Membrane nitrogen generation technology is an innovative gas separation method widely used across various industries. Its primary advantages include low energy consumption, compact equipment, and environmental friendliness, making it an efficient solution for modern industrial gas production. This article will systematically explain the definition, process, and technology of membrane nitrogen generation.

Membrane nitrogen generation technology utilizes the selective permeation principle of hollow fiber membranes to separate nitrogen from other components in the air, such as oxygen and carbon dioxide, yielding high-purity nitrogen (95%-99.9%). This technology is energy-efficient, environmentally friendly, and compact, with widespread applications in sectors like oil and gas, electronics, and new energy. A membrane nitrogen system includes pre-treatment, membrane separation, and intelligent control, supporting modularity and high-pressure output, and is suitable for extreme environments with a long service life.

1. Definition and Core Principles of Membrane Nitrogen Generation Technology

1.1 Technology Definition

Membrane nitrogen generation (Membrane Nitrogen Generation) is a gas separation technology based on the selective permeation principle of hollow fiber membranes. The technology utilizes polymer membranes with differing permeation rates for various gas molecules to separate nitrogen (N₂) from oxygen (O₂), water vapor (H₂O), carbon dioxide (CO₂), and other components in the air, resulting in nitrogen with a purity of up to 95%-99.9%.

1.2 Core Physical Principle

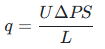

- Selective Permeation Formula:Permeation rate

where U is the gas permeability coefficient,ΔP is the pressure differential across the membrane, S is the membrane surface area, and L is the membrane thickness.

- “high-permeability gases” and “low-permeability gases“(gases with higher/lower permeation rates through the membrane) Separation:Oxygen, water vapor, CO₂, and other “high-permeability gases” preferentially permeate through the membrane wall, while nitrogen, with a lower diffusion coefficient, is concentrated as the “low-permeability gases” output.

2. Components and Process of Membrane Nitrogen Generation System

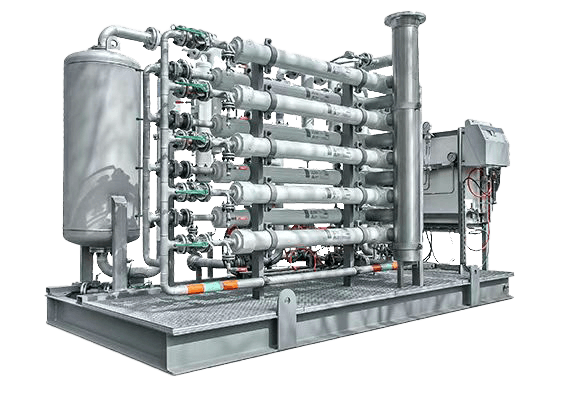

2.1 Core Components

- Hollow Fiber Membrane Modules:Composed of millions of polymer fibers, each about 50 microns in diameter, providing a vast separation surface area.

- Pre-treatment System:Includes a three-stage filtration system (oil removal, dust removal, and a dryer), a heater (maintaining an optimal temperature of 40–50°C), and a buffer tank (for pressure stabilization).

- Intelligent Control System:A PLC automatically adjusts pressure, flow, and purity, with some high-end devices equipped with PID algorithms to optimize parameters (e.g., K_P = 0.827 , T_I = 1.198 ).

2.2 Process Flow

- Air Compression:The air compressor provides compressed air at 0.7–2.4MPa.

- Deep Purification:Activated carbon filters remove oil mist (<0.003ppm) and particulate matter (<0.01μm).

- Membrane Separation:Air heated to 45–60°C enters the membrane module. “high-permeability gases” like oxygen permeate through the membrane, while nitrogen is concentrated and output.

- Post-treatment (optional):Deoxygenation towers (using carbon deoxygenators to remove residual O₂) and adsorption drying (dew point ≤ -65°C).

3. MINNUO’s 10 Technological Advantages in Membrane Nitrogen Generation

- Revolutionary Energy Reduction:Energy savings of 30–40% compared to cryogenic methods and 15–25% compared to PSA.

- Extreme Environmental Adaptability:Stable operation from -40°C to 55°C, in high humidity and salty environments, ideal for offshore platforms and desert oilfields.

- Military-grade Reliability:Membrane modules have a lifespan of 12–15 years.

- Intelligent Control Breakthrough:Valve position actuators combined with PID algorithms allow for precise control of oxygen content to ±0.1%.

- Modular Expansion:Single equipment produces 10–5000Nm³/h of nitrogen, with easy expansion through parallel membrane modules.

- Zero-emission Eco-friendly Design:No chemical waste is produced, and the oxygen-enriched exhaust can be recovered for combustion enhancement, meeting ship emissions standards.

- Super High-Pressure Output:Special membrane design supports nitrogen output pressures up to 5MPa, meeting requirements for deep well fracturing and aerospace filling.

- Mobile Solution:Skid-mounted units are 60% lighter than traditional systems, suitable for oilfield drilling rigs and emergency fire trucks.

