For decades, industries reliant on nitrogen—from food packaging to electronics manufacturing—have been tethered to a costly and cumbersome supply chain: ordering, storing, handling, and returning high-pressure gas cylinders or managing bulk liquid nitrogen deliveries. This dependency creates a constant cycle of logistical headaches, unpredictable costs, and potential safety hazards. What if you could cut the cord and produce this essential gas exactly where and when you need it?

This is the promise of the nitrogen generator: a self-contained system that transforms the air around you into a reliable, high-purity stream of nitrogen. Moving from a gas consumer to an independent producer represents a fundamental shift in how businesses secure this critical resource. This complete guide will demystify nitrogen generators, explain how they work through two main technologies, detail their compelling advantages, explore their wide-ranging applications, and provide a framework for selecting the right system for your operation.

What is a Nitrogen Generator?

A nitrogen generator is a piece of industrial equipment designed to separate nitrogen gas (N₂) from the other components of ordinary compressed air, primarily oxygen (O₂), to produce a continuous, on-demand supply of high-purity nitrogen.

The core principle is elegantly simple: utilize the Earth’s atmosphere—which is approximately 78% nitrogen and 21% oxygen—as a free and unlimited feedstock. By drawing in this air and selectively removing the oxygen, water vapor, carbon dioxide, and other trace gases, the generator delivers a purified nitrogen stream. This process effectively turns your facility into its own mini gas plant, eliminating the need for external gas suppliers and the entire associated logistics network.

How Does a Nitrogen Generator Work? The Two Main Technologies

While the goal is the same, two distinct and mature technologies dominate the market, each with its own mechanism for separating gases: Pressure Swing Adsorption (PSA) and Membrane Separation.

1. Pressure Swing Adsorption (PSA) Nitrogen Generators

PSA technology is renowned for its ability to deliver very high purity nitrogen and is the most common choice for industrial applications.

Core Principle: PSA systems exploit the fact that different gas molecules are attracted to, or “adsorbed” onto, the surface of a porous material called a Carbon Molecular Sieve (CMS) at different rates under pressure. Oxygen molecules are slightly smaller and have a faster diffusion rate than nitrogen molecules. Under high pressure, oxygen is preferentially adsorbed into the pores of the CMS, allowing nitrogen to pass through as the product gas.

The Four-Step Cycle (Typically using two adsorption towers):

- Adsorption: Compressed, cleaned, and dried air is fed into the first adsorption tower (Tower A). The CMS adsorbs oxygen, water vapor, and CO₂. High-purity nitrogen exits the top of the tower and is delivered to your process.

- Pressure Equalization: Once Tower A’s CMS becomes saturated with impurities, the inlet air flow switches to Tower B. Before Tower A is depressurized, a portion of its high-pressure nitrogen is used to partially pressurize Tower B. This energy-saving step is crucial for efficiency.

- Desorption (Regeneration): Tower A is rapidly depressurized to atmospheric pressure. This sudden drop in pressure causes the adsorbed oxygen and other gases to be released from the CMS and vented out of the system.

- Purge and Repressurization: A small stream of pure nitrogen from the now-adsorbing Tower B is used to “purge” Tower A, flushing out any remaining impurities. Tower A is then repressurized with feed air and is ready to begin the adsorption cycle again when Tower B becomes saturated.

This continuous, alternating cycle between two (or more) towers ensures a non-stop supply of nitrogen.

2. Membrane Nitrogen Generators

Membrane technology offers a simpler, maintenance-free alternative for applications with moderate purity requirements.

Core Principle: A membrane generator contains thousands of hollow, polymer fibers bundled together. When compressed air is introduced into these fibers, gases permeate through the fiber walls at different rates based on their solubility and diffusivity. Water vapor, oxygen, and carbon dioxide are “fast gases” that permeate quickly through the membrane walls and are vented off. Nitrogen, as a “slow gas,” travels down the length of the fibers and is collected as the product gas.

The Process: The system is elegantly simple—compressed air enters one end of the membrane module, and nitrogen emerges from the other. The separation happens passively without moving parts or switching valves. The purity of the output nitrogen is controlled primarily by adjusting the feed air pressure and flow rate; a higher flow rate typically results in lower purity, and vice versa.

