In key areas such as medical, industrial and environmental protection, oxygen systems play a vital role – not only in relation to the life support of ICU patients and the combustion efficiency of high-temperature furnaces, but also in influencing the continuous operation of green production processes such as water treatment and waste gas treatment. A stable and efficient oxygen supply system is the core foundation for production and service safety.

However, in the face of a wide variety of oxygen equipment on the market with huge price differences, how to scientifically assess the reliability and applicability of the brand has become a real problem that procurement decision makers urgently need to solve. The brand’s technology accumulation, system integration capability, after-sales service response speed, etc., directly determines the performance of the equipment in the actual application and the long-term cost of use.

In this article, we will take MINNUO oxygen equipment as a research sample, and analyze its ability to land in the three major fields of medical+industrial+special environment from the perspectives of product series, performance, certification, application scenarios, user feedback, etc., and analyze it with the mainstream brands in the market, so that we can help you to establish a clear and practical logical framework of brand evaluation and make a more scientific judgment of model selection.

1.Product Range Overview

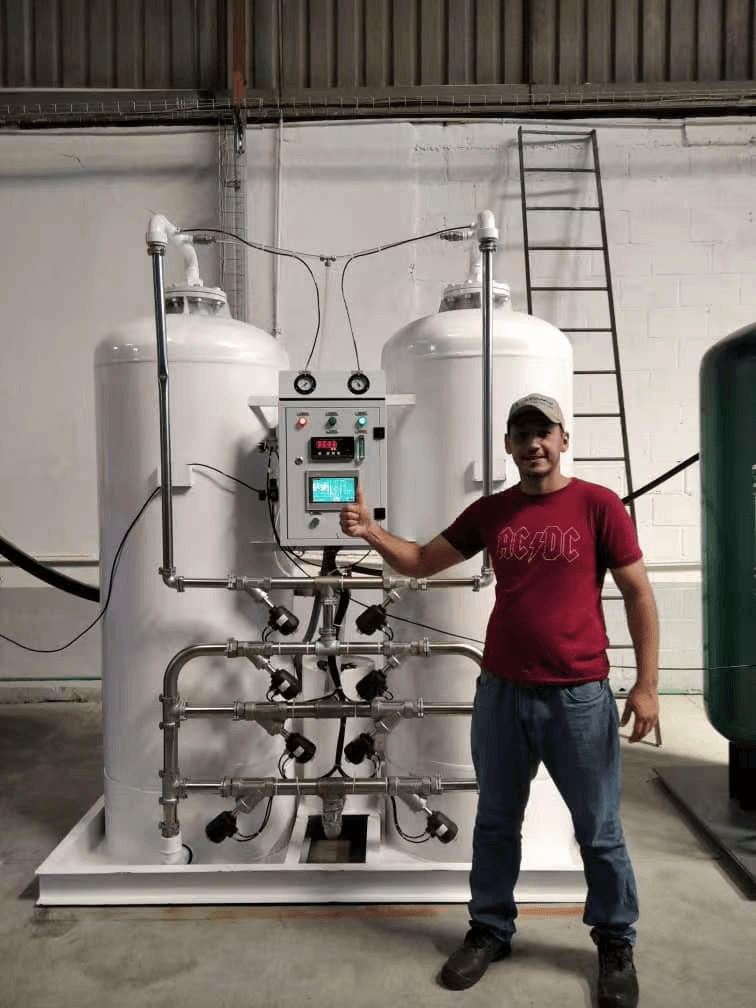

MINNUO has a complete and clear structure of oxygen equipment product system, which can be divided into three series according to the application, covering the diversified needs from medical rescue to industrial application, from fixed site to mobile scene:

Medical PSA Oxygen Generation System

Mainly serves in hospital ICU, operating room, negative pressure ward, community site, etc. It adopts medical molecular sieve adsorbent technology, and stably outputs 93% ±3% of the oxygen concentration. Adopting medical molecular sieve adsorption technology, it has a stable output of 93% ±3% oxygen concentration and meets the medical specifications such as YY/T 0298 and ISO13485. The system supports dual-tower switching, centralized monitoring, oxygen concentration alarm and UPS emergency switching to ensure uninterrupted oxygen supply.

Industrial VPSA / PSA system

Widely use in metallurgy (iron and steel refining), glass combustion, ozone system, water treatment, etc. It supports medium and large flow ranging from 50~3000Nm³/h. VPSA system adopts low-pressure adsorption+vacuum desorption structure, which has low energy consumption and is suitable for long-term high-load operation; while the PSA structure is more compact and is suitable for small and medium-sized continuous oxygen supply occasions. The system supports centralized oxygen supply, remote control and tail gas treatment.

