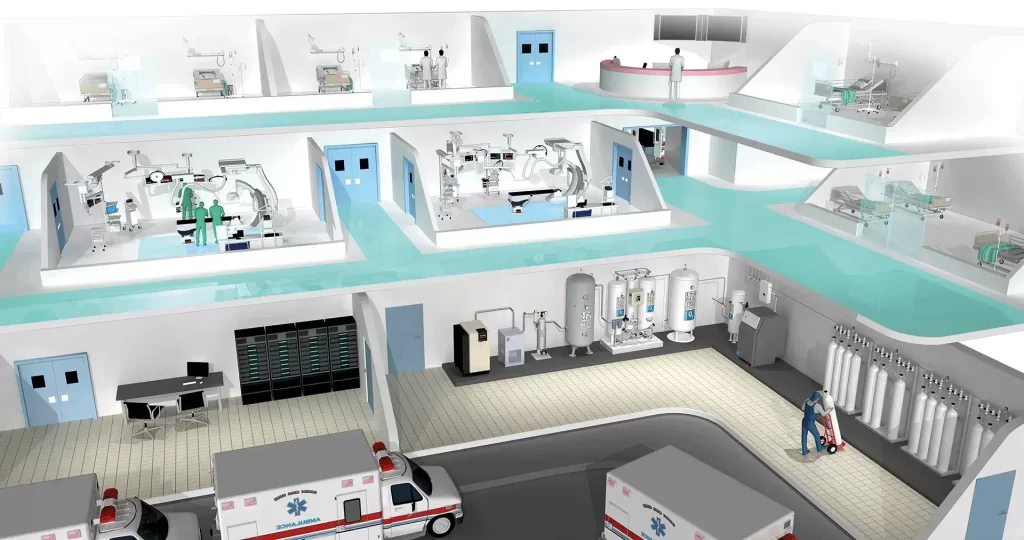

In the daily operation of medical institutions, oxygen is like a lifeline that sustains the safety of countless patients. From the tense craniotomy in the operating room to the continuous operation of ventilators in the hospitals ICU ward, from the critical moments of rescuing patients with myocardial infarction in the emergency room to the daily oxygen supply needs of elderly patients in general wards, the stability and reliability of oxygen supply are directly related to medical quality and patient safety.

For a long time, many hospitals have relied on purchasing bottled oxygen or liquid oxygen from outside to meet their oxygen supply needs, but this model has unavoidable drawbacks: The potential risks of collision and leakage during the transportation of bottled oxygen, the high-pressure safety hazards of liquid oxygen storage tanks, the supply delays caused by logistics disruptions in extreme weather, and the increasingly obvious price fluctuations in recent years have all made hospital administrators worried about the sustainability of the oxygen supply system.

It is precisely against this backdrop that an increasing number of hospitals have begun to turn to building their own oxygen generation systems. Among them, PSA (Pressure Swing Adsorption) oxygen generators have become the mainstream choice due to their high efficiency, stability and economy. As a hospital procurement decision-maker, when choosing oxygen generation equipment, a comprehensive consideration from a professional perspective is required. This article will, from the perspective of a buyer, deeply analyze the core issues that must be considered when purchasing oxygen generators for hospitals, providing practical procurement references for medical institutions.

Common pain points for hospitals when purchasing oxygen generators

The special demands of medical institutions for oxygen generation equipment present them with procurement challenges that are different from those of ordinary industrial equipment. The most worrying issue for hospital administrators is the stability of oxygen supply – even a few minutes of oxygen cut-off during a critical stage of surgery or when ICU patients rely on ventilators to stay alive can lead to irreversible medical accidents. A certain tertiary hospital once had to urgently activate the backup oxygen cylinders due to a sudden malfunction of the liquid oxygen supplier, which led to an interruption in oxygen supply.

Whether the purity of oxygen meets the standards is another key point. Medical oxygen has strict purity standards. Once the purity is insufficient, it will not only affect the treatment effect but also may cause direct harm to patients. Especially during anesthesia, fluctuations in oxygen purity may lead to an out-of-control depth of anesthesia. However, if critically ill patients supported by ventilators inhale low-purity oxygen, it will directly cause hypoxia complications.

Potential safety hazards are like sharp swords hanging over our heads. The high-pressure state during the operation of oxygen production equipment, the strong flammability of oxygen, and the oxygen pipeline network spread throughout the hospital, any oversight in any link may cause serious safety accidents such as fires and explosions. The fire caused by a leak in the oxygen pipeline of a hospital in a certain area in 2023 remains a warning case in the industry to this day.

