In today’s global procurement landscape, whether you’re sourcing oxygen generators for an industrial production line in Germany or configuring medical oxygen systems for a hospital in Canada, one reality is becoming increasingly clear: global trade has entered a stage of heightened sensitivity. According to a recent CNN report, the U.S. government’s ongoing round of tariff policies is not only driving up the cost of raw materials—including steel, electronic components, and gas equipment—but also affecting the stability of international supply chains.

In this context, you may be grappling with several critical questions: Is it riskier to procure oxygen equipment now? How can you ensure that a product meets the necessary certifications and customs clearance requirements amid changing regulations? Will future after-sales support be impacted by regional policy shifts? These concerns aren’t theoretical—they are real challenges faced by manufacturers, medical system operators, and environmental project stakeholders across Europe and North America.

This article will break down the complexities business owners are facing—from trade conditions and policy fluctuations to compliance pressures and supply chain uncertainty—while drawing from MINNUO’s real-world export cases in the oxygen equipment sector. Whether you’re focused on equipment performance, documentation readiness, or optimizing energy consumption and maintenance costs, the following sections will provide actionable insights tailored to your procurement priorities.

The Challenges Facing Business Owners in 2025

According to the latest Beige Book report from the US Federal Reserve and a CNN survey, the current economic environment is exerting unprecedented pressure on manufacturers and equipment purchasers:

Steel and aluminum import tariffs have doubled to 50%

This is the most significant tariff policy escalation in recent years, directly impacting the procurement costs of components such as casings, brackets, gas storage tanks, and support structures for industrial equipment. For gas equipment, this means that the overall project budget must be readjusted.

Weakened industrial purchasing confidence and significant fluctuations in terminal demand structure

From retail stores to large factories, purchasing decisions are being significantly delayed. Many businesses are “waiting to see if the funding policy stabilizes.” Especially for procurement projects related to green energy, healthcare, and clean manufacturing, many have been suspended due to tightened federal subsidies.

Logistics delays and port congestion have become the norm

The loading and unloading cycles at major ports on the East and West Coasts have been extended to over 15 days. Some imported equipment is being held up at the customs clearance stage due to incomplete documents or stricter compliance review standards. This is extremely costly for hospitals, laboratories, and water treatment units that need to deploy oxygen systems quickly.

Customer Record: Ordering 6 Months in Advance Is No Longer “Exaggerated Conservatism”

The purchasing manager of a chemical plant in Pennsylvania said:

“We ordered an industrial VPSA oxygen equipment set at the beginning of the year. Considering the new round of tariffs on metal raw materials in the United States, we decided to place the order six months in advance. Looking back now, it was a very wise decision – otherwise, we would have faced at least a 12% increase in equipment prices.”

If you are planning the oxygen supply system for a new production line in your factory or considering replacing bottled oxygen with a local oxygen generation solution, we suggest:

Advance your purchasing decision-making cycle by 3 to 6 months;

Cooperate with brands that have export experience and confirm that they have complete CE/ASME certifications;

Ask the supplier to provide the “DDP (Delivered Duty Paid)” clause to lock in customs clearance risks.

What does this mean for oxygen equipment procurement?

With the increase in tariffs on steel and aluminum and the growing uncertainty of green energy subsidies, oxygen system procurement is no longer just a matter of equipment selection. It has become a strategic decision that affects the overall process continuity, compliance, and financial stability.

Why is the impact so significant?

Because whether you are purchasing a PSA or VPSA oxygen system, it involves the following key components:

Stainless steel pressure vessels: tanks, buffer tanks, and adsorption towers, which typically account for 30% to 40% of the total weight of the equipment and are the most significantly affected by current tariffs.

PLC control systems and display panels: most systems require the integration of touch screens, PLC mainboards, and signal interfaces. These high-precision electronic components are greatly affected by tariff fluctuations and export controls.

