Whether in hospitals, factories or remote project sites, equipment alarms often come suddenly, the user’s greatest fear is not a machine failure, but “do not know what the alarm means”, worried about “is not to shut down”, and even more do not know “Should I handle it myself”. This makes many non-technical people feel anxious when faced with a red light, buzzer or fault code, or even fall into misuse and misjudgment, which can lead to more serious problems.

The core of this guide is to help users build up “beginner troubleshooting confidence” and no longer be intimidated by complex codes such as “E1, F3, red light blinking”, etc. We will systematically explain the meaning, type and processing sequence of common alarm signals, and teach you how to carry out the first round of troubleshooting based on visual cues, audible alarms, and control panel prompts, so that you can “judge the level of the problem, and distinguish between repairable and unrepairable”.

Mastering these basics is not complicated, you do not need to become an expert, but as long as you can read the lights, listen to the sound, check the code, adjust the record, you can make the right judgment in the first time, reduce waiting costs, protect the stability of the system. Now, let us start from the understanding of the alarm color and code type, to take you out of the “can not read the panic” predicament.

1. Understanding Alarm Indicators & Fault Code Categories

Reading what the equipment is trying to “tell you” is the first step in troubleshooting.

Modern oxygen systems are not only highly automated, but also have a variety of fault indication mechanisms. These can range from colorful lights and audible alarms to digital fault codes and PLC logs. Understanding what they mean and what they do can help pinpoint problems and avoid misjudgments.

Visual signals

are usually red (alarm), yellow (warning) and green (normal operation).

Purpose: To help the site staff without viewing the screen can also be the first time to determine the status of the equipment.

Red light is always on: indicates that the equipment has detected a serious fault (such as low purity, abnormal pressure)

Yellow light is flashing: most of the early warning (such as sensor drift, valve delay)

Green light is constantly on: the system is running normally, no need to intervene

Operation Suggestions:

If the red light is constantly on, please do not force to reboot, should be according to the control panel prompts to check one by one.

AUDIO ALARM

A buzzer sounds, usually accompanied by a flashing light or LCD code. There are intermittent (alert) and continuous (alarm) types.

Intermittent beeping: such as water level warning, cartridge pre-clogging

Continuous beeping: such as system emergency stop, sudden pressure drop, low purity

Response strategy:

First time ringing: check the screen or fault indicator panel to confirm the cause of the alarm

Continuously ringing + red light: according to the emergency stop procedure, do not force to run

Numeric/alphabetical fault codes

Modern PSA systems often display E, F, C fault codes through the panel:

| Category | Example Codes | Meaning |

| Category E (Error) | E01-E99 | usually represents abnormal system operation or quality problems, such as low purity, high humidity, etc. |

| Category F (Fault) | F01-F30 | Abnormalities in mechanical or electrical components, such as valves not switching, abnormal solenoid coils |

| Category C (Communication) | C10-C99 | Communication failures, control modules responding to time-outs, PLCs disconnected from sensors |

Tips: MINNUO control panel built-in code description document, can be accessed through the “Help” menu; recommended to paste a Chinese and English alarm comparison table on the inside of the operating box door, so that operators can easily judge the first time.