Mobile Oxygen System

includes vehicle-mounted all-in-one machine, box integrated equipment, etc. It is suitable for temporary or plateau application scenarios, such as rescue fleet, field medical point, plateau post, etc. The system is equipped with compressor, buffer tank and oxygen tank. The equipment comes with compressor, buffer tank and touch screen control, and some models support vehicle power supply/generator interface and solar energy replenishment to meet the deployment needs of remote and power failure places.

Comprehensive coverage of model parameters and strong adaptability:

Oxygen purity: 93%, 95%, 99.5%

Flow rate range: 10 L/min ~ 3000 Nm³/h

Power range: 1.5kW~100kW+

Working pressure: 0.3~200bar

Support for non-standard customization capabilities:

MINNUO has rich engineering experience, and can be customized to meet the needs of customers’ environments, including:

Plateau-adapted design (customized air compressor unit)

Voltage/frequency adjustable module (supporting 220V/380V/50Hz/60Hz)

Special material anti-corrosion structure (adapted to high humidity/salt spray working conditions)

Intelligent remote control interface (supporting PLC/485/Modbus)

2. Performance Evaluation

The performance evaluation of oxygen equipment should not be confined to the theoretical parameters, but should also take into account the stability of actual operation, energy consumption, maintenance frequency and the degree of intelligence to build a scientific and comprehensive evaluation system. The following is an analysis of the performance of the MINNUO oxygen system in the core performance dimensions:

Oxygen purity stability

Whether the equipment can continue to output oxygen concentration that meets the standard after a long period of operation is one of the basic indexes that medical and industrial users are most concerned about.

MINNUO system adopts ±0.5% accuracy on-line concentration monitoring, which can maintain the concentration in the range of 93%~95% (PSA) or 95%~99.5% (VPSA) even after long-term operation.

The system is equipped with the function of abnormal oxygen concentration alarm + automatic switching of backup gas source, which effectively reduces the risk of fluctuations in purity for end-use.

Comparative Analysis of Energy Consumption

Compared with traditional PSA or similar equipment in the market, MINNUO’s highly recommended VPSA series shows significant energy consumption advantages in medium and large flow rate scenarios:

Adsorption tower with low-pressure operation + vacuum resolution design, the overall energy consumption per unit of gas production is less than 0.45kWh/Nm³ (some models).

Variable frequency blower and energy-saving vacuum pump can be configured to save energy and adjust speed according to real-time oxygen consumption, which is suitable for electricity price-sensitive areas (e.g. Middle East/Southeast Asia).

Operation Stability and Maintenance Frequency

System reliability directly affects the economy and operation risk of long-term use:

Compressor/molecular sieve module design life ≥ 3 years, molecular sieve does not need to be replaced under normal use conditions;

Long maintenance cycle: compressor/air-cooled module only needs 4000~6000 hours of maintenance;

Fewer wearing parts, easy maintenance, especially suitable for remote areas or lack of technicians on-site use.

Customer feedback shows:

In the Middle East, Africa and other high-temperature and high-humidity areas running more than 8000 hours/year, the system is highly stable, basically no fault shutdown records.

Intelligent Control Capability

Whether the equipment supports remote management and data linkage is an important concern for modern users. MINNUO has mature solutions in this regard:

Control system: integrated PLC + touch screen HMI, supporting multi-language interfaces, permission grading;

Data protocol: compatible with SCADA, Modbus, 485, 4-20mA, TCP/IP, can be accessed to the hospital HIS system or factory MES; Remote Management Data protocol: compatible with SCADA, Modbus, 485, 4-20mA, TCP/IP, and can be connected to hospital HIS system or factory MES;

Remote management function: remote parameter configuration, alarm linkage, and cloud view of operation data, which is convenient for centralized operation and maintenance and remote debugging support in different regions.

3.Certifications and Compliance

Oxygen system as a key equipment in medical and industrial fields, its compliance not only relates to whether the equipment itself can be put into use safely, but also is an important foundation for users to smoothly pass customs acceptance and docking international standards.MINNUO has solid system and certification achievements in this dimension, which can provide full endorsement for all kinds of project landing.

