Oxygen, this intangible industrial blood and life-protecting gas, is becoming the core driving force in modern manufacturing and medical health fields – from the intense tempering in metal cutting, the biological activation in wastewater treatment, to the life-sustaining in ICU wards, its stable supply directly determines production efficiency and the success or failure of treatment. However, the constraints of traditional bottled oxygen are becoming increasingly prominent: high hidden costs erode profits, safety hazards of high-pressure gas cylinders follow closely, and the risk of logistics supply disruptions constantly threatens operational continuity.

Are you trapped in such a cycle? Cost out of control: 30% of the gas fees paid are actually paid for logistics, leasing and waste. Safety anxiety: High-pressure gas cylinder warehouses are like time bombs, and operators face the risk of explosion every time they change cylinders. Nightmare of supply disruption: When the production line stops due to bottle changing or transportation is delayed due to heavy rain, medical rescue is forced to be suspended. The breakthrough value of on-site oxygen production lies precisely here: it is not merely a simple replacement of the gas source, but rather a technological reconstruction that upgrades oxygen from a “high-cost, high-risk, and highly uncertain” consumable to an “independently controllable, safe and stable, and continuously cost-reducing” infrastructure.

In the mining area hospital at an altitude of 4,000 meters in the Andes Mountains, the heavy snowfall blocked the road, completely interrupting the transportation of bottled oxygen. However, the adjacent hospital that uses on-site oxygen generators continuously supplies oxygen of stable purity, achieving zero delay in the treatment of critically ill patients. In the electronic glass furnace workshop in Munich, Germany, the defect rate of products caused by fluctuations in bottled oxygen pressure was reduced from 3.5% to zero error. This alone led to an annual loss stop of over 550,000 euros. These cross-continental empirical evidence declare that when the traditional bottled oxygen supply chain frequently fails in extreme environments and precision industrial scenarios, enterprises with independent oxygen supply capabilities are quietly building a golden triangle barrier of cost control, intrinsic safety, and sustainable operation.

Analysis of the true cost of bottled oxygen: Far exceeding the surface price

Many industrial or medical institutions that rely on bottled oxygen often only pay attention to the unit price of each bottle of gas. However, the overall cost of bottled oxygen is far more than that, involving significant explicit and implicit expenditures. A thorough understanding of these costs is the basis for evaluating a better oxygen supply solution.

Explicit costs: Clearly visible expenditure items

Cumulative cost of gas purchase: Bottled oxygen is priced per bottle (for example, 40L industrial oxygen @ 150 bar). For medium or large-scale users (such as metal cutting factories consuming 100 bottles per month and hospital icus consuming dozens of bottles per day), the annual gas procurement cost can reach hundreds of thousands or even millions of US dollars. This is the most intuitive part of the cost structure.

Gas cylinder-related costs

Rental fee: Users usually need to pay the gas cylinder rental fee on a monthly or annual basis.

Deposit: A one-time high deposit for gas cylinders, which occupies working capital and may not be fully refunded.

Logistics and transportation costs: The supply of bottled oxygen relies on frequent delivery (full bottles) and recycling (empty bottles). Transportation costs are significantly influenced by factors such as distance, oil prices, and labor. For users in remote areas, logistics costs may cause a significant increase in the actual unit price of oxygen.

Hidden costs: Efficiency and resource consumption that are easily overlooked

Management costs: The full-cycle management of bottled oxygen consumes human resources, including:

Ordering process (communication, confirmation)

Coordinate delivery and reception

Warehouse space occupation and full/empty bottle inventory management

Arrange the bottle changing operation

Downtime loss (efficiency cost) : The bottle-changing operation will inevitably lead to a temporary interruption of gas supply. On the production line, this might mean shutting down or restarting. In a medical setting, it may affect the treatment process. The production losses or reduced medical efficiency caused by such unplanned disruptions have accumulated considerable costs.

Gas waste: There is an inevitable loss of bottled oxygen in actual use.