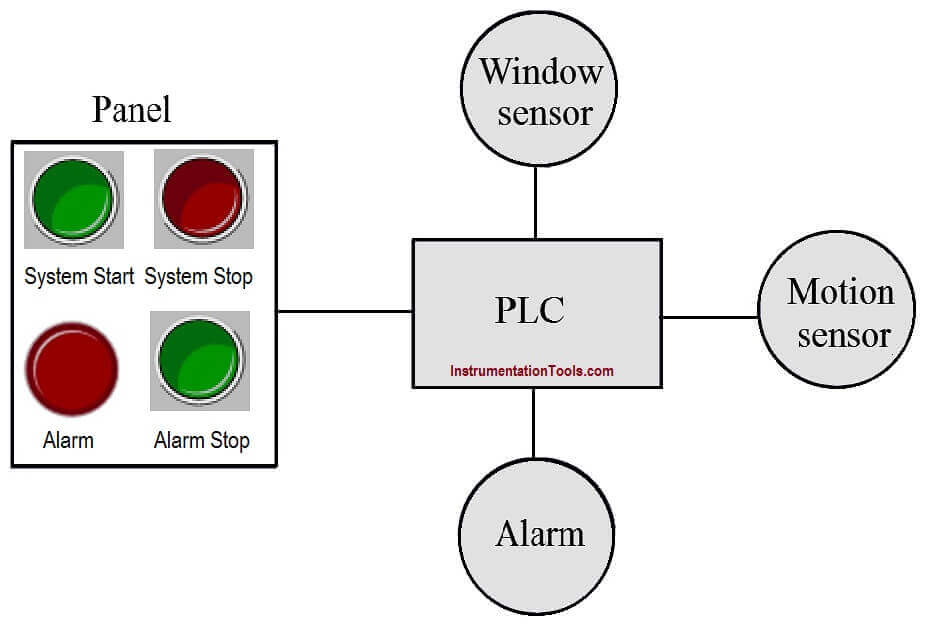

System Log / PLC Alarms

For screened models or networked control systems, alarm records will be stored in the internal PLC, supporting export and query.

Highlights:

Retains hundreds of recent alarm records

Displays fault time, duration, and processing status

Helps analyze the root cause of repeated alarms (e.g., repeated alarms for the same valve → fatigue aging)

Suggested Practices:

Export alarm logs for archiving every time maintenance is performed

Use “Alarm Frequency Sorting” to identify potential weaknesses

2.Top 10 Most Common Error Codes & Their Meaning

Common codes summarized for MINNUO and generic PSA models

| Fault Code | Alarm Meaning | Possible Cause | Immediate Action |

| E01 | Low oxygen purity (<90%) | Saturated sieve, dirty filter | Check purity sensor, replace filter |

| E02 | High outlet pressure | Valve stuck, blocked pipeline | Inspect relief valve & outlet line |

| E03 | High humidity in intake | Air dryer fault or desiccant exhausted | Check dryer, replace cartridge |

| F05 | Compressor overheat | Intake clogged, oil low, ambient hot | Improve ventilation, check filters |

| F09 | No tower switching detected | Solenoid fault, PLC timing error | Test valve coil & control logic |

| C11 | Power supply unstable | Voltage fluctuation or wiring issue | Check input voltage and connectors |

| C20 | Sensor error (O2 or pressure) | Drifted or unplugged sensor | Recalibrate or reconnect sensor |

| F10 | Emergency stop triggered | Manual E-stop or cover opened | Check safety interlock switch |

| F15 | Auto-drain failure | Drain valve blocked or actuator stuck | Clean or replace drain valve |

| E99 | General system error | Mixed fault condition | Run system diagnostics, call support |

3. Step-by-Step Troubleshooting Logic Tree

Teaching you to use structured thinking to identify the root cause of a problem instead of the “blind operation + reboot method”.

When an oxygen system alarm occurs, the operator’s first reaction is often to “reboot and try”. However, in modern PLC control systems, an incorrect reset may cover up the problem or even cause a second alarm. Through the following five-step logical investigation method to help you establish a fault judgment thinking framework to avoid panic and misuse.

✅ Step 1: Determine the type of alarm

Classification identification is the first step in localization.

Red light continuously on + beeping = Serious fault

Yellow light flashing + intermittent sound = Operational but with hidden problems

LCD display fault code = Need to be analyzed with the manual

Purity monitoring alarm ringing = Possible sensor problem or aging of the adsorption system

MINNUO equipment supports a multilingual interface to display the type of alarms and the cause of the prompts, which helps non-English speakers to understand the meaning.

✅ Step 2: Confirm fault codes and display clues

Decode + Auxiliary evidence to avoid misjudgment.

Check the alarm codes on the control screen (e.g. E05, F07)

Note whether there are any secondary clues (e.g. “VALVE FAIL” or “LOW O₂”) accompanying the alarm.

See whether there are any other fluctuations in the indicators (e.g. drop in flow rate, rise in temperature, etc).

Case tip:

If F03 + “Purity < 87%” appear at the same time, prioritize checking the status of the cartridge and the molecular sieve instead of replacing the sensor immediately.

✅ Step 3: Check the latest maintenance log

Checking the recent service log is one of the most overlooked but effective steps.

Has the filter cartridge been changed just recently? → Is the genuine product being used?

Is the last calibration past the recommended cycle?

Have alarms also appeared in the last few days? Has the frequency increased?

Suggested tool:

Logs can be exported through the system PLC logging interface, or with an Excel sheet or a cloud-based maintenance app (e.g. the Log Assistant applet provided by MINNUO).

