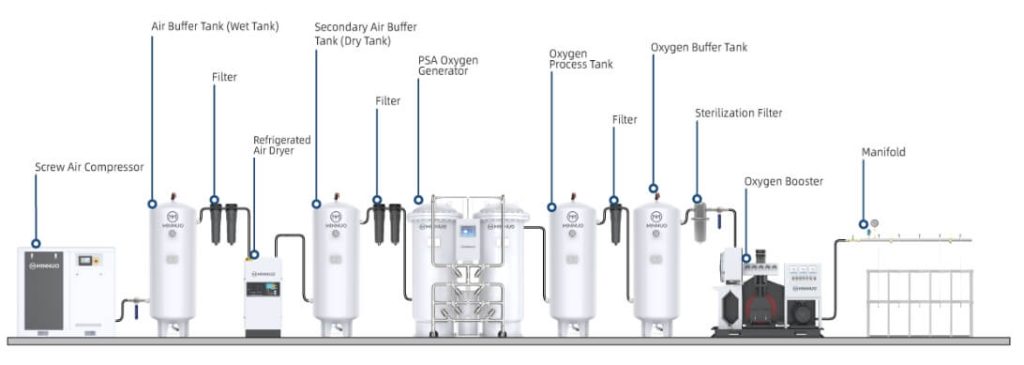

In the world of oxygen generation, PSA (Pressure Swing Adsorption) technology has become a cornerstone for delivering high-purity oxygen in both medical and industrial environments. These generators work by selectively adsorbing nitrogen from compressed air using molecular sieves, leaving behind concentrated oxygen. The precision of this process, however, depends heavily on the condition of core components like the molecular sieve, compressor, and filtration systems.So how often should you service your PSA oxygen generator?

This is a critical question for hospital administrators, factory engineers, and OEM operators alike. Without timely maintenance, oxygen purity can drop, energy consumption can increase, and unplanned shutdowns may disrupt essential operations. Regular service not only ensures consistent gas quality but also significantly extends the generator’s lifespan and prevents costly emergency repairs.

Whether you’re managing a rural clinic’s life support systems or operating a high-throughput manufacturing line, understanding the proper maintenance schedule is essential. This guide will walk you through all the key service intervals—from filter replacements to compressor checks—so you can confidently optimize performance and safeguard your investment.

1. Core Components That Require Regular Maintenance

Inadequate maintenance is the core cause of unstable operation and degradation of oxygen purity in PSA systems. Below are the detailed descriptions of the three key components, the problems that are easy to be neglected and the corresponding solution suggestions:

Molecular sieve

Function: selective adsorption of nitrogen, the core material of PSA technology.

Common deterioration factors:

Oil mist contamination: Oil from compressed air is not thoroughly filtered.

Excessive vapor: Failure of the pretreatment system or high ambient humidity.

High Temperature Aging: Prolonged operation at high temperatures reduces adsorption efficiency.

Life expectancy recommendation:

3-5 years under normal operating conditions.

If you often find that the purity decreases, you should first check whether the molecular sieve is pulverized or agglomerated.

Maintenance advice:

Check the pressure drop and adsorption efficiency of the molecular sieve tower annually to assess the risk of early replacement.

In high humidity, high oil mist environment, it is recommended to shorten the replacement cycle to 2-3 years.

Air Compressor Unit

Role: Provide stable air source for PSA, its operation efficiency directly affects the oxygen production and system life.

Key maintenance items:

Oil change

Air and oil filter change

Belt tension check and adjustment

Maintenance intervals recommended:

| Items | Time/Hours of Operation |

| Initial Maintenance | 500 hours |

| Oil and Filter Change | Every 2,000-3,000 hours |

| Complete Overhaul | Every 8,000 hours |

Problem Solving Tips:

If the air compressor runs louder or the temperature rises, usually the oil filter is clogged or the lubrication is insufficient, you should check the oil quality and the replacement cycle in time.

If the equipment often jumps to a stop due to overload, prioritize the cooling system and motor load status.