Transportation and storage leakage: Gas loss is caused by poor valve sealing or slight leakage.

Residual gas: When the pressure inside the bottle drops to a certain level, it cannot be effectively utilized. The proportion of residual gas usually reaches 10% to 15%, which means that users pay for the unused oxygen.

On-site oxygen generation: The core solution for cost optimization

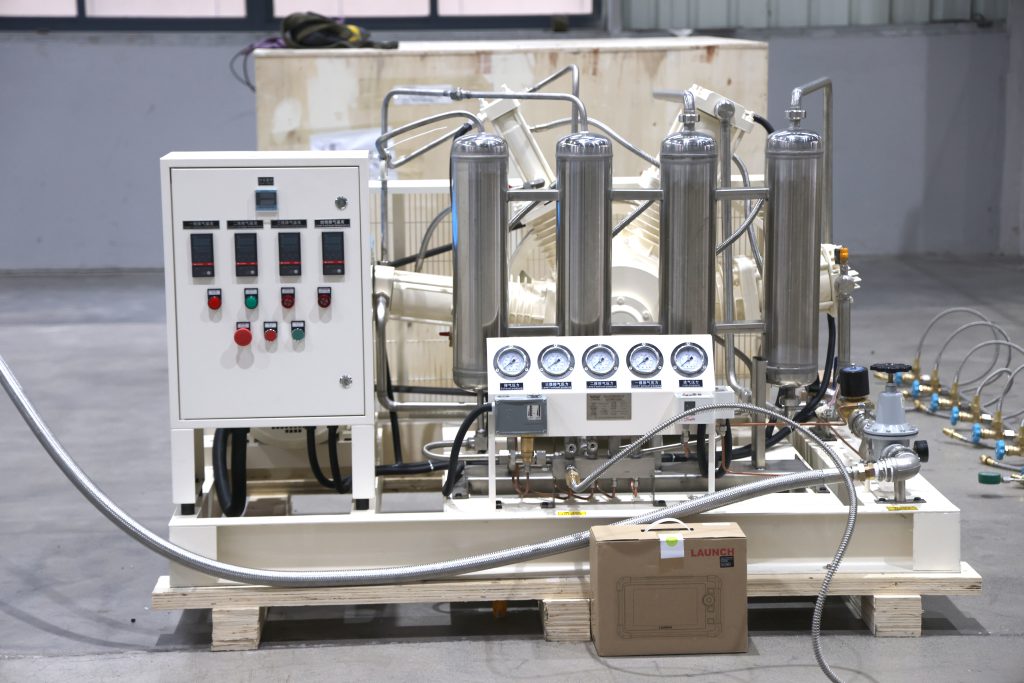

On-site oxygen generation technology (PSA/VPSA) fundamentally addresses the cost pain point of bottled oxygen by changing the way oxygen is obtained:

Significantly reduce the unit oxygen cost

Zero raw material cost: Oxygen is directly separated from the air, which is a free and abundant raw material.

The main operating cost is electricity: the energy consumption of equipment operation is the main cost, supplemented by predictable annual maintenance expenses.

Empirical data: According to actual cases (such as the application in a certain traditional Chinese medicine hospital), after switching to on-site oxygen production, the comprehensive cost of oxygen generally decreased by more than 51%. If the annual expenditure on bottled oxygen is 150,000 US dollars, the annual operating cost of on-site oxygen production can be reduced to below 50,000 US dollars.

Cost transparency and controllability: The unit oxygen cost is mainly calculated based on electricity consumption, which is clear and stable.

Eliminate associated fees

No gas cylinder rental fee or deposit is required.

Completely eliminate the logistics and transportation costs that rely on external suppliers.

Enhance operational efficiency

Eliminate the human and time consumption in ordering, receiving and managing gas cylinders.

Provide a continuous and stable oxygen flow to prevent production or treatment interruptions caused by bottle changes.