✅ Step 4: Inspection of Suspicious Components

Lock out the alarm module and perform a physical inspection.

| Alarm type | First Component to Check |

| Low purity | Molecular sieves, sensors, dryer outlet humidity |

| Low pressure | Pressure gauges, buffer tank drain valves, compressors |

| Delayed switching | Solenoid coils, power supply wiring, PLC delay logic |

| Frequent beeps + red light | Communication disconnect, unstable power supply, sensor failure |

Check points:

Unscrew the cartridge → check whether it is discolored and black

Open the control cabinet → see whether there is a loose jumper

Unplug the sensor cable → whether the contact is loose

✅ Step 5: Reset if resolved, upgrade if not resolved

Do not reset indiscriminately, and make sure that you have confirmed that the problem has been solved before resetting.

After checking, you can try to clear the alarm manually (through the control panel “ALARM RESET”)

If the alarm is raised again and the content is the same, you should immediately contact a professional engineer to intervene

Do not repeatedly force the reset operation to avoid the system misjudged as “abnormal normalization”, resulting in subsequent non-alarm

4. When to DIY vs. When to Call Support

Teaches you to determine which alarms can be resolved on-site and which you must call for immediate assistance.

During the use of PSA oxygen generating equipment, operators are often faced with two extremes: either they “fix everything themselves” or “they are afraid of breaking down if they move”. But in fact, the key to stable operation of the equipment is to judge the level of failure and distinguish the authority to deal with it.

✅ Problems that can be handled by yourself (field maintenance level)

These faults generally belong to the consumables alarm or simple external anomalies, with a clear and visible physical phenomena, you can refer to the instructions for troubleshooting, does not involve the system program or the depth of the electronic control:

| Failure manifestation | Suggested Actions |

| Drain failure, buffer tank water accumulation alarm | Check the automatic drain valve, manually drain if necessary; clean the drain port |

| Slight fluctuation in purity <5%, no shutdown triggered | Check the pretreatment cartridge for blockage, reset the sensor and observe the changes |

| Filter cartridge alarm | Remove the old cartridge to check the level of contamination, replace with a spare part of the same type |

| Air compressor temperature alarm but not over the limit | Check the ventilation, clean the air inlet and the oil level; avoid overloading |

| Localized beeping + yellow light blinking | Mostly belongs to the early warning level, you can try to reset it once after observing PLC recordings |

Tips:

The MINNUO system supports a graphical alarm module that displays a “reset/manual check” status indication.

It is recommended to record the alarm number + time of operation for each reset to facilitate follow-up.

❌ Problems that are not recommended to be handled by yourself (professional support level)

If any of the following situations occur, please shut down immediately and contact the support team to avoid damage to the control system or triggering an emergency shutdown by mistake:

| Performance | Dangerous reasons |

| Control screen black screen/program stuck | PLC program may be damaged, misoperation is easy to trigger program abnormalities |

| Electrical short circuit, abnormal current trip | involves relays, power modules and other high-voltage components, non-professionals do not touch |

| System continuous false alarm (error code repeatedly) | communication failures or damage to the main control board, you must use a special diagnostic tool to troubleshoot the |

| Alarm code can not be recognized (e.g., E98, F99, etc.) | indicates that the non-generic error, you must check the PLC bottom of the technical port of the logs |

| LCD flashes/cannot enter the setting interface | unstable voltage or the human-machine interface touch module is damaged |

MINNUO supports 48-hour remote diagnosis or on-site service (depending on the region). It is recommended to provide the following information in the first instance:

Model number of the equipment + screenshot of the alarm code

Last maintenance record

Operating environment (temperature and humidity, power supply with or without UPS protection, etc.)

Safe shutdown procedure in case of an emergency

In case of alarms that cannot be confirmed and that involve a persistent drop in purity, electrical anomalies, strong noises, etc. it is recommended to do the following Emergency Response:

Immediately close the air inlet and oxygen outlet valves in front of the main power supply.

Press and hold the emergency stop button (if available) and cut off the main power supply.

Mark the scene and notify the technical department or supplier.

Prohibit repeated restart attempts to avoid repeated voltage shocks to the main control board.

Retain the alarm record and alarm interface to facilitate remote diagnosis by support engineers.

5. Preventive Measures to Reduce Alarm Frequency

Reducing alarms does not depend on “ignoring”, but on daily scientific operation and maintenance.

