In the first half of 2025, the U.S. manufacturing sector contracted for the third consecutive month. According to the ISM Manufacturing Index, firms’ willingness to invest is weakening significantly – especially in energy-intensive, high-maintenance industries – and capital expenditures are gradually shifting from “expansionary investment” to “prudent choices. choice”. Purchasing is no longer about comparing prices, but about systematically evaluating long-term O&M costs, energy efficiency and payback.Therefore it is crucial to plan industrial oxygen investments.

As a key equipment in manufacturing and environmental protection system, industrial oxygen system is at the crossroads of “generation change”. In the face of rising prices of upstream raw materials, increased pressure on power costs and fluctuations in the technology supply chain, many companies are facing the dilemma of “high energy consumption of the old system and long ROI cycle of the new equipment”. So, in an environment of heightened uncertainty, is there still room for rational decision-making? Are there still ways to reduce operating expenses and improve project stability?

This article will focus on “how to optimize industrial site OPEX and safeguard return on investment through intelligent, energy-efficient oxygen system planning in the market slowdown cycle”, combined with real cases and procurement advice, to help you clarify the direction of the next step – to build a robust, viable and reliable system in the midst of the turbulence. turbulence to create a robust and controllable equipment selection strategy. Read on for an in-depth analysis of hidden costs, energy mix and investment logic reconstruction.

1.What the Slowdown Means for CAPEX Decisions

With manufacturing contracting for the third month in a row and uncertainty about end orders increasing, many companies are reviewing their capital expenditure (CAPEX) strategies. But slowing down investment is not the same as stagnation, but more importantly, how to “put money to work”.

1.1 CAPEX ≠ Stop Spending, but rather be more selective

In the downturn phase of the economic cycle, companies should focus on the cost-effectiveness and long-term value of “durable assets”. Take the oxygen system as an example, as one of the key energy and process infrastructures, it has the following two sensitivities:

High-energy consuming equipment will face elimination: such as the traditional deep-cooling, bottled oxygen and other solutions not only have high operating costs, but also face transportation instability and safety compliance issues.

High-maintenance equipment is no longer suitable for the current manpower and capital constraints of the corporate environment: frequent breakdowns of old equipment, spare parts are difficult to find, slow after-sales response will significantly slow down the pace of plant operations.

Inefficient systems become “black holes” in costs: In a context of high energy prices and controlled carbon emissions, inefficient equipment can directly eat into profit margins.

Particularly suitable for customers in the following scenarios:

Industries with continuous oxygen supply needs: e.g. glass, metal smelting, chemical industry, electronics manufacturing, etc.

Alternative customers who are considering switching from bottled/deep-cooled solutions to “self-produced oxygen”

Customers applying for carbon tax exemption, energy subsidies, or governmental green technological reform projects

→ For the above users. For the above customers, PSA/VPSA solution with “more energy-saving, more stable and more compliant” is a more forward-looking choice.

1.2 New vs. Replacement: Which end of the investment decision are you on?

Different enterprises face different investment cycles and considerations, and their strategies should be differentiated:

New construction projects: modular and scalable oxygen systems are recommended

Small initial investment, rapid expansion with production scale growth

Fast deployment of containerized structure, no need for civil construction, suitable for rapid advancement of EPC projects

Suitable for supporting SCADA/MES systems, easy to integrate and manage remotely in the later stage

Replacement and retrofitting projects: assessing the potential and life-cycle benefits of energy saving Evaluation of energy saving potential and full life cycle benefits

Switching from bottled oxygen/liquid oxygen to PSA/VPSA system

Reducing electricity consumption from ≥0.7kWh/Nm³ to ≤0.45kWh/Nm³, saving 20%~30% of the annual electricity bill

Supporting customized operation strategy (night mode/PID adjustment), adapting to the process rhythm of multiple shifts

Stronger equipment life guarantee after replacement, extending maintenance interval to 4000~6000 years. Maintenance intervals can be extended to 4000~6000 hours

Management advice: focus not only on initial purchase price, but also on

Controllable installation period

Optimized cost of electricity for subsequent operation

Ability to meet ESG requirements and subsidy compliance

Brand’s ability to deliver on turn-key basis (e.g., DDP + fully certified + after-sales response)

2.The Hidden Operating Cost of Conventional Oxygen Supply

In the current climate of tight money in the global manufacturing industry, many organizations are re-evaluating the “true cost” of traditional oxygen supply solutions. If you are still utilizing bottled oxygen, liquid oxygen or older PSA systems, the following operating expenses are silently eating into your bottom line.

