For plant managers and engineers in heavy industries, the reliability and cost of nitrogen supply are constant concerns. Relying on external liquid nitrogen deliveries exposes you to price volatility, delivery delays, and supply chain risks, turning a critical utility into a vulnerability. Meanwhile, inefficient on-site generation can silently drain profitability through excessive energy consumption and high maintenance costs.

When your daily demand scales to thousands of cubic meters, the path to security and savings narrows to two major investments: a Cryogenic Air Separation Unit (ASU) or a Pressure Swing Adsorption (PSA) Nitrogen Generator. This guide cuts through the complexity, providing a data-driven comparison to help you select the optimal nitrogen supply solution for your operational and financial goals.

Understanding the Core Technologies: How They Work

Cryogenic Air Separation: The Industrial Powerhouse

This process mimics nature’s method of air separation at an industrial scale. Ambient air is compressed, purified, and then cooled to cryogenic temperatures (below -172°C) until it liquefies. The liquid air is separated into its components (nitrogen, oxygen, argon) in a distillation column based on their different boiling points. Its key traits are the production of Liquid Nitrogen (LIN), ultra-high purity (easily 99.999%+), and valuable byproducts like liquid oxygen and argon.

PSA Nitrogen Generation: The On-Demand Specialist

This technology uses a Carbon Molecular Sieve (CMS) to separate nitrogen from air at ambient temperature. Clean, compressed air is passed through the CMS, which selectively adsorbs oxygen and other gases, allowing nitrogen to pass through. A twin-tower system ensures continuous flow by cycling between adsorption and regeneration phases. It is defined by on-demand gaseous nitrogen production, modular scalability, and purity typically ranging from 95% to 99.999%.

Head-to-Head Comparison: 4 Critical Decision Factors

1. Capital Investment (CAPEX)

| Factor | Cryogenic ASU | PSA Nitrogen Generator |

| Project Scope | Major greenfield/retrofit engineering project. | Modular equipment installation. |

| Cost Scale | Multi-million to tens of millions USD. | Tens of thousands to a few million USD. |

| Lead Time | 12 to 24+ months for design and commissioning. | 3 to 6 months from order to operation. |

| Footprint | Large; requires space for cold boxes, distillation columns, and storage. | Compact; can be installed in existing plant areas. |

Verdict: PSA offers a significantly lower barrier to entry and faster deployment, ideal for controlling upfront costs. Cryogenic ASUs are long-term, capital-intensive infrastructure commitments.

2. Operational Costs & Efficiency (OPEX)

- Energy Consumption – The Core of OPEX:

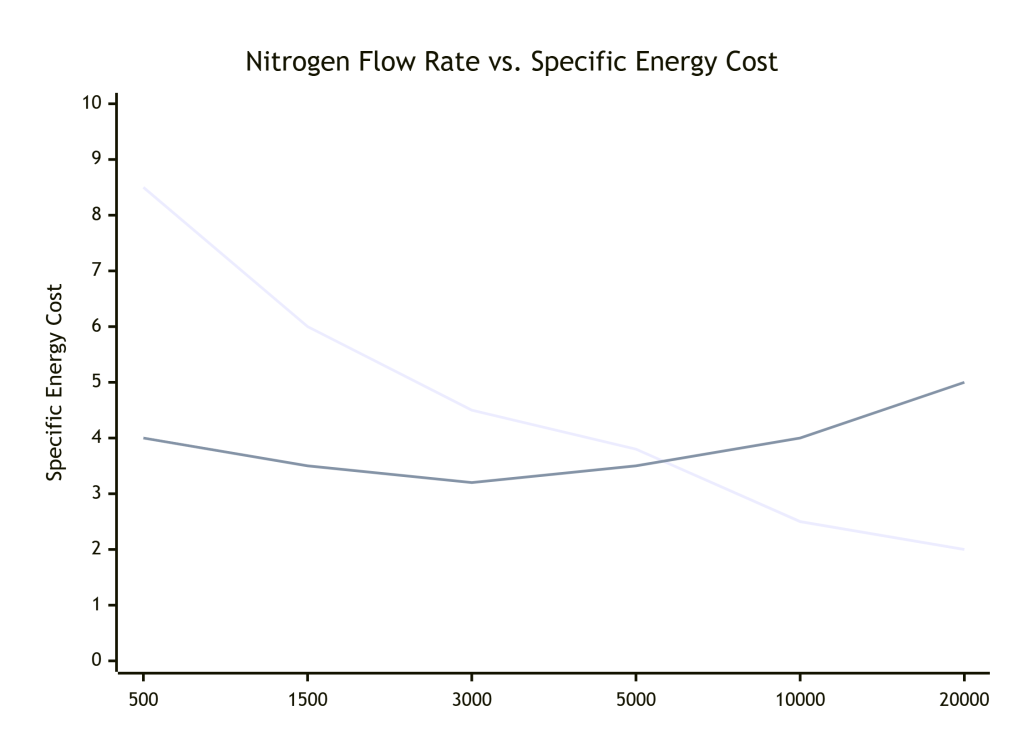

Understanding the relationship between scale and energy efficiency is paramount. The following graph illustrates the typical “crossover point” where the economic advantage shifts between technologies.

