In the precise and complex field of semiconductor manufacturing, temperature control is a core element that affects product quality and performance. The semiconductor manufacturing process involves a series of extremely delicate steps such as photolithography, etching, and ion implantation. Any slight temperature fluctuation may cause changes in material properties and deviations in equipment operation, ultimately leading to a decline in chip performance and a reduction in yield. For instance, during the chip manufacturing process, a mere 1°C temperature change can cause deviations of several nanometers in the critical dimensions of the chip. This has a significant impact on the semiconductor industry, which pursues ultimate refinement.

Liquid nitrogen, as an ultra-low-temperature cooling medium with a temperature as low as -196°C, plays an irreplaceable role in semiconductor manufacturing due to its unique advantages. Compared with traditional cooling methods, liquid nitrogen can achieve more rapid and precise temperature reduction, efficiently absorbing and removing a large amount of heat generated during equipment operation, thereby maintaining a stable low-temperature state of the process environment.

As the semiconductor industry continues to move towards smaller chip sizes and higher integration, the requirements for the precision and stability of manufacturing processes are becoming increasingly strict, and the application of liquid nitrogen is also showing a rapid growth trend. According to data from market research institutions, the compound annual growth rate of global semiconductor manufacturing demand for liquid nitrogen has reached 8% over the past five years, and it is expected that this trend will continue in the future.

The core application of liquid nitrogen in semiconductor manufacturing

Photolithography cooling

The photolithography process in semiconductor manufacturing is like a “master encoder”, shouldering the responsibility of precisely transferring circuit patterns onto silicon wafers. Its precision directly determines the performance and functionality of the chips. During the photolithography process, the light source and optical system inside the photolithography machine generate a large amount of heat due to high-intensity operation. If this heat cannot be dissipated in a timely and effective manner, it will cause thermal expansion of optical components, resulting in changes in the light propagation path and subsequently causing deviations in the circuit patterns projected onto the silicon wafer, seriously affecting the precision of the chip.

Liquid nitrogen plays a crucial cooling role here. Through a carefully designed cooling system, liquid nitrogen can continuously and stably absorb the heat generated by the light source and optical system, ensuring that its temperature fluctuations are strictly controlled within an extremely small range. Take a well-known semiconductor manufacturing enterprise as an example. After introducing the liquid nitrogen cooling system, the temperature stability of the key components inside the photolithography machine has increased by five times, and the key dimensional deviation of the chip has decreased by 30%, greatly improving the photolithography accuracy.