2.1 The “Hidden Expenses” of the Liquid Oxygen/Cylinder Solution

While a “one-time purchase” may sound convenient on the surface, the indirect costs of transportation, storage, and compliance are significant:

Transportation Challenges:

Cylinder distribution costs fluctuate depending on fuel prices, tolls, and labor. Upward trend.

Most customers’ feedback: the distribution cost per cubic meter of oxygen is 30%~50% of the gas price, which is very low cost-effective for long-term use.

Filling loss:

Oxygen cylinders inevitably have gas loss during handling, transshipment and filling.

Common valuation in the industry: each transfer loss of about 3% ~ 5%, directly increasing OPEX (operating costs).

Safety and regulatory risks:

Liquid oxygen is a dangerous goods transportation, in addition to the high license and qualification requirements, but also need to be regularly calibrated.

Some countries or regions (e.g. Germany, Belgium) have regarded centralized oxygen distribution as a high-risk process, and are promoting the transformation of hospitals and factories into “self-built oxygen supply”.

Alternative Suggestion:

Adopting PSA/VPSA local oxygen generation system can significantly cut down the logistics and safety compliance cost, especially suitable for areas with high frequency of gas consumption, long transportation distance or clear policy direction.

2.2 Older systems with high energy consumption = electrical capital outflow

Many companies are already using self-built oxygen systems, but if the equipment is too old, they may be falling into the trap of “low efficiency and high electricity costs”:

⚡ Excessive energy consumption for operation:

Early PSA units operated on ≥ 0.7 kWh/Nm³, meaning thousands of euros per month in areas with high electricity prices (e.g., Europe. Canada), Canada), implying thousands of euros per month in additional expenses.

High frequency of maintenance and spare parts replacement:

Aging problems such as compressor relief valves, PLCs, molecular sieve components, etc. are frequent, which not only increase maintenance costs, but also frequently interrupt the normal production rhythm.

According to MINNUO’s data model, the annual maintenance costs for an old 10Nm³/h model can reach 10% to 15% of the total investment.

Risk of unplanned downtime:

For continuous production scenarios (glass, metallurgy, environmental reactors), any unplanned downtime will result in wasted raw materials and increased product defects, directly affecting revenue.

Alternative Suggestion:

Choose energy-saving VPSA system or a new generation of intelligent PSA system (power consumption ≤ 0.45kWh/Nm³), which not only reduces electricity expenses, but also supports intelligent alarm and remote diagnosis, and greatly improves system stability.

Cost comparison table (taking 100Nm³/h oxygen system as an example)

| Project | Traditional Liquid Oxygen Distribution | Older high energy PSA | MINNUO New VPSA |

| Average operating energy consumption | None (but high distribution costs) | ≥0.7 kWh/Nm³ | ≤0.45 kWh/Nm³ |

| Maintenance frequency | High | high | Low (6,000 hour replacement cycle) |

| Safety compliance costs | High (special transportation required) | medium | Low (full CE/PED certification) |

| Annual OPEX expenditures (estimated) | High | medium-high | Low |

3.Why Energy-Efficient PSA/VPSA Is a Smart Move in 2025

Against the backdrop of cautious investment in manufacturing, tightening energy subsidies and ESG compliance in 2025, choosing an energy efficient PSA/VPSA oxygen generation system is not only a way to control operating costs, but also a “plus” for companies to achieve long term robust operation.

3.1 How to reduce OPEX (cost per ton of oxygen) with energy-saving solutions

Take MINNUO high-efficiency VPSA system as an example, its power consumption can be stably controlled at ≤0.45kWh/Nm³, which is significantly lower than that of traditional PSA equipment. According to customers’ feedback, in high load operation scenarios (e.g. glass, metallurgy, paper making), it can bring the following benefits:

Direct cost reduction: compared with the old model, the cost of electricity per unit of oxygen is reduced by 25%;

Load-tracking operation mode: the capacity can be adjusted according to the fluctuation of gas consumption, avoiding the “no-load power consumption” and matching with the actual production;

PID Intelligent Control + Night Energy Saving Strategy: Reduce energy waste and support users to realize energy management compliance (suitable for ESG target enterprises);

Optional Tail Gas Recovery Unit: Further reduce the oxygen loss rate and improve the overall system efficiency, especially suitable for gas billing sensitive places (such as plateau, high temperature plants).