Reduce leakage and residual waste during the transportation, storage and use of gases.

Investment return Analysis: From Cost Center to Benefit Source

The purchase of on-site oxygen generation equipment is an investment with clear financial benefits:

Fast return on investment (ROI) : In typical application scenarios, on-site oxygen generation systems usually recover their equipment investment within 6 to 12 months solely by relying on the saved operating costs (compared to the original bottled oxygen cost). Calculation example: The annual cost of bottled oxygen is 60,000 US dollars, and the annual operating cost of on-site oxygen production is 30,000 US dollars, saving 30,000 US dollars annually. The equipment investment is 30,000 US dollars and it takes about 13 months to recoup the investment.

Long-term economic benefits: After the equipment investment is recovered, throughout its service life (typically 10 to 15 years), users will continue to enjoy a unit cost far lower than that of bottled oxygen. The saved funds can be used for the development of other businesses or to increase profits.

Unleash hidden value: Reduce management burden, avoid downtime losses, and lower waste. The comprehensive benefits brought about exceed the direct savings in oxygen costs

Pain Point Two: Safety Hazards of bottled oxygen – Risks that cannot be ignored

Oxygen, as an oxidizer, its storage and usage methods are directly related to the safety of personnel and facilities. The inherent characteristics of bottled oxygen bring multiple risks that cannot be ignored, while on-site oxygen generation technology has achieved an essential safety improvement by fundamentally changing the oxygen supply mode.

The inherent safety risks of bottled oxygen

High-pressure physical risk (>150-200 bar) :

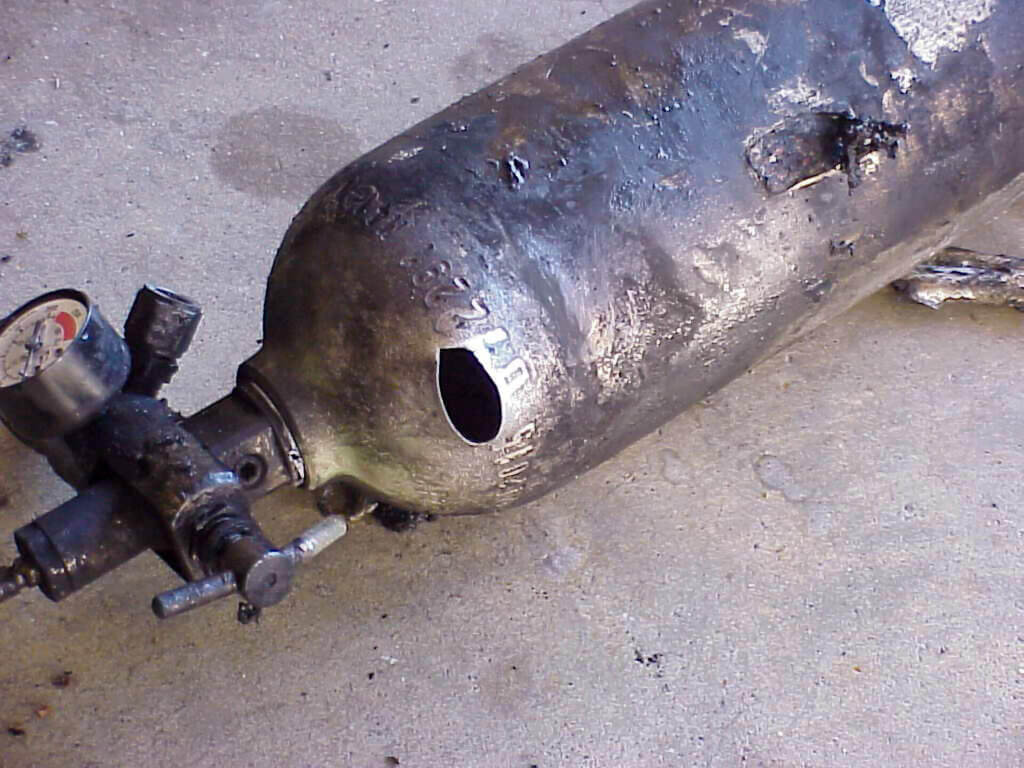

Explosion and ejection hazards: Oxygen cylinders are high-pressure vessels. Physical explosions may occur during handling drops, external impacts, exposure to high temperatures (such as outdoor storage in summer), or valve damage. High-speed flying debris is lethal (” rocket effect “).