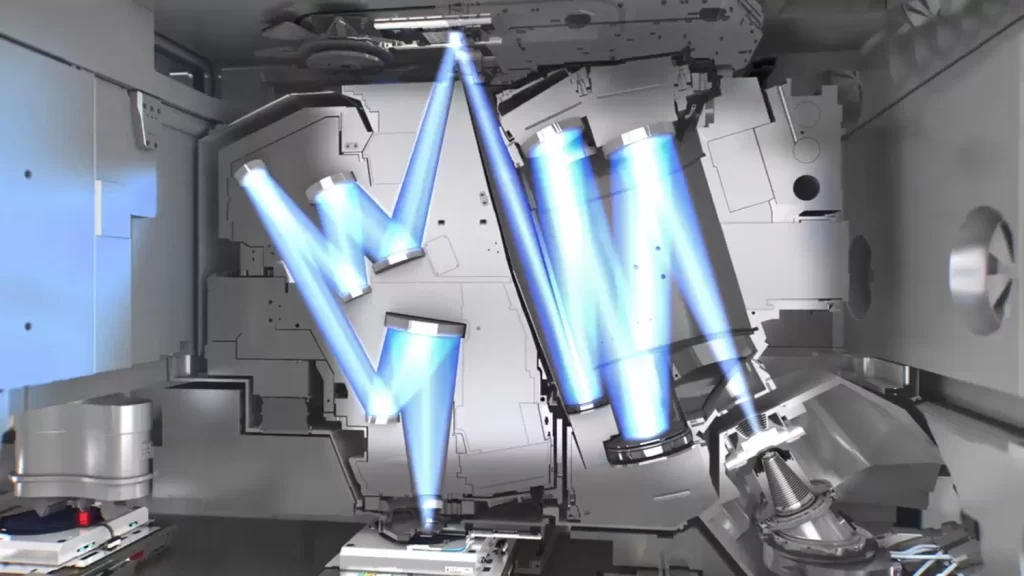

In the cutting-edge field of extreme ultraviolet lithography (EUV), the role of liquid nitrogen is even more crucial. EUV lithography technology uses extremely short-wavelength extreme ultraviolet light (13.5nm) for pattern exposure, and the precision requirements for the optical system are almost exacting. Due to the extremely high energy of EUV light, optical components will produce significant thermal effects after absorbing part of the light. Even minor thermal deformation can lead to serious imaging quality issues. To solve this difficult problem, the industry has adopted liquid nitrogen low-temperature mirror cooling technology. Inside the reflectors of the EUV lithography machine, a micro-channel network is ingeniously designed, with liquid nitrogen circulating within it. This enables precise temperature control at the sub-0.1K level, effectively suppressing the deformation of the mirror surface caused by heat and ensuring the ultra-high resolution and imaging quality of EUV lithography.

Temperature Management for Ion Implantation

Ion implantation is a key process that precisely introduces specific impurity atoms into silicon wafers to alter the electrical properties of semiconductors. During the injection process, the high-speed ion beam bombards the target material, generating a large amount of heat. If the target material is not cooled in time, the excessively high temperature will not only cause lattice damage, affecting the integrity of the crystal structure of the semiconductor material, but also lead to a decline in the stability of the ion beam, causing deviations in the distribution of doped atoms, and ultimately reducing the yield of the chip.

The liquid nitrogen cooling system plays the role of a “temperature guardian” during the ion implantation process. By efficiently cooling the target material, the temperature during the injection process can be effectively reduced, minimizing lattice damage. Meanwhile, a stable low-temperature environment helps maintain the stability of the ion beam, making ion implantation more uniform and precise. Relevant studies show that after cooling with liquid nitrogen, the lattice damage during the ion implantation process is reduced by 40%, the doping deviation is decreased by 25%, and the chip yield rate is increased by 10% to 15%.

