Under the current background of increasing demand for high purity and high flow oxygen, traditional deep cooling oxygen generation and conventional PSA process are facing multiple challenges in terms of energy consumption, investment and land occupation, and VPSA (Vacuum Pressure Swing Adsorption) technology, by virtue of its low-pressure inlet, vacuum resolution, energy-saving and high-efficiency, has gradually replaced the traditional process as the mainstream choice for medium and large industrial projects and regional centralized oxygen supply systems.

So, how does the VPSA oxygen system operate? What is the essential difference between it and PSA process? Why is it more advantageous in complex scenarios such as plateau, tropics and large-scale factories? This article will focus on the principle of oxygen production, the core process, key equipment control logic and layout structure to develop a detailed graphic analysis, to help users establish a complete cognitive framework of VPSA technology.

If you are planning an oxygen system project, or are facing high energy consumption, operation and maintenance complexity and other problems, then please read on, MINNUO will restore a visualization, engineering, standardized VPSA oxygen program for you, to help you select a scientific, reasonable deployment.

1. Introduction to the principle of VPSA oxygen generation process

In modern medium and large-scale oxygen supply scenarios, VPSA (Vacuum Pressure Swing Adsorption) technology has become an important technological path for replacing the traditional PSA and liquid oxygen supply program due to its low energy consumption, high gas production and system stability.

1.1 Analysis of the working principle

VPSA process is essentially a process of realizing the separation of oxygen and nitrogen in air under the conditions of low-pressure adsorption and vacuum resolution:

Adsorption stage: under atmospheric pressure or slightly positive pressure, air is sent to the adsorption tower after pretreatment, and molecular sieve (e.g., LiX) adsorbs nitrogen in the air in preference to the oxygen enriched and then enters into the production pipeline;

Resolution stage: the adsorption tower is switched to the state of suction of vacuum pump (-0.05 to -0.09%), which is the first stage of the process. 0.05~-0.09MPa), the adsorbed nitrogen is resolved and discharged, and the molecular sieve can be regenerated;

Adsorption tower alternating operation: usually adopts double tower or four tower structure to realize continuous and stable oxygen output.

1.2 Essential differences with PSA process

| Comparison dimensions | PSA (Pressure Swing Adsorption) | VPSA (Vacuum Pressure Swing Adsorption) |

| Adsorption pressure | 0.6~0.8 MPa | Atmospheric pressure (approx. 0.1 MPa) |

| Resolution mode | Reduced to atmospheric or slightly negative pressure | Reduced to deep vacuum (-0.09 MPa) |

| Energy performance | High, relies on medium-pressure air source | Lower, combination of blower + vacuum pump |

| Applicable flow rate | ≤300 Nm³/h | ≥ 300 Nm³/h More economical |

| System complexity | Lower | Relatively high, but more energy efficient |

Conclusion: VPSA technology is especially suitable for high flow rate, continuous oxygen supply, energy-sensitive scenarios, such as smelters, regional medical oxygen supply centers, large-scale water treatment plants and so on.

1.3 Key role of molecular sieve materials

Molecular sieve (such as LiX lithium-based molecular sieve) is the “core consumables” of VPSA technology, and its selective adsorption capacity of nitrogen determines the performance of the oxygen generation system:

Advantages of choosing LiX:

Strong nitrogen adsorption capacity, high oxygen throughput rate;

Long cycle life (8,000~12,000 hours); suitable for high load adsorption tower for long time. Long cycle life (8,000~12,000 hours);

Suitable for long cycle operation of highly loaded adsorption towers;

Maintenance advice: the system should be equipped with a dust filter and a regular blowback module to avoid molecular sieve failure.

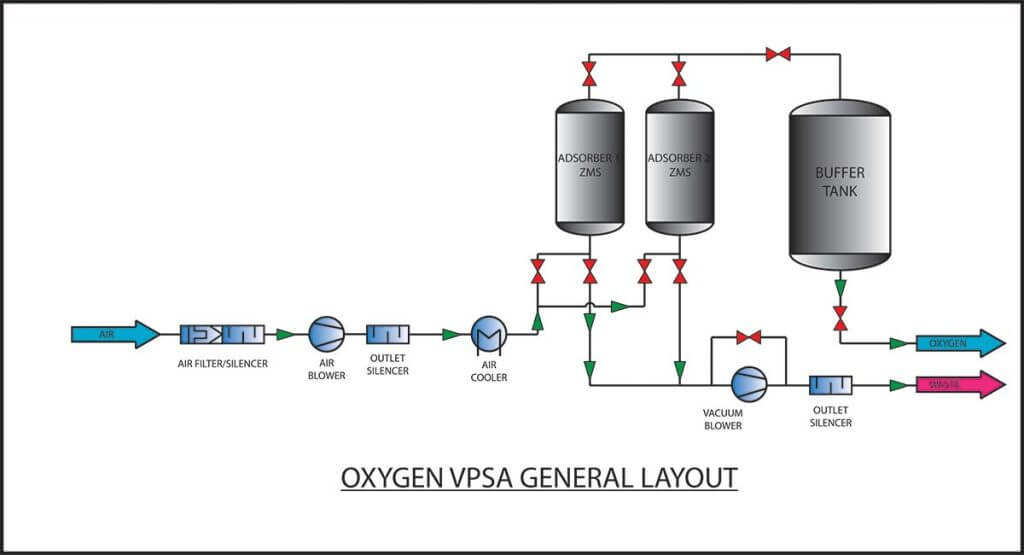

2. VPSA Oxygen Generation Complete Flow Chart

VPSA (Vacuum Pressure Swing Adsorption) oxygen generation system realizes high-efficiency and low-energy consumption on-site oxygen supply solution through multi-stage combination of equipments and time sequence control. The structural composition and operation logic are as follows:

2.1 System structural composition

The structure of a typical VPSA system can be divided into the following core modules:

blower → air pretreatment (dust, oil and water removal) → adsorption tower (LiX molecular sieve)

→ vacuum pump system → oxygen buffer tank → oxygen terminal/distribution piping network

The system operates as an alternating cycle of multi-towers, always keeping one tower adsorption, one tower resolution, to realize continuous oxygen supply.

2.2 Step-by-step analysis of process flow

In order to help readers understand the function of each process node, the flow charts and diagrams are explained as follows:

① Primary air treatment section

Air is sent from the blower under normal temperature and pressure;

passes through triple treatment equipments: dust collector (filtering out particulate matter), degreaser (adsorption of oil mist), and desiccant (lowering the dew point);

outputs clean and dry air, which enters the next section of the adsorption system.

② Adsorption and oxygen enrichment section

The treated air enters into the adsorption tower with low pressure (about 0.1MPa);

High-efficiency LiX molecular sieve is chosen to give priority to adsorption of nitrogen;

Oxygen is enriched and outputted through the lower part of the tower, and enters into the oxygen buffer tank.

③Vacuum desorption section

Another adsorption tower is sucked down to -0.09MPa by vacuum pump;

The adsorbed nitrogen is completely released and discharged, and the regeneration of molecular sieve is completed.

④ Buffer storage and output section

Oxygen-enriched gas flows into the oxygen buffer tank to stabilize the pressure and flow rate;

Oxygen is output to the terminal oxygen supply system (e.g., medical oxygen station, pipeline network, etc.) through the regulator;

Oxygen concentration is maintained at 93%±3%, and real-time monitoring.

⑤ Multi-tower alternating operation, cyclic work

Control system (PLC) manages adsorption/analysis switching beats;

Realizes uninterrupted oxygen supply, suitable for 24h continuous oxygen demand.

2.3 Suggested Supplementary Style for Process Flow Diagram

[ Blower ] → [ Dust Removal ] → [ Degreasing ] → [ Dryer ] → [ Adsorption Tower A ]

↓ ↑

[ Adsorption Tower B ← Vacuum Pump Pumping ]

↓

[ Oxygen Buffer Tank ] → Outlet/Distribution System

Description: The adsorption tower is a double-tower alternating structure, which can be expanded to a triple-tower or quadruple-tower system to meet the demand for large flow rates.

3. Key Equipment and Functional Distribution of VPSA Oxygen Generation System

The performance stability of VPSA (Vacuum Pressure Swing Adsorption) system relies on the synergistic cooperation of multiple core subsystems. Each link of equipment in the operation of different responsibilities, a correct understanding of their functional distribution will help system configuration, fault judgment and energy consumption optimization.

3.1 Blower: provide atmospheric air inlet, is the gas source power of the whole system

Role: send the atmospheric air into the pretreatment system and the adsorption tower, maintain the positive pressure of the whole system;

Requirements: continuous and stable operation, low noise, adapt to the high load conditions;

Technical suggestions: the use of frequency control blower can be adjusted according to the adsorption beat of the air volume, reduce energy consumption.

3.2 Vacuum pump: core energy-saving equipment, determining the thoroughness of resolution

Role: reduce the pressure of the adsorption tower to -0.05 ~ -0.09MPa, realize the effective desorption of nitrogen and complete the regeneration of molecular sieve;

Configuration suggestions:

Configure bypass energy-saving module, partition vacuum in the process of resolution, reducing power consumption;

Vacuum pump needs to meet ≥99.5% pumping efficiency, and it is recommended to use rotary vane or Roots vacuum pumps;

Attention: Note: Vacuum pump is the source of energy saving advantage of VPSA over PSA system, but at the same time, it requires higher requirements for sealing and thermal management.

3.3 Adsorption tower and molecular sieve (LiX/NaX): the core structure of gas separation

Role: complete the adsorption of nitrogen and oxygen enrichment in the air within the molecular sieve;

Dual/triple/quadruple tower structure can be expanded according to the scale of oxygen production;

Suggested Configurations:

The adsorption tower should be equipped with thermal insulation and anti-condensation design;

It is recommended to use LiX-type highly selective molecular sieve as the inner packing, which will result in a more thorough analysis and lower energy consumption.

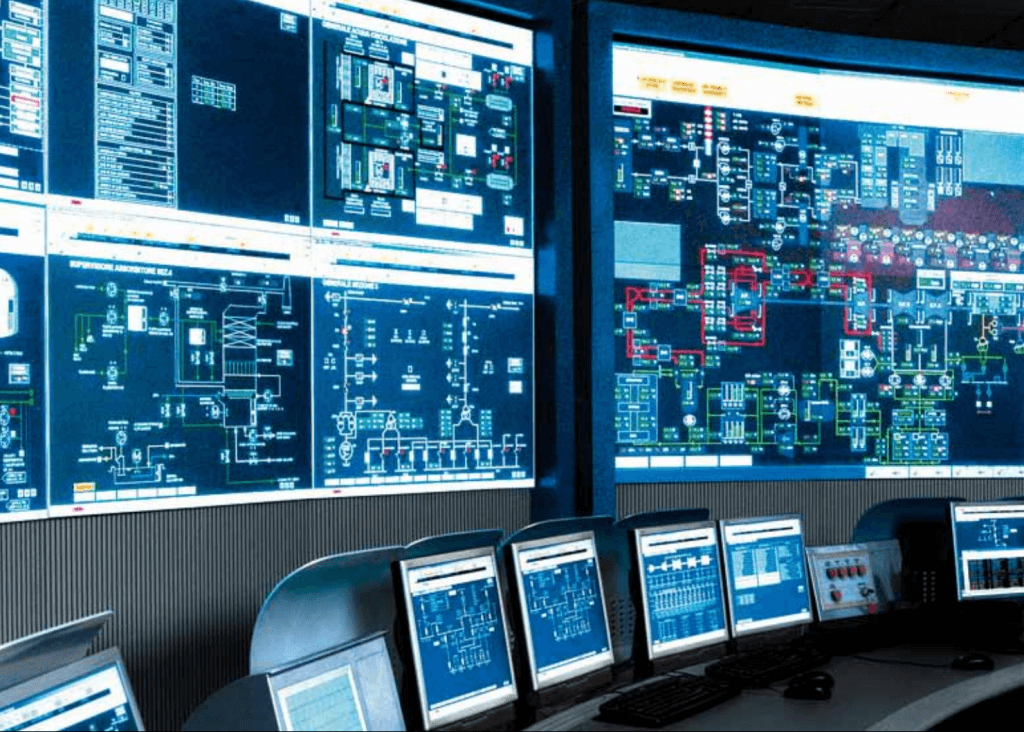

3.4 Automatic control system (PLC + touch screen): central control, management of switching and concentration monitoring.

Control functions:

switching beat setting (adsorption/analysis/equalization);

real-time analysis of oxygen concentration, automatic recording and alarm;

fault linkage protection and remote debugging interface;

Recommended: integration of support for communication protocols such as Modbus, 485, 4-20 mA and so on, compatible with SCADA or industrial platforms in hospitals.

3.5 Oxygen Buffer Tank and Gas Distribution Network: Stable Output, Guaranteeing Constant Pressure of Oxygen Supply to Terminal

Role:

Buffer tank absorbs fluctuation and stabilizes instantaneous pressure and flow;

Pipeline network is configured with zonal regulators, check valves, residual pressure alarms and other components according to needs;

Application Expansion:

Medical scenarios need to set up a switching interface for the spare bottle group;

Industrial applications suggest configuring tail gas recovery interface to improve system utilization.

4. Operation parameters and control logic of VPSA system

The operation effect of VPSA (Vacuum Pressure Swing Adsorption) oxygen generation system depends largely on the scientific setting of the time beat of each stage of “adsorption-resolution-pressure equalization-charging” and the precise control of key parameters such as oxygen concentration, flow rate, vacuum and so on.

4.1 Adsorption/Resolution Beat Time Configuration

Different raw gas compositions, molecular sieve types, and tower sizes determine the “dynamic beat time” of the system, which needs to be set according to the actual working conditions.

Typical beat parameter setting (take double tower as an example):

Adsorption stage: 60s (oxygen enrichment output)

Resolution stage: 45s (vacuum resolution of nitrogen, molecular sieve regeneration)

Pressure equalization/recharging stage: 5~10s (pressure balancing and filling)

Technical suggestions:

Adopting variable beat logic control to automatically extend the resolution stage when the concentration of exported oxygen is lower than the threshold (e.g., 92%).

Supports the “beat self-learning function”. Support “beat self-learning function”, dynamically adjust the time allocation through the concentration trend and vacuum recovery speed.

4.2 Oxygen purity range setting and fluctuation treatment

Target setting range: 93%~95% (in accordance with YY/T 0298 or medical/industrial norms)

Fluctuation source analysis:

Adsorption tower switching delay, resulting in a short time of gas mixing;

Decrease in efficiency of the vacuum pump, incomplete parsing;

Unstable composition of the raw material gas (e.g., changes in humidity).

Control strategy:

Configure online oxygen concentration meter (±0.5% accuracy) at the outlet, and linkage with PLC;

Trigger alarm during fluctuation time + automatic switching of backup gas source (e.g. bottle group, the second host);

Long-term operation fluctuation is recommended to increase the molecular sieve regeneration temperature control/pressure feedback compensation function.

4.3 Adjustment logic of gas production flow rate and vacuum degree

In the VPSA system, “gas production flow rate” and “vacuum degree” are closely related, and the vacuum pumping speed determines the desorption efficiency, which affects the beginning of the next adsorption cycle.

Vacuum setting suggestion:

The vacuum at the bottom of adsorption tower should reach -0.08 ~ -0.09 MPa;

Small system can accept -0.07MPa; large system is recommended to configure two-stage vacuum pumps in parallel control.

Adjustment method:

adopts frequency conversion vacuum pump control strategy: low load energy-saving operation, high load fast pumping;

flow and vacuum form double closed-loop control logic to guarantee gas quality and beat precision.

4.4 Suggested configuration of online monitoring module

In order to ensure the stability of system operation, support remote operation and maintenance and data traceability, it is recommended to install the following modules:

| Module name | Monitoring parameters | Installation location | Interface type |

| Oxygen concentration analyzer | O₂ concentration (±0.5%) | Outlet main | 4~20mA / RS485 |

| Thermal flow meter | Real-time gas flow | Buffer tank front section | 4~20mA |

| Pressure transmitter | Tower pressure, outlet pressure | Adsorption