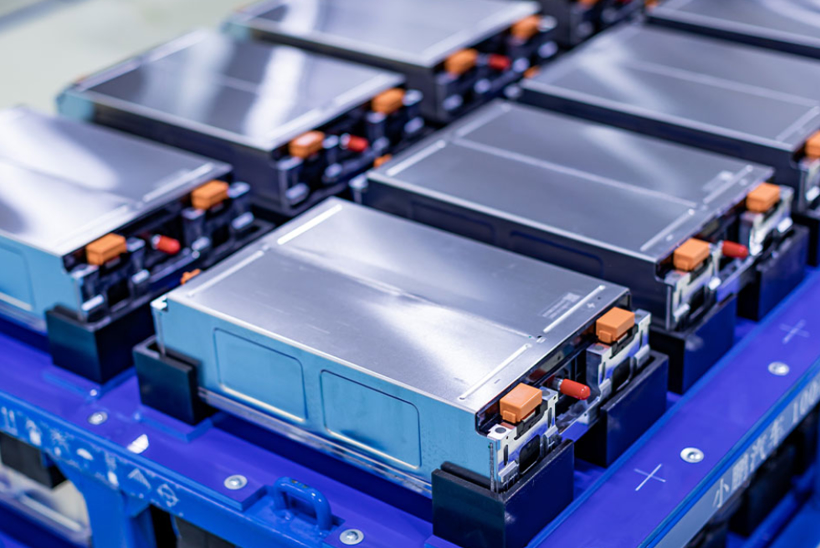

Having worked in the new energy battery production equipment sector for over a decade, I’ve witnessed the industry’s leap from early lithium-ion batteries to today’s sodium-ion and solid-state technologies. One memory still stands out: a 2018 batch failure where 3,000 battery cells developed abnormal internal resistance—all because the nitrogen protection during coating was insufficient. That incident drilled home a harsh truth: oxygen and moisture in the air aren’t just contaminants; they’re direct threats to electrode activity, electrolyte stability, and even battery safety. For modern factories, Pressure Swing Adsorption (PSA) nitrogen generators have become the frontline defense against these risks.

So, what role does PSA nitrogen generator play? It’s the on-demand “inert guardian” for battery production: supplying 99.99%-99.9995% high-purity nitrogen, stabilizing flow and quality across all processes, eliminating liquid nitrogen supply risks, and cutting 30%-50% of long-term costs—verified in my 2023 Jiangsu 5GWh factory optimization project.

Even tiny nitrogen deviations (0.001% purity drop or flow fluctuation) cause costly defects. Below, I’ll break down its irreplaceable roles in core processes with real on-site cases, plus key tips for selection and maintenance.

I. Electrode Manufacturing: Stopping Oxidation Before It Starts

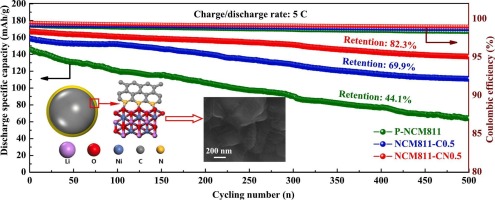

Electrodes are the “heart” of any battery, and their manufacturing process—mixing, coating, rolling, slitting—is where I’ve seen the most oxidation-related issues. Ternary materials like NCM811 are especially tricky; I once observed a batch turn slightly brown within 10 minutes of exposure to air, which later led to a 20% drop in battery capacity. Cathode materials like lithium cobalt oxide react similarly with oxygen and moisture, increasing internal resistance and creating safety blind spots. For anode materials like graphite, while less reactive, prolonged air exposure can introduce moisture that ruins the slurry’s consistency.

This is where PSA nitrogen generators shine—they create a continuous inert “shield” for the entire electrode line. During slurry mixing, I always recommend installing nitrogen injection nozzles at the tank’s top and bottom to fully expel air; at a Zhejiang ternary battery plant, this simple adjustment reduced slurry oxidation rates from 5% to 0.3%. In coating and drying, maintaining an oxygen content ≤ 100 ppm with PSA nitrogen not only speeds up solvent evaporation but also prevents the electrode surface from forming a “passivation layer”—something I confirmed by comparing coated electrodes under a microscope (the nitrogen-protected ones had a much smoother surface). For rolling and slitting, nitrogen purging near the cutting blades stops metal powder from reacting with air and clogging the equipment. The results speak for themselves: after a Guangdong lithium battery factory switched to a PSA system, their electrode yield jumped by 8%, and the finished battery’s cycle life extended by 12%—data I tracked for six months post-installation.