Medical grade certification guarantee (applicable to hospitals, ICUs, community sites)

CE certification: conforms to the EU Medical Device Directive, representing that the product meets the safety and performance standards of the EU market access;

ISO 13485: an internationally recognized quality management system certification for medical devices, emphasizing process control, risk management, and regulatory compliance, which is the core qualification for hospitals’ bidding and purchasing;

YY/T 0298: China’s industry standard for “medical molecular sieve oxygen generating equipment”, which is the key indicator for most of the audits in medical places.

✅ Applicable scenarios: government procurement projects, tertiary hospitals expansion, mobile ambulance support, emergency center system renovation, etc..

Industrial grade safety compliance (applicable to chemical/gold cure/glass/environmental protection industries)

PED (Pressure Equipment Directive): EU Pressure Equipment Directive, applicable to vessel systems with working pressure greater than 0.5 bar, a mandatory entry threshold for the export of oxygen systems to Europe;

ASME (American Society of Mechanical Engineers) U Mark: a globally recognized Pressure Vessel Manufacturing License, applicable to export to North America and use of high pressure oxygen/hazardous media environment.

MINNUO industrial oxygen system core modules such as adsorption tower, buffer tank, vacuum tank can be customized to meet PED/ASME requirements, to meet the project acceptance needs of petrochemical, marine, pharmaceutical and other highly regulated fields.

International export capability certification

Regional adaptability verification: according to the Middle East, Africa, Southeast Asia and other different climatic zones to provide the appropriate anti-corrosion, dustproof, anti-temperature and other designs;

Third-party reports issued: support SGS/BV/TÜV/CIQ and other international inspection agencies to issue performance tests or certificates of origin;

Complete information to support customs clearance: the equipment is accompanied by standard export documents such as Chinese and English instruction manuals, electrical drawings, certified originals, quality assurance cards, packing lists and so on. Complete documentation to support customs clearance: the equipment comes with English and Chinese manuals, original certification drawings, warranty cards, packing lists and other standard export documents.

✅ Up to now, MINNUO has exported to more than 20 countries and regions such as Southeast Asia (Myanmar, Indonesia), Middle East (Saudi Arabia, UAE), Africa (Somalia, Algeria), etc., accumulating rich experience in project landing and local benchmarking ability.

4. Application Scenarios

In the global oxygen system deployment practice, MINNUO provides PSA/VPSA products have been widely used in medical, industrial, environmental protection and emergency response and other scenarios. The following is an in-depth description of a representative case:

Medical Case: Oxygen Supply System for Public Hospitals in the Middle East

Project Background: A national general hospital located in a Middle Eastern country, which used to rely on bottled oxygen supply, with transportation risks and fluctuations in oxygen source.

Configuration plan: Deploy 10~50Nm³/h PSA medical oxygen system with dual-tower switching, online monitoring of oxygen concentration, and automatic switching module for backup bottles.

Operation effect:

Oxygen purity is maintained at 93%±3% with a fluctuation range of ≤0.5%

The system has been in continuous operation for more than 16 months, with no sudden shutdowns during the period

Feedback from the customer: “The feedback from patients is good, and the system stability is highly recognized by the medical staff of the emergency department, and the project is considering expanding the ICU area for oxygen use.”

Industrial Case: High-temperature Combustion Auxiliary Project for Glass Manufacturing Factory in Southeast Asia

Customer Background: The customer is a well-known glass manufacturer in Southeast Asia, which needs continuous oxygen supply to improve the combustion efficiency of the kiln.

Deployment: MINNUO VPSA four-tower system with a design flow rate of ≥500Nm³/h, combined with an energy-saving vacuum pump and oxygen buffer tank.

Results:

More uniform combustion flame, 8% increase in glass yield

18% savings in electricity consumption compared to the original bottled oxygen solution, with annual operating costs reduced by more than US$50,000

Customer feedback: “The system is stable and reliable, and requires only routine maintenance for one year of operation, which makes it suitable for our high temperature and dusty production environment”.

Environmental Case: Oxygen Distribution for Ozone System in European Customer’s Municipal Water Treatment Plant

Project Background: A Scandinavian municipal water plant upgraded its ozone disinfection module, which required high oxygen stability and purity (≥95%).

Solution Configuration: Customized MINNUO PSA system, supporting 0.5bar low pressure smooth output, combined with proportional valve + flow control feedback system.

Project Highlights:

Oxygen concentration fluctuates less than 1% per year

The whole system is integrated into the existing ozone master station without the need for an additional server room

Customer Comments: “The system was installed and commissioned quickly, and it meets our EU PED compliance requirements, which makes it a trustworthy green gas solution.”

