According to data from the International Energy Agency (IEA), global clean energy(such as nitrogen) investment is expected to increase by 17% year-on-year in 2024, with investment in energy storage technologies and clean fuels accounting for more than 40%. The profound transformation of the energy structure has made the search for safe, efficient and low-cost energy storage methods and clean fuels the focus of competition among countries.

Nitrogen, as the most abundant gas in the Earth’s atmosphere (accounting for approximately 78%), possesses numerous unique properties. Its chemical properties are stable and inert, and it is not prone to react with other substances, which makes it extremely safe in energy-related fields. Meanwhile, nitrogen is abundant in reserves and relatively easy to obtain, providing sufficient resource guarantees for its large-scale application. These characteristics have enabled nitrogen to gradually stand out in the fields of energy storage and clean fuel preparation, demonstrating huge application potential.

This article will, from the perspective of industrial buyers, deeply analyze the specific applications, advantages, and practical problems that nitrogen can solve for enterprises in the fields of energy storage and clean fuels. By exploring the current development status and future trends of nitrogen-related technologies, this paper provides valuable references for energy enterprises, the hydrogen energy and fuel cell industry, industrial gas users, and clean energy research and development enterprises, etc., to help enterprises make better decisions during the energy transition process.

Common pain points for buyers

Energy enterprises/factories

The traditional energy storage methods are highly dependent on fossil fuels, which not only leads to high costs but also puts huge carbon emission pressure on enterprises. According to statistics, the cost per kilowatt-hour of the energy storage auxiliary system of traditional coal-fired power generation is 30% to 50% higher than that of new energy storage technologies, and its carbon emission intensity is more than ten times that of new energy storage methods. In the current context where global restrictions on carbon emissions are becoming increasingly strict, it is urgent to seek an economical and environmentally friendly alternative to energy storage.

The hydrogen energy and fuel cell industry

The storage and transportation of hydrogen face numerous challenges. Its flammable and explosive nature places extremely high demands on storage equipment and transportation conditions, posing significant safety risks. Data shows that the accident rate during hydrogen transportation is 2 to 3 times that of other gases, and the storage cost accounts for 25% to 30% of the total cost of the hydrogen energy industry chain. Therefore, there is an urgent need for a safe and stable alternative or auxiliary gas to optimize the supply chain system of the hydrogen energy industry.

Industrial gas user

Nitrogen, as a commonly used gas in industrial production, has led some enterprises to face the problem of unstable supply, which poses a potential threat to continuous production. At the same time, long-term reliance on externally sourced nitrogen is costly and not conducive to enterprises reducing operating costs and enhancing market competitiveness. Research shows that for enterprises that purchase nitrogen from outside, the annual production loss caused by unstable supply accounts for 1% to 3% of their total revenue, and the cost of purchasing nitrogen from outside is 40% to 60% higher than that of self-built nitrogen production machines.

Clean energy research and development enterprise

Many research and development enterprises still lack in-depth understanding and systematic research on the application of nitrogen in the synthesis of new fuels, which leads to the failure to fully tap the potential value of nitrogen on the road of exploring new clean energy. Relevant data shows that currently only about 20% of clean energy research and development enterprises take nitrogen as the research focus for the synthesis of new fuels.

The potential of nitrogen in energy storage

Low-temperature liquid nitrogen energy storage technology

Working principle: Low-temperature liquid nitrogen energy storage technology utilizes the physical changes of liquid nitrogen under specific conditions to achieve energy storage and release. During the energy storage stage, gaseous nitrogen is cooled to an extremely low temperature (approximately -196 ℃) by consuming electrical energy, causing it to liquefy and be stored. This process converts electrical energy into the cold energy and chemical potential energy of liquid nitrogen. When energy needs to be released, liquid nitrogen is heated and vaporized, with its volume expanding rapidly. The high-pressure gas generated drives a turbine to produce electricity, thereby converting the stored energy into electrical energy to feed back into the power grid.