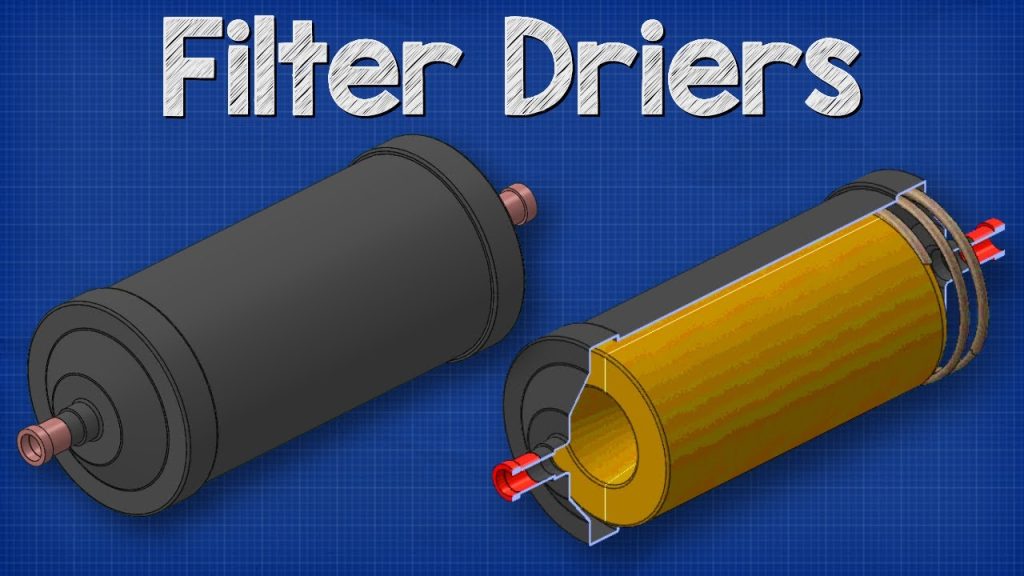

Pre-treatment System: Filter and Dryer

Function: Remove water, oil and particles in the air beforehand to protect the PSA mainframe from contamination.

Key components:

Coalescing Filter: removes oil mist and particles

Activated Carbon Filter: adsorbs residual oil and gas

Dryer: refrigerated or adsorptive, removes moisture

Replacement Frequency:

It is recommended to change the filter cartridge every 6,000 hours or every 6 months (whichever comes first)

It is recommended to check for pressure drop changes every 4,000 hours if the equipment is subjected to a prolonged period of time in a shop environment with high levels of high humidity, dust, or oil and gas.

Practical advice:

Establish an “intake quality monitoring log” to determine the degree of clogging by comparing the pressure difference between the front and rear of the filter.

The use of filters with differential pressure indicators is recommended to improve the timeliness and accuracy of replacement.

Adsorption dryers should be tested for regeneration capacity on a regular basis to avoid affecting the water vapor handling capacity.

2. PSA Oxygen Machine Service and Maintenance Schedule: Not only the cycle, but also the system health guarantee.

2.1 Molecular Sieve Replacement: Don’t Wait Until Oxygen Concentration Decreases

Recommended Cycle: 3~5 Years

Molecular sieve is the “heart” of PSA system, and its adsorption performance directly determines the purity of oxygen. Although most of the manuals indicate that the service life is 5 years, the actual service life is greatly affected by air cleanliness, system pressure fluctuations and operating time.

Suggestion: If the operating environment is dusty and high humidity, the adsorption performance of molecular sieve should be evaluated within 3 years in advance, and whether it meets the standard can be monitored by online oxygen concentration analyzer.

2.2 Air compressor oil and oil/gas filter element: Ignore these, and “small failure” will evolve into “big shutdown”.

First time to replace air compressor oil: 500 hours.

After that, the replacement cycle: every 2,000 to 3,000 hours.

Oil/air separator cartridge replacement: every 2000 hours

Aged lubricant or clogged cartridge will lead to high temperature alarm or even compressor jamming. If you use non-OEM lubricating oil or filter element, it often leads to premature failure due to mismatch.

✅ Suggestion: Under high temperature and high load environment, the oil replacement cycle should be controlled within 2000 hours, and the oil color and viscosity should be monitored regularly.

2.3 Pre-treatment System: Don’t let the water vapor become the equipment killer.

Recommended replacement cycle for pre-treatment cartridge (including cold dry, pre-filter, degreaser):

Every 6,000 hours or every 6 months (whichever comes first).

Moisture accelerates saturation of the cartridge, which leads to the entry of water vapor into the adsorption tower, resulting in molecular sieve “poisoning” and inability to regenerate.

✅ Suggestion: In the south or coastal areas, the inspection can be carried out 3-4 months in advance; at the same time, monitor whether the dew point of the cold dryer is stable (preferably ≤3℃).

