Pressure Swing Adsorption (PSA) oxygen generators are widely used in medical, industrial, and laboratory applications due to their reliability, energy efficiency, and on-demand oxygen production. At the heart of this technology lies a repetitive process of adsorption and desorption, where molecular sieves—typically zeolite—separate oxygen from atmospheric air. This process requires not only precise control, but also maintain consistently to ensure that performance and purity remain stable throughout the system’s lifecycle. This guide aims to provide a comprehensive roadmap for maintaining PSA oxygen systems effectively and economically.

When maintenance is neglected, the consequences are not just technical—they are financial and operational. A poorly maintained system can experience a rapid drop in oxygen purity, pressure instability, or even complete shutdown. Components like filters, valves, and molecular sieves degrade faster under stress, leading to frequent unplanned downtimes and skyrocketing repair costs. In critical fields such as hospitals or high-volume manufacturing, these risks translate into real-world safety hazards or production losses.

This guide is designed to help operators, technicians, and plant managers understand not only what needs to be done, but why it matters. Whether you’re dealing with early-stage PSA systems or advanced PLC-controlled units, the insights here will help you extend equipment life, minimize energy waste, ensure regulatory compliance, and avoid costly system failures. Read on to learn how proactive maintenance strategies—supported by brands like MINNUO—can be the difference between stable oxygen delivery and unexpected breakdowns.

1.What is PSA Oxygen Generator?

A PSA (Pressure Swing Adsorption) oxygen generator utilizes zeolite molecular sieves to separate oxygen from ambient air. The oxygen generator cycles pressurization and depressurization in twin towers – adsorbing nitrogen and allowing oxygen to pass through. This modular technology is widely used in hospitals, laboratories and industry due to its high efficiency and on-site oxygen supply capability.

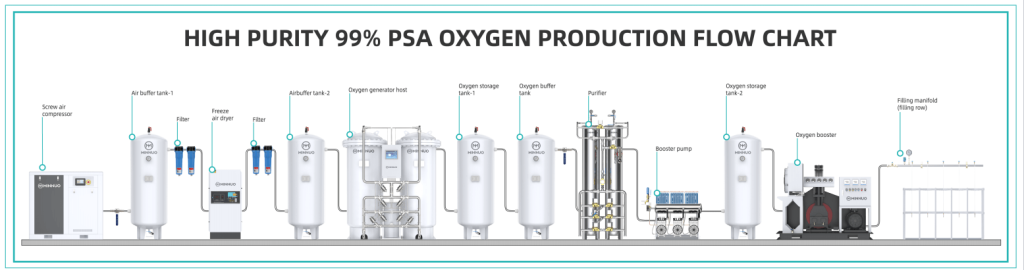

Below is a simplified flow chart of the process:

2.Daily Maintenance Checklist

The following visual and operational checks should be performed every 24 hours and are recommended to be recorded in the inspection log by a trained operator:

2.1 Checking Oxygen Purity

Target range: MINNUO medical models are generally stabilized at 93% ± 3%

Purpose: To confirm that the molecular sieve adsorption is in normal condition and that the oxygen system is operating without any deviation.

Abnormalities: Oxygen concentration consistently falling below the lower limit of the set point may indicate deterioration of the molecular sieve, deviation of the tower pressure, or mixing of unseparated nitrogen gas. Mixing of unseparated nitrogen

Suggestions for operation:

If the reading drops but still operable, please make a record of the trend and be prepared to replace the molecular sieve in advance.

If the reading plummets, it is recommended to shut down immediately to check the system valves or whether there is any air leakage.

2.2 Checking the System Operating Pressure and Flow Rate

Check Points: Main unit outlet pressure gauge, pre/post-tower pressure gauges, and the oxygen flow meter display values.

Purpose: To confirm that the adsorption process and the desorption process are within the design parameter ranges.

Abnormal performance:

System pressure is too high: it may be clogged outlet pipe, poor drainage of buffer tank

Pressure is too low: it may be insufficient air inlet, abnormal air supply from compressor, or faulty valve

Operation suggestions: record the trend of value changes, and pay attention to whether it is accompanied by alarm beeps or fluctuations in air flow

2.3 Drainage: low-point drain of receiving tank, dryer, precision filter, etc.

Purpose: To avoid water accumulation, which may affect the drying state of molecular sieve and adsorption efficiency Operation suggestions: Open the receiver tank, dryer, precision filter, etc. every day. Adsorption efficiency

Operation suggestions:

Open the drain valve every day and observe whether there is milky white or oil-water mixture (may be compressor lubricant infiltration)

Be sure to close the drain port after draining to prevent the system from relieving the pressure.