Advantages: Liquid nitrogen has excellent chemical stability and inertness, and is not prone to react with other substances. Therefore, the safety of the energy storage process is high, and there are almost no safety hazards such as explosions. Compared with traditional energy storage methods such as lead-acid batteries, liquid nitrogen has a higher energy storage density and can store more energy in a relatively small space, which is particularly important in areas with limited land resources. In addition, this technology can effectively achieve peak and off-peak regulation of electricity, storing energy during off-peak hours and releasing electrical energy during peak hours, balancing the load on the power grid and enhancing the stability and reliability of power supply.

Actual cases/Research progress: Currently, there are multiple liquid nitrogen energy storage projects both at home and abroad that are in the research or pilot stage. For instance, a certain research institution successfully built a small-scale liquid nitrogen energy storage demonstration system. After long-term testing, the system demonstrated excellent stability and efficiency in multiple charge and discharge cycles, with an energy storage efficiency of over 60%. In addition, in some areas where wind farms and photovoltaic power stations are concentrated, efforts are also being made to explore the combination of liquid nitrogen energy storage technology with them to address the intermittent and fluctuating issues of new energy power generation and achieve stable power output.

The Role of nitrogen in compressed air energy storage systems

Enhancing system stability and avoiding oxidation risks: In compressed air energy storage systems, nitrogen, as the primary working medium, can significantly improve system stability. Due to the stable chemical properties of nitrogen, it is less likely to undergo chemical reactions during compression and expansion, which can effectively prevent equipment corrosion and performance degradation caused by gas oxidation, and extend the service life of equipment.

Reduce safety hazards and extend equipment lifespan: Compared with other flammable and explosive gases, the use of nitrogen significantly reduces the safety risks of the system. Meanwhile, a stable working environment helps to reduce mechanical wear of equipment, lower maintenance costs, and enhance the reliability and economy of the entire compressed air energy storage system.

The application prospects of nitrogen in the preparation of clean fuels

Nitrogen and ammonia Synthesis (Green Ammonia fuel)

Renewable energy + nitrogen to prepare green ammonia → Clean fuel & energy storage carrier Green ammonia is produced by electrolyzing water with electricity generated from renewable energy sources such as solar and wind power to produce hydrogen, and then synthesizing ammonia from hydrogen and nitrogen separated from the air under specific conditions through the Haber-Bosch process. Ammonia prepared with renewable energy as the driving force is called green ammonia. Green ammonia can not only be directly applied as a clean fuel to equipment such as internal combustion engines and gas turbines, but also produce only nitrogen and water after combustion, with almost no greenhouse gas emissions. It can also serve as an efficient energy storage carrier, storing renewable energy in the form of chemical energy and releasing it through cracking or combustion when needed, thus achieving cross-temporal and spatial transmission and utilization of energy.

The maritime and power generation applications of green ammonia: In the maritime sector, due to ammonia’s high energy density and relatively mature storage and transportation technologies, it is expected to replace traditional heavy oil as the main fuel for ocean-going vessels, significantly reducing carbon emissions in the maritime industry. It is estimated that a 100,000-ton ocean-going cargo ship using ammonia fuel can reduce carbon emissions by approximately 50,000 tons annually. In terms of power generation, power generation units fueled by green ammonia can achieve stable power output, and their emission indicators are far superior to those of traditional coal-fired and oil-fired power generation, providing a new approach for the green transformation of the power industry. At present, some international shipping giants have begun to conduct research and development and pilot applications of ammonia-fueled ships, and some countries are also actively building demonstration projects for power generation using green ammonia as fuel, demonstrating a promising development prospect.

The supporting role of nitrogen in the hydrogen energy industry

Protective gas in hydrogen production and storage processes: In the hydrogen production stage, whether it is the traditional hydrogen production through fossil energy reforming or the emerging hydrogen production through water electrolysis, nitrogen can be used as a protective gas. It can create an inert environment during the reaction process, preventing reactants and catalysts from undergoing oxidation reactions with oxygen in the air, thereby enhancing hydrogen production efficiency and product purity. During the hydrogen storage process, for high-pressure gaseous hydrogen storage and low-temperature liquid hydrogen storage, nitrogen can fill the gaps in the hydrogen storage containers, playing a buffering and isolating role, reducing the risk of hydrogen leakage and explosion, and enhancing the safety of the hydrogen storage system.