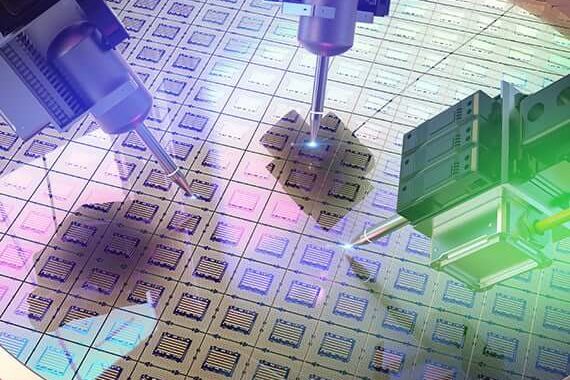

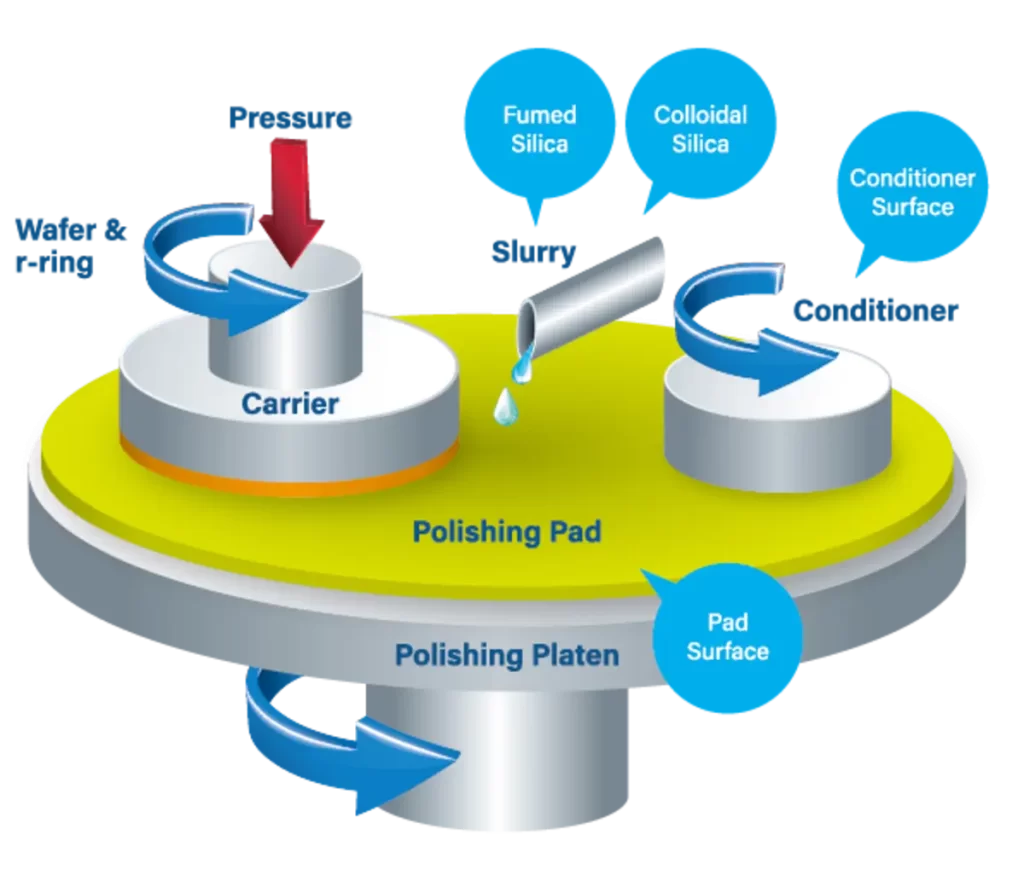

CMP (Chemical Mechanical Polishing) process slurry temperature control

The CMP process aims to flatten the surface of silicon wafers through a combination of chemical etching and mechanical grinding, in order to meet the strict requirements for surface flatness in subsequent processes. During the CMP process, the temperature of the polishing liquid (slurry) has a significant impact on its viscosity and fluidity. An increase in temperature will lead to a decrease in the viscosity and an increase in the fluidity of the polishing liquid, making it difficult to precisely control the polishing rate. This can easily cause defects such as over-polishing or uneven polishing on the surface of silicon wafers, seriously affecting the quality of chip manufacturing.

Liquid nitrogen indirect cooling technology provides an ideal solution for slurry temperature control in the CMP process. By transferring the coldness of liquid nitrogen to the heat exchange medium and then having the heat exchange medium indirectly cool the polishing liquid, the temperature of the polishing liquid can be precisely and stably controlled. After a certain semiconductor manufacturing factory adopted the liquid nitrogen indirect cooling system, the temperature fluctuation of the polishing liquid was controlled within ±0.5°C, effectively maintaining the viscosity and fluidity stability of the polishing liquid. The surface defect rate of silicon wafers was reduced by 60%, significantly improving the quality and consistency of the CMP process.

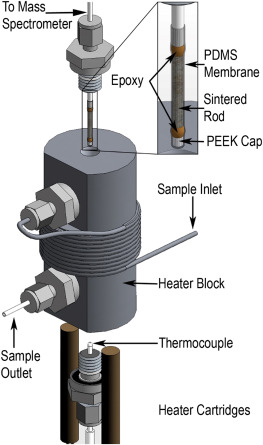

The vacuum chamber condenses with the gas

In the high vacuum system of semiconductor manufacturing, residual water vapor and impurity gases are potential threats to process stability and product quality. These impurities may deposit on the surface of the silicon wafer, forming a contamination layer that interferes with subsequent process steps, leading to a decline in chip performance and reliability. Liquid nitrogen plays a crucial role in gas condensation in this stage.

Taking advantage of the ultra-low temperature characteristics of liquid nitrogen, a liquid nitrogen cold trap is set up in the vacuum system. When the gas containing water vapor and impurities flows through the cold trap, it will be rapidly condensed into solid or liquid state, thus being efficiently removed from the vacuum system. For instance, in the vacuum coating equipment of a certain chip manufacturing workshop, after the introduction of a liquid nitrogen cold trap, the water vapor content inside the vacuum chamber was reduced by 90%, and metal contamination and particle defects were decreased by 70%, creating a clean and stable vacuum environment for high-quality coating processes. In addition, liquid nitrogen cold trap technology can effectively reduce the maintenance frequency and cost of vacuum systems and improve the operational efficiency of equipment.