According to the statistics of MINNUO Customer Service Center, more than 70% of the alarm problems are related to improper operation and maintenance habits rather than the quality of the equipment itself. Through the following specific preventive measures, you can significantly reduce false alarms, frequent alarms, and extend the service life of key components.

5.1 Regularly replace filter cartridges and desiccant

Clogged filter cartridges are the number one cause of increased alarm frequency, especially in high humidity and dusty environments.

Recommendations:

Replace the coarse filter (pre-filter) every 2000-3000 hours

Replace the fine filter/oil mist filter every 4000-6000 hours

It is recommended to replace or regenerate the desiccant (e.g., silica gel or activated alumina) every 6-12 months

Tip: Set the cartridge differential pressure indicator threshold warning to detect the clogging trend in advance.

5.2 Maintain Good Ventilation and Voltage Stability

Overheating andvoltage fluctuations are important causes of PLC crashes and frequent sensor alarms.

Recommendations:

Ensure ≥1 meter of ventilation space around the compressor and electronic control cabinet.

Configure the system with a UPS power supply or a voltage regulator to avoid voltage dips.

Increase ventilation or air conditioning to assist with cooling in summer when the ambient temperature is >35°C.

⚡ Tip: Mains voltage excursions of ±10% can affect the response of the touch screen and solenoid valves, so it is recommended that you configure a voltage logger.

5.3 Calibrate the sensors regularly to avoid false alarms.

Common false alarms:

Low oxygen concentration but normal measurement

Pressure fluctuation but normal air path

Recommendation:

Calibrate the sensors of oxygen concentration, voltage, flow rate, etc. every 6-12 months.

Use the manufacturer’s original or recommended standard calibration tools.

After calibration, record the “Calibration time + Calibration reference value” for subsequent comparison with MINNOVA. After calibration, record the “calibration time + calibration reference value” for subsequent comparisons.

The MINNUO system is equipped with a “sensor calibration reminder” module, which can be set to remind you of the hourly timer.

5.4 Establish a knowledge base for recording and handling alarms

Many enterprises report the same errors every year, but do not record how they were solved in the previous one, thus wasting a lot of time on repeated investigations.

Suggestions:

Use Excel or CMMS to record the alarm number, processor, cause and solution

Classify and file the alarms into three categories: “False alarms / can be solved on site / must support processing”

Regularly train operators to browse through the history of the alarm processing process

MINNUO can provide “Alarm Log Template” and “Typical Trouble Code Handling Manual” to help build the knowledge management system.

Hands-on reminder: Abnormal alarm frequency = warning signals of hidden problems.

| Performance | Possible hazards | Recommended actions |

| The same alarm repeats every week | Aging filter element, sensor drift, parameters not updated | Replace spare parts + Check setup parameters |

| Multiple alarms on the same machine but running normally | PLC program cache abnormality, power supply instability | Restart program + Measure voltage fluctuations |

| Sudden increase in “Purity Alarms” in logs | Dryer failure, molecular sieve degradation | Check dew point of compressed air + Observe adsorption tower switchover time |

6. MINNUO Support: What We Offer Beyond Equipment

Buying equipment is not the end, it’s the beginning of support.

The biggest anxiety for many of our customers lies not in the equipment itself, but in:

Don’t know how to read the code when you encounter an alarm?

Can’t quickly determine the cause of downtime?

When there is a shortage of spare parts, the delivery time is too long and recovery is delayed?

MINNUO provides a complete set of “post-delivery service ecology” to help customers realize the combination of self-help + professional + rapid response in the whole cycle of use.

Multi-language document support: Don’t let language be a barrier

User manuals, fault code descriptions, alarm light meaning documents, support for Chinese/English/French/Spanish/Arabic and other multi-language versions

can provide “factory training PPT” or “first-time use of frequently asked questions card”

all documents are All documents are in PDF electronic + printable format, easy to post on site or use in multiple positions

✅ Practical example: South African customer found desiccant clogging problem on site in 3 minutes by using MINNUO Arabic version of the alarm table, no remote support required.

Remote diagnostic assistance by engineers: not delivery, but online at any time

Support remote video guidance (e.g. WhatsApp, Zoom, WeChat)

Response time for technical problems < 6 hours (working days)

Alarm screenshots + parameter readings = guidance on judgment logic formulas

✅ Example: Alarm F7 appeared → customer demonstrated through video → MINNUO technician judged it as sensor drifting → guided customer to local Re-calibration, to avoid mistaken replacement

can also be customized “free annual remote review after one year of use” service.