- Mixed System Innovation:Integration of membrane separation and PSA technology pushes purity limits to 99.999%.

4. Industry Applications of Membrane Nitrogen Generation

4.1 Oil & Gas

- Gas Drilling: Nitrogen replaces air to prevent blowouts.

- Mixed Gas Fracturing: Injecting nitrogen foam to improve fracturing fluid recovery.

- Tank Inerting: Nitrogen is used to seal LNG tanks on offshore platforms to reduce hydrocarbon emissions.

4.2 New Energy & Electronics

- Lithium Battery Manufacturing: 99.9% pure nitrogen is used for electrode drying to prevent SEI film oxidation.

- Solar Panel Packaging: High dryness nitrogen prevents silicon wafer water-oxygen corrosion.

4.3 High-end Manufacturing

- Aerospace: Nitrogen is provided at high pressure for aircraft hydraulic system inerting.

- Marine Dual Fuel Systems: Nitrogen is used to suppress fuel tank vapor explosion risks.

4.4 Food & Medicine

- Supercritical Extraction: Nitrogen protects active ingredients, replacing traditional CO₂ methods.

- Vaccine Cold Chain Transportation: Nitrogen-dry ice mixture for cooling and temperature fluctuation control.

5. Equipment Selection and Key Maintenance Indicators

5.1 Five Key Selection Factors

- Membrane Material Type:Polyphenylsulfone hollow fiber membrane (pressure resistance ≥ 2.4MPa). Used in Middle East oilfields.

- Pre-treatment Level:Three-stage filtration (oil content < 0.003ppm). Required for offshore platforms with activated carbon filters.

- Intelligent Control System:PID algorithm + IoT remote monitoring. Intelligent purity control systems.

- Energy Efficiency Ratio:≥57% nitrogen recovery rate. NGM⁺ series.

- Certification Standards:ATEX explosion-proof, DNV-GL ship classification certification. Marine systems.

5.2 Golden Maintenance Rules

- Extending Membrane Life: Monthly backflushing maintenance to avoid membrane pore blockage.

- Precise Temperature Control: Air inlet temperature is stabilized at 45–60°C, with shutdown protection triggered if it exceeds limits.

- Consumable Replacement Cycle: Replace activated carbon filters every 2000 hours and precision filters every 5000 hours.

6. Technological Challenges and Future Trends

6.1 Current Technological Bottlenecks

- Dependence on Imported Membranes: Domestic nitrogen recovery rates are low at 15–20%.

- Limitations in High Purity Applications: The purity limit of membrane technology is typically 99.9%. Higher purity requires integration with PSA or cryogenic methods.

6.2 Future Innovation Directions

- Nanocomposite Membranes: R&D on new membranes to increase separation efficiency by 300%.

- AI Predictive Maintenance: Machine learning-based data analysis, with fault prediction accuracy ≥ 95%.

- Renewable Energy-Integrated Systems: Achieving “zero-carbon” nitrogen production.

7. Common Membrane Nitrogen Generation FAQs

7.1 What are the main differences between Membrane Nitrogen, PSA Nitrogen, and Cryogenic Nitrogen?

- Principle Differences:Membrane nitrogen relies on selective permeation through hollow fiber membranes without phase change or chemicals; PSA uses molecular sieves; cryogenic nitrogen separates nitrogen and oxygen by distillation.

- Applicable Scenarios:Membrane nitrogen is suitable for small to medium-scale production and applications sensitive to energy consumption and equipment size; PSA is used for medium purity needs; cryogenic nitrogen is for large-scale, high-purity nitrogen requirements.

7.2 Can membrane nitrogen achieve purity above 99.99%?

- The purity limit for single membrane separation technology is usually 99.9%. For higher purity, post-treatment equipment or a membrane-PSA hybrid system is required.

7.3 What are the operating costs of membrane nitrogen generation equipment?

- Compared to PSA, energy consumption is reduced by 15–25%. Energy consumption per ton of nitrogen is about 0.5–1.2kWh, resulting in lower long-term operating costs.

7.4 How long does installation and commissioning take for membrane nitrogen generation equipment?

- Installation cycle: Standard skid-mounted equipment can be completed in 1–3 days, and modular design supports plug-and-play.

7.5 Is membrane nitrogen generation equipment safe in flammable and explosive environments?

- Explosion-proof Design: Equipment can be fitted with ATEX-certified components, making it suitable for hazardous areas.

8. Conclusion

Membrane nitrogen generation technology, with its high efficiency, energy savings, and environmental benefits, is gradually replacing traditional gas separation methods. It demonstrates immense potential in industries like oil and gas, new energy, and high-end manufacturing. As MINNUO‘s technology continues to advance, the performance of membrane nitrogen generation will further improve, offering reliable nitrogen supply solutions to more industries.

sales2:+86 17506119168

sales2:+86 17506119168