The storage environment is strict: a dedicated explosion-proof storage area is required, meeting regulations such as fire separation distance, anti-tipping fixation, ventilation and heat dissipation (such as NFPA/OSHA standards), which occupies space and increases management complexity.

Explosion risk of high-concentration oxygen leakage:

Environmental rich oxidation: Once high-pressure oxygen leaks, it will rapidly increase the oxygen concentration in the local area (greater than 23.5% will significantly increase the risk of fire).

The flammability of materials has increased dramatically: In an oxygen-rich environment, the ignition energy of common materials such as oils, fabrics, plastics, and metal powders has dropped sharply. They can burn fiercely or even explode upon encountering static sparks or tiny heat sources.

The oil ban requirements are strict: All components (valves, pipes, tools) that come into contact with oxygen must be strictly degreased, and operators need professional training; otherwise, residual oil is very likely to cause accidents.

Operation and maintenance risks

Connection/disassembly risk: Improper operation during the installation of pressure reducing valves or the switching of gas cylinders (such as failure to release pressure, misaligned threads, or poor sealing) can lead to high-pressure oxygen ejection or high-speed component detachment, causing injury.

Valve and pipeline aging: Long-term used bottle valves and hoses may experience sealing failure, leading to chronic leakage or sudden rupture.

On-site oxygen generation: Building an intrinsically safe oxygen supply system

On-site oxygen production (PSA/VPSA technology) systematically resolves the safety hazards of bottled oxygen by eliminating high-pressure storage and altering the oxygen supply mechanism.

Eliminate the risk of high-voltage storage

Low-pressure/normal-pressure operation: The oxygen production pressure of PSA oxygen generators is typically 4-8 bar (much lower than the 150-200 bar of gas cylinders), and core components such as molecular sieve adsorption towers are designed as low-pressure vessels. Although the VPSA system operates under vacuum, its working pressure is still significantly lower than that of high-pressure gas cylinders.

There is no large static hyperbaric oxygen source: The equipment itself does not store a large amount of finished oxygen, fundamentally eliminating the inherent explosion and ejection risks of high-pressure vessels.

Immediate production and use, minimizing leakage risk

On-demand production: Oxygen is generated in real time and directly delivered to the usage point (pipeline gas supply). There is no high-pressure oxygen storage tank on site (or only a very small buffer tank is configured), which significantly reduces the total amount of gas that can leak.

Controllable leakage volume: Even if a micro-leak occurs in the pipeline, the leakage rate of the low-pressure system is much lower than that of the high-pressure bottled system, and it is easy to be detected in real time through flow monitoring.

Integrated security protection design

Multiple safety interlocks

Oxygen purity monitoring: Real-time monitoring of oxygen concentration (automatic alarm/switch/shutdown if <90%) to prevent the output of substandard gas.

Pressure protection: Automatic cut-off or adjustment in case of overpressure or underpressure.

Power-off protection: UPS backup power supply or safety shutdown program to ensure controllable interruption.

Self-diagnosis of faults: Automatically identify abnormal operation and issue an alarm.

Intrinsically safe components: Electrical components comply with explosion-proof/increased safety standards (Ex d/e), and key valves are made of special materials for oxygen.

Simplify operations and reduce human risks

Gas cylinder-free operation: No need for frequent handling and loading/unloading of high-pressure gas cylinders, eliminating the risks of handling injuries and connection errors.

Automated operation: The system starts, stops and adjusts automatically, reducing the need for manual intervention. Operators only need to conduct regular inspections.