2.4 Auscultation and Observation: Whether there is any abnormal noise, vibration or leakage

Suggested Inspection Areas:

The main body of the compressor

PSA tower inlet and outlet piping connector

Various solenoid valves area (cyclic action)

Suspicious manifestations:

Strange noises like Abnormal noises such as “clacking” or “hissing” sound persist

The equipment vibrates more frequently than usual

Suggestions: Mark the abnormal area, record the time point and check with a technician as soon as possible to see if it belongs to the maintenance window

2.5 Acknowledgement of Alarms and Indicator Lights

Green light is always on/blinking: indicates normal operation of the system Yellow light: warning signals. Normal operation

Yellow light: warning signal, it is recommended to record the corresponding alarm code

Red light + beep: abnormal system shutdown, you should immediately switch to the backup system (if any)

Operation Suggestions:

Check the alarm panel before and during each operation

If there is an alarm, you should take a photo/screenshot of the record, so as to allow technical support to diagnose it remotely

Additional Suggestions:

Record the core parameters of the oxygen purity, pressure, alarm status, and drainage after each inspection

For hospital users, it is recommended to use a special inspection panel to check the oxygen purity and pressure. For hospital users, it is recommended to use a special inspection form and have it cross-signed by two people.

can be used with remote monitoring module to realize automatic daily inspection reminder (optional for MINNUO equipment).

3. Weekly and Monthly Checkpoints

Weekly Check: Basic Health Monitoring

Oil Level Check (Oil Lubricated Type):

OPERATION: Perform after the compressor has been completely shut down, the system has been relieved of pressure, and the oil temperature has cooled to a safe range. Use a dipstick or sight glass to check that the oil level is within the calibration range (usually between Min and Max).

Cleaning/blowing out the intake filter:

OPERATION: Remove the intake filter element (or cotton/strainer) and use low pressure compressed air (< 0.3MPa) to blow out the dust from the inside to the outside. Seriously clogged or broken cartridges should be replaced promptly (even if the monthly replacement point has not been reached).

PSA Nitrogen/Oxygen Tower Temperature and Pressure Readings Check:

Operation: Under the normal operating condition of the equipment, record the adsorption/desorption pressure, adsorption temperature (usually referred to as tower temperature or inlet/outlet temperature) and other key parameters of each adsorption tower.

Monthly Check: Deep Maintenance and Performance Optimization

Pre-Filter Replacement (if visibly dirty):

Action: Check the pre-filter differential pressure indicator at the air outlet or dryer inlet, if present, or visually determine the degree of filter element soiling. Replace as soon as the differential pressure exceeds the limit (usually indicated by red color) or visual confirmation of severe clogging/oil contamination is obtained, without being bound to a fixed cycle.

Cleaning the Compressor Air Intake Grille and Cooling Fan Filter/Fin:

Operation:

Air Intake Grille: Remove any dust, wicker, leaves, and other debris adhering to the outside of the grille to ensure smooth air intake.

COOLING FAN FILTER (IF EQUIPPED): Remove for cleaning or replacement (refer to unit manual).

Cooler fins: Use a soft brush or low pressure compressed air (pay attention to the direction, avoid blowing backward) to remove the dust and oil accumulated between the fins. Serious oil contamination requires special cleaning agents.

System operation data logging and trend analysis:

Operation: Detailed records for this month:

Total hours of operation.

Peak air consumption and duration.

Deviation of key parameters: e.g. exhaust temperature, operating pressure, dew point (after dryer), oil temperature, PSA tower differential pressure/temperature deviation, etc. from normal values.

Maintenance operation records: consumables replaced (cartridge, oil), amount of oil added, abnormal phenomena found and treatment measures.

Valve and solenoid valve function check:

Operation:

Visual check: Any obvious leakage (oil, gas), mechanical damage, abnormal icing (cold dryer related).

Auditory inspection: When the equipment is running or during manual testing, listen to the sound of valve action to see if it is crisp and powerful, with or without jamming, delay or continuous exhaust sound (possible internal leakage).

Manual Test (if feasible): Under safe conditions (e.g., shutdown or in a specific test mode), manually activate a solenoid or air control valve to see if it is in place and responds in a timely manner.

Check coil temperature: An overheated coil may be about to fail.

4.MINNUO Runtime Maintenance Plan

In order to ensure the long-term stable, efficient and safe operation of the system and maximize equipment life, it is recommended to establish the following refined maintenance mechanism based on the runtime:

4.1 Interpretation of Standard Maintenance Cycle

| Components | Initial Service Recommendations | Recommendations for follow-up service intervals |

| Oil filter | 500 hours | Replacement every 2,000 hours |

| Intake filter | 500 hours | Replacement every 2,000 hours or 3,000 hours |

| Oil-air separator | 500 hours | Replacement every 3,000 hours |

| Compressor oil | 500 hours | Replacement every 3,000 hours |

| Molecular sieve (zeolite) | n/a (related to physical purity) | Replacement at approximately 12,000 to 15,000 hours or when purity deteriorates |

| PLC and oxygen sensor, flow sensor | n/a (ongoing operation) | Replacement annually or calibration or replacement in case of abnormal accuracy |

4.2 Tips for operating environment influencing factors

The applicability of regular maintenance cycles is affected by the following environmental factors, which should be fine-tuned in accordance with the actual site:

High temperature and high humidity environment → shorten the lubricating oil and separator replacement cycle

Area with serious dust/particle pollution → increase the frequency of intake filter checking and replacing

Frequent startups at low temperatures → check the lubrication status regularly and prevent waxing and clogging

Area of unstable voltage → it is recommended that the PLC module be increased Protection module of PLC module or frequent calibration

4.3 Failure prevention maintenance recommendations

| Frequently Asked Questions | Suggested Prevention Strategies |

| Compressor Starting Load, High Running Current | – Regularly clean air intake passages, fan filters |

Check oil quality and oil separator status |

| Outgoing gas contains oil and dust | – Check and replace oil separator core and filter

Ensure adsorbent material is dry and not pulverized |

| Oxygen purity fluctuation, frequent alarms | – Check molecular sieve usage hours

Calibrate oxygen sensor accuracy

Clean residual condensate or dust in tower piping |

| Fluctuating system operation or sudden shutdowns | – Check PLC alarm records

Check solenoid valve action delays, limits Feedback abnormality |

4.4 Establish digital maintenance mechanism

Running hours electronic totalizer linkage reminder: regular reminder of replacement schedule to prevent forgetting.

Maintenance records electronically: each maintenance content recorded to the system, including the operator, time, content, parts replacement.

Two-dimensional code parts traceability system: ensure that the filter element and oil used are genuine products of the manufacturer to reduce the risk of failure.

Common problems and troubleshooting

| Symptoms | Possible Causes | Recommended Actions |

| Decreased oxygen purity | Aging molecular sieve | Replace screen, check tower for leaks |

| High dew point/water vapor | Failed dryer or saturated filter | Replace filter, check dryer circulation |

| Fluctuating system pressure | Failed or leaking valve | Check valves, tighten connections |

| Noisy compressor | Worn bearings or lack of oil | Check lubrication, replace bearings |

| System won’t start up | PLC error or pressure mismatch | Restart controller, check sensors |

5. Real Customer Insights

Case 1|Stability Verification for Heavy Industry

“Our iron processing plant has been running the MINNUO 150Nm³/h PSA unit 24/7 for 9 months.

The predictive maintenance program allowed us to avoid a costly failure – a filter blockage was flagged as an alarm at the 580th hour of start-up. Luckily, we heeded the advice.”

— Daniel H., Maintenance Supervisor, Czech Republic

Analysis Highlights:

Intervention 600 hours in advance by setting pre-alarm thresholds effectively prevents production stoppages.

The combination of the system and the maintenance program strengthens the customer’s control over the pace of operations.

Clear service intervals increase maintenance certainty, and the customer has commented that the system is “more predictable”.

Case 2|High-frequency maintenance feedback in a medical scenario

“We didn’t expect such good support after the sale. The remote team guided our staff through valve logic testing and flow meter commissioning during vacation shifts, which we have now incorporated into our duty roster for daily checks.”

— Chief Engineer, Private Hospital, South Africa

Explaining the highlights:

The healthcare industry requires a high level of system stability, with response time and guidance efficiency being particularly critical.

Duty system + daily inspection = complete microcirculation maintenance mechanism.

Remote commissioning + spare parts pre-stocking mechanism has become the key support for international users to widely accept MINNUO solutions.

Extended customer insight: what do they really care?

| Customer Focus | Solutions provided by MINNUO |

| Avoiding Unplanned Downtime | Setting running hours threshold, configuring alarm function and cycle replacement reminder |

| Prompt After-Sales Response | Overseas customers can get WhatsApp/email + video remote support, completing the initial processing recommendations within 48h |

| Spare Parts Availability | Configuring spare parts packages to be shipped along with the equipment or stocking up on core consumables at the nearest warehouse to shorten the waiting time |

| Data Transparency and Control | Supporting the export of operation records to help users analyze the operation trend and form the health file of the equipment. Provide graphic SOP and remote guidance, customers can complete 80% of the basic maintenance work by themselves. |

| Simple, Trainable Maintenance | Solutions provided by MINNUO |

Conclusion

Good maintenance of PSA oxygen generation systems should not be a reactive approach to deal with failures when they occur, but rather a preventive mechanism that should be integrated into daily management. Through the previous checkpoints (weekly/monthly), uptime maintenance programs and real customer feedback, we have come to a central point: Maintenance is a double safeguard of “cost control + risk management”.

Whether you come from a hospital, a factory or a rural clinic, standardized maintenance can help you obtain a stable supply of high-purity oxygen and reduce the risk of operational fluctuations and unplanned downtime.

MINNUO is committed to providing perfect PSA oxygen/nitrogen systems for customers all over the world, combining early warning mechanisms, standardized spare parts, remote technical support and the accumulation of customer usage data to create a full-cycle service system from installation to operation and maintenance. We not only provide equipment, but also assist customers to build up a “predictable, controllable and optimized” operation rhythm.

sales2:+86 17506119168

sales2:+86 17506119168