Reduce explosion risks and enhance system safety: Hydrogen is flammable and explosive, with a wide explosive limit range. When its volume concentration in the air reaches 4% to 75%, it is highly prone to explosion upon encountering a fire source. The addition of nitrogen can dilute the concentration of hydrogen, keeping it away from the explosive limit range and effectively reducing the safety hazards in the hydrogen production and storage processes. Meanwhile, nitrogen can also serve as an inerting gas in emergency situations, quickly extinguishing flames and preventing the spread of explosions, providing a strong guarantee for the safe development of the hydrogen energy industry. According to relevant experimental data, after adding an appropriate amount of nitrogen to the hydrogen storage tank, the risk of explosion was reduced by more than 80%.

Research and development of new fuels (nitrogen-based fuels)

Research Frontier: Nitrogen-based Compounds as Candidates for Clean Energy: In recent years, researchers have gradually turned their attention to nitrogen-based compounds in the process of exploring new types of clean energy. Some nitrogen-based compounds, such as hydrazine and azides, have a high energy density. Under appropriate conditions, they can release a large amount of energy, and their combustion products are relatively clean. They are expected to become important candidates for clean energy in the future. However, at present, these nitrogen-based compounds still face many challenges in terms of synthesis process, stability, safety and cost, which require further in-depth research and technological innovation.

The Necessity of Nitrogen in Experiments and process Optimization: Nitrogen plays an indispensable role in the research and development of new nitrogen-based fuels. On the one hand, nitrogen is an important raw material for the synthesis of nitrogen-based compounds, and its purity and quality directly affect the performance and quality of the final product. On the other hand, during the experimental research and process optimization stages, nitrogen can be used to create a specific reaction environment, control reaction conditions, help researchers better understand the reaction mechanism, screen out the best reaction path and process parameters, and promote the research and development process of new nitrogen-based fuels.

Comparison Table of Different Nitrogen Acquisition Methods

| Acquisition method | Cost (yuan/cubic meter) | Supply stability | Purity adjustability | Environmental friendliness | Applicable scenarios |

| Bottled nitrogen | 3-5 | Poor quality, greatly affected by transportation and other factors | Fixed purity, not adjustable | Generally, there are carbon emissions from transportation | Small enterprises with small usage and intermittent use |

| External extraction of liquid nitrogen | 2-4 | Generally, it is easily affected by tight supply | Fixed purity, not adjustable | Poor quality, high energy consumption for transportation and storage | Enterprises with moderate usage and fixed purity requirements |

| Self-built nitrogen generator | 1 to 2 | Ok. Production can be independently controlled | It can be adjusted as needed | Ok, no carbon emissions from transportation | Enterprises with large consumption, continuous production, and different purity requirements |

Why should enterprises consider building their own nitrogen generators?

Reduce costs

Compared with long-term reliance on bottled nitrogen or liquid nitrogen for external procurement, enterprises building their own nitrogen generators can significantly reduce operating costs. The purchase of nitrogen from outside not only requires the payment of the gas itself, but also a series of additional costs such as transportation and storage. Moreover, as the purchase volume increases, the cost pressure becomes more and more obvious. After the self-built nitrogen generator makes a one-time investment in equipment procurement and installation costs, in the subsequent long-term operation, it only consumes a small amount of electricity and air to continuously produce nitrogen that meets the enterprise’s needs, significantly reducing the production cost per unit of nitrogen. In the long run, it saves a large amount of funds for the enterprise. Take an enterprise with an annual nitrogen consumption of 1 million cubic meters as an example. By using self-built nitrogen generators, it can save 1 to 2 million yuan in costs each year.

