Pressure Swing Adsorption (PSA) technology plays a pivotal role in the gas separation, particularly in oxygen and nitrogen generation. The technology is based on the principle of selective adsorption, where specific gases are adsorbed by a solid material (commonly a molecular sieve) at varying pressures. This method ensures high purity and efficient separation, making PSA technology integral in various industrial applications, from medical oxygen generation to industrial nitrogen production.

This article will delve into the fundamental principles of calculating PSA system separation efficiency, providing insight into key performance indicators like purity, recovery, and the role of adsorption materials. It will explore how different operating conditions impact the separation process and how optimization techniques can improve system performance. By discussing these key factors, we aim to provide a comprehensive understanding of how to achieve optimal gas separation efficiency in PSA systems.

Understanding and calculating PSA system separation efficiency is essential for optimizing performance and enhancing energy use. Through this article, engineers and industry professionals will gain practical insights into improving PSA system operations, ensuring higher output and reduced energy costs. We will also address the impact of different materials and system designs, offering recommendations on selecting optimal components for maximum efficiency. Whether you are a system designer, engineer, or technician, the insights provided here will be valuable for optimizing PSA technology and enhancing industrial gas generation systems.

Ⅰ.Basic Concepts of PSA Gas Separation Efficiency

1. Definition of Separation Efficiency

Separation efficiency is a key metric for evaluating the performance of a PSA (Pressure Swing Adsorption) system, which describes the performance of the system in terms of purity of the separated gas, recovery rate, and flow rate of the gas. Specifically, separation efficiency can be measured by the following metrics:

Purity: the percentage concentration of the target component (e.g., oxygen or nitrogen) in the gas, which is usually required to be of a specific purity value to meet standards for industrial or medical applications.

Recovery: The percentage of active gas (e.g. oxygen or nitrogen) that the system extracts from the incoming gas. Higher recovery rates help improve gas utilization efficiency and production economics.

Gas flow rate: the volume of gas that the system is capable of handling. The gas flow rate directly affects the production capacity of the system, and a flow rate that is too high or too low may affect the separation efficiency.

2. Factors affecting the separation efficiency of PSA system

The separation efficiency is affected by a variety of factors, among which temperature, pressure, flow rate, and the selection of adsorption materials play a vital role in the overall performance of PSA system.

a. Influence of operating conditions

Temperature: at high temperatures, the adsorption capacity of molecular sieves may decrease, resulting in lower separation efficiency. Elevated temperatures may lead to instability in the adsorption and desorption processes, affecting the purity of the target gas.

Pressure: The higher the pressure, the longer the retention time of the gas in the adsorbent bed, the more target gas the molecular sieve is able to adsorb, thus improving the separation efficiency. However, if the pressure is too high, the energy consumption of the system will also increase, and it is necessary to balance the energy consumption and separation efficiency.

Flow rate: The gas flow rate affects the contact time of the molecular sieve, and too fast a flow rate may cause the gas to not fully contact the molecular sieve, thus affecting the effect of gas separation. Appropriate adjustment of the flow rate helps to improve the separation efficiency.