Spare parts recommendation package: eliminate “can’t buy” anxiety

According to the equipment configuration of the prefabricated list of recommended spare parts (including the original factory number + annual frequency of use)

Including: sensors, solenoid valves, desiccant, drain, power supply board, oil filter, etc.

Support one-time package purchase (the whole machine spare parts 1-2 years of protection) or on demand Order

to also order the “Project General Quick Fix Kit”, which includes common failure parts + repair tools, suitable for hospitals and industrial sites.

Regional response service network: no dropouts across time zones

MINNUO has established regional warehouses/engineering service response points in the following regions:

| Region | Support | Benefits |

| Middle East | Spare Parts Warehouse + Arabic Technical Assistance | Available for shipment within 48 hours |

| South East Asia | Replacement Equipment Preparation Program + Online Troubleshooting Team | Fixable without returning to the factory |

| Africa | Multilingual On-Site Training (English/French) + Annual Spare Parts Recommendation Mechanism | Reduced risk of out-of-stocks |

| Europe | Local Assistance with CE Files + Remote HMI Commissioning | Medical Program Delivery Compliance Support |

Additional services: add a layer of protection for the stable operation of the project

Can apply for “equipment operation monitoring monthly report service” (by the PLC remote data regularly send analysis reports)

For project users, to provide quarterly “operator remote training” or “maintenance hands-on training” opportunities Provide “application scenario fit assessment” proposal before purchase to ensure that the model matches the actual needs Conclusion For project users, provide quarterly “operator remote training” or “maintenance practice” opportunities

Provide “application scenario fit assessment” proposal before purchase to ensure that the model matches the actual needs

Frequently Asked Questions (FAQs)

Q1: What does the “E1” error code mean on my oxygen concentrator?

A: In PSA oxygen generators (like MINNUO models), an E1 code typically means Low Oxygen Purity. This is a critical alarm. The most common causes are a saturated molecular sieve, clogged air filters, or a faulty oxygen sensor. You should immediately check and replace the pre-filters and verify system pressure.

Q2: Why is my oxygen machine beeping with a red light?

A: A continuous beep with a steady red light is a serious system alarm. It often indicates a major fault such as a purity failure, over-pressure, or compressor overload. Do not ignore it. Your first step is to note the exact error code on the control panel and then follow a structured troubleshooting process to identify the root cause.

Q3: What should I do if my oxygen concentrator keeps beeping (but no red light)?

A: Intermittent beeping (usually without a red light, or with a flashing yellow light) is most often a warning or reminder. Common reasons include: the water drain tank is full, the pre-filter is becoming clogged, or routine maintenance is due. Check the drain valve and inspect the air intake filters first.

Q4: Where can I find a complete list of oxygen concentrator error codes?

A: Error codes can vary by manufacturer and model. This guide explains the most common fault code systems (E, F, and C series codes) used in many industrial PSA oxygen generators. For the definitive list for your specific unit, you must consult the official user manual provided by the equipment manufacturer.

Q5: My machine shows a code not listed here (like “1e” or “CCC2”). What should I do?

A: Uncommon or alphanumeric codes (e.g., “1e”, “CCC2”) are often manufacturer-specific. Do not attempt to guess the fix. 1.) Safely note the exact code and your machine’s model number. 2.) Refer to your manufacturer’s manual. 3.) If the issue isn’t resolved, contact your supplier’s technical support directly, providing them with the code and model information for accurate diagnosis.

Conclusion

Many users panic when they see the red light, buzzer ringing, in fact, the essence of the device’s alarm mechanism is a “self-protection reaction”, “self-protection reaction”. In fact, the alarm mechanism of the device is essentially a “self-protection response”, which does not mean that the system has been paralyzed, but rather sends out a signal to repair and intervene in advance. The earlier the response, the lower the cost.

Understanding the meaning of the alarm, familiarizing with the structure of the fault code, and mastering the initial troubleshooting logic not only reduces unnecessary downtime, but also improves response efficiency and extends equipment life. This is a highly rewarding skill for every operator, engineering manager and even purchasing manager.

Finally, if you want to stop being alone when troubleshooting, MINNUO offers more than just equipment: multilingual alarm code manuals, remote diagnostic support, spare parts recommendation kits, and a Middle East/South East Asia Regional Warehouse Response Mechanism. By choosing MINNUO, you are choosing a technical support that is always online to ensure your stable operation.

sales2:+86 17506119168

sales2:+86 17506119168