Hello, there, today I will introduce the containerized oxygen generator, with a flow rate: of 30Nm3/h, 95% oxygen purity

Our customer is from Korea, the company name is WR system Co., LTD. which is the biggest energy company in Korea. they design and produce coal gasification systems, hydrogen-energy systems of water tires, cooper recovery devices of waste, and fly ash cement makers. They contribute to global environmental cleanup.

They purchase containerized oxygen plant generator oxygen for hydrogen generator

Container Oxygen Generator Parameter requirements:

1, flow rate: 30Nm3/h

2, Oxygen purity: more than 95%

3, local voltage frequency:3ph 380V 60hz

4, local altitude:125-500m

5, local humidity:10%-60%

6, Outlet pressure:9.9bar

Because we work outdoors, we recommend the 30Nm³ 40HQ containerized PSA oxygen generator. send detailed quotation sheet, together with Equipment configuration, quotation, after-sales, maintenance, and installation.

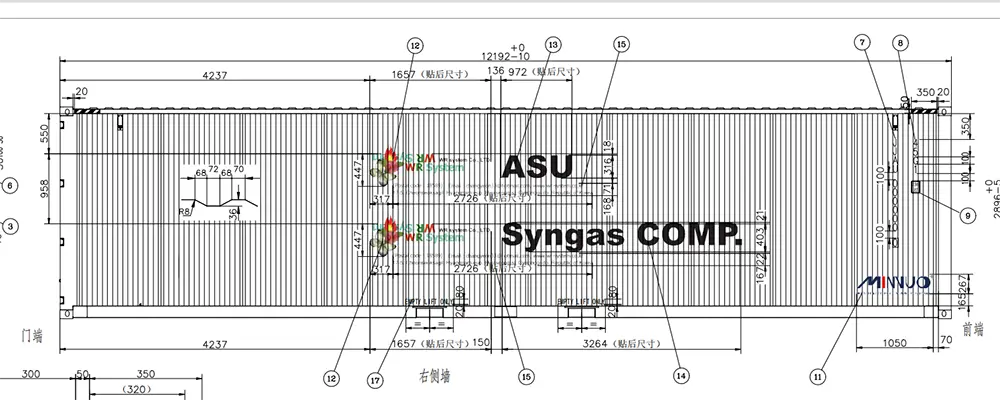

then we design container with the customer logo

Why choose container-type oxygen generator?

The containerized oxygen generator style is an economical, customized oxygen production system that requires no plant and is a turn-key on-site oxygen system solution with a one-touch start-up.

The oxygen generator is integrated with the compressor and cylinder tank system in a 10, 20 or 40 HQ container, customized for oxygen concentration 95%-99%, oxygen capacity: 5-60Nm³, altitude, voltage, easy transportation, and low cost.

Features of container oxygen generator:

- The whole equipment outside the storage tank is assembled as a whole, and the whole unit is commissioned from the factory.

- Oxygen purity stability >95%, gas production decay rate <0.8%.

- tower process, 360 smooth cycles, unloading optimization, 25% reduction in electricity consumption

- Three-year warranty for the whole machine.

- The overall floor space is reduced by 40%

- Quick installation, 1-day completion, no debugging on site, maintenance-free operation, fast return on investment

- GPRS 24-hour synchronous data monitoring, oxygen generator, fault alarm.

- The high degree of automation of the whole set of equipment, a finger of operation, simple maintenance, equipment does not require personal supervision;

Application:

1、Metallurgical industry: electric arc furnace steelmaking, blast furnace iron enriched oxygen, blast furnace enriched oxygen combustion;

2、Nonferrous metallurgy: gold, silver, lead, copper, zinc, aluminum smelting, various furnaces oxygen-rich combustion;

3、Environmental protection industry: drinking water treatment, wastewater treatment, pulp bleaching, biochemical treatment of dirt, waste incineration;

4、Chemical industry: various oxidation reactions, ozone production, coal gasification, pharmaceutical production;

5、Health care industry: medical oxygen, oxygen therapy, oxygen health care;

6、Aquatic industry: sea and freshwater aquaculture;

7、Other industries: fermentation, welding and cutting, glass furnace, air conditioning, waste incineration;

8、Electric furnace steelmaking: decarburization, oxygen combustion heating, foam slag dissolution, metallurgical control and subsequent heating;

9, wastewater treatment: activated sludge oxygen-enriched aeration, pool oxygenation and ozone sterilization; glass melting, cutting;

10、Increase glass production, extend the life of the furnace;

11, non-ferrous gold smelting: smelting copper, gold, lead, nickel, etc. need to use rich oxygen, PSA method is gradually replacing the deep order method;

12, field cutting construction: field steel pipe, steel cutting with oxygen-rich, mobile or small oxygen generator can meet the requirements;

13、Oxygen for petrochemical and industrial use: The oxygen reaction in the petroleum and chemical process is carried out by using compound oxygen instead of air;

14, oxidation reaction, can improve the reaction speed and chemical product yield;

15, ore processing: used in gold and other production processes, can improve the extraction rate of metals;

16, application of water: provide oxygen to the ozone generator, ozone sterilization.

sales2:+86 17506119168

sales2:+86 17506119168