In extreme oilfield operating conditions, the protection design of a PSA Nitrogen Generator must center on multi-stage filtration systems and enhanced thermal management. Effective protection strategies include using self-cleaning air filters to block dust from entering the compressed air system, employing containerized micro-positive pressure technology to isolate harsh external environments, and configuring redundant radiators with industrial-grade explosion-proof HVAC systems to handle temperatures exceeding 45°C. By implementing an integrated “Physical Isolation + Active Cooling + Precision Monitoring” solution, the lifespan of Carbon Molecular Sieves (CMS) can be extended by over 30%, ensuring stable nitrogen output in complex climates.

1. Multi-Stage Intake Filtration Systems in Dusty Environments

The intake air quality of a PSA Nitrogen Generator directly dictates the lifespan of the Carbon Molecular Sieve (CMS). In oilfields prone to frequent sandstorms, standard industrial filters are insufficient.

- Primary Protection: Inertial Cyclone Pre-filter. Utilizes centrifugal force to settle large sand particles, reducing the load on downstream filter elements.

- Secondary Protection: Self-Cleaning Air Filter. Uses timed compressed air back-pulses to prevent filter cartridges from clogging rapidly during heavy dust storms.

- Tertiary Protection: High-Precision Coalescing Filters. Ensures that compressed air entering the PSA towers maintains a residual oil content of $\le 0.01\text{mg/m}^3$ and a dust particle size of $\le 0.01\mu\text{m}$.

2. Thermal Management Strategies for Extreme Heat

High-temperature environments reduce air compressor efficiency and accelerate molecular sieve aging. When ambient temperatures exceed 45°C, conventional cooling methods often fail.

- Increased Radiator Redundancy: Increase the cooling surface area by 30%–50% over standard designs.

- Independent HVAC Rooms / Containerization: Utilize insulated containers (e.g., polyurethane sandwich panels) equipped with industrial-grade explosion-proof air conditioning.

- Exhaust Duct Optimization: Ensure that hot air from the compressor is vented directly outdoors to prevent “thermal short-circuiting” (recirculation of hot air).

3. Protection Comparison: Standard vs. Enhanced (Oilfield Grade)

The following table compares a standard PSA Nitrogen Generator with a protective solution optimized for extreme oilfield environments:

| Key Component | Standard Industrial Config | Enhanced Oilfield Protection (Recommended) | Expected ROI Impact |

|---|---|---|---|

| Intake Filtration | Single-stage paper element | Cyclone pre-filter + Self-cleaning secondary stage | 60% reduction in filter replacement costs |

| Cooling System | Air-cooled (Ambient < 40°C) | Enhanced air-cooling + VFD forced exhaust | Prevents high-temp shutdowns; guarantees output |

| Enclosure Rating | IP54 | IP55/IP65 (Explosion-proof & fully sealed) | Extends electrical component life by 3–5 years |

| CMS Compaction | Cylinder compaction | Dual Cylinder + Spring auto-compensation | Prevents CMS pulverization due to sand/vibration |

| Instrument Protection | Exposed installation | Stainless steel junction boxes + Sunshades | Lower instrument failure rate |

4. Key Steps for Implementing Protection Design

Environmental protection for a PSA Nitrogen Generator follows a logic of “External Isolation to Internal Optimization.”

- Environmental Survey: Record historical peak temperatures, prevailing wind directions, and peak dust concentrations at the site.

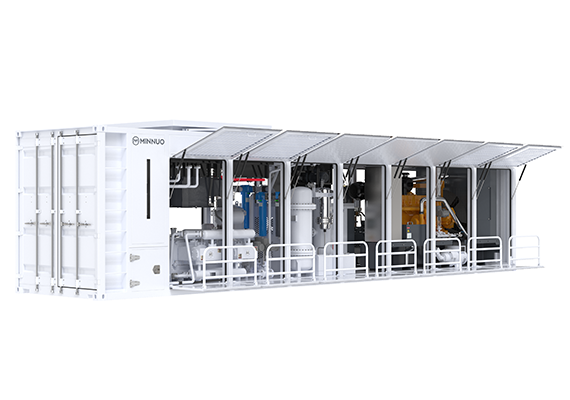

- Containerized Integration: Integrate the PSA unit, compressor, and air tanks within a customized 20/40ft container.

- Positive Pressure Ventilation: Maintain a micro-positive pressure inside the container to prevent dust ingress through gaps.

- High-Temperature Lubricants: Use synthetic high-temperature oil for compressors to prevent oil emulsification or coking.

- Real-time Dew Point Monitoring: Install online dew point meters to automatically trigger alarms or shut down the system if moisture levels exceed limits (signaling cooling/drying failure).

5. Frequently Asked Questions (FAQ)

Q: Why does high temperature affect the gas production of a PSA Nitrogen Generator?

A: According to the Ideal Gas Law $PV = nRT$, rising temperatures decrease air density, altering the oxygen content per volume of compressed air. Additionally, the adsorption efficiency of molecular sieves drops significantly at high temperatures.

Q: How often should filters be cleaned in high-dust areas?

A: Industry experience suggests 2,000 hours for standard regions. However, during oilfield sandstorm seasons, check pre-filters every 200–500 hours or follow the differential pressure gauge indicators.

Q: How much do these protective designs increase the cost?

A: Initial investment typically increases by 15%–25%. However, considering that a single day of unplanned downtime in an oilfield can cost tens of thousands of dollars, the investment is usually recouped within 6–12 months through maintenance savings and production security.

Q: Why focus on PSA Nitrogen Generator standards when discussing nitrogen units?

A: Both rely on the same Pressure Swing Adsorption principles and share similar pretreatment systems (compression, filtration, cooling). Understanding high-standard protection for oxygen units (e.g., oil-free processing, stricter explosion-proofing) helps improve the design redundancy of nitrogen systems.

Q: What should I do if nitrogen purity drops in high temperatures?

A: This occurs because the kinetic selectivity of the molecular sieve decreases as temperature rises. The solution is to increase the radiator area or the capacity of the refrigerated dryer. During the design phase, “performance derating” calculations based on $45^\circ\text{C}$ extremes are mandatory.

Q: Are sand-proof louvers actually effective?

A: Extremely. Specially designed sand-trap louvers capture large particles and allow them to slide out. Combined with internal positive pressure, they effectively block dust from reaching sensitive solenoid valves.

Conclusion

For high-temperature, high-dust oilfield environments, protection design is not just “adding a cover”—it is a system engineering feat involving fluid dynamics, thermal management, and materials science. By utilizing the combination of “Multi-stage Filtration + Positive Pressure Container + Enhanced Cooling,” you ensure robust operation in the harshest climates.

If you are planning an oilfield nitrogen project, it is recommended to conduct a third-party assessment of site environmental data first. You may contact Minnuo to provide a Draft Equipment Thermal Load Calculation Report tailored to your specific geographical coordinates.

The author, Engineer Li, has over 15 years of experience in industrial gas separation and oilfield surface engineering. He has led numerous nitrogen injection and recovery projects in the Middle East and Northwest China deserts and is an expert in equipment selection for deep-sea and desert extreme environments.

sales2:+86 17506119168

sales2:+86 17506119168