Introduction: Behind the Rigid Demand for Oxygen, a Revolution in Oxygen Generation Technology

Oxygen, known as the “industrial blood” in fields such as industrial production, medical and health care, energy conservation and environmental protection, its stable supply and cost control are directly related to enterprises’ production capacity, operational efficiency and core competitiveness. Traditional oxygen generation methods such as cryogenic air separation and liquid oxygen storage have long faced pain points such as large investment scale, high energy consumption, large floor space and inconvenient start-up and shutdown, making it difficult to meet the urgent demand for flexible, efficient and energy-saving oxygen supply in modern industries.

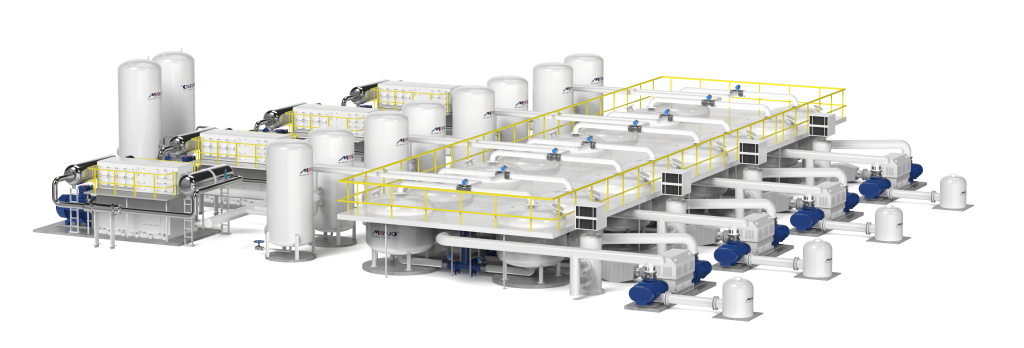

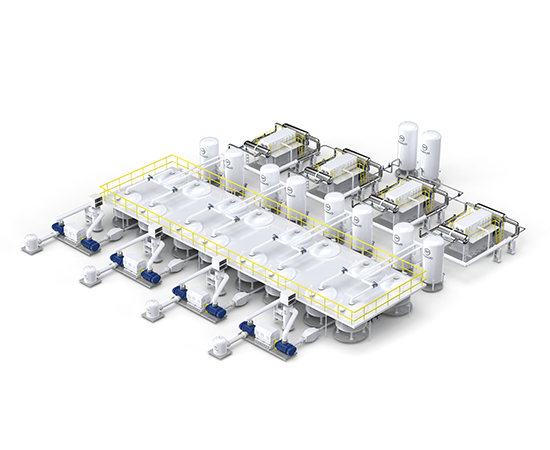

Against this background, Vacuum Pressure Swing Adsorption (VPSA) oxygen generation technology has emerged as the mainstream choice in the oxygen generation field with its disruptive advantages. As a high-tech enterprise specializing in the R&D, production, sales and service of VPSA oxygen generation equipment, Jiangsu Minnuo Group has created high-performance VPSA oxygen generation equipment suitable for multiple scenarios based on more than 20 years of industry accumulation and core technological breakthroughs. It injects green and efficient oxygen supply power into thousands of industries and redefines the value standards of the oxygen generation industry.

I. VPSA Oxygen Generation Technology: Decoding the Core Logic of Efficient Oxygen Supply

VPSA (Vacuum Pressure Swing Adsorption) oxygen generation technology, its core principle is to use the selective adsorption characteristics of molecular sieves for nitrogen and oxygen in the air to achieve the separation and purification of oxygen through pressure changes. Compared with traditional oxygen generation technologies, the advantages of VPSA oxygen generation equipment can be called “all-round crushing”:

1. Energy Conservation and Consumption Reduction, Operational Costs Reduced by 30%+

Traditional cryogenic air separation equipment needs to cool air to -196℃ to achieve gas-liquid separation, which consumes a lot of energy; while VPSA oxygen generation equipment operates at normal temperature and pressure, completing the adsorption and desorption cycle only through the coordination of vacuum pumps and compressors. The energy consumption per unit of oxygen is as low as 0.35-0.5kWh/Nm³, which is more than 40% energy-saving compared with cryogenic air separation and saves 30%-50% of operational costs compared with liquid oxygen supply. Long-term use can accumulate huge energy-saving benefits for enterprises.