The Impact of liquid nitrogen on the quality and capacity of semiconductor manufacturing

Enhance the consistency of chip electrical performance

In semiconductor chips, thermal noise is one of the important factors affecting the consistency of their electrical performance. Thermal noise mainly stems from the thermal motion of electrons. The higher the temperature, the more significant the thermal noise becomes. Excessive thermal noise can lead to an increase in interference during the signal transmission process of the chip, reduce the accuracy and stability of the signal, and thereby affect the overall performance of the chip.

The low-temperature environment provided by liquid nitrogen can effectively suppress the thermal motion of electrons and significantly reduce the level of thermal noise. According to the Johnson-Nyquist noise theory, the power density of thermal noise is proportional to the absolute temperature. Reducing the operating temperature from room temperature (about 300K) to around liquid nitrogen temperature (77K) theoretically can lower the thermal noise power density to approximately one quarter of that at room temperature. This makes the chip perform more stably and consistently in signal transmission, data processing and other aspects, effectively enhancing the electrical performance and reliability of the chip. For instance, in high-performance processor chips, after adopting liquid nitrogen cooling technology, the computing speed of the chips has increased by 15%, and the data transmission error rate has decreased by 80%, significantly enhancing the market competitiveness of the chips.

Enhance the operational stability of the equipment

Semiconductor manufacturing equipment is usually structurally complex and highly precise, with extremely strict requirements for the temperature stability of the operating environment. Temperature fluctuations may cause thermal expansion and contraction of equipment components, leading to a decline in the fit accuracy between mechanical parts and affecting the normal operation of the equipment. For instance, when the temperature fluctuates greatly, the precision mechanical transmission components of a photolithography machine may experience positioning deviations, which can affect the nesting accuracy of the photolithography patterns.

The liquid nitrogen cooling system can provide a constant and low-temperature operating environment for the equipment, effectively reducing the thermal stress and deformation of components caused by temperature changes. Production data from a certain semiconductor manufacturing enterprise shows that after using liquid nitrogen cooling equipment, the failure rate of key manufacturing equipment has decreased by 40%, and the mean time between failures (MTBF) of the equipment has been extended by 50%. This has significantly improved the stability and reliability of equipment operation, providing a strong guarantee for large-scale and high-efficiency chip production.

Economic value of shortening the preheating and stabilization time of equipment

In the semiconductor manufacturing process, the preheating and stabilization time of equipment is an important factor affecting production efficiency and cost. After traditional equipment is started up, it often takes a relatively long time to preheat to reach a stable working temperature. During this period, the equipment cannot produce normally, resulting in waste of time and energy.

The liquid nitrogen cooling system can significantly shorten the preheating and stabilization time of the equipment. Because liquid nitrogen can quickly reduce the temperature of the equipment to the working temperature range, the equipment can enter a stable operating state more quickly. Take a certain ion implantation equipment as an example. After adopting a liquid nitrogen cooling system, the preheating and stabilization time of the equipment was shortened from the original 2 hours to 30 minutes, and the production of chips could be increased by 1-2 batches per day. Based on the production scale and product profit of this enterprise, the economic benefits brought by shortening the preheating and stabilization time of equipment each year can reach several million yuan. This fully demonstrates the huge economic value of liquid nitrogen cooling in enhancing production efficiency and reducing production costs.

Frequently Asked Questions (FAQ) of Customers and their solutions

Will liquid nitrogen affect the structure of chip materials?

Under the correct temperature control strategy, liquid nitrogen will not have a negative impact on the structure of the chip material. The key lies in avoiding thermal shock stress caused by sudden temperature changes. Firstly, when introducing liquid nitrogen for cooling, a gradual cooling method should be adopted to slowly lower the temperature of the chip or related materials, allowing the internal stress of the materials to be gradually released. Meanwhile, the flow rate and temperature distribution of the cooling system should be reasonably designed to ensure uniform cooling of all parts of the chip and prevent rapid changes in local temperature. For instance, in some advanced semiconductor manufacturing processes, a multi-stage liquid nitrogen cooling scheme is adopted. Firstly, the chip temperature is reduced to a certain range through the pre-cooling stage, and then it enters the deep cooling stage, effectively avoiding the generation of thermal shock stress.