Reduce oil ban requirements: The front-end air treatment has already filtered oil and gas, and the low-pressure oxygen pipeline at the back end is relatively less sensitive to grease (still requires standardized maintenance).

Pain Point Three: Supply Disruption – It is difficult to ensure a truly continuous supply of bottled oxygen

The fatal weakness of the logistics chain

Extreme environmental dependence: Severe weather (heavy snow, typhoons), traffic control or insufficient supplier capacity can all lead to supply disruptions. For instance, delays in the transportation of oxygen cylinders during the transfer of ECMO patients may directly endanger their lives.

Blind spots in regional coverage: Factories or medical institutions in remote areas face higher risks. Logistics costs may account for more than 30% of the total oxygen cost, and emergency response lags behind.

The inevitability of bottle changing interruption

Even if the operation is proficient, the bottle-changing process can still cause an oxygen supply interruption for 3 to 5 minutes. In medical Settings, this may lead to a sudden drop in the blood oxygen saturation of critically ill patients. In semiconductor production, pressure fluctuations may cause an entire batch of wafers to be scrapped.

The paradox of high inventory and high risk

To prevent supply disruptions, users need to store at least 3 days’ worth of bottled oxygen, which takes up precious space (for instance, an additional 50 square meters is required for hospital warehouses), and the centralized storage of high-pressure gas cylinders itself poses a safety hazard (increasing the fire risk by 200%).

Structural deficiency in emergency response capabilities

During public emergencies (such as epidemics), the supply chain of bottled oxygen has repeatedly collapsed: At the peak of the 2020 Wuhan epidemic, many hospitals were forced to limit the use of ventilators due to delayed oxygen delivery. The “hierarchical response” mechanism of suppliers often fails when there is a sudden surge in cross-regional demand.

On-site oxygen generation: Building an autonomous system for uninterrupted oxygen supply

True 24/7 continuous production

Immediate production and use mode: Directly separate oxygen from the air, eliminating the logistics link. As long as the power grid is normal, the equipment can operate continuously for several years without interruption (the average mean time between failures of industrial-grade PSA equipment is over 50,000 hours).

Precise and stable output control

The pressure fluctuation range is less than ±0.05MPa, and the oxygen purity fluctuation is less than ±1% (for example, the medical oxygen generator maintains 93%±3%), meeting the high-precision requirements of laser cutting, fermentation processes, etc., and avoiding pressure fluctuations during bottled oxygen bottle replacement.

Redundant design ensures “no worries about faults”

| Risk scenario | Redundant solutions for on-site oxygen production | Effect |

| Main equipment failure | Dual-machine parallel operation (one in use and one on standby) | 0-second switching, zero interruption |

| The mains power was cut off. | The UPS and diesel generator are linked | Continuous power supply > 24 hours (hospital standard) |

| Sudden surge in demand | Small liquid oxygen storage tank buffer (reserve for 8-hour usage) | Capacity elasticity has increased by 50% |

Flexible architecture for on-demand expansion

Modular design supports rapid capacity upgrades: Adding an adsorption tower can increase production by 30%, which is 90% more efficient than expanding the purchase contract for bottled oxygen (usually requiring renegotiation of prices and logistics).

Essential value: From passive emergency response to active control

The cost of bottled oxygen: Users have to pay hidden costs for supply chain uncertainties – including emergency drill investment (such as 40 oxygen supply suspension drills in hospitals each year), inventory backlog funds, and compensation for production suspension losses.

The transformative nature of on-site oxygen production:

Economic autonomy: Eliminate supplier premiums and reduce long-term costs by 51%.

Emergency autonomy: The built-in redundant system can withstand a 99.99% risk of power outage (industrial measurement data).

Management autonomy: Eliminating the need for gas cylinder scheduling, inventory management and other links, reducing human input by 70%.