When a single oxygen generator suddenly malfunctions, whether there is a complete redundant backup mechanism determines the risk resistance capacity of the oxygen supply system. Many small and medium-sized hospitals have been unable to continue treatment when equipment malfunctions due to the lack of backup plans.

In addition, the balance between cost and return on investment is also an important consideration in hospital decision-making. Although the initial investment in building an oxygen production system is relatively high, its economic efficiency in long-term operation is often superior to that of the external procurement model. How to accurately calculate the investment payback period has become a focus of attention.

Oxygen purity: A rigid requirement of medical-grade standards

The purity of medical oxygen is not necessarily the higher the better, but must strictly comply with international and domestic standards. The currently prevailing standards include the ISO 7396 international standard, the US FDA medical oxygen specification, and the European EN 14223 standard. All these standards clearly stipulate that the oxygen concentration of medical oxygen must reach 93%±3%. The setting of this range not only ensures the therapeutic effect but also avoids the risk of oxygen poisoning that may be caused by high concentrations of oxygen.

The PSA oxygen generator achieves oxygen separation through the selective adsorption of nitrogen and oxygen molecules in the air by molecular sieves. Its purity control ability is the core indicator for evaluating the performance of the equipment. High-quality oxygen generators use imported molecular sieve materials and ensure that the purity of the produced oxygen remains stable within the standard range through precise pressure control and airflow regulation technology. When the equipment is in operation, if the purity drops below the warning value of 90%, the system should be able to automatically alarm and initiate remedial measures.

The harm of insufficient oxygen purity to patients cannot be ignored. During general anesthesia, fluctuations in oxygen purity can lead to unstable concentrations of anesthetic gases, which may cause respiratory depression or delayed recovery in patients. For ICU patients on ventilators, long-term inhalation of low-purity oxygen can lead to tissue hypoxia, aggravate organ function damage, and even increase mortality.

To ensure stable purity, the oxygen production system must be equipped with real-time online monitoring devices, which continuously track the oxygen concentration through high-precision oxygen sensors and transmit the data to the central monitoring platform. When the purity is abnormal, the system should immediately issue an audible and visual alarm, and at the same time automatically start the purity adjustment program or switch to the backup oxygen supply source, adding double insurance for medical safety.

Safety: The core consideration of the hospital environment

Hospitals are special places with a high concentration of people, and the safety design of oxygen production equipment must meet strict standards. High-quality PSA oxygen generation equipment should be equipped with multiple safety protection mechanisms: the overpressure automatic pressure relief device can promptly release pressure when the system pressure abnormally rises; The temperature monitoring system can monitor the operating temperature of key components such as compressors in real time to prevent malfunctions caused by overheating. The automatic shutdown function in case of faults can quickly cut off the power supply when circuit abnormalities or core component failures are detected, preventing the danger from escalating.

The safety protection of the oxygen pipeline network is equally crucial. The material of the pipes must be seamless copper pipes or stainless steel pipes that meet medical standards. The connection points should be made by silver welding to ensure reliable sealing. The system should be equipped with multi-point leakage detection devices. When the oxygen concentration is detected to exceed the standard (the oxygen content in the air exceeds 23%), an alarm should be triggered immediately. In terms of pipeline layout, it is necessary to keep away from fire sources and high-temperature equipment. When passing through firewalls, fire dampers must be installed. At the same time, it is prohibited to lay pipelines in the same trench with cables, gas pipelines, etc.

Establishing a sound regular maintenance and safety inspection system is the key to ensuring the long-term safe operation of the system. Key parameters such as pressure, purity and temperature should be checked daily. Filters and valves need to be inspected weekly. Pipeline leakage detection should be conducted every month. Every year, professional institutions should be invited to conduct a comprehensive safety assessment. Maintenance records need to be filed and preserved as an important basis for inspections by the health department.

Compliance review is the last line of defense for security. The purchased oxygen generation equipment must have the medical device registration certificate issued by the National Medical Products Administration and pass the ISO 13485 medical device quality management system certification. After installation is completed, it is necessary to file with the local health and wellness department and pass the acceptance test by a third-party testing institution to ensure that all indicators meet the requirements of the “Technical Specifications for Medical Gas Engineering”.

Redundancy and backup design: Assurance for Dealing with unexpected situations

In the field of medical oxygen supply, “redundancy” is not superfluous but a necessary design to ensure life safety. When a single oxygen generator stops due to a malfunction, a well-developed redundant system can ensure that the oxygen supply is not interrupted. The most common solution is a dual-machine or multi-machine parallel design – the main machine and the standby machine adopt the same technical parameters. During normal operation, they can share the load. When the main machine malfunctions, the standby machine will automatically start within 30 seconds and seamlessly take over all oxygen supply tasks.