2. Ready to Use, Flexibly Adapting to Multiple Working Condition Requirements

VPSA oxygen generation equipment has a short start-up time, which can produce qualified oxygen in only 15-30 minutes. The shutdown operation is simple, without complex preheating or cooling processes. The equipment has a wide load adjustment range, which can be flexibly adjusted between 30%-110% according to the actual oxygen demand. Whether it is stable oxygen supply for continuous production or dynamic adaptation for intermittent production, it can accurately match to avoid oxygen waste.

3. Compact Floor Space, Significantly Reducing Infrastructure Investment

Compared with the huge workshop demand and complex infrastructure projects of cryogenic air separation equipment, VPSA oxygen generation equipment has a compact structure and high integration, occupying only 1/5-1/3 of the area of traditional equipment. It does not require special low-temperature storage tanks and pipelines, and can be installed near the production workshop to reduce oxygen loss during transportation and pipeline investment. It is especially suitable for small and medium-sized enterprises with limited space or old factory renovation projects.

4. Safe and Stable, Operation and Maintenance Costs Negligible

VPSA oxygen generation equipment adopts a non-low temperature and non-high pressure operation mode, avoiding the safety risks in the storage and transportation of liquid oxygen. The equipment operating temperature is stable in the normal temperature range, and the failure rate is extremely low. The service life of the core component molecular sieve is as long as 8-10 years. Daily operation and maintenance only need to regularly check filters and valves, without the need for professional technical teams to be on duty, which greatly reduces the enterprise’s operation and maintenance manpower and cost investment.

As a leader in VPSA oxygen generation technology, Jiangsu Minnuo Group has achieved three major breakthroughs in core technologies through continuous technological iteration and innovation: first, the independently developed high-efficiency molecular sieve adsorbent, which increases the adsorption capacity by 20% and improves the oxygen purification efficiency; second, the optimized process flow design, which reduces equipment resistance loss and further reduces energy consumption by 15%; third, the integrated application of intelligent control systems, realizing real-time monitoring, data tracing and remote diagnosis of equipment operation status, making oxygen supply management more intelligent and worry-free.

II. Global Coverage: Diversified Application Scenarios of VPSA Oxygen Generation Equipment

With its outstanding performance advantages, Jiangsu Minnuo Group’s VPSA oxygen generation equipment has been widely used in various fields such as industrial production, medical and health care, environmental protection, agricultural breeding, and has become an “oxygen supply weapon” for the high-quality development of various industries.

1. Industrial Production Field: Empowering Production Capacity Improvement and Energy Conservation Transformation

In the iron and steel metallurgy industry, oxygen is a key raw material for converter steelmaking and blast furnace oxygen-enriched blast. Jiangsu Minnuo Group’s VPSA oxygen generation equipment can provide industrial oxygen with a purity of 93% for steelmaking workshops. Oxygen-enriched blast can improve the smelting intensity of blast furnaces, reduce the coke ratio, save 15-20kg of coke consumption per ton of steel, and increase production capacity by 10%-15%. After a large iron and steel enterprise adopted Minnuo’s VPSA oxygen generation system, it saved more than 8 million yuan in annual oxygen costs, and the investment return period was only 14 months.

In the chemical industry, oxygen is widely used in the production process of products such as synthetic ammonia, methanol and ethylene as an oxidant or reaction raw material. VPSA oxygen generation equipment can provide oxygen with a purity of 90%-93% according to the precise needs of chemical reactions, and the stable oxygen concentration ensures reaction efficiency and product quality. Aiming at the production characteristics of small batches and multiple varieties of fine chemical enterprises, Minnuo’s customized small VPSA oxygen generation equipment can flexibly switch oxygen supply parameters to meet the production needs of different products, reducing costs by more than 40% compared with liquid oxygen supply.