Key conclusion: The supply continuity of bottled oxygen is based on a fragile “external dependency chain”, while on-site oxygen production converts oxygen into a “controllable production factor” through technological reconstruction. When oxygen supply stability becomes a core competitiveness (such as when the hospital’s JCI certification requires an oxygen supply interruption response of less than 10 minutes), on-site oxygen production is not an option but a must.

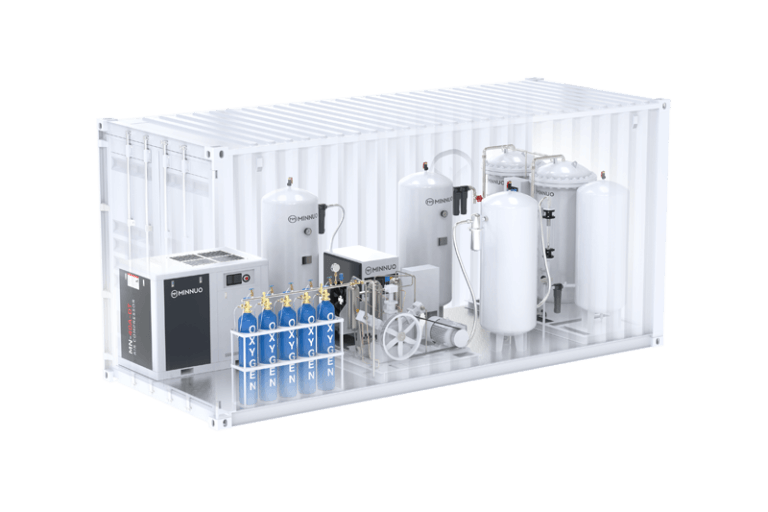

Beyond pain Points: Additional Advantages of on-site oxygen production

On-site oxygen generation technology not only addresses the pain points of bottled oxygen in terms of cost, safety and continuity, but also creates additional value in dimensions such as sustainability, space efficiency, gas quality and technological intelligence. As an innovator in PSA oxygen generation technology, MINNUO further amplifies these values through the following advantages, providing users with solutions that exceed expectations.

Sustainability Upgrade: From Carbon Footprint Reduction to ESG Competitiveness

Zero carbon emissions from transportation: The logistics chain of bottled oxygen (production – transportation – recycling) generates an average of 2.5 tons of CO₂ per thousand bottles of oxygen annually (based on the usage of medium-sized factories), while the MINNUO PSA equipment uses air as raw material and uses it immediately within the factory, completely eliminating carbon emissions from the transportation process.

Green Technology Label: MINNUO devices are compatible with green power inputs such as photovoltaic and wind power, supporting enterprises in achieving “Scope 2” emission reduction targets. For instance, after a certain chemical enterprise connected to the photovoltaic system in its factory area, the carbon intensity in the oxygen production process dropped by 68%, which became a highlight of its ESG report.

Resource recycling design: The service life of molecular sieves is ≥10 years (the industry average is 8 years), and 90% of the components can be recycled, which is in line with the concept of circular economy.

MINNUO’s distinctive features: The device is equipped with a built-in carbon footprint monitoring module that generates real-time carbon reduction reports and is directly connected to the enterprise’s ESG management system, facilitating green certifications (such as ISO 14064).

Spatial Reconstruction: Unleashing Land Value and Optimizing production flow lines

Comparison of space efficiency between bottled oxygen storage and MINNUO PSA equipment:

| Scene | Demand for bottled oxygen | MINNUO PSA solution | Unleash value |

| Medium-sized hospital (500 beds | Specialized gas cylinder warehouse ≥50 square meters + handling passage | 10㎡ computer room (including buffer tank | Expand the ICU or add new consultation rooms |

| Metal processing plant (monthly consumption: 300 bottles) | Explosion-proof warehouse 80 square meters + loading and unloading area | The skid-mounted equipment occupies an area of 15 square meters | A new production line has been added, increasing production capacity by 20% |

| Plateau Station | Reserve warehouse (subject to logistics restrictions) | Integrated container design, outdoor deployment | No infrastructure construction required, quick commissioning |

MINNUO technical support

Modular compact design: A single machine covers a production capacity of 1-300 nm ³/h, supports vertical stacking or horizontal parallel connection, and is suitable for narrow Spaces.