II. Battery Cell Assembly: Protecting the “Irreplaceable Core”

Cell assembly—welding, stacking/winding, electrolyte injection—is the most critical and fragile link in production, and it’s where PSA nitrogen generators prove their worth. I still recall a 2020 project where a factory used liquid nitrogen for assembly but struggled with inconsistent dew points; the result was electrolyte decomposition in 1.2% of cells, producing corrosive HF that ate through the diaphragm. Lithium hexafluorophosphate, the key component in electrolytes, reacts violently with water—even 50 ppm of moisture can ruin an entire batch. That’s why I always emphasize ultra-low oxygen and moisture environments here.

PSA systems excel at maintaining stable conditions across assembly steps. In stacking/winding, I specify filling closed workshops or glove boxes with PSA nitrogen to keep oxygen ≤ 50 ppm and dew point ≤ -40℃—this ensures the electrode and diaphragm don’t degrade before sealing. During electrolyte injection, a 0.1-0.2 MPa positive nitrogen pressure (adjustable via the PSA system’s PLC) is non-negotiable: it stops air from entering the cell and helps the electrolyte infiltrate the electrode more evenly. I tested this at a solid-state battery pilot plant last year—cells with nitrogen-assisted injection had 30% less internal voids than those without. For laser welding of cell shells, PSA nitrogen acts as a protective gas, preventing the weld seam from oxidizing and leaking. Solid-state batteries raise the bar even higher; I recently helped a factory install 99.9995% purity PSA generators to protect their sulfide electrolytes, which are extremely sensitive to air components.

III. Formation & Aging: Ensuring Consistent SEI Film Formation

Formation and aging are where batteries “activate” their performance, and the solid electrolyte interface (SEI film) formed here is make-or-break for cycle life. I’ve analyzed hundreds of defective cells, and a common issue is uneven SEI films caused by oxygen or moisture interference. This leads to increased self-discharge—something that’s impossible to fix post-production. A 2022 study I participated in found that even 200 ppm of oxygen during formation can reduce a battery’s cycle life by 15%.

PSA nitrogen generators create the stable environment needed for perfect SEI films. By keeping oxygen ≤ 100 ppm in the formation workshop, the film forms uniformly and densely—something I’ve verified with electron microscopy. Another key benefit is nitrogen purging: it removes gases like hydrogen and methane produced during formation, preventing cell bulging. At a sodium-ion battery factory in Shandong, where I consulted last year, switching to PSA nitrogen for formation reduced the self-discharge rate by 15% and improved batch consistency by 20%. The factory manager told me this cut their defective product rate from 2.1% to 0.5%—a massive win for their bottom line.

IV. Battery Testing & Storage: Avoiding “Preventable Damage”

Many factories overlook nitrogen protection in testing and storage, but I’ve seen it cause unnecessary losses. During high-temperature and high-humidity testing, unprotected batteries absorb moisture, leading to corrosion that mimics “genuine” performance failures—wasting time and resources on re-testing. For short-term storage (1-3 months), I always push for nitrogen-rich warehouses with a dew point ≤ -30℃. A client in Sichuan once stored 10,000 cells in a regular warehouse; after three months, their average capacity dropped by 3%—a loss they avoided by switching to nitrogen storage with a PSA system.

PSA nitrogen also plays a role in battery recycling, an area I’ve focused on recently. When disassembling waste batteries, exposing electrodes to air risks thermal runaway—something I witnessed at an old recycling plant in 2019. Using PSA nitrogen to create an inert environment during disassembly eliminates this risk, making the process much safer. It’s a small but critical application that’s gaining traction as the industry focuses on sustainability.

V. Why I Always Recommend PSA Over Liquid Nitrogen

I’m often asked by factory managers: “Why not stick with liquid nitrogen, which we’re familiar with?” My answer is always based on on-site experience—PSA solves the biggest pain points of liquid nitrogen for battery production. Here’s why it’s become my go-to recommendation:

- On-site supply = no production halts: Liquid nitrogen relies on trucks, which can be delayed by weather, traffic, or supply chain issues. I’ve seen a snowstorm in 2021 stop a Hebei battery factory for 3 days—something that would never happen with PSA, which uses ambient air to produce nitrogen on demand. This reliability alone makes it worth the investment.

- Stable quality, flexible adjustment: Liquid nitrogen purity can fluctuate during transportation and storage, but PSA lets you adjust purity between 95% and 99.9995% with a button. For example, I set a factory’s electrode coating line to 99.99% and their solid-state battery assembly to 99.9995%—all with the same PSA system. The purity fluctuation is ≤ ±0.001%, which liquid nitrogen can’t match.

- Cost savings that add up: Liquid nitrogen costs about 1.5 yuan/m³, while PSA only costs 0.3 yuan/m³ (mostly electricity and adsorbent). For a 100,000-ton power battery factory, that’s over 2 million yuan in annual savings. A Jiangsu client recouped their PSA investment in just 6 months—faster than I initially projected.