Compressors, vacuum pumps, and control valve groups: especially high-end products from the United States, Japan, Germany, and other regions, which face price increases and uncertainties in delivery times.

The three real challenges you will face:

1. Prices are no longer stable

In the past quarter, some equipment quotations have fluctuated by 8% to 12% within 30 days.

The reason is that manufacturers’ quotations need to be recalculated based on the “spot price of raw materials + exchange rate + tariffs”.

2. Delivery is no longer certain

Some key components from high-tariff regions (such as North America, Japan, and South Korea) have seen their delivery times extend from 6 weeks to 10 to 14 weeks.

Without local inventory support, the overall project duration risk increases sharply.

3. Compliance risks have expanded

Systems and equipment without CE, ASME, and other certifications face the risks of being detained at customs, returned, and project construction suspension.

Especially in the medical and environmental protection industries, regional certifications such as ISO13485 and EAC are increasingly becoming entry barriers.

MINNUO’s solutions:

Export-oriented equipment is provided with default CE + ASME + ISO13485 quadruple certification documents, supporting project implementation in Europe, the United States, Asia, the Middle East, and other regions.

Pressure vessels support domestic substitution + modular design, saving tariff budgets and shortening manufacturing cycles.

PLC systems reserve standard protocol ports such as Modbus and TCP/IP to ensure seamless integration with local SCADA platforms in the future.

Small suggestion: Start project selection at least 4 weeks in advance and clearly define the certification, tariff, and logistics special requirements of the project location. We recommend prioritizing manufacturers with complete export experience to avoid losing the big picture for small gains.

If you need project selection advice or certification list samples, contact MINNUO’s team of overseas engineering consultants today for project selection advice or sample certification checklists to unlock the full range of solutions for cross-border oxygen generation system deployment!

How MINNUO helps you reduce procurement risks

Facing the procurement challenges in 2025 such as high tariffs, supply chain disruptions, fluctuations in energy subsidies, and certification barriers, MINNUO offers not only equipment but also a comprehensive export-oriented solution that reduces risks, lowers costs, and boosts efficiency. No matter if you are in the EU, the UK, the US, or Canada, we can guarantee your selection safety and delivery certainty from the following four dimensions:

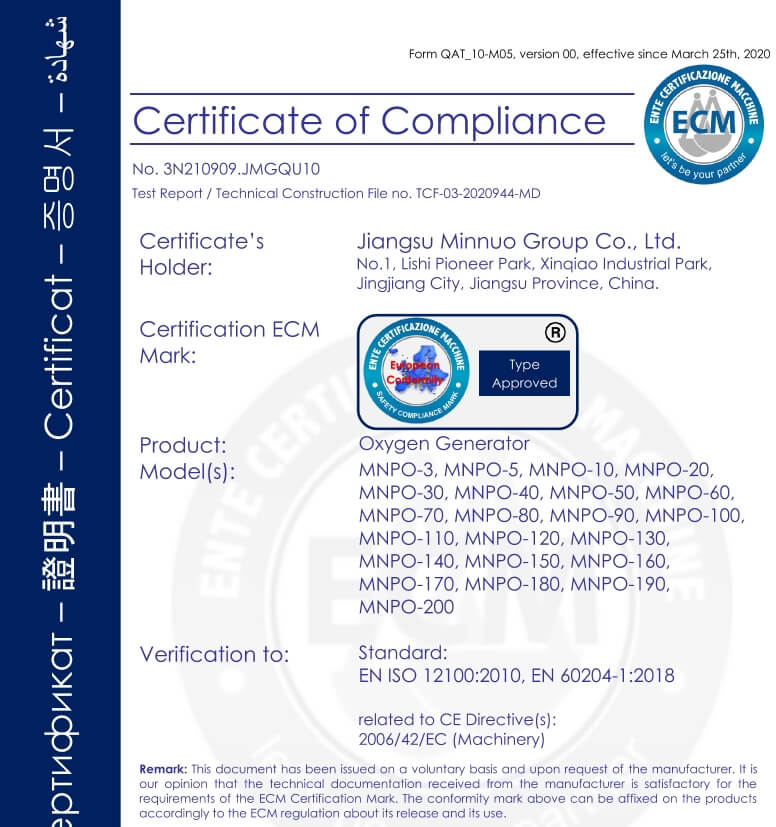

✅ Multiple certification systems to ensure smooth customs clearance

The oxygen generation systems we provide come with the following certifications by default:

CE (Conformité Européenne)

ISO13485 (Medical Device Quality Management System)

ASME (American Society of Mechanical Engineers Pressure Vessel Standards)

These certifications not only facilitate quick customs clearance in the EU and North American markets but also help customers smoothly obtain government project qualifications, subsidy eligibility, and procurement permits from medical institutions.

✅ Tariff Optimization and Alternative BOM Solutions

During the technical selection stage, we will recommend a more reasonable component configuration route based on the tariff policies of the customer’s location.

For tariff-sensitive components (e.g., compressors, control manifolds, PLCs), alternative brands from non-high-tariff-barrier regions such as China, Korea, and Turkey are available.

For structural components and shells, we offer a domestic stainless steel pressure vessel solution to avoid the high additional costs of imported steel.

The goal is to reduce the total cost by 10-18% without compromising core performance and ensure the smooth launch of the project.

✅ Intelligent Energy-saving Structure, Reducing Operational Pressure

With the reduction of IRA subsidies and the risk of rising electricity prices, energy efficiency has become a focus in industrial selection. MINNUO specifically configures for overseas projects:

VPSA energy-saving units, which consume approximately 20% less energy per Nm³ of oxygen than traditional PSA units.

Standard ≤ 0.45kWh/Nm³ operating energy consumption indicators, to meet the energy-saving needs of glass, metallurgy, water treatment and other high load industries.

Optional tail gas recovery system + PID frequency regulation solution to help customers achieve dual goals of energy conservation and emission reduction.

It can help customers control OPEX costs independently without subsidies.

Remote control and after-sales support to keep the project online

To address the difficulties of on-site commissioning and engineering support for European and American projects, MINNUO provides the following for all export projects:

Multi-language touch PLC interface (English/French/German)

Compatibility with Modbus / TCP/IP / Profibus communication protocols

Remote PLC debugging, remote diagnosis, and remote alarm forwarding functions

Can be connected to the customer’s SCADA platform or MES system to achieve local and remote collaborative operation and maintenance

Ensuring that customers can complete system stable operation and maintenance without relying on on-site factory personnel.

Real-world use case: Leading the market impact

Customer background

Location: Saxony, Germany

Industry: A medium-sized biofuel factory dedicated to green fuel alternatives and regional energy security.

Application scenario: In the process of biogas purification and CO₂ separation, high-purity oxygen needs to be continuously supplied for the operation of the reaction tower.

Challenges faced

High standards for oxygen supply

The customer requires a stable oxygen supply of ≥50 Nm³/h with a purity of 93% ± 3%, and requires 24-hour uninterrupted operation.

Contradiction in supply cycle

The average delivery time of local European equipment manufacturers exceeds 120 days, and key components (such as oxygen molecular sieves and pneumatic control valves) are highly dependent on imports, with a high risk of delivery delays.

Tight funding and policy window

If the project cannot be launched within 90 days, it will lose the tax rebate qualification of the Saxony “Clean Energy Acceleration Fund”, amounting to $87,000.

MINNUO solution

✅ Equipment configuration: MINNUO provides an integrated UPS power supply system + integrated frequency control cabinet + containerized modular PSA unit.

✅ Delivery strategy: Utilizing domestic factory inventory + pre-locking of core components, shipment can be completed within 28 days.

✅ Installation method: Modular pre-commissioning structure design, pre-assembled and debugged in the factory, customers only need to connect the gas source and power supply on-site, and can complete trial operation within 3 days.

