The Nitrogen plant plays a crucial role in industrial applications, providing a vital source of nitrogen for various industries, including chemicals, food preservation, healthcare, and manufacturing in China. These plants are essential for maintaining efficient production processes, ensuring safety, and improving product quality.

China’s dominance in the nitrogen plant industry is driven by its strategic manufacturing position and continuous advancements in gas separation technologies. This leadership is reflected in the growing global demand for Chinese nitrogen plants, which offer cutting-edge solutions that address both industry and environmental needs.

For customers, selecting the right nitrogen plant manufacturer involves considering key factors such as reliability, cost-effectiveness, and energy efficiency. As industries move towards greener solutions, understanding these needs will help businesses make informed decisions on nitrogen generation systems that meet both operational and sustainability goals.

Criteria for Selecting a Trusted Nitrogen Plant Manufacturer

Product Quality:

High-Efficiency Nitrogen Generators and Their Impact on Operational Costs

The performance and efficiency of nitrogen generators are crucial factors that directly affect operational costs. A high-efficiency nitrogen generator not only ensures a steady and reliable supply of nitrogen but also reduces energy consumption, lowering both upfront and long-term operational expenses. When selecting a nitrogen plant manufacturer, customers should assess the energy efficiency of the equipment, as efficient nitrogen generation systems can cut energy consumption by up to 25-30%. Additionally, a high-quality generator will have a longer lifespan, reducing the need for frequent maintenance and replacements, which leads to lower overall costs.

Customer Insight: The long-term cost savings associated with high-efficiency generators are often overlooked in favor of cheaper, short-term solutions. For instance, MINNUO’s high-efficiency PSA nitrogen generators have helped clients in the chemical industry save more than 15% annually on energy costs, leading to a rapid return on investment.

Technology and Innovation:

The Role of Advanced Technologies in Nitrogen Production

Innovation plays a vital role in ensuring that nitrogen generation plants meet the modern industry’s growing demands. Technologies such as membrane separation and PSA (Pressure Swing Adsorption) are essential in improving the efficiency and purity of nitrogen generation.

Membrane Separation Technology: Membrane-based systems use selective permeability to separate nitrogen from air, providing high purity with minimal energy consumption. These systems are particularly effective in scenarios where a steady and reliable nitrogen supply is needed for extended periods, such as in the food industry and healthcare sectors.

PSA Technology: PSA nitrogen generators are widely used due to their high efficiency, ability to produce high-purity nitrogen, and ease of integration into existing systems. Advanced PSA systems optimize energy use by utilizing pressure swings to separate nitrogen from air, making them ideal for industries with fluctuating nitrogen demand.

Customer Case Study: MINNUO uses both membrane and PSA technologies in its nitrogen plants. For instance, their membrane nitrogen generation system installed at a food processing plant increased production efficiency by 18%, with the plant reporting a 20% reduction in energy costs.

Customer Service and Support:

The Influence of Post-Sales Service, Maintenance Packages, and Technical Support

The manufacturer’s commitment to customer service is just as important as the equipment itself. A trusted manufacturer will provide comprehensive post-sales service, ensuring that customers can quickly address any operational issues that arise. Additionally, offering regular maintenance packages can prevent downtime, extend the lifespan of equipment, and maintain optimal system performance.

Post-Sales Support: Ensure that the manufacturer provides a clear communication channel for troubleshooting, repairs, and system optimization.

Maintenance Packages: Look for manufacturers offering flexible maintenance schedules, which help minimize disruptions in operation and reduce maintenance costs.

Technical Expertise: Consider manufacturers who offer continuous technical support, such as system monitoring and optimization services, to help improve nitrogen plant performance.

Customer Insight: A leading manufacturer will not just sell the equipment but also ensure it is maintained and optimized throughout its lifecycle. For instance, MINNUO provides a 24/7 support service and customized maintenance plans that have significantly reduced operational downtime for its clients.