PSA vs. Membrane: A Quick Comparison

| Feature | PSA Nitrogen Generator | Membrane Nitrogen Generator |

| Purity Range | High & Adjustable: 95% to 99.999%+ | Moderate: Typically 95% to 99.5% |

| Flow Capacity | Excellent for medium to very high flow rates | Best suited for low to medium flow rates |

| Energy Efficiency | High, especially with advanced cycle designs | Good, but purity is tied to flow and pressure |

| Maintenance | Requires periodic CMS change (every 5-10 years) | Virtually maintenance-free; no consumables |

| Footprint | Larger, due to towers and valves | Compact and lightweight |

| Ideal For | Applications demanding high, stable purity (e.g., electronics, chemicals) | Applications with stable, moderate purity needs (e.g., tire inflation, fire prevention) |

Key Advantages of On-Site Nitrogen Generation

Shifting from delivered gas to on-site generation delivers transformative benefits that impact the bottom line, operational resilience, and safety.

- Significant and Predictable Cost Savings: This is the most compelling advantage. On-site generation eliminates recurring rental fees, delivery charges, and fuel surcharges. You also avoid the “evaporation loss” inherent in liquid nitrogen storage (typically 1-3% per day). After the initial investment, your primary operating cost becomes electricity to run the compressor, which is predictable and often far lower than traditional supply costs. The return on investment (ROI) is typically clear and achievable within 1-3 years.

- Unmatched Supply Security and Independence: Your production schedule is no longer at the mercy of a supplier’s delivery truck, weather, or supply chain disruptions. You produce nitrogen 24/7, exactly to your specifications. This independence is particularly valuable for remote locations or industries with critical, uninterrupted processes.

- Enhanced Safety: Removing high-pressure gas cylinders or cryogenic liquid tanks from your facility eliminates significant hazards: cylinder handling injuries, potential for valve damage, and risks associated with cryogenic burns or oxygen displacement. Nitrogen generators produce gas at safe, manageable pressures.

- Consistent Purity and Pressure: You have direct control over the output. The system can be set to deliver a specific, consistent purity level tailored to your process, improving product quality and yield. Pressure can also be stabilized, optimizing the performance of downstream equipment.

- Environmental and Sustainability Benefits: On-site generation drastically reduces the carbon footprint associated with the frequent transportation of heavy gas cylinders or bulk liquid nitrogen. It also promotes a circular model—using the ambient air and returning it (minus the separated nitrogen) to the environment.

Major Industrial Applications of Nitrogen Gas

Nitrogen’s inert properties make it indispensable across a vast spectrum of industries. Here’s how it’s commonly used:

- Food and Beverage Packaging (Modified Atmosphere Packaging – MAP): Nitrogen displaces oxygen in food packaging to prevent spoilage, oxidation, and insect growth, dramatically extending shelf life. Used for snacks, coffee, dried foods, fresh pasta, and ready-to-eat meals.

- Electronics Manufacturing: In solder reflow and wave soldering ovens, nitrogen creates an inert atmosphere that prevents oxidation on component leads and PCB pads, resulting in stronger, shinier, and more reliable solder joints. It’s also critical in semiconductor fabrication.

- Pharmaceuticals and Biotechnology: Used to create inert atmospheres over sensitive products during production, storage, and transport (blanketing), to purge reactors, and in lyophilization (freeze-drying) processes.

- Metalworking and Heat Treatment: Nitrogen is used in annealing, sintering, and brazing furnaces to prevent oxidation and scaling on metal surfaces, ensuring bright, clean finishes. It’s also a key component in laser cutting assist gases.

- Chemical and Petrochemical: Used to purge pipelines and vessels to prevent explosive atmospheres, to blanket storage tanks of volatile chemicals, and as an inert carrier gas in chemical processes.

How to Choose the Right Nitrogen Generator: 5 Key Considerations

Selecting the optimal system requires a clear analysis of your needs:

- Required Flow Rate: Determine your peak and average consumption in standard cubic feet per minute (SCFM) or normal cubic meters per hour (Nm³/h). Account for all simultaneous processes and include a margin for future growth.