- PSA Systems exhibit excellent efficiency at lower flow rates, with costs rising gradually as multiple units are deployed for higher capacities.

- Cryogenic ASUs have high initial energy costs that drop dramatically with scale, benefiting from powerful economies of scale at very high, constant volumes.

- The crossover zone (approx. 3,000 – 6,000 Nm³/hr) is where a detailed, site-specific analysis becomes critical.

- Maintenance & Labor:

- Cryogenic ASUs require a specialized, skilled team for 24/7 operation. Maintenance is complex and spare parts are costly.

- PSA Systems are highly automated for unattended operation. Maintenance is predictable, primarily involving filter changes and sieve replacement every 5-10 years.

Verdict: The precise “crossover point” depends on your specific scale, target purity, and local energy costs. The graph above provides a conceptual framework, but only a detailed TCO analysis can pinpoint the optimal choice for your plant.

3. Product & Operational Flexibility

- Purity & Pressure: Cryogenic plants excel at producing ultra-high-purity gas and liquid nitrogen, which can be pumped to high pressures. PSA is the champion for standard high-purity (up to 99.999%) gaseous needs at moderate pressures.

- Turndown & Start-up: PSA systems win on agility. They can adjust output from 30% to 100% nearly instantly and start up in minutes. Cryogenic plants are designed for steady-state operation, with poor turndown and start-up times lasting hours to days.

- Supply Security: An ASU with integrated LIN storage creates an on-site strategic reserve, protecting against outages. PSA systems depend entirely on continuous, stable power and compressed air.

4. Strategic Value & Risk Profile

- Cryogenic ASU: A core utility and potential profit center. It offers maximum control and security but locks you into a specific technology and scale.

- PSA Nitrogen Plant: A flexible production asset. It mitigates reliance on external suppliers and allows you to adapt to changing demand, tying your security to the reliability of your plant’s utilities.

Industry Case Studies: Real-World Applications

- Chemical Plant Saves with PSA: A European chemical manufacturer with a variable demand profile up to 2,500 Nm³/hr replaced delivered liquid nitrogen with a custom PSA system. The project resulted in a 35% reduction in annual nitrogen costs, with a full ROI achieved in under 2.5 years, while eliminating delivery dependency.

- Steel Mill Optimizes with Hybrid System: A large steel mill with a baseload demand of 8,000 Nm³/hr and significant peak shaving needs implemented a hybrid solution. A mid-sized cryogenic plant covers the baseload and produces liquid backup, while a modular PSA skid handles peak demand. This strategy lowered their overall energy consumption by 18% compared to an oversized cryogenic plant alone and provided unmatched operational resilience.

FAQ: Your Nitrogen Generation Questions Answered

Q1: What is the typical payback period for a large cryogenic air separation plant?

A1: Given the high capital expenditure, payback periods are typically 5 to 10 years. This timeline can shorten significantly if revenue from selling liquid oxygen and argon byproducts is substantial, turning the unit into a profit center.

Q2: Can multiple PSA nitrogen generators match the output of a cryogenic plant for high-volume supply?

A2: Yes, systems can be paralleled. For the very largest volumes (e.g., >10,000 Nm³/hr), a single-train cryogenic plant often holds an efficiency advantage. However, a multi-unit PSA approach provides superior redundancy and operational flexibility. A site-specific feasibility study for large-scale nitrogen production is essential to compare total cost.

Q3: How does the choice impact nitrogen purity for sensitive applications like electronics manufacturing?

A3: Both technologies can achieve the required high purity (e.g., 99.999%+). The key is working with a provider who understands your exact process requirements—including not just purity but also dew point and consistency—to design and guarantee a system that meets your specifications for high-purity nitrogen for electronics.

Q4: We currently use bulk liquid nitrogen but want to reduce costs. Is switching to on-site generation feasible?

A4: Absolutely. The first step is a comprehensive feasibility study for converting from liquid nitrogen to on-site generation. This study models your specific consumption data, delivery costs, and site conditions against potential on-site solutions, often revealing significant savings and a clear ROI pathway for an on-site nitrogen plant.

Q5: What about the total cost of ownership beyond the initial price?

A5: A true TCO analysis for nitrogen systems is critical. It must include not just the purchase price, but also energy costs over the system’s lifespan, maintenance expenses, labor, cost of downtime, and even floor space. This holistic view often reveals that the lowest upfront cost option is not the most economical long-term choice.