2.4 Tower Valve System Maintenance: Preventing Air Leakage and Malfunction

Suggested inspection cycle: once a year

Adsorption tower valves belong to electromagnetic or air control system, once the sealing fails and the action is sluggish, it will cause the failure of airflow switching, resulting in incomplete adsorption and unstable oxygen production.

✅ Suggestion: the inspection should include: spool wear, seal aging, actuator lubrication status.

2.5 Full System Audit: the real sense of the annual “physical examination”

Suggested frequency: every 12 months

A third party or professional service engineers to carry out a comprehensive inspection, including: gas line leakage detection, electronic control system operation stability assessment, PLC control strategy review, and so on.

✅ Recommendation: Combine the system audit with annual maintenance, develop a complete “Operation and Maintenance Record Sheet”, and retain at least 3 years of data for trend analysis.

3. Warning Signs You’re Overdue for Maintenance

Minor problems in daily operation are often precursors to major failures. The following five types of common warning signals should not be ignored, with accurate judgment and timely treatment, can effectively avoid system paralysis or oxygen interruption.

3.1 Significant Drop in Oxygen Purity

If the oxygen purity is lower than the set threshold (e.g. 93% ±3%), it indicates that the molecular sieve adsorption efficiency has dropped or there is a leak.

Suggested actions:

Check whether the molecular sieve has reached the end of its service life (3-5 years is preferable), and whether there is any pulverization or failure;

Check whether there is any air mixed in the gas outlet;

Clean the oxygen analyzer probe to eliminate measurement errors.

3.2 Increased Cycle Frequency of the Compressor

Frequent starting and stopping of the compressor means that the system load is abnormal or the efficiency of the adsorption bed is reduced, resulting in a shortened adsorption/desorption cycle.

Suggested Actions:

Check if the compressor oil is out of date or out of oil;

Check if the adsorption tower switching valve is delayed;

Check the pressure fluctuation of the foreground storage tank to see if there is a problem of insufficient air supply from the compressor.

3.3 Abnormal Pressure or Flow Readings

Abnormal system pressure or flow readings may be related to clogged pipes, stuck valves or faulty sensors.

Suggested Actions:

Regularly calibrate the pressure sensor and flow meter;

Check the outlet piping for increased resistance due to clogged condensate or saturated filters;

Replace the aging regulator or relief valve.

3.4 Alarm Signals from PLC/Control Panel

PLC alarms are not “false alarms” but are the system’s self-protection response. Ignoring alarms may cause the problem to accumulate.

Suggested Actions:

Query the manual according to the alarm code to pinpoint the problem;

Check whether the solenoid valve, thermostat, current protection module responds normally;

If the system alarms frequently, it is recommended to shut down the system for a comprehensive inspection.

3.5 Unusual Noise or Overheating

Unusual noise and overheating usually come from the wear and tear of moving parts or poor heat dissipation.

Suggested Actions:

Check whether the bearings are insufficiently lubricated and whether the fan is running normally;

Clean the dust in the compressor cooling system;

Change the compressor oil regularly to prevent high temperature stagnation caused by carbon buildup.

4. Long-Term Benefits of a Preventive Maintenance Plan

The long term value of preventive maintenance is not only “failure reduction”, but also the core of “operational security”.

4.1 Maximizing Oxygen Purity and System Efficiency

Regular replacement of molecular sieves and precision cartridges prevents contaminants from clogging the adsorbent bed and ensures that oxygen purity remains within the set range (e.g., 93% ± 3%). Especially in medical scenarios, the deviation of purity may directly affect the safety of patients’ oxygen consumption.

Suggested Initiatives:

Monthly testing of oxygen outlet purity

Quarterly online flow rate and purity calibration comparison

Annual molecular sieve testing program

4.2 Reduce the risk of sudden breakdowns and emergency repairs

Overloading of the air compressor, abnormalities of the air cooler, or interruptions of the PLC signals are commonly seen in the “reactive maintenance” users, who wait until the equipment alarms or stops to deal with them, which can lead to a “chain reaction” of problems and “chain reactions”. The risk of a “chain reaction”: a failure in one place brings the whole system down.

Preventive benefits:

Through the daily oil level check and vibration noise analysis to detect hidden problems in advance

Through regular maintenance to form a “spare parts replacement rhythm”, to avoid waiting for long time repair parts

4.3 Extend the life of the equipment, improve the return on investment (ROI)

Oxygen production equipment, such as molecular sieve, air compressor, solenoid valves and other core components, once overloaded, their life is greatly reduced. Once overloaded, the life expectancy is greatly reduced. A maintenance program that keeps the equipment in the optimal load range (e.g., 60-80% operating rate) maximizes its lifecycle.