- Required Purity: Identify the minimum purity level your application demands. Tip: Using higher purity than necessary increases cost and energy use. Match the technology to the need (e.g., >99.5% likely points to PSA).

- Inlet Air Supply: A nitrogen generator is only as good as the compressed air fed into it. You must have a reliable, oil-free (or properly filtered) compressed air source with sufficient pressure (typically 100-150 psig) and capacity. Include adequate air drying.

- Technology Selection (PSA vs. Membrane): Use the comparison table above as a guide. For high-purity, high-flow, or fluctuating demand, PSA is usually the answer. For simple, low-maintenance, moderate-purity needs, membrane may be ideal.

- Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in installation, energy consumption, maintenance schedules, expected lifespan of consumables (like CMS), and the guaranteed cost savings from eliminating gas purchases. A slightly higher upfront cost for a more efficient, reliable system often yields a better long-term ROI.

FAQ

Q1: What is the typical payback period for a nitrogen generator?

A1: Payback periods vary based on your current gas consumption and costs, but typically range from 12 to 36 months. High-volume users often see the fastest returns. A detailed analysis of your current spending versus the projected operating costs of a generator will provide a precise figure.

Q2: Can I adjust the purity and flow of the nitrogen produced?

A2: Yes, with PSA systems, purity is easily adjustable via the system’s controller, often with minimal impact on flow. With membrane systems, purity and flow are inversely related; increasing flow usually decreases purity, and vice versa. Both allow for tuning to match process needs.

Q3: What maintenance does a nitrogen generator require?

A3: PSA systems require periodic replacement of inlet air filters (every 3-6 months) and the Carbon Molecular Sieve (every 5-10+ years). Membrane systems primarily require only inlet air filter changes. Both benefit from having clean, dry, oil-free inlet air to maximize lifespan and performance.

Q4: Is the nitrogen produced by a generator safe for food contact?

A4: Absolutely. The nitrogen produced is the same molecule (N₂) found in the air and supplied by gas companies. The key is ensuring your inlet compressed air meets food-grade standards (e.g., ISO 8573-1 Class 1 for oil content), which any properly designed system will include.

Q5: What happens if my compressed air supply fails?

A5: The nitrogen generator will stop producing gas, as it requires compressed air as its feedstock. For critical applications, it is essential to have a backup compressed air system (like a standby compressor) or a small buffer of backup nitrogen to cover short outages.

Conclusion

Investing in a nitrogen generator is more than just purchasing a piece of equipment; it’s a strategic decision to gain control over a critical utility. It represents a shift from an unpredictable operating expense to a manageable capital asset that delivers reliable performance, enhanced safety, and substantial financial savings.

By understanding the technologies, benefits, and selection criteria outlined in this guide, you are equipped to evaluate how on-site nitrogen generation can streamline your operations and strengthen your competitive edge. For businesses looking to secure their supply chain, reduce costs, and build a more resilient and sustainable operation, the question is no longer if to generate on-site, but how to implement the right system effectively.

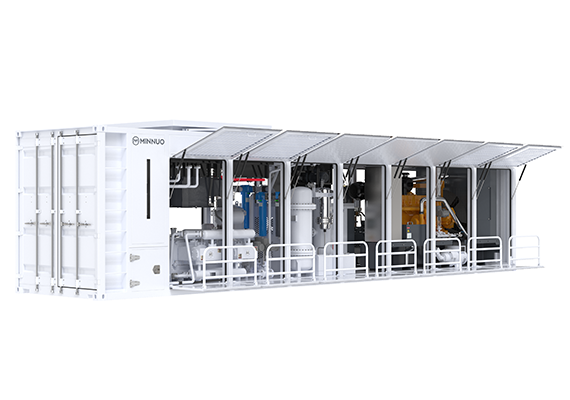

As a trusted provider of industrial gas solutions, MINNUO offers expertise in both PSA and membrane technologies. We partner with clients to analyze their specific needs, design optimized systems, and provide reliable equipment that delivers nitrogen exactly as your process requires, ensuring you reap the full benefits of production independence.

sales2:+86 17506119168

sales2:+86 17506119168