Reputation and Reliability:

Industry Certifications and Company Trustworthiness

The reputation and reliability of a manufacturer are paramount when selecting a trusted nitrogen plant supplier. Certifications such as ISO 9001 for quality management and ISO 13485 for medical-grade equipment ensure that the manufacturer meets global standards of production and safety.

Additionally, the manufacturer’s track record in the industry and their history of successful deployments in relevant sectors are strong indicators of their reliability. Working with a manufacturer that has a proven history of delivering high-quality products can provide peace of mind and guarantee that the equipment will meet industry standards.

Customer Insight: Industry certifications can be a powerful indicator of the manufacturer’s credibility and adherence to high standards. For example, MINNUO’s nitrogen plants are certified by ISO 9001 and ISO 13485, ensuring that their systems comply with international quality standards and are ideal for high-demand industrial and medical applications.

Cost-Effectiveness:

Evaluating Overall Cost, Energy Consumption, Operational Costs, and Long-Term Savings

Cost-effectiveness is one of the most important factors when selecting a nitrogen plant manufacturer. While the initial purchase cost is important, the total cost of ownership over the equipment’s lifespan is what matters most.

Energy Consumption: The operational efficiency of nitrogen generation systems plays a significant role in determining long-term costs. Efficient systems consume less energy, contributing to lower operational expenses.

Operational Costs: Manufacturers should offer transparent pricing and demonstrate how their nitrogen plants help reduce operational costs. Factors such as ease of maintenance, energy consumption, and system downtime directly affect long-term expenses.

Long-Term Savings: A comprehensive cost-benefit analysis should factor in potential savings from reduced maintenance, energy consumption, and extended operational life. This evaluation ensures that clients are making an investment that offers value for money over time.

Customer Insight: Companies should focus on evaluating the total cost of ownership rather than just the purchase price. For instance, MINNUO’s nitrogen plants have helped clients in the automotive and chemical industries save up to 25% annually on operational costs through energy-efficient systems and minimized downtime.

Top 6 Trusted Nitrogen Plant Manufacturers in China

Air Liquide (China)

Overview:

As a global leader in industrial gases, Air Liquide’s China branch is renowned for providing high-end nitrogen solutions to large-scale industries. With its decades of experience, the company brings cutting-edge technologies to the Chinese market and supports industries such as steel, petrochemicals, and electronics.

Key Product:

Air Liquide specializes in cryogenic nitrogen generation systems, ideal for industries that require large quantities of ultra-pure nitrogen. The systems are capable of handling extreme temperatures and varying environmental conditions, offering consistent high-performance output.

Technology:

Air Liquide utilizes advanced cryogenic distillation techniques, which are optimal for large-scale nitrogen production. Their cryogenic plants ensure continuous production with extremely low nitrogen losses and operate at high efficiency.

Customer Case Study:

Steel Industry: Air Liquide implemented a large cryogenic nitrogen generation system for a steel mill to ensure steady production processes. This system enhanced the efficiency of their production line by providing a consistent, high-purity nitrogen supply, reducing downtime by 20% and cutting operational costs by 10%.

MINNUO

Overview:

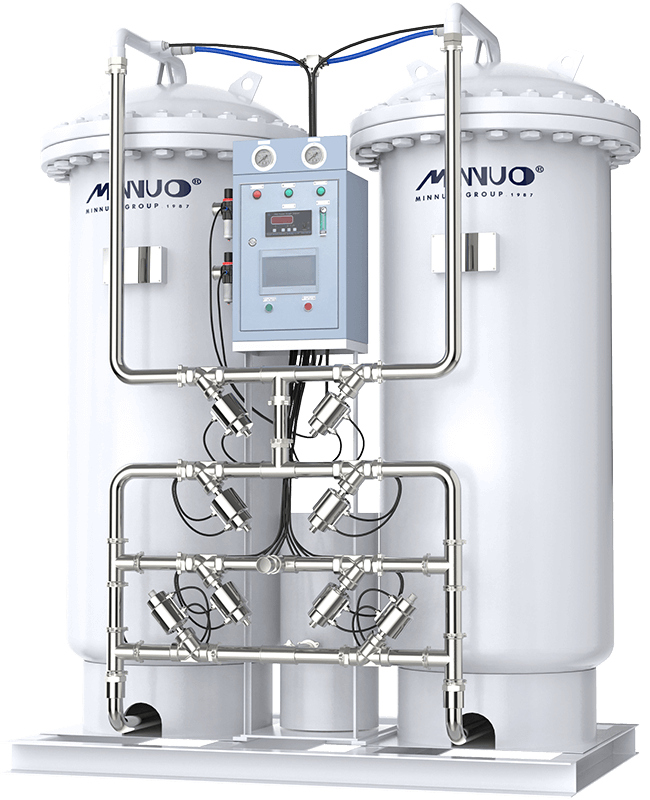

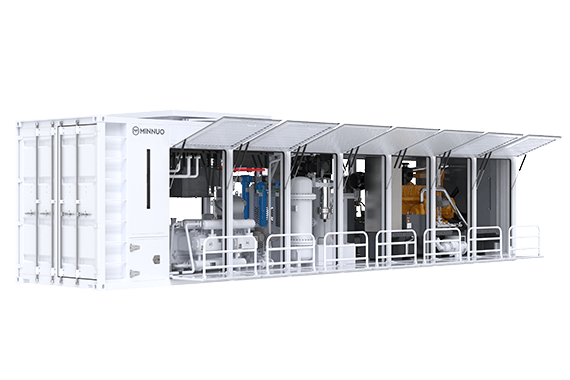

MINNUO is a leading manufacturer specializing in high-efficiency PSA nitrogen generators. The company is known for its technical expertise and commitment to energy-saving solutions. With a strong focus on advanced membrane nitrogen generation, MINNUO has a significant presence in various sectors such as petrochemical, food preservation, and healthcare.

Technology:

MINNUO’s nitrogen generation systems utilize cutting-edge membrane separation technology, alongside PSA systems for enhanced performance and energy efficiency. Their generators achieve nitrogen purities of up to 99.999%, making them ideal for industries with stringent nitrogen purity requirements.

Customer Case Study:

Chemical Industry: MINNUO helped a large-scale chemical plant reduce nitrogen supply costs by 20%. By optimizing their existing nitrogen generation systems with MINNUO’s advanced PSA technology, the plant was able to improve nitrogen output, minimize waste, and enhance process reliability while cutting energy consumption by 15%.

Hangzhou Oxygen Plant Engineering Co., Ltd. (HOPL)

Overview:

Hangzhou Oxygen Plant Engineering Co., Ltd. (HOPL) has carved a niche in the design and manufacturing of PSA nitrogen plants tailored for a wide array of industrial applications. The company is known for its ability to deliver both standard and custom nitrogen solutions, particularly in the pharmaceutical and food industries.

Key Product:

PSA nitrogen plants designed for industries that require high-purity nitrogen. These systems are energy-efficient and offer low maintenance costs, providing a stable and cost-effective nitrogen supply.

Technology:

HOPL’s PSA systems incorporate the latest filtration and adsorption materials, providing nitrogen with purity levels of up to 99.99%. Their systems are particularly known for their low energy consumption, which is critical for businesses seeking to reduce operating costs while maintaining the required nitrogen output.

Customer Case Study:

Pharmaceutical Industry: HOPL partnered with a pharmaceutical company to provide high-purity nitrogen for use in laboratory and production environments. Their PSA nitrogen generators enabled the company to maintain consistent nitrogen purity, critical for drug formulation, while reducing nitrogen supply costs by 18% annually.

Jiangsu Linde Gas Co., Ltd.

Overview:

Jiangsu Linde Gas Co., Ltd. is a prominent figure in China’s nitrogen generation market, with a strong focus on offering innovative, energy-efficient nitrogen generation solutions. The company specializes in providing nitrogen solutions across a wide range of industries, from small-scale applications to large industrial plants, ensuring that the systems are optimized for both efficiency and long-term sustainability.