3.2 How Modular Design Relieves CAPEX Pressure

In addition to energy saving, modular design is also an important direction for investment in oxygen systems in 2025. MINNUO has been designed with full consideration of deployment efficiency, capital arrangement, and flexibility of expansion at later stage, which brings the following advantages:

Support for customized flow bands: wide range of single models (30Nm³/h~3000Nm³/h), no need for “one-size-fits-all” selection, can accurately match the initial gas load;

Simplified container structure: can be equipped with skid-mounted, containerized structure, directly installed on the ground, no need for civil engineering, to reduce the construction cycle of more than 30%;

Compatible with multi-stage expansion planning: according to the project’s future growth is expected, can be configured with reserved interfaces or sub-modules, to reduce the cost of future transformation;

CE/PED/ASME certified standard structure: a machine universal EU, U.S., Canada, the Middle East and other markets, to avoid secondary adjustment of the structure design.

Real-World Case: Oxygen Cost Reduction Amid Budget Constraints

| Plant Region | Industry Type | Replacement options | Results |

| Texas | Industrial Coating Plant | VPSA 80Nm³/h, tail gas recovery + night operation | Reduced annual operating electricity costs $28,000+ |

| Netherlands | Water Treatment Center | PSA module + UPS storage | Avoided government subsidy lapse, 99.6% system continuity |

| France | Metal Cutting Shop | Replacement of old bottled oxygen supply with PSA | ROI payback reduced to 18 months |

4.Actionable Steps: How to Make a Smart Purchase in a Uncertain Market

In the unstable market environment, enterprise procurement is no longer just a “price comparison + order” process, but a strategic decision-making process involving risk assessment, cost prediction and long-term operational security. Below are five highly recommended practical steps to help you avoid stepping on mines when purchasing an oxygen system and realize long-term stable benefits:

4.1 Review the supplier’s “Energy + O&M + Delivery” cost structure

Why is it important?

Purchase price is only a part of the whole life cycle cost of the equipment, especially in 2025, when the cost of electricity is rising and subsidies are tightening, the difference in energy efficiency will directly determine your OPEX (Oxygen cost per unit).

How to do it:

Evaluate the nominal power consumption of the equipment (e.g. whether VPSA ≤ 0.45kWh/Nm³ is compliant with the standard)

Ask for a report on the measured energy consumption or operational field records

Examine the maintenance intervals (compressor, molecular sieve, controller replacement intervals > 4,000 hrs)

Calculate the frequency of required manpower for maintenance and the average risk of downtime

4.2 Calculate the payback period of PSA/VPSA investment (ROI tool available)

Why is it important?

The key to the viability of an investment is “whether it pays for itself in 3 to 5 years”, which depends on the efficiency of the system, the level of energy consumption and the matching of the actual gas consumption.

MINNUO provides a free ROI simulation tool:

Input: target oxygen flow rate, tariff, operating hours, gas consumption scenarios

Output: average annual operating costs, savings from substitution of bottled/liquid oxygen, estimated payback years

4.3 Does the consulting brand have certification support

Why is it important?

Whether the equipment can enter the customs smoothly, whether it meets the government procurement requirements, whether it can apply for subsidies, all depend on the completeness of the certification.

MINNUO can provide the following certification combinations for all export models:

CE (EU General Compliance)

PED (EU Pressure Equipment)

ASME (American Standard Pressure Vessel)

ISO13485 (Medical Device Quality System)

and provide electronic preview + customs clearance instructions + customs declaration package, which is convenient for customers to declare in advance and release in one go.