Examples of practical benefits:

An industrial customer with a maintenance program can expect a PSA mainframe to last more than 10 years, whereas in an unscheduled scenario it is often replaced in 5-6 years.

4.4 Ensuring Regulatory Compliance in Medical or Industrial Use

In hospitals, pharmaceutical factories, or the food industry, the oxygen system needs to comply with standards such as EN ISO 7396-1, US FDA 21 CFR Part 210/211, and others. 210/211. Equipment disrepair can lead to cross-contamination of oxygen, line backflow, control system failure, etc., which can lead to disqualification or safety incidents.

Recommendations:

Develop a maintenance record document that complies with GxP or GMP

It is recommended that the maintenance program be tied to the compliance annual review cycle to ensure that the annual review does not expire!

5.Tailored Solutions and Service Contracts

Customized service not only saves costs, but also provides in-depth understanding of the operation of complex systems.

5.1 Why Site-Specific Maintenance Planning Matters

Oxygen generation system is not a “plug and play” standard, the operation of the equipment is affected by the following factors:

Altitude (affecting intake density and compressor load)

Process oxygen volatility (e.g. medical nighttime oxygen trough vs. Ambient temperature and humidity (affects cold drying system and molecular sieve adsorption efficiency)

Process oxygen volatility (e.g., medical nighttime oxygen troughs vs. industrial oxygen pulse spikes)

Power stability (frequent power failures can damage solenoid valves, PLCs)

Therefore, MINNUO technical team provides each customer with a “scenario diagnostic report” after deployment, according to which the maintenance cycle, spare parts replacement rhythm, and monitoring frequency are determined to maximize the matching of actual scenarios instead of “paper recommendations”.

5.2 Custom Maintenance Kits & Service Scheduling by MINNUO

Based on the equipment model, intensity of use, and the environment where the customer is located, we offer “modular service packages”

Basic maintenance kit: with air filter, oil filter, oil separator, silencer and other consumables, suitable for users with <3,000 hours of operation per year

Enhanced operation kit: with thermal element for cold dryers, solenoid valves, oxygen concentration sensors, PLC maintenance guide, suitable for users with continuous industrial operation

Highland special kit: with special compressor intake regulator kit for altitudes >2,500m

In addition, the service package comes with a visual scheduling calendar, which allows the customer to be automatically alerted to the replacement nodes through monthly planning, reducing the risk of forgetting.

5.3 Remote Monitoring and Predictive Diagnostics

The traditional maintenance model is characterized by “passive repair” and “reactive response only when problems occur”. The “Remote Health Monitoring” system, through the integration of MODBUS communication protocol and PLC acquisition terminal, provides the following capabilities:

Real-time view of oxygen purity, pressure, flow, temperature and humidity, and other key indicators

Abnormal trends in advance warning, such as the flow rate continues to decline → suggests that cartridge clogging may be

Automatically generate operation logs, support the export of reports to third-party audits or hospitals for the record. Support report export for third-party auditing or hospital filing

For large and medium-sized industrial customers, we also provide “24/7 Remote Operation and Maintenance Platform Access Service”, in which dedicated engineers review the operation data once a week and make suggestions for adjustments. These predictive services have prevented major system downtime risks and reduced unplanned equipment downtime by up to 45% at several overseas customers.

Conclusion

Regular service of your PSA oxygen generator is not just a technical necessity—it’s a long-term investment in performance, safety, and reliability. From monthly filter checks to annual component replacements, each maintenance step plays a vital role in maximizing oxygen purity, reducing unexpected downtime, and extending equipment lifespan. Tailoring your service intervals to your operational environment—be it medical, industrial, or remote—ensures your system continues delivering high-purity oxygen consistently and cost-effectively.

If your current maintenance routine feels reactive rather than preventive, now is the time to reassess. Many system failures and compliance issues stem not from equipment defects, but from overlooked service intervals and incompatible maintenance strategies.

At MINNUO, we offer more than just equipment—we provide custom service kits, remote diagnostics, and consultation-based servicing plans tailored to your application and usage intensity. Whether you operate a rural clinic or a high-demand industrial facility, our experts can help you design a proactive maintenance strategy that safeguards both performance and compliance.

Review your service schedule today—and if in doubt, consult MINNUO to build a maintenance program that truly fits your needs.

sales2:+86 17506119168

sales2:+86 17506119168