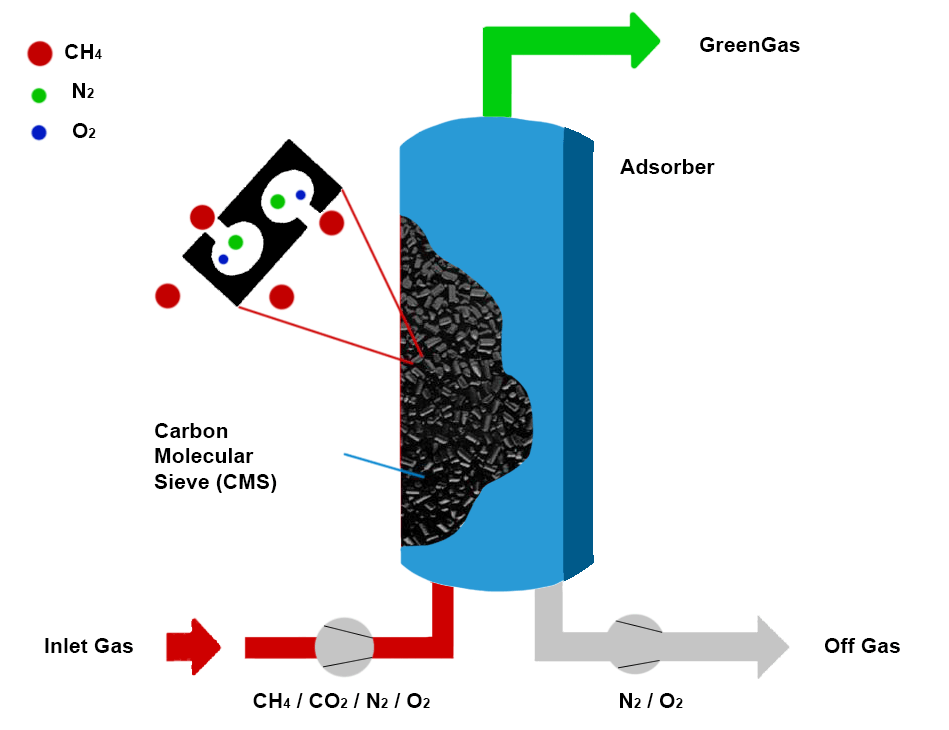

b. Selection of adsorption materials

Type of molecular sieve: different adsorption materials (e.g. molecular sieve, activated carbon, etc.) have different physical and chemical properties. For example, certain molecular sieves are suitable for adsorption of oxygen, while others are more suitable for adsorption of nitrogen. The choice of adsorption material determines whether the PSA system can effectively separate the desired target gas.

Adsorption capacity: The capacity of the adsorbent material directly affects the separation capacity of the system. Materials with higher adsorption capacity can handle more gases and improve recovery and separation efficiency.

Durability and Stability: High temperature and corrosion resistant adsorbent materials can prolong the service life of the system and ensure that the system maintains high efficiency under long-term operation.

c. System Design and Gas Flow Layout

Piping Layout and Adsorbent Bed Design: Reasonable piping and adsorbent bed design can help improve the efficiency of gas flow in the PSA system. Optimizing the layered design of the adsorption bed and the design of the gas flow path can effectively reduce the resistance of the gas flow and improve the contact time and separation efficiency of the gas.

Configuration of adsorbent beds: The use of multi-stage adsorbent beds and more efficient distribution systems can ensure that the gas flows uniformly over the surface of the molecular sieve, thus improving the separation efficiency.

Ⅱ.PSA Gas Separation Efficiency Calculation Methods

1. Purity Calculation

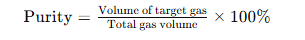

Definition of Purity: Purity refers to the ratio of the target gas (e.g., oxygen or nitrogen) to the total gas mixture in the PSA system. Purity is a key indicator for measuring gas separation efficiency.

Purity Calculation Formula:

Practical Application:

The purity calculation is used to determine the concentration of the target gas under various operating conditions (e.g., pressure, temperature, flow rate). In applications requiring high purity gases (e.g., medical oxygen, semiconductor industries), purity demands are generally strict.

By adjusting operational parameters (such as increasing the pressure in the adsorption tower or changing cycle times), the target gas purity can be improved, taking into account the impact on other system parameters like recovery rate.

2. Recovery Rate Calculation

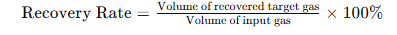

Definition of Recovery Rate: Recovery rate refers to the proportion of the target gas extracted from the input gas. It measures the gas recovery capability of the PSA system.

Recovery Rate Calculation Formula:

Practical Application:

The recovery rate calculation reflects not only the system’s performance but also its impact on gas production costs. A higher recovery rate means the system is more efficient in utilizing feed gas and reducing gas production waste.

Optimizing the adsorption materials, adjusting cycle times, or tweaking pressure and temperature conditions can improve recovery rates.