In the glass manufacturing industry, oxygen-enriched combustion is a core technology to reduce energy consumption and improve glass quality. VPSA oxygen generation equipment provides oxygen-enriched air with a purity of 85%-93% for glass kilns. Oxygen-enriched combustion can increase the flame temperature, enhance heat transfer, reduce fuel consumption by 30%-40%, reduce nitrogen oxide emissions, improve glass melting quality, and increase the glass yield by 5%-8%. After a glass product enterprise adopted Minnuo’s VPSA oxygen generation system, it saved more than 5 million yuan in annual natural gas costs, and the environmental emission indicators were better than the national standards.

In addition, in industries such as non-ferrous metal smelting, coal gasification and papermaking bleaching, Jiangsu Minnuo’s VPSA oxygen generation equipment can provide customized oxygen supply solutions to help enterprises achieve the dual goals of energy conservation, consumption reduction and production capacity upgrading.

2. Medical and Health Field: “Oxygen Guarantee” for Guarding Life and Health

Medical oxygen has extremely high requirements for purity, stability and safety. Jiangsu Minnuo Group’s medical VPSA oxygen generation equipment strictly follows the “Medical Oxygen” (GB 8982-2014) standard, and can produce medical oxygen with a purity of ≥93%, meeting the oxygen supply needs of hospital wards, intensive care units, operating rooms and other scenarios.

Compared with traditional bottled oxygen or liquid oxygen supply, medical VPSA oxygen generation equipment can achieve 24-hour continuous oxygen supply, without worrying about the risk of oxygen supply interruption, and avoiding the safety hazards of gas cylinder transportation and storage. The equipment is equipped with multiple filtration and disinfection systems to ensure that the oxygen cleanliness meets medical standards, and the operation noise is low, which does not affect the hospital’s diagnosis and treatment environment. At present, Minnuo’s medical VPSA oxygen generation equipment has been successfully applied in more than 200 hospitals at all levels across the country, from township health centers to tertiary hospitals, providing stable and reliable medical oxygen supply services to protect life and health.

3. Environmental Protection Field: Assisting Green and Low-Carbon Development

In the sewage treatment industry, the microbial degradation in the aeration tank requires sufficient oxygen. The traditional aeration method has low oxygen utilization rate and high energy consumption. Jiangsu Minnuo’s VPSA oxygen generation equipment provides high-purity oxygen for sewage treatment plants. Through the efficient aeration system, it improves the dissolution efficiency of oxygen in sewage, accelerates the degradation of organic pollutants by microorganisms, increases sewage treatment efficiency by 30%-50%, and reduces energy consumption by 25%-35%. After a municipal sewage treatment plant adopted Minnuo’s VPSA oxygen generation aeration system, its daily sewage treatment capacity increased from 50,000 tons to 70,000 tons, saving more than 3 million yuan in annual electricity costs, and the effluent quality stably reached the first-class A standard.

In the waste incineration power generation industry, injecting oxygen during waste incineration can improve combustion efficiency and reduce the emission of harmful gases such as dioxins. VPSA oxygen generation equipment provides oxygen-enriched air for incinerators, promotes full combustion of waste, increases power generation capacity, reduces flue gas treatment costs, and helps waste incineration power generation enterprises achieve environmental compliance and benefit improvement.

4. Agricultural Breeding Field: Activating the Yield Potential of the Breeding Industry

In the aquaculture industry, the dissolved oxygen content in water is a key factor affecting the breeding density and survival rate. Especially in high-temperature seasons or high-density breeding scenarios, traditional aeration equipment is difficult to meet the demand, which is likely to cause fish and shrimp to float up and die. Jiangsu Minnuo’s VPSA oxygen generation equipment quickly dissolves high-purity oxygen into the breeding water through an efficient oxygen dissolution device, stabilizing the dissolved oxygen content in the water above 8mg/L. The breeding density can be increased by 50%-100%, the survival rate by 20%-30%, and at the same time, it reduces the occurrence of diseases and lowers the cost of breeding drugs. After a Penaeus vannamei breeding base adopted Minnuo’s VPSA oxygen generation system, the per mu yield increased from 800 catties to 1,500 catties, and the per mu income increased by more than 20,000 yuan.