Technology:

Linde’s nitrogen generation systems incorporate both small and large-scale nitrogen plants that feature modular designs. This flexibility enables them to cater to both growing industrial demands and cost-saving needs for businesses. Their plants utilize advanced air separation technology, which offers exceptional nitrogen purity and consistent output, optimizing operations while minimizing energy consumption.

Customer Case Study:

In a recent project, Linde installed their nitrogen generation systems at a large-scale metal fabrication plant. By switching to Linde’s PSA nitrogen generation system, the plant was able to reduce nitrogen supply costs by 15%, while maintaining consistent nitrogen purity of 99.99%. The success of this project highlighted how modular nitrogen plants could be integrated seamlessly into complex industrial processes, providing significant cost savings and operational efficiency.

Shanghai Huayi Oxygen Plant Engineering Co., Ltd.

Overview:

Shanghai Huayi Oxygen Plant Engineering Co., Ltd. stands as a leading provider of nitrogen plants in China, specializing in industrial-scale applications for the petrochemical sector. The company’s advanced technology helps meet the rigorous demands of industries such as oil refining and chemical production.

Technology:

Huayi’s nitrogen generation systems are specifically designed to handle high-volume and continuous nitrogen demand. Their PSA nitrogen generators are built to provide a steady and reliable nitrogen supply, even under high-pressure conditions, making them ideal for industries like petrochemicals, where the continuous availability of nitrogen is critical.

Customer Case Study:

In a project with an oil refinery, Huayi Oxygen Plant Engineering installed their PSA nitrogen generators to improve nitrogen supply for catalyst protection and gas blanketing. The system not only improved operational safety by ensuring consistent nitrogen purity but also resulted in a 20% reduction in nitrogen-related operational costs for the refinery.

Sinochem International Corporation

Overview:

Sinochem International Corporation is a global leader in chemical solutions, with a comprehensive range of nitrogen generation plants for industrial applications. They have made a significant impact in industries such as chemical processing, pharmaceuticals, and food manufacturing by offering nitrogen generation systems that meet stringent quality and efficiency standards.

Technology:

Sinochem focuses on sustainable and energy-efficient solutions by utilizing the latest PSA (Pressure Swing Adsorption) and cryogenic technologies. Their systems are designed to deliver both high-quality nitrogen output and a minimal environmental footprint. The integration of energy-saving technologies ensures the long-term cost-effectiveness of the nitrogen plants.

Customer Case Study:

Sinochem successfully deployed their nitrogen generation system in a large chemical processing plant. The installation led to a significant reduction in operational costs, with a 12% decrease in energy consumption and an improvement in nitrogen purity, all while meeting the strict environmental regulations. This project showcased Sinochem’s ability to provide customized solutions that address both cost-saving and regulatory challenges.

How to Evaluate the Best Nitrogen Plant Manufacturer for Your Business

Assessing Your Business Needs

Understanding Operational Requirements Before Purchasing a Nitrogen Generator

The first and most crucial step in selecting the best nitrogen plant manufacturer is understanding your business’s operational needs. The ideal nitrogen plant should align with the specific demands of your industry, whether it’s for medical applications, food preservation, or industrial processes. Assessing factors such as the required nitrogen purity, volume, pressure, and operational flexibility will help you determine the best solution.

Key Considerations:

Purity Requirements: Different industries require different levels of nitrogen purity. For instance, food packaging and pharmaceuticals may need higher purity nitrogen, while industrial applications may work with lower purity levels.

Flow Rate: Determine the required nitrogen flow rate based on your business size and production scale. Larger operations will need a higher capacity to ensure a continuous supply.

Operating Environment: Whether your operation is in a controlled indoor environment or a more challenging outdoor or offshore setting, make sure the equipment is designed to operate under the given conditions.

Scalability: Consider how the nitrogen plant can scale with your business growth. It is essential to choose a manufacturer that can provide modular systems capable of expansion.

Customer Case Study: A food processing company installed a PSA nitrogen generator from MINNUO to meet its growing demand for nitrogen. By precisely assessing their needs, they optimized the system’s capacity to reduce nitrogen waste by 10%, achieving significant cost savings.