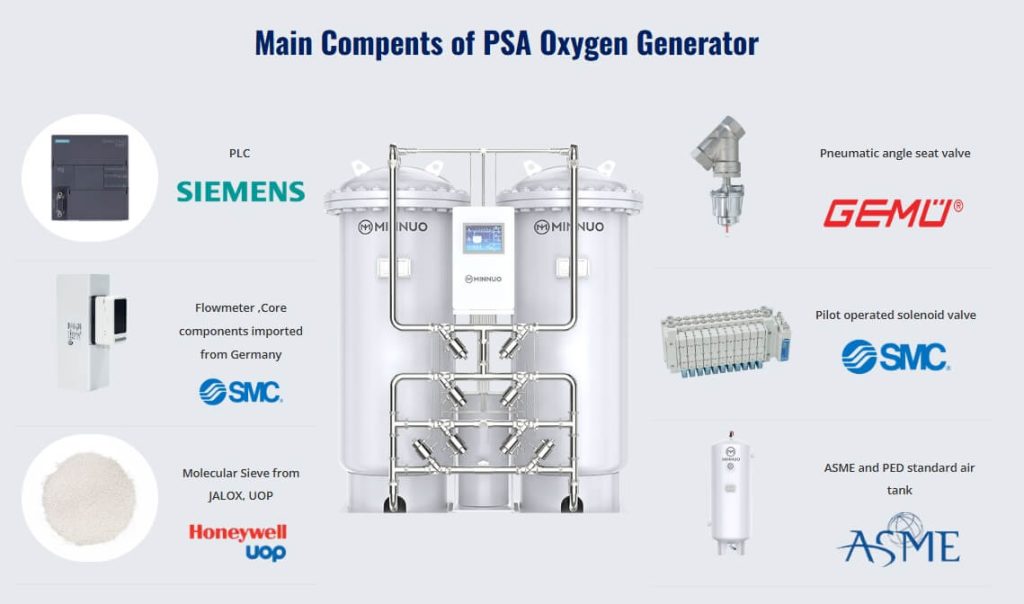

4.4 Select equipment brands that support “Flexible BOM Substitution”

Why is it important?

A fixed BOM from a single brand or source is susceptible to “uncontrollable lead times”, “incompatible certifications”, or “out-of-stock critical parts” in a fluctuating supply chain, which can cause projects to come to a standstill.

MINNUO’s solution:

PLC support Siemens, Huichuan, Omron free switching

Valves/solenoid valves support domestic Baoshuo and Korean KCC interchange

Pressure vessels support domestic 304/316 stainless steel instead of German imports

All the substitutes are matched with the certified version in advance to ensure overall compliance.

4.5 Clarify DDP quotation requirements: locking in delivery time and customs clearance risks

Why is it important?

In the current context of port congestion + frequent tariff changes, traditional FOB or CIF terms can easily lead to budget overruns and clearance delays.

Suggestions:

Require DDP clause, clarify delivery port, routing and tax responsibility

Require contract to include: HS categorization statement, list of declaration materials, customs declaration warning instructions

Clearly define the responsibility division and alternative solution activation mechanism in case of unexpected tariff policy

Practical reminder: MINNUO can provide you with a full set of “Intelligent Selection + Certified List + ROI Analysis + DDP Solution” service.

If you are selecting an oxygen system for a factory, hospital or environmental project and are not sure if you should start immediately, you may want to start the evaluation from these five points, avoid the pitfalls in advance, and lock in the most certain purchasing path in 2025.

Contact a MINNUO engineer today for your own procurement risk analysis and recommended configuration list. We’ll help you “solidify” your uncertainty into a robust system go-live plan.

Conclusion

When the manufacturing industry continues to contract and the global economy enters the “CAPEX Refinement Cycle”, the core of equipment investment has shifted from the “total budget” to the “operational return”. At this moment, whether to choose the industrial oxygen system with energy saving advantages, friendly operation and maintenance, strong compliance, will determine the cost structure of enterprises in the next 3 to 5 years.

Energy saving is not a slogan, but a real path to OPEX reduction. The more uncertain the market, the more you need the long-term value of sound assets. Those who act now will be more resilient and competitive in the “budget winter”.

MINNUO provides complete PSA/VPSA oxygen system energy efficiency solutions and export compliance delivery services for European and American companies to help them navigate the challenges of 2025. Contact us for investment analysis and customized advice to meet your site needs.

sales2:+86 17506119168

sales2:+86 17506119168