3. Comprehensive Calculation of Separation Efficiency

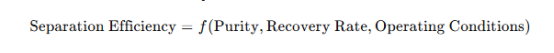

Gas separation efficiency is not only affected by purity or recovery rate alone but needs to be comprehensively considered. Separation efficiency indicates how effectively the PSA system separates the target gas from the gas mixture under given conditions.

Comprehensive Separation Efficiency Formula:

Influencing Factors:

Operating Conditions: Temperature, pressure, and flow rates directly impact separation efficiency. Generally, higher pressures and lower temperatures improve gas separation, but they also increase energy consumption.

Adsorption Material: The choice of adsorption material is critical. Different adsorbents (e.g., molecular sieves, activated carbon) have different affinities for target gases, directly influencing separation efficiency. Proper selection can maximize separation efficiency and reduce system energy consumption.

Ⅲ. Efficiency Calculation Under Different Operating Conditions

In PSA systems, the efficiency of gas separation can be influenced by various operating parameters. These include temperature, pressure, and flow rate, all of which significantly impact the separation efficiency, purity, and recovery rates. This section will delve into the impact of each of these factors on the efficiency calculations, offering practical solutions for optimizing performance.

1. Impact of Temperature

The temperature of the incoming gas significantly affects the adsorption process in PSA systems. As temperature increases, the gas molecules move more rapidly, which can reduce the adsorption capacity of the molecular sieve. This results in lower separation efficiency and potentially reduced oxygen or nitrogen purity.

Temperature’s Impact on Efficiency: Increased temperature can result in faster desorption of gases, reducing the system’s overall ability to separate oxygen and nitrogen effectively. This is especially true in systems where precise control of adsorption and desorption times is essential.

Calculation Method: To account for temperature variations, efficiency calculations should incorporate a correction factor based on the temperature difference from the standard operating conditions. Using the ideal gas law, the gas density and behavior at various temperatures should be modeled to estimate efficiency losses.

Practical Approach: Optimizing the PSA system’s cooling mechanisms or selecting advanced molecular sieves that perform well at higher temperatures can mitigate this impact, ensuring consistent efficiency levels.

2. Impact of Pressure

Pressure is another critical factor that directly affects the separation efficiency in PSA systems. As pressure increases, the gas density also increases, improving the adsorption capacity of the molecular sieve.

Pressure’s Influence on Efficiency: Higher pressures typically lead to improved oxygen or nitrogen separation efficiency, as the adsorbent material can capture more gas molecules at elevated pressures. However, excessive pressure can lead to higher energy consumption, thus affecting the overall operational cost.

Calculation Method: Efficiency calculations under varying pressures can be adjusted using the Van der Waals equation or other state equations that account for the gas behavior at different pressure levels. The goal is to find the optimal pressure range that maximizes the system’s performance without unnecessary energy expenditure.

Practical Approach: Using pressure swing optimization and designing PSA systems to operate within a specific pressure range can ensure that the system operates efficiently and with lower energy consumption.

3. Impact of Flow Rate

Flow rate plays a pivotal role in determining the performance of a PSA system. High flow rates can lead to increased adsorption times, reducing the system’s ability to achieve optimal separation efficiency.

Flow Rate’s Impact on Efficiency: When flow rates are too high, the system may not have enough time to properly separate the gases, leading to lower purity and recovery rates. Conversely, low flow rates may increase cycle times, which can reduce the system’s throughput.

Calculation Method: Flow rate optimization involves calculating the maximum allowable flow rate that maintains a high level of separation efficiency while ensuring that the system operates within its designed cycle time. Flow rates should be adjusted to balance the trade-off between throughput and separation efficiency.

Practical Approach: Implementing a dynamic flow rate control system that adjusts the flow in real-time based on system demands can improve both efficiency and system longevity, ensuring that the PSA process remains efficient even under fluctuating conditions.

IV. Strategies to Optimize PSA System Separation Efficiency

Achieving high separation efficiency in PSA (Pressure Swing Adsorption) systems is crucial for maximizing output and reducing operational costs. By optimizing various parameters and implementing advanced technologies, significant improvements in efficiency can be realized. This section discusses key strategies for optimizing PSA system performance, focusing on parameter optimization, adsorbent material selection, and system automation.