Decision Guide: Find Your Optimal Solution

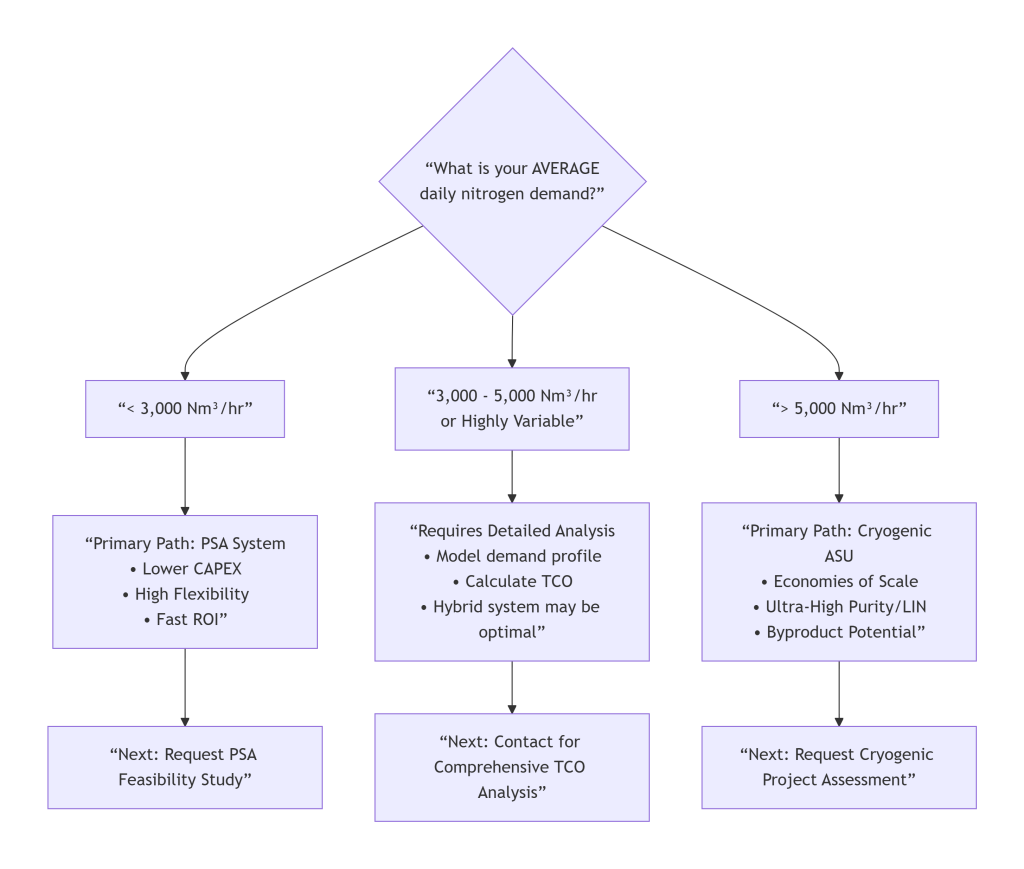

Selecting the right technology is a strategic decision. Use the decision path below to identify the most promising path for your specific situation.

Use the decision path above to quickly identify the most promising technology for your scale. Remember, these are guidelines; a detailed, site-specific TCO analysis is the only way to confirm the optimal choice.

When PSA Usually Wins:

If your operation falls in the < 3,000 Nm³/hr range, a PSA nitrogen generator system typically offers the best balance of cost, flexibility, and efficiency. These systems are particularly advantageous when your demand fluctuates, you need frequent start/stop cycles, capital budget is a concern, or you lack specialized cryogenic operation expertise.

When Cryogenic Makes Sense:

For steady-state demands exceeding 5,000 Nm³/hr, cryogenic air separation plants leverage massive economies of scale. They become compelling when your facility operates 24/7 with minimal variation, you require liquid nitrogen or ultra-high purity, byproducts can be utilized, or supply security is a critical priority.

The Gray Area Requires Expert Analysis:

The 3,000-5,000 Nm³/hr range—or any operation with highly variable demand—demands careful evaluation. This is where hybrid systems often shine, and a detailed Total Cost of Ownership (TCO)analysis becomes indispensable to factor in local energy costs, space constraints, and future expansion plans.

Conclusion

The choice between cryogenic and PSA technology is a defining one for your plant’s operational and financial future. There is no universal winner—only the optimal solution for your unique combination of scale, demand pattern, purity needs, and financial constraints.

Investing in a rigorous, unbiased Total Cost of Ownership (TCO) analysis is the most critical step you can take. This moves the decision from speculation to data-driven strategy.

For over decades, the engineering team at MINNUO has specialized in conducting these precise analyses for global industrial clients. We model your complete operational profile to provide a clear, quantified comparison between all viable nitrogen supply options, ensuring your investment delivers both immediate performance and long-term value.

sales2:+86 17506119168

sales2:+86 17506119168