Will the liquid nitrogen cooling system cause condensation problems?

During the operation of the liquid nitrogen cooling system, due to its low-temperature characteristics, if it does not come into contact with the external environment properly, it may indeed cause condensation water problems. However, this problem can be effectively solved by adopting an anti-condensation solution that combines dry gas isolation with a high vacuum system. On the one hand, a dry gas purging device is set up outside the cooling system to continuously blow nitrogen or other inert gases that have undergone drying treatment onto the system surface, forming a dry gas barrier between the system and the external environment to prevent external water vapor from coming into contact with the low-temperature surface. On the other hand, for some process links with extremely high environmental requirements, placing the cooling system in a high vacuum environment fundamentally eliminates the possibility of water vapor existence. For instance, in the liquid nitrogen cooling system of EUV lithography equipment, by combining high vacuum sealing technology with dry nitrogen purging, the problem of condensation water has been successfully avoided, ensuring the stable operation of the equipment.

How to safely manage liquid nitrogen in semiconductor workshops?

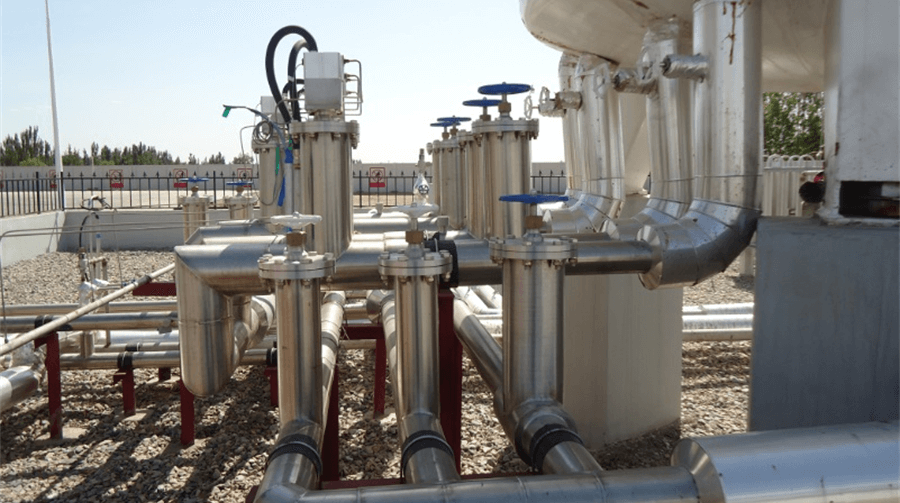

The design of the liquid nitrogen storage and distribution pipeline network in semiconductor factories is of vital importance. Liquid nitrogen storage should be carried out in specially designed cryogenic storage tanks. These tanks have excellent thermal insulation performance, which can effectively reduce the evaporation loss of liquid nitrogen. They are also equipped with complete pressure monitoring and safety pressure relief devices to ensure that gas can be discharged in time when the pressure abnormally rises, preventing the tanks from overpressure and bursting. In terms of the distribution network, low-temperature and corrosion-resistant pipe materials should be selected, and strict insulation treatment should be carried out to reduce the cold loss and vaporization of liquid nitrogen during transportation. At the same time, a leakage monitoring system should be set up to monitor in real time whether there is any liquid nitrogen leakage in the pipeline network. Once a leakage occurs, emergency response measures can be promptly initiated, such as closing relevant valves and conducting ventilation and air exchange. In addition, providing professional safety training to workshop operators to familiarize them with the characteristics of liquid nitrogen, operating procedures, and emergency response methods is also an important link in ensuring the safety management of liquid nitrogen.

Will the supply of liquid nitrogen become a production bottleneck?