For larger hospitals, it is recommended to adopt a hybrid backup solution of “oxygen generator + liquid oxygen storage tank”. When the oxygen generation system is operating normally, the liquid oxygen storage tank is in a standby state and maintained at a low temperature for storage. When a large-scale failure occurs in the oxygen generator system, the automatic switching valve will immediately open the liquid oxygen supply and issue a high-level alarm at the same time. This dual backup mode is particularly important during the peak of the epidemic or in extreme weather conditions. During the 2022 epidemic, a certain infectious disease hospital relied on this hybrid system to ensure the continuous oxygen supply of hundreds of ICU beds.

The response speed of the automatic switching system directly determines the effectiveness of the redundant design. A high-quality system should adopt a PLC programmable controller to achieve millisecond-level response by real-time monitoring of the pressure in the main gas supply network. During the switching process, the pressure fluctuation in the pipeline network should be controlled within ±0.02MPa to avoid affecting precision medical equipment such as ventilators.

When dealing with peak cases or public health emergencies, the load-bearing capacity of the oxygen generation system is put to the test. When designing, at least 30% redundant oxygen production capacity should be reserved, and a quick expansion interface should be provided. If necessary, oxygen generation modules can be temporarily added. During the typhoon disaster, a hospital in a prefecture-level city successfully dealt with the peak oxygen demand caused by the sharp increase in the number of injured people by activating the backup oxygen generation module.

Oxygen supply guarantee: Achieve 24/7 uninterrupted operation

The oxygen supply demand of medical institutions is 24/7, which requires the oxygen generation system to have the ability to operate continuously. To deal with sudden power outages, the system must be equipped with both uninterruptible power supplies (UPS) and emergency generators for dual protection. The UPS should be capable of supporting the core control system to operate for at least 30 minutes, while the emergency generator needs to start within 15 seconds to ensure the continuous operation of key equipment such as oxygen generators and air compressors. The fuel reserve of the generator should meet the demand for 72-hour full-load operation, and a regular oil sample inspection and start-up test system should be established.

The intelligent centralized monitoring platform is the “nerve center” of the modern hospital oxygen supply system. The platform should be capable of displaying in real time key data such as the operating parameters of each oxygen generation unit, pipeline pressure, and oxygen consumption in each section, and predicting possible faults through trend analysis. When the system malfunctions, the platform can automatically send text messages and wechat alarm messages to the on-duty personnel, and at the same time highlight the fault location and handling suggestions on the monitoring screen. A provincial hospital successfully issued an early warning for a wear fault of an air compressor bearing through an intelligent monitoring system, thus avoiding potential downtime risks.

There are significant differences in pressure and flow requirements among different departments, which demands that the oxygen generation system have flexible adjustment capabilities. Operating rooms and icus typically require an oxygen supply pressure of 0.4 to 0.6MPa and a relatively high instantaneous flow rate, while the pressure in general wards can be controlled at 0.2 to 0.4MPa. The system should adopt a zonal pressure reduction design, ensuring stable pressure in each area through precision pressure reducing valves. At the same time, it should be equipped with flow monitoring devices to provide data support for the hospital’s oxygen management.

The oxygen supply strategies for large tertiary hospitals and small and medium-sized hospitals should be different. Tertiary hospitals usually require multiple oxygen generators to operate in parallel and are equipped with large-capacity liquid oxygen storage tanks as emergency backups. At the same time, they consider the oxygen supply network connection with regional medical centers to form a larger-scale guarantee system. Small and medium-sized hospitals can choose single or double oxygen generators based on the number of beds, and use bottled oxygen as a backup to control investment costs under the premise of meeting safety requirements.

Cost and return on investment analysis

From a long-term operational perspective, the economic efficiency of building an oxygen production system independently is significantly superior to that of the external oxygen procurement model. The cost of extracting liquid oxygen from outside includes the price of liquid oxygen itself, transportation expenses, and the rent for storage tanks. In recent years, affected by fluctuations in energy prices, the price of liquid oxygen has soared from $115 per ton to over $289, and the transportation cost has increased by an average of 5% to 8% annually. For a hospital with 500 beds, the annual cost of purchasing oxygen from outside can reach 110,000 to 170,000 US dollars.