Customization Options

Tailored Solutions for Industry-Specific Needs

Not all nitrogen generators are created equal, and a one-size-fits-all approach may not be suitable for every industry. A good manufacturer should offer flexibility and be able to customize the nitrogen generation system to meet the unique requirements of your application.

Customization Considerations:

Technology Adaptation: Depending on your industry, you may require membrane-based systems, PSA, or cryogenic technology. A manufacturer that offers multiple technology options can ensure that the system is well-suited to your specific application.

Integration with Existing Systems: Custom solutions should also include seamless integration with your current operations, whether it’s for production lines, storage facilities, or safety systems like fire suppression.

Energy Efficiency Solutions: Custom-designed systems that optimize energy consumption will reduce operating costs in the long run. Ensure the manufacturer uses the latest energy-efficient technologies, such as variable speed drives, advanced heat recovery systems, and smart monitoring.

Customer Case Study: MINNUO tailored a PSA nitrogen generator system for a pharmaceutical manufacturer. The system was designed to ensure a consistent supply of nitrogen while keeping energy usage minimal. The customized solution resulted in a 25% reduction in energy costs for the customer.

Post-Installation Support and Maintenance

Reliability of Customer Support and Maintenance Services

After purchasing a nitrogen generation system, ongoing support is essential for maximizing uptime and minimizing disruptions. The best manufacturers offer robust post-installation support, which should include reliable customer service, technical support, and maintenance plans.

Support Considerations:

Response Time: Assess how quickly the manufacturer responds to inquiries and issues. Fast response times can significantly reduce the downtime of your operations.

Service Contracts: Look for manufacturers that provide flexible maintenance contracts tailored to your needs, including preventive maintenance schedules, emergency repairs, and technical consultations.

Training and Support: Ensure that the manufacturer offers training for your staff on the proper operation and maintenance of the nitrogen system. This will help optimize the system’s performance and extend its lifespan.

Customer Case Study: A large-scale steel manufacturer partnered with MINNUO to provide nitrogen for its production lines. Thanks to MINNUO’s comprehensive maintenance service and training program, the client experienced minimal downtime and a 40% reduction in emergency service calls over the first year of operation.

Energy Efficiency

The Role of Energy-Efficient Systems in Reducing Operational Costs

Energy consumption is one of the highest ongoing expenses for businesses that rely on nitrogen generation. Selecting a manufacturer that prioritizes energy-efficient systems can significantly reduce operating costs and improve sustainability.

Key Factors in Energy Efficiency:

Low Power Consumption: Nitrogen generators should be designed to consume as little energy as possible. Look for systems with low specific power consumption (kWh/Nm³) and optimized energy management features.

Energy Recovery Systems: Advanced nitrogen plants may incorporate energy recovery systems that reuse waste energy to reduce the overall energy input, leading to lower operational costs.

Smart Monitoring and Optimization: Some manufacturers offer smart control systems that allow real-time monitoring of energy use, enabling businesses to make adjustments for optimal energy efficiency.

Customer Case Study: MINNUO’s energy-efficient PSA nitrogen generator solution helped a chemical plant reduce its nitrogen generation energy consumption by 30%. The client also saved approximately 15% on overall energy costs, thanks to the incorporation of intelligent monitoring that ensured the system was always operating at peak efficiency.

Conclusion

The nitrogen generation industry in China is rapidly advancing, driven by the increasing demand across sectors like healthcare, manufacturing, and environmental protection. Innovations in nitrogen generation technologies, particularly PSA and membrane separation, are enhancing efficiency and cost-effectiveness.

The industry’s focus is shifting towards sustainability, with energy-efficient systems reducing operational costs and carbon footprints. These developments are pivotal as businesses move towards greener and more efficient practices.

MINNUO continues to lead the way, providing cutting-edge nitrogen generation solutions. Committed to sustainability and innovation, MINNUO supports industries in achieving both operational efficiency and environmental responsibility.

sales2:+86 17506119168

sales2:+86 17506119168