Mobile Scenario: Oxygen Supply System for Post-Disaster Emergency Points in Africa

Background: The project targets a post-flood refugee settlement in Central Africa, where medical resources are strained and power supply fluctuates.

Solution: Deploy vehicle-mounted all-in-one unit (MINNUO Mobile Oxygen Station) with built-in PSA generation system + UPS module + diesel emergency power generation.

On-site effect:

Each unit outputs 20Nm³/h of oxygen stably every day, supporting 15 beds’ oxygen consumption

The system is equipped with GPS positioning and remote monitoring to ensure uninterrupted oxygen supply

Customer comment: “It can still operate without network and power grid, which greatly improves the efficiency of the frontline diagnosis and treatment.”

5. Customer Feedback

MINNUO oxygen systems are in operation in hospitals, factories and government projects in many countries around the world, and customer feedback is generally positive, especially in terms of system stability, after-sales response and flexibility of customization:

Medical Customer Feedback:

Feedback from tertiary care hospitals in the Middle East: “The system operates reliably, with only regular cartridge replacements, which is a light burden on maintenance staff. Equipment alarms and automatic switching are very timely.”

A national CDC in Asia said: “During the peak of the epidemic, MINNUO’s oxygen system operated continuously without failures, and the after-sales engineers responded remotely in a timely manner, which was an important guarantee for our respiratory ward.”

Industrial Customer Testimonials:

A glass company commented, “The VPSA solution saves energy significantly, the equipment configuration is flexible and supports customization according to high temperature and dusty working conditions, which greatly optimizes our energy costs.”

Feedback from a chemical enterprise in South America: “Supporting off-site module expansion, we are the first to use Chinese products, and the overall cost-effectiveness far exceeds that of European and American brands.”

Word of mouth from overseas customers:

Southeast Asian water treatment customer said: “MINNUO provides SCADA interface and overseas remote commissioning service, with no language barriers, clear payment and guaranteed delivery cycle.”

The technical officer of NGO project in Africa said, “The system can be deployed quickly, the oxygen can be supplied after commissioning, and it can support the operation of local non-professional team.”

6.Pros and Cons

Main advantages:

Product line covers all scenarios: there are supporting programs for medical, industrial and mobile fields, and all products are based on standard modular structure, which is easy to expand and rapid deployment.

Stable performance and strong ability of continuous oxygen supply: precise control of oxygen concentration, supporting 7×24 hours continuous operation, suitable for large-scale centralized oxygen supply needs.

Outstanding intelligent control: Integrated PLC+SCADA+Modbus interface supports remote monitoring, early warning linkage, equipment status uploading, and can be docked with hospital HIS and factory MES systems.

Mature international delivery capability: CE, ISO13485, PED, ASME and other certifications are complete, suitable for export projects.

Fast after-sales response: engineering team supports global deployment, remote diagnosis and video debugging, suitable for overseas operation and maintenance inconvenience scenarios.

Possible limitations:

Slightly higher starting investment: Compared with some domestic low-end brands, MINNUO has slightly higher costs in material selection and system integrity, suitable for projects with higher requirements for performance and reliability.

Extreme scenarios require options: such as plateau (>3000m), high-temperature wetland areas, need to be equipped with another booster, cooling towers or reinforced cabinets, it is recommended to plan ahead of the power supply and heat dissipation conditions.

Customization for mobile use: If the vehicle/all-in-one system needs to work continuously for more than 12 hours, it needs to be equipped with a high-capacity UPS or a backup power generation system.

Conclusion

To summarize, MINNUO oxygen equipment has built up a good reputation among users in many key fields such as medical, industrial and environmental protection, thanks to its stable performance, excellent intelligent control capability and engineering process in compliance with many international certifications. It is especially suitable for hospitals, enterprises and organizations that have continuous oxygen supply needs and focus on long-term stable operation and compliance safety and security.

We do not recommend ignoring operating costs and system reliability in pursuit of a low initial price. Compared with some products that only meet the standard of “working”, MINNUO focuses on providing a total solution in the dimensions of “energy-saving efficiency + engineering adaptation + after-sales response + remote diagnosis”.

If you are looking for a stable, energy-efficient, remote-supported and medically certified oxygen system, take a look at MINNUO’s customized PSA/VPSA solutions – it’s one of the most important brands to consider.

sales2:+86 17506119168

sales2:+86 17506119168