To prevent liquid nitrogen supply from becoming a production bottleneck, enterprises can adopt various coping strategies. On the one hand, sign redundant supply contracts with gas suppliers to ensure that liquid nitrogen supplies can be obtained promptly from backup suppliers when the main supplier encounters supply issues, thus guaranteeing the continuity of production. On the other hand, it is considered to adopt a local integrated nitrogen production and refrigeration solution, building small-scale nitrogen production and refrigeration facilities within or around the enterprise to achieve independent production of liquid nitrogen. This solution not only enhances the stability of liquid nitrogen supply but also reduces the costs and risks associated with long-distance transportation. For instance, after a certain semiconductor manufacturing enterprise adopted a local integrated nitrogen production and refrigeration solution, the stability of liquid nitrogen supply was enhanced by 90%, and transportation costs were reduced by 50%, effectively resolving the production bottleneck issues that might arise from liquid nitrogen supply.

Future Trends of Liquid nitrogen systems

Energy-saving Optimization of Liquid Nitrogen System

In the semiconductor manufacturing process, the energy consumed by the liquid nitrogen system cannot be ignored. By recovering the cooling capacity of liquid nitrogen to cool other auxiliary equipment, such as air conditioning systems and exhaust gas treatment systems, significant energy-saving effects can be achieved. For instance, in an air conditioning system, a liquid nitrogen cooling capacity recovery device is introduced to transfer the cooling capacity released during the vaporization of liquid nitrogen to the air conditioning circulating water, which is used to lower the indoor temperature.

After actual tests, it has been found that adopting this method can reduce the energy consumption of the air conditioning system by 20% to 30%. In the waste gas treatment system, the use of liquid nitrogen cooling capacity to pre-cool high-temperature waste gas not only helps to improve the efficiency of waste gas treatment but also reduces the energy consumption of subsequent treatment equipment. Through this method of cold energy recovery and reuse, enterprises can significantly reduce overall energy consumption without affecting production and achieve the goal of energy conservation and emission reduction.

Intelligent Liquid Nitrogen Management

By integrating IoT (Internet of Things) sensors to monitor parameters such as liquid nitrogen flow, temperature, and pressure in real time and coordinating with equipment for automatic adjustment, intelligent liquid nitrogen management can be achieved. Install various sensors in liquid nitrogen storage tanks and distribution networks to transmit the collected data in real time to the central control system. By analyzing these data, the control system can promptly grasp the operating status of the liquid nitrogen system and automatically adjust the relevant equipment according to the preset parameter range, such as regulating the rotational speed of the liquid nitrogen delivery pump to control the flow rate and adjusting the refrigeration power of the cooling system to maintain temperature stability, etc. This intelligent management approach not only enhances the operational efficiency and stability of the liquid nitrogen system, but also promptly detects and warns of potential fault hazards, reduces the cost of manual inspection, and improves the production management level of enterprises.

Liquid Nitrogen Cooling and Green Manufacturing

Liquid nitrogen has the characteristic of being free from chemical pollution, which gives it a unique advantage in helping semiconductor factories achieve their ESG (environmental, social and corporate governance) goals. Compared with traditional cooling methods, liquid nitrogen cooling does not produce any harmful chemical substances during the process and is environmentally friendly. Against the backdrop of the global semiconductor industry’s increasing emphasis on sustainable development, the adoption of liquid nitrogen cooling technology helps enterprises enhance their environmental image, meet regulatory requirements, and strengthen their market competitiveness. For instance, a certain semiconductor manufacturing enterprise has taken liquid nitrogen cooling technology as one of the key measures in its green manufacturing strategy. By promoting the application of liquid nitrogen cooling in all production links, it has successfully reduced the overall carbon emissions of the enterprise and gained high recognition within the industry.