Although the initial investment for a self-built oxygen generation system is relatively high (about 430,000 to 720,000 US dollars for a 500-bed hospital), the operating costs are significantly reduced. The main consumption of the system is electricity (about 0.3 to 0.5 kilowatt-hours per cubic meter of oxygen) and a small amount of molecular sieve consumables. The annual operating cost is only 30% to 50% of that of the external procurement mode. Depending on the scale, the payback period of investment is usually 3 to 7 years, while the service life of the equipment can reach 10 to 15 years, and a significant amount of costs can be saved throughout the entire life cycle.

Maintenance cost is an important factor affecting long-term economy. The annual maintenance cost of high-quality oxygen generators is approximately 3% to 5% of the original value of the equipment, mainly including filter replacement, molecular sieve activation, sensor calibration, etc. Choosing a manufacturer with a complete after-sales service system can effectively control maintenance costs. A certain hospital has stabilized its maintenance fees at 3.5% of the original value of the equipment by signing an annual maintenance contract with the manufacturer, and has also avoided indirect losses caused by downtime due to faults.

Actual cases can better illustrate the issue: A tertiary hospital in the central region built a PSA oxygen production system in 2020, replacing the original liquid oxygen supply mode. Operation data shows that its oxygen cost has dropped from $0.46 per cubic meter to $0.16, saving approximately $94,200 annually. After deducting equipment depreciation, the actual payback period is only 4.2 years. Meanwhile, by getting rid of the reliance on purchasing oxygen from outside, the hospital was not affected in any way during the period when the price of liquid oxygen soared in 2022, ensuring the normal medical order.

A list of key points for hospitals to purchase oxygen generators

To assist hospitals in making scientific decisions, we have compiled the following key points for selection:

Oxygen purity guarantee: Confirm whether the equipment has real-time purity monitoring function, can stably reach the medical standard of 93%±3%, and whether it has passed the purity test and certification of a third-party institution.

Oxygen production capacity matching: Calculate the peak oxygen demand based on the number of hospital beds, the number of operating rooms, and the scale of the ICU, ensuring that the rated oxygen production of the oxygen generator is more than 30% higher than the actual demand, and reserve sufficient redundancy.

Redundant design plan: Check whether a backup oxygen generation unit is equipped, whether the switching time between the backup unit and the main unit is within 30 seconds, and whether it has a linkage interface with liquid oxygen or bottled oxygen.

Safety certification qualifications: It is required to provide documents such as the medical device registration certificate, ISO 13485 certification, and fire protection acceptance certificate, and verify whether the equipment complies with the GB 8982-2009 “Oxygen for Medical and Aviation Respiratory Use” standard.

After-sales service system: Confirm whether the manufacturer can provide 7× 24-hour technical support, whether the spare parts warehouse has sufficient reserves of key components, and whether it can respond within 2 hours and reach the site for repair within 24 hours.

Intelligence level: Examine whether the monitoring system has remote diagnosis capabilities, can be integrated with the hospital HIS system, and supports oxygen usage data statistics and cost analysis.

Energy consumption index: Compare the unit oxygen production energy consumption of different equipment, and give priority to choosing the model with a high energy efficiency ratio. In the long term, this can significantly reduce operating costs.

Conclusion

The selection of oxygen generators for hospitals is by no means a simple equipment purchase; rather, it is a systematic project that concerns patients’ life safety, medical quality assurance, and the operational efficiency of hospitals. The stable compliance of oxygen purity is the foundation of therapeutic effects. Comprehensive safety protection design is the key to avoiding accidents. A complete redundancy backup mechanism is the guarantee for dealing with emergencies. And the continuous and reliable oxygen supply capacity is the core goal of system design.

For hospital administrators, they should formulate a scientific oxygen generation system construction plan in light of their own scale, departmental setup and future development plans. While attaching importance to initial investment, it is even more important to focus on long-term operating costs and safety risks, and choose oxygen production equipment that is technologically mature, reliable in quality and well-serviced.

If you are confused about the selection of an oxygen generation system for your hospital, you might as well contact the professional oxygen generation equipment team of MINNUO to obtain a customized solution and a detailed return on investment calculation. MINNUO also offers free on-site investigation and oxygen supply demand assessment services to help medical institutions make the most suitable choices.

Building a safe, efficient and economical self-constructed oxygen generation system can not only provide more reliable life protection for patients, but also lay a solid foundation for the sustainable development of the hospital. MINNUO’s ultimate pursuit for medical oxygen supply systems is to ensure that every breath is filled with peace of mind.

sales2:+86 17506119168

sales2:+86 17506119168