In fields such as industrial production and medical security, the stable supply of oxygen is one of the core requirements. VPSA (Vacuum Pressure Swing Adsorption) oxygen generators have become the mainstream choice for large-scale, high-efficiency oxygen supply due to their unique technical approach. Using air as raw material, they achieve oxygen-nitrogen separation through precise pressure regulation, combining economy and reliability, with continuously expanding application scenarios.

I. Core Working Principle of VPSA Oxygen Generators

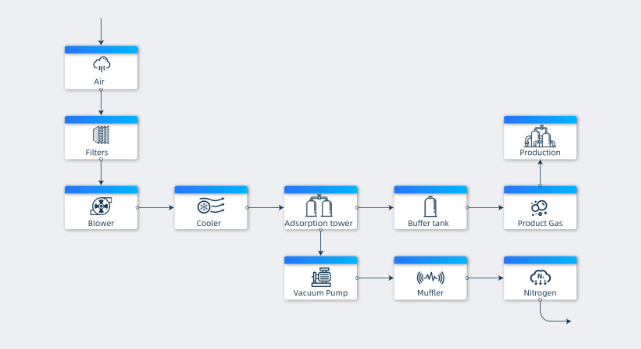

The technical core of VPSA oxygen generators lies in utilizing the selective adsorption characteristics of molecular sieves and pressure cycle mechanism to complete the continuous cycle of “adsorption-desorption-regeneration”. The specific process can be divided into four key steps:

- Feed Gas Pretreatment: Taking atmospheric air as raw material, the air is slightly pressurized to slightly above atmospheric pressure (approximately 0.1MPa absolute pressure) by a blower. Meanwhile, impurities such as dust are removed through filters, and some systems are equipped with coolers to eliminate compression heat and moisture, ensuring the air entering the adsorption system is clean and dry.

- Low-Pressure Adsorption Separation: The pretreated air enters an adsorption tower filled with lithium-based molecular sieves. Under near-atmospheric pressure conditions, the molecular sieves preferentially adsorb nitrogen, while the unadsorbed oxygen flows out from the top of the tower as product gas and enters a buffer tank for temporary storage. The characteristics of lithium-based molecular sieves enable them to efficiently adsorb nitrogen even at low pressure, providing guarantee for separation efficiency.

- Vacuum Desorption Regeneration: When the molecular sieves in one tower are nearly saturated with nitrogen adsorption, the system automatically switches to the other tower for adsorption. At the same time, the saturated tower is evacuated to a vacuum state (0.02–0.05MPa absolute pressure) by equipment such as roots vacuum pumps. Under low-pressure environment, the adsorbed nitrogen is rapidly desorbed and discharged with exhaust gas, allowing the molecular sieves to be completely regenerated and restore their adsorption capacity.

- Dual-Tower Alternating Oxygen Supply: The equipment usually adopts a dual-tower structure. Through precise coordination of valve switching and equipment operation by the PLC control system, the two towers alternately perform adsorption and regeneration processes, realizing continuous and stable oxygen production.

II. Core Application Advantages of VPSA Oxygen Generators

Compared with traditional oxygen generation technologies, VPSA oxygen generators show significant advantages in energy consumption, scale adaptability, operation and maintenance, making them the preferred solution in multiple fields.

(I) Lower Energy Consumption and Controllable Operation Costs

VPSA adopts the mode of “low-pressure adsorption and vacuum desorption”, which does not require an air compressor to pressurize air to 0.6–0.8MPa like PSA oxygen generators. Only a low-power blower is needed to meet the air intake demand. Meanwhile, vacuum desorption can achieve more thorough regeneration of molecular sieves, reducing ineffective energy consumption. The unit oxygen production cost is significantly lower than that of traditional technologies. For large-scale oxygen use scenarios, substantial energy expenditure can be saved during long-term operation.

(II) Flexible Scale Adaptability and Strong Oxygen Supply Stability

The modular design of VPSA oxygen generators supports capacity adjustment according to needs, covering from small medical equipment to large industrial installations, and can be flexibly expanded based on oxygen demand. The purity of the produced oxygen is stable, and the buffer tank can effectively balance the flow fluctuation during the switching cycle, providing a continuous and stable oxygen source for downstream processes. Whether it is oxygen-enriched combustion in the metallurgical industry or continuous oxygen therapy in hospitals, it can meet the stringent oxygen supply requirements.

(III) Longer Equipment Service Life and Low Maintenance Requirements

The vacuum desorption process can minimize the residual nitrogen and moisture in molecular sieves, avoiding accelerated wear of adsorbents due to repeated inefficient regeneration. Combined with the excellent performance of lithium-based molecular sieves themselves, the service life of adsorbents is greatly extended. At the same time, the equipment operates at low pressure, so the mechanical stress on pipelines and valves is small, and the failure probability is significantly reduced. With the assistance of intelligent early warning systems, the downtime for maintenance can be minimized.

(IV) Low Operating Noise and Good Environmental Adaptability

VPSA oxygen generators have low requirements for compressor power, and most adopt a horizontally opposed four-cylinder structure design, which can effectively reduce vibration and noise during equipment operation. Compared with the noise problem caused by high-power compressors in traditional PSA oxygen generators, they are more adaptable to scenarios sensitive to environmental noise such as medical institutions and laboratories, improving the comfort of use.

III. Summary

Supported by the core principle of “low-pressure adsorption-vacuum desorption”, VPSA oxygen generators have formed prominent advantages in energy consumption control, scale adaptability, operation and maintenance. From large-scale oxygen use in industrial fields such as metallurgy and chemical industry to precise oxygen supply in scenarios such as medical treatment and scientific research, they have become an important development direction of modern oxygen generation technology due to their efficient, stable and economical characteristics. With the iteration of new molecular sieve materials and the upgrading of intelligent control technology, the application value of VPSA oxygen generators will continue to improve.

sales2:+86 17506119168

sales2:+86 17506119168