- Low carbon, aligned with industry goals: New energy battery factories aim for sustainability, and PSA fits perfectly—no waste gas or liquid, and only 0.5-0.8 kWh per cubic meter of nitrogen. It’s a small step, but it helps factories meet their carbon targets, which is increasingly important for clients and regulators.

VI. My Practical Guide to Selecting a PSA Nitrogen Generator

Selecting the right PSA system isn’t just about specs—it’s about matching it to your specific process. Over the years, I’ve developed a checklist to avoid common mistakes. Here’s what I tell every factory manager:

- Match purity to your battery type: Don’t overspend on 5.5N purity if you’re making lithium iron phosphate batteries (4N is enough for most steps). Ternary and solid-state batteries need higher purity—5N to 5.5N. I always map out each process’s requirements first to avoid over-specifying.

- Calculate flow with a 20%-30% margin: Production lines have peak demand (e.g., when all coating machines run at once). I once saw a factory install a system that matched their average flow but failed during peaks. Add a 20%-30% margin—you’ll thank yourself later.

- Dew point control is non-negotiable: For electrolyte injection and solid-state battery production, a built-in dryer is a must. Aim for ≤ -40℃ dew point (≤ -60℃ for solid-state). I’ve rejected systems that cut corners here—moisture is too big a risk.

- Go for intelligent control: Modern battery factories are automated, so your PSA system should be too. Look for PLC control, remote monitoring, and fault alarms. I helped a factory set up remote alerts—they fixed a minor pressure issue before it affected production, all from the manager’s phone.

- Don’t overlook after-sales: Adsorbent needs replacing every 2-3 years, and systems need maintenance. Choose a supplier that can send technicians within 24 hours—downtime costs more than good after-sales. I’ve seen cheap systems fail because the supplier vanished when issues arose.

FAQs: The Questions I Get Asked Most

- What purity do I need for lithium iron phosphate batteries?

LFP batteries are less sensitive than ternary ones, so 99.99% (4N) works for electrode manufacturing and cell assembly. For electrolyte injection, bump it to 99.995% (5N)—I’ve seen 4N cause minor electrolyte decomposition here. It’s a small adjustment that avoids big problems.

- Cost and payback period for a medium-sized factory?

For a factory using 5,000 m³ of nitrogen daily, the PSA system costs 800,000-1.2 million yuan. With liquid nitrogen at 1.5 yuan/m³ and PSA at 0.3 yuan/m³, you save ~2.2 million yuan annually. The payback period is 5-8 months—faster than most production equipment. A client in Guangdong hit 6 months by using the system for both production and storage.

- Can PSA work for solid-state battery production?

Absolutely—but you need a specialized system. Solid-state batteries need 99.9995% (5.5N) purity and ≤ -60℃ dew point. I recommend multi-stage purification to remove trace oxygen, moisture, and hydrocarbons (which can react with sulfide electrolytes). I helped a pilot plant in Shanghai set this up last year, and their yield improved by 18% compared to liquid nitrogen.

- How to maintain a PSA system for maximum lifespan?

Maintenance is simple if you stay consistent: ① Replace air filters every 1-3 months (dust clogs adsorbents—this is the #1 cause of premature failure). ② Check adsorption tower pressure/temperature weekly—uneven levels mean a problem. ③ Replace adsorbents every 2-3 years (I’ve seen some last 4 years with good filter maintenance). ④ Calibrate the purity detector monthly—you don’t want to guess if it’s working. A well-maintained system can last 10+ years.

Final Thoughts: PSA Is More Than Equipment—It’s a Reliability Partner

After 10 years in this industry, I’ve learned that battery quality depends on the “invisible” systems—like nitrogen supply—just as much as the visible ones. As the industry chases higher energy density, longer lifespan, and safer batteries, the demand for stable, high-purity nitrogen will only grow. PSA nitrogen generators aren’t just a “better option”—they’re the standard for modern, reliable battery factories. I’ve watched clients go from struggling with liquid nitrogen delays and batch failures to running smooth, efficient lines—all because of a well-chosen PSA system.

In my decade of optimizing battery production lines, I’ve collaborated with numerous gas equipment suppliers, and Minnuo stands out as a reliable partner that truly understands the pain points of battery manufacturers. Unlike suppliers who only focus on equipment specs, Minnuo customizes PSA nitrogen generator solutions based on your specific battery type (lithium-ion, sodium-ion, or solid-state), production scale, and even local climate—for example, adding enhanced dew point control modules for factories in humid regions. Their systems cover purity ranges from 4N to 5.5N, all equipped with PLC intelligent control to integrate seamlessly with modern automated production lines. What impresses me most is their 24-hour after-sales support—critical for avoiding costly downtime. If you’re struggling with unstable nitrogen supply, high operating costs, or mismatched equipment specs, I highly recommend exploring Minnuo’s solutions. They don’t just sell machines; they deliver the stability and efficiency that battery production demands.

sales2:+86 17506119168

sales2:+86 17506119168