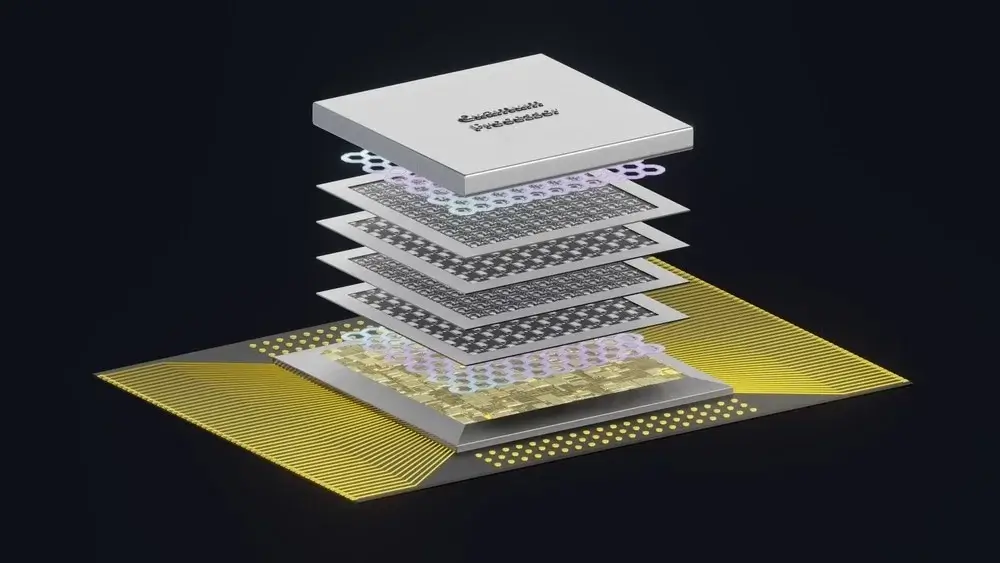

Emerging Applications of Liquid Nitrogen in Advanced Packaging

In the field of advanced packaging, such as wafer bonding and three-dimensional packaging thermal management, the ultra-low temperature characteristics of liquid nitrogen are demonstrating huge application potential. During the wafer bonding process, the use of liquid nitrogen for cooling can effectively lower the bonding temperature, reduce the impact of thermal stress on the chip, and enhance the bonding quality and reliability. In three-dimensional packaging, due to the increase in the number of chip stacks, the heat dissipation issue has become increasingly prominent. Liquid nitrogen cooling can be used as an efficient thermal management method to quickly remove the heat generated by the chips, ensuring that the packaged chips can still maintain good performance under high-load operation. For instance, after a certain advanced packaging enterprise introduced a liquid nitrogen cooling system into its three-dimensional packaging process, the operating temperature of the chip was reduced by 15°C, and the performance of the packaged chip was enhanced by 10% to 15%, providing strong support for the development of advanced packaging technology.

Conclusion

Liquid nitrogen plays a core role in key process links such as photolithography, ion implantation, and CMP in semiconductor manufacturing due to its outstanding cooling performance. It has comprehensively enhanced the quality and production capacity of semiconductor manufacturing, from improving the consistency of chip electrical performance, enhancing the stability of equipment operation to shortening the preheating and stabilization time of equipment. At the same time, there is also a series of mature and effective solutions for the common problems that customers are concerned about during the use of liquid nitrogen. In addition, the unique advantages of liquid nitrogen systems in energy conservation optimization, intelligent management, and green manufacturing, as well as their emerging applications in advanced packaging, have all injected new vitality into the sustainable development of the semiconductor industry.

For semiconductor manufacturing enterprises, evaluating the ROI (Return on Investment) of liquid nitrogen system upgrades is of great significance. Although the introduction of an advanced liquid nitrogen cooling system may require a certain amount of initial investment, in the long run, with reasonable planning and efficient operation, the comprehensive benefits it brings can cover and exceed the initial investment. For instance, by enhancing the yield rate of chips, enterprises can reduce losses from defective products and increase sales revenue. By shortening the preheating and stabilization time of the equipment, the utilization rate of the equipment can be improved, and the production efficiency can be further enhanced.

As an enterprise with profound technical accumulation in the fields of liquid nitrogen supply systems, storage and transportation equipment, and customized cooling solutions, MINNUO is capable of providing comprehensive and one-stop solutions for semiconductor manufacturing enterprises. Its advanced liquid nitrogen supply system ensures a stable and efficient supply of liquid nitrogen. High-quality storage and transportation equipment minimizes the loss of liquid nitrogen during storage and transportation. Customized cooling solutions can be tailored to the specific process requirements and production environment of enterprises to create the most suitable liquid nitrogen cooling solution. Help enterprises achieve higher quality, efficiency and benefit goals in the field of semiconductor manufacturing.

sales2:+86 17506119168

sales2:+86 17506119168