✅ Compliance support: Complete CE, ASME, ISO13485 documentation + exporter/origin declaration + German version of the certificate of conformity are provided with the equipment, directly meeting the requirements of the state government’s environmental filing and subsidy application.

Final results

The customer successfully completed the deployment before the policy deadline, retained the tax rebate qualification, and avoided an additional budget gap of $78,000.

The system operates stably, with an annual oxygen concentration fluctuation rate controlled within ±0.5%, and a response time for later maintenance of less than 24 hours.

The project experience was adopted by the local government’s energy agency as one of the recommended procurement paths for similar projects.

What can you do today?

Facing the rising trade costs, policy uncertainties and global supply chain bottlenecks, the earlier and more proactively you make decisions, the higher the cost control and compliance efficiency will be. Here are four actionable suggestions we have compiled for you:

1. Verify the “qualification classification” and HS tariff code of your suppliers

Why is it important?

The HS code (product code) determines the applicable tariff policy for products during import and export, and is the key to determining whether you have crossed the tariff red line. A wrong code may directly result in an additional 25% to 50% tax on the equipment, or even its detention at customs.

What you can do:

Ask your suppliers to provide the HS Code of the equipment and the customs declaration records of the past 12 months.

Gas equipment requires special attention to be classified as ‘medical devices’ or ‘industrial pressure vessels’.

If in doubt, contact the MINNUO team for code classification suggestions and compliance statement templates.

2. Request DDP terms (Delivered Duty Paid) to ensure delivery time and landed cost

Why is it important?

Although terms like FOB or CFR have lower prices, all the risks of customs clearance, declaration and tariffs are borne by you, especially in the current environment where tariff policies are frequently changing, which may lead to problems such as “unable to clear customs” or “sudden increase in taxes”.

What you can do:

Clearly request DDP delivery terms from your suppliers and include them in the contract.

Require the other party to plan the transportation route in advance and declare the tariff policy of the ports passing through, so as to avoid additional taxes and fees due to tariff barriers in the transshipment places.

3. Incorporate “tariff sensitivity” analysis into the investment return model

Why is it important?

Many ROI calculations only consider the cost of the equipment itself and the operating electricity cost, but in fact, the differences in customs duties, delay costs, and raw material premiums during customs clearance have become the largest hidden expenditures in OPEX.

What you can do:

Suggest that the finance team establish a “tax-inclusive model” and a “delayed delivery loss model” for equipment procurement.

Use the ROI calculation tool provided by MINNUO, input electricity price, power, freight, expected tax rate, etc., to obtain a complete cost estimate.

4. Prioritize certification compliance and do not settle for “pending documents”

Why is it important?

“Certificate pending” or “documents to be provided after delivery” are the most common excuses from non-standard suppliers at present, which may ultimately lead to the equipment being rejected or inability to apply for policy subsidies.

What you can do:

Request to preview the original scanned copies of the CE/ISO13485/ASME certificates of the equipment.

Check if the certificates contain the language version of your country or region (such as German or English).

For important places (such as hospitals, chemical plants), request complete test reports and third-party issued compliance statements.

MINNUO can provide you with these documents and data support.

We provide for each set of equipment:

Three-in-one certification package (CE + ASME + ISO13485)

Cross-border trade documents (Certificate of Origin + Chamber of Commerce Certification + Tariff Classification Description)

Transport risk warning and delay cost prediction model

Final conclusion: In times of turmoil, only reliable infrastructure can prevail.

The market will react and policies will change, but the oxygen your system delivers must be uninterrupted 24/7, whether for patients, steel mills or reactors.

By choosing MINNUO, you are not just purchasing a machine, but building certainty in a year full of uncertainties.

Contact us immediately for a compliant quote or a customized solution. Need delivery to North America or Europe? We offer end-to-end logistics, documentation and after-sales support.

sales2:+86 17506119168

sales2:+86 17506119168