Zero gas cylinder management: No need for storage or circulation areas, completely avoiding the occupation of safety isolation zones for high-pressure vessels.

Precise Purity Control: From “Just Enough” to “Adapting to Process Revolution”

Dynamic adjustment capability

Medical scenario: Stably maintain a purity of 93%±2% (conforming to the GB 8982-2009 medical oxygen standard), avoiding concentration fluctuations affecting the therapeutic effect of respiratory therapy.

Industrial scenarios: Wide range adjustment from 90% to 99.5%. For instance, oxygen-enriched combustion in glass furnaces requires a purity improvement of over 95%, while aeration in wastewater treatment only needs 90%. MINNUO equipment can be optimized in real time according to the process.

Intelligent purity guarantee

Built-in laser oxygen analyzer, calibrated every 5 seconds, with automatic compensation for deviation threshold.

Compared with the purity decline of bottled oxygen after opening (residual nitrogen mixed in), the purity of on-site produced oxygen output remains stable throughout the process. MINNUO’s technological breakthrough: Patented multi-stage adsorption tower buffering technology. When dealing with grid fluctuations or intake air pollution, the purity fluctuation range is compressed to ±0.5% (industry average ±2%).

Technological Evolution: Generational Leap in Reliability and Intelligence

Modern PSA/VPSA technology has broken through its early bottlenecks, and MINNUO has reshaped industry standards through three innovations:

Reliable full life cycle

Oil-free compressor + ceramic valve core component, with a failure interval (MTBF) of over 50,000 hours, and maintenance frequency reduced to once a year.

The molecular sieve moisture-proof module (H-SHIELD™) enhances humidity tolerance by three times and extends the lifespan of the adsorbent.

Intelligent operation and maintenance system

MINNUO Cloud Platform: Remote monitoring of energy consumption, purity, and fault codes, predictive maintenance reminders (such as molecular sieve remaining life estimation).

Automatically generate oxygen usage reports, identify peak demand and idle periods, and assist in optimizing production scheduling.

Seamless expansion capability

Capacity elasticity: The flow rate of a single device can be adjusted within a range of 30% to 110%, and multiple machines can be connected in parallel to support stepwise capacity growth (without the need to replace the entire machine).

Mixed gas supply: Optional VPSA module (MINNUO Dual-Tech system), which combines the flexibility of PSA with the large-scale energy efficiency of VPSA.

Conclusion

The era limitations of bottled oxygen are undeniable – it makes enterprises continuously pay excessive costs (with hidden expenses accounting for more than 30%), treading on thin ice under high-pressure risks, and entrusting their lifeline to the fragile logistics chain. On-site oxygen generation technology has completely ended this predicament with three deterministic innovations: economic transformation: The investment that can quickly recoup the cost within 6 to 12 months has led to a long-term reduction of over 50% in oxygen usage costs. Intrinsic safety reconstruction: Eliminate the risks of high-voltage storage and transportation, and lower the safety level from “hazardous chemicals” to “industrial equipment”. Supply autonomy control: 7× 24-hour uninterrupted production, capable of withstanding black swan events such as extreme weather and supply chain disruptions.

This is not merely a technological substitution, but also a strategic upgrade of the oxygen supply paradigm – as verified by the world’s top enterprises: When oxygen transforms from a “consumable” to a “fundamental element for self-production”, operational resilience is enhanced exponentially. MINNUO is also dedicated to the research and exploration of on-site oxygen generation technology and provides each customer in need of oxygen equipment with MINNUO’s exclusive customized services.

sales2:+86 17506119168

sales2:+86 17506119168