and at critical use points. Total hydrocarbon (THC) analyzers may also be used.

- Purge Protocols: Before initial use and after any maintenance, the system undergoes an extensive purge and bake-out procedure with dry, high-purity gas to drive off surface contaminants.

- Certification: Systems are validated to deliver gas meeting ISO 8573 Class 1.1.1 or even more stringent custom specifications, with documented performance data.

V. Industry Spotlight: Where the Last 0.1% Matters Most

The engineering of UHP systems is driven by the uncompromising demands of these critical fields:

- Semiconductor Fabrication & Wafer Manufacturing:

- The Need: In processes like chemical vapor deposition (CVD) and ion implantation, trace oxygen or moisture can create defective oxide layers or alter doping profiles, scrapping entire wafer batches. For photolithography, impurities cause haze and reduce yield.

- The UHP Solution: A system delivering 99.999% nitrogen for semiconductor wafer manufacturing integrates catalytic deoxidation and continuous ppb-level oxygen monitoring. The guarantee is not just purity at the source, but at every valve across the cleanroom, ensuring the inert environment is never compromised.

- Pharmaceutical Synthesis & Biotech:

- The Need: Oxygen-sensitive reactions and the storage of active pharmaceutical ingredients (APIs) require an absolute inert blanket. Oxidation can degrade product potency, create unsafe by-products, or invalidate regulatory batches.

- The UHP Solution: A pharmaceutical-grade ultra-high purity nitrogen inerting system provides a dry, oxygen-free environment for reactors and storage vessels. Validation protocols are as critical as the hardware, ensuring compliance with cGMP and data integrity requirements.

- High-Precision Laser Cutting & Welding:

- The Need: In cutting stainless steel or sensitive alloys, even minute oxygen levels in the assist gas cause edge oxidation, burring, and discoloration, requiring costly secondary finishing.

- The UHP Solution: A dedicated 99.999% purity nitrogen system for laser cutting ensures a perfectly inert gas shield. This results in clean, oxide-free cuts with superior edge quality, often eliminating post-processing steps and reducing consumable gas costs compared to lower-purity alternatives.

VI. Proof in Performance: A Case for Certainty

Challenge: A leading semiconductor packaging and testing facility experienced a persistent 0.5% failure rate due to pin oxidation during a high-temperature molding process. Their existing 99.9% nitrogen supply, with oxygen impurities around 1,000 ppm, was the culprit.

Solution: MINNUO designed and installed a turnkey Ultra-High Purity nitrogen system, featuring a catalytic deoxygenizer and a fully electropolished stainless steel distribution loop. The system was validated to deliver nitrogen at >99.999% purity, with oxygen content consistently below 5 ppm.

Result: Post-installation, the pin oxidation defect rate plummeted to below 0.01%. For a high-volume production line, this translated to annual savings exceeding $2 million USD in reduced scrap and rework. The complete UHP system achieved full ROI in under 6 months, transforming a quality headache into a competitive advantage.

Frequently Asked Questions

Q: How do you verify that a nitrogen system is actually delivering 99.999% purity?

A: Verification requires continuous analytical instrumentation at the point of generation and key use points. We use calibrated trace oxygen analyzers (capable of ppb measurement) and high-precision dew point mirrors. Third-party certification against standards like ISO 8573-1 provides the final audit. You cannot rely on spot checks; certainty comes from continuous data.

Q: Is the maintenance cost for a UHP nitrogen system significantly higher?

A: UHP system maintenance is more specialized but not necessarily more frequent. It focuses on catalyst bed monitoring, analyzer calibration, and integrity checks of the sealed distribution system. While some consumables (e.g., catalyst) are costly, the total cost is dwarfed by the value it protects. Preventative maintenance is paramount to avoid catastrophic process contamination.

Q: Can we upgrade our existing 99.9% PSA system to achieve 99.999% purity?

A: Rarely as a simple retrofit. The core PSA system upgrade path typically involves adding downstream purification modules (deoxygenizer, final polisher) and, most critically, replacing the entire distribution network with electropolished stainless steel and high-integrity fittings. Often, a purpose-built UHP skid alongside the existing system is more cost-effective and reliable.

Q: How do we choose between 99.999% and 99.9995% purity?

A: The choice between 99.999% vs 99.9995% nitrogen purity is dictated by your most sensitive process specification. The cost and complexity increase non-linearly. A rigorous analysis of the impurity tolerance (e.g., “O₂ must be < 5 ppm”) is essential. We recommend targeting the specification with a safety margin, not an arbitrary extra “9”. Let your process define the need.

Conclusion: The Value of Absolute Purity

Investing in an ultra-high purity nitrogen system is a strategic decision, justified by the astronomically higher value of the processes it protects. The cost is not in the nitrogen gas itself, but in the absolute certainty of its inertness.

When a single wafer batch is worth thousands of dollars, a laser crystal must be perfectly shielded, or a chemical reaction must proceed without trace side reactions, the ROI on a system that guarantees 99.999% purity is immediate and total. It transforms nitrogen from a commodity utility into a critical process enabler.

At MINNUO, we understand that the final 0.1% defines the frontier of performance. Our expertise spans from robust industrial PSA systems to the exacting discipline required for ultra-high purity solutions. We engineer not just for output, but for certainty—ensuring that the gas reaching your most sensitive process is as flawless as your ambition demands.

sales2:+86 17506119168

sales2:+86 17506119168