Stable supply

Self-built nitrogen generators can ensure the stability and continuity of nitrogen supply for enterprises. The supply of external nitrogen is prone to interruption or delay due to various factors such as the production capacity of suppliers, transportation conditions, and market supply and demand relationships, which has a serious impact on the normal production and operation of enterprises. By building their own nitrogen generators, enterprises can flexibly adjust the output of nitrogen according to their own production plans and demands, achieve self-controlled nitrogen supply, effectively avoid production halts caused by gas supply disruptions, and ensure the smooth progress of enterprise production.

High flexibility

The nitrogen generators built by enterprises themselves have a high degree of flexibility and can adjust the purity and output of nitrogen at any time according to the actual production needs. Different production processes and application scenarios have varying requirements for the purity of nitrogen. Self-built nitrogen generators can precisely control various parameters during the nitrogen production process through advanced control technology and regulating devices, and produce nitrogen products that meet different needs. For instance, in some electronic chip manufacturing processes with extremely high requirements for nitrogen purity, nitrogen generators can produce nitrogen with a purity of over 99.999%. In some industrial production processes, the requirement for nitrogen purity is relatively low, and nitrogen generators can adjust production parameters accordingly to reduce production costs.

Conform to the trend of environmental protection

With the continuous enhancement of global environmental awareness, enterprises are increasingly strict in their environmental protection requirements during the production process. The combination of self-built nitrogen generators and new energy projects can achieve efficient energy utilization and carbon emission reduction, helping enterprises better implement the “dual carbon goals”. For instance, in some enterprises near wind or photovoltaic power stations, the surplus green electricity can be utilized to drive nitrogen generators, separating nitrogen from the air for production. This not only enables the local consumption of clean energy but also reduces the consumption of traditional fossil energy and carbon emissions, establishing a good environmental protection image for the enterprises and enhancing their sense of social responsibility and market competitiveness.

The future trends and market prospects of nitrogen application

Global energy structure adjustment → Nitrogen demand steadily rises

As the global energy structure accelerates its adjustment towards clean and low-carbon directions, the proportion of renewable energy in energy consumption is constantly increasing. In this process, the development of energy storage technology and clean fuels is of vital importance. As a key medium in the preparation of energy storage and clean fuels, the market demand for nitrogen will show a steady upward trend. It is expected that the global demand for nitrogen will grow at an annual rate of 5% to 8% in the coming years. Especially in regions where the new energy industry is developing rapidly, such as China, Europe, and the United States, the nitrogen market will have a broader space for development.

In the new energy and clean fuel industry, nitrogen becomes the basic guarantee gas

In the new energy and clean fuel industries, nitrogen will gradually become an indispensable basic guarantee gas. In the fields of solar and wind power generation, nitrogen can be used to protect energy storage systems and equipment, improving energy utilization efficiency and system stability. In the clean fuel industries such as hydrogen energy and ammonia energy, nitrogen, as a raw gas and protective gas, runs through all links including hydrogen production, hydrogen storage, and hydrogen-ammonia synthesis, playing a crucial role in ensuring product quality and production safety. With the rapid development and large-scale expansion of these industries, the application scenarios of nitrogen will continue to expand, and its fundamental guarantee position will become increasingly prominent.

The development trends of nitrogen preparation technologies (PSA, membrane separation, cryogenic) in the next 5 to 10 years

Pressure swing Adsorption (PSA) technology: PSA technology is one of the most widely used nitrogen production technologies at present. In the next 5 to 10 years, this technology will develop in the direction of improving nitrogen purity, reducing energy consumption, simplifying process flow and achieving intelligent control. By developing new adsorbents and optimizing adsorption processes, PSA nitrogen generation equipment is expected to achieve higher nitrogen recovery rates and lower operating costs. Meanwhile, with the help of advanced automatic control systems, remote monitoring and unattended operation of the equipment can be realized, thereby enhancing production efficiency and management levels. It is expected that by 2030, the energy consumption of PSA nitrogen generation technology will be reduced by more than 20%.