In the poultry breeding industry, an oxygen-enriched environment can improve the survival rate and growth rate of chicks and enhance the immunity of poultry. VPSA oxygen generation equipment provides oxygen-enriched air for breeding greenhouses, improves the air quality in the greenhouses, reduces the concentration of harmful gases such as ammonia, shortens the growth cycle of poultry by 7-10 days, and increases the feed conversion rate by 10%-15%, bringing significant economic benefits to breeding enterprises.

III. Minnuo’s Strength: More Than 20 Years of Deep Cultivation, Casting a Benchmark in the Oxygen Generation Industry

Jiangsu Minnuo Group Co., Ltd. was established in 2002. For more than 20 years, it has been focusing on the R&D and manufacturing of VPSA oxygen and nitrogen generation equipment, and is one of the earliest enterprises in China to realize the industrialization of VPSA technology. The company has a modern production base covering an area of 50,000 square meters, equipped with advanced production and processing equipment and testing instruments, with an annual production capacity of more than 500 sets. It can produce a full range of VPSA oxygen generation equipment with oxygen output from 5Nm³/h to 20,000Nm³/h and purity from 80% to 93%.

In terms of technological R&D, Minnuo Group has established a provincial-level enterprise technology center, with a core R&D team composed of doctors and senior engineers. It has accumulated 23 invention patents and 47 utility model patents, and participated in the formulation of multiple industry standards. The company has established industry-university-research cooperation relationships with Southeast University, Nanjing Tech University and other universities, continuously promoting technological innovation and product upgrading, and ensuring that product technology is always at the leading level in the industry.

In terms of quality control, Minnuo Group strictly follows the ISO9001 quality management system, ISO14001 environmental management system and ISO45001 occupational health and safety management system. From raw material procurement, production and processing to finished product inspection, each process is strictly controlled to ensure that each piece of equipment meets quality standards. The company has a sound after-sales service network, with more than 20 service outlets across the country, providing one-stop services such as on-site installation, commissioning and maintenance with 24-hour response, so that customers can use it without worry.

With excellent product quality and high-quality services, Jiangsu Minnuo Group’s VPSA oxygen generation equipment has won wide recognition from customers at home and abroad. The products not only cover 31 provinces, municipalities directly under the Central Government and autonomous regions across the country, but also are exported to more than 20 countries and regions in Southeast Asia, the Middle East, Africa, serving more than 3,000 customers and establishing a good brand reputation in the industry.

IV. Conclusion: Choose Minnuo VPSA, Choose an Efficient and Energy-Saving Oxygen Supply Future

Under the guidance of the “dual carbon” goal, energy conservation, consumption reduction and green development have become the core development directions of various industries. An efficient, energy-saving and stable oxygen supply solution is the key for enterprises to reduce operational costs and enhance core competitiveness. Jiangsu Minnuo Group’s VPSA oxygen generation equipment, driven by technological innovation and oriented by scene needs, provides customized oxygen supply solutions for thousands of industries, allowing every customer to enjoy “low-cost, high-efficiency and high-stability” oxygen supply services.

Whether you have production capacity upgrading needs in industrial production, life guarantee needs in medical and health care, or green development needs in environmental protection, Jiangsu Minnuo Group can tailor the most suitable VPSA oxygen generation plan for you with more than 20 years of industry experience and core technical strength. Choosing Minnuo means choosing a worry-free, cost-saving and more reliable oxygen supply partner; choosing VPSA oxygen generation technology is a wise move to comply with the trend of the times and empower the high-quality development of enterprises.

Jiangsu Minnuo Group, hand in hand with you, takes oxygen as the medium, and builds a green and efficient industrial future!

sales2:+86 17506119168

sales2:+86 17506119168