1. Parameter Optimization

One of the fundamental strategies to enhance PSA system separation efficiency is through the optimization of operational parameters, such as temperature, pressure, and cycle time.

Temperature and Pressure Control: Adjusting the temperature and pressure is crucial to maintaining optimal performance. Temperature variations can impact the adsorption rate of gases, so careful regulation can ensure that the system operates at its highest efficiency. Similarly, pressure control plays a direct role in maximizing the adsorbent’s capacity to separate gases. Optimizing these parameters allows for higher purity and recovery rates while minimizing energy consumption.

Practical Application: It is essential to adjust the PSA system’s operating parameters dynamically based on real-time conditions. For example, controlling pressure at various stages of the cycle can improve oxygen or nitrogen separation and reduce energy costs.

Cycle Time Adjustment: The timing of adsorption and desorption cycles directly affects the purity of the separated gases. Shortening cycle times without compromising efficiency can increase system throughput while reducing wear and tear on components. Cycle times should be adjusted according to the operational demands to balance purity and production rate.

2. Optimization of Adsorbent Materials

The choice of adsorbent material is one of the most critical factors influencing PSA system performance. The molecular sieve or other adsorbent materials used in the system determine the efficiency of gas separation.

Selecting High-Efficiency Adsorbents: It is important to choose adsorbents with higher adsorption capacity and faster adsorption/desorption cycles. Modern adsorbent materials, such as advanced molecular sieves, can withstand harsher operating conditions and maintain high efficiency over extended periods.

Practical Application: Select materials that are optimized for the specific gases being separated. For example, activated carbon may be suitable for separating gases with larger molecular structures, while zeolite-based materials may offer better performance for smaller gas molecules like nitrogen.

Improved Adsorbent Design: Incorporating innovations in adsorbent design, such as tailored pore sizes or enhanced regeneration capabilities, can greatly enhance system efficiency. Adsorbent materials that offer higher thermal stability and greater resistance to contaminants will contribute to extended lifespans and reduced maintenance needs.

3. System Control and Automation

Integrating advanced control systems and automation is essential for optimizing PSA performance. Real-time monitoring and automated control adjustments can significantly improve the efficiency and stability of the system.

Real-Time Monitoring and Control: Implementing sensors and control systems to continuously monitor key parameters, such as pressure, temperature, and gas purity, allows operators to make informed adjustments to optimize performance. Automated feedback loops can be used to adjust the system’s operating conditions dynamically, ensuring that the system always operates within its optimal parameters.

Practical Application: Use IoT-based sensors to monitor gas quality, pressure fluctuations, and temperature variations. These sensors can send real-time data to the control system, which can automatically adjust the cycle or pressure settings to optimize gas separation.

Automated Process Control: By incorporating advanced predictive analytics and machine learning algorithms, PSA systems can automatically adjust operational parameters based on historical data and real-time conditions. This reduces the need for manual intervention, enhances consistency, and minimizes human error.

Conclusion

In summary, this article has explored the critical role of gas separation efficiency in PSA (Pressure Swing Adsorption) oxygen and nitrogen systems. By understanding how to calculate and optimize the separation efficiency, we can significantly enhance the overall performance of these systems, improving both production output and energy management. The calculations for purity, recovery, and gas flow distribution have been highlighted as key components in optimizing PSA system operations.

As technology advances, PSA systems will continue to evolve, incorporating intelligent automation and more efficient materials. This progression will allow for further improvements in gas separation efficiency, offering higher production rates with lower energy consumption. The application of advanced control systems and continuous optimization will be integral in achieving these goals.

MINNUO is a leading supplier of high quality PSA oxygen and nitrogen systems, integrating the latest technologies to provide optimized solutions.MINNUO’s systems are focused on improving the efficiency of gas separation, helping industries to optimize their production processes and ensuring the consistent production of high purity gases at lower operating costs.

sales2:+86 17506119168

sales2:+86 17506119168