Membrane separation technology: Membrane separation nitrogen generation technology has the advantages of simple equipment, small floor space, and fast start-up speed. In future development, it will focus on breaking through the performance bottleneck of membrane materials, improving the selectivity and stability of membranes, and reducing the cost of membrane modules. In addition, through integrated innovation with other technologies, such as combining with PSA technology to form a composite nitrogen generation process, the competitiveness of membrane separation nitrogen generation technology is further enhanced, and its application scope in the medium and small-scale nitrogen demand market is expanded.

Deep cryogenic technology: Deep cryogenic nitrogen production technology can produce high-purity nitrogen products and is suitable for scenarios with large-scale nitrogen demand. In the next 5 to 10 years, cryogenic nitrogen production technology will make breakthroughs in improving energy utilization efficiency, reducing equipment investment costs and enhancing system reliability. By optimizing the refrigeration cycle system, adopting new low-temperature materials and advanced control technologies, cryogenic nitrogen generation equipment will achieve lower energy consumption and higher production efficiency. At the same time, it will further enhance the degree of automation and operational stability of the equipment, meeting the demands of different industries for large-scale and high-purity nitrogen.

Conclusion

Nitrogen has demonstrated tremendous potential in the fields of energy storage and clean fuels. Whether it serves as the core medium of low-temperature liquid nitrogen energy storage technology or plays a significant role in compressed air energy storage systems, clean fuel preparation, and the research and development of new fuels, it provides new solutions for the green transformation and sustainable development of the energy industry. For all kinds of enterprises, fully recognizing the value of nitrogen and actively exploring its application in their own business, especially considering building their own nitrogen generators to reduce costs and ensure supply, will help enterprises seize the initiative in the wave of energy transformation and enhance their competitiveness.

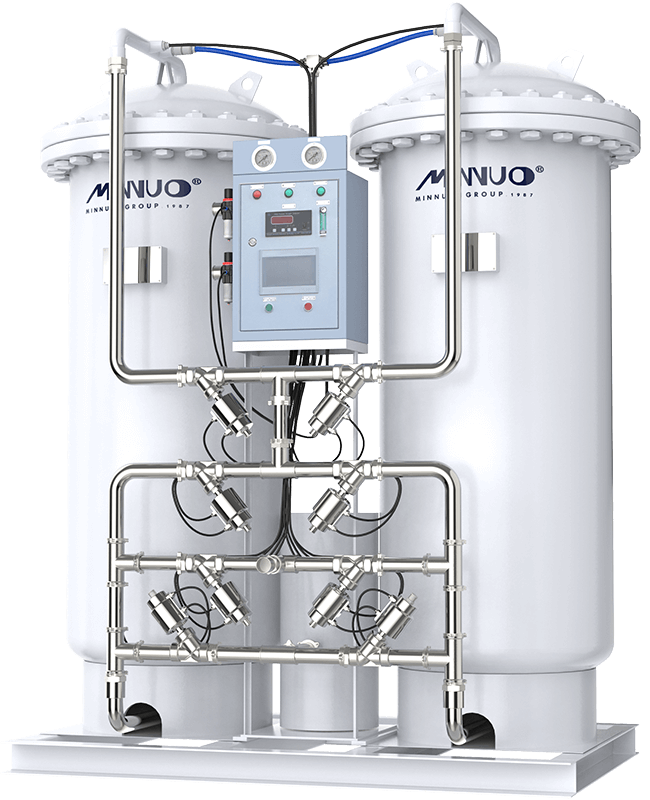

If your enterprise hopes to reduce the cost of nitrogen procurement and ensure a stable supply of nitrogen, you are welcome to consider building your own nitrogen generator. As a professional nitrogen generator supplier, MINNUO has rich industry experience and advanced technology, and is capable of providing you with comprehensive nitrogen generator selection consultation and customized solutions. Our team will recommend the most suitable nitrogen generator model for you based on your specific needs, and provide one-stop equipment installation, commissioning, training and after-sales maintenance services. For more information or to obtain a quotation, please feel free to contact us at any time.

sales2:+86 17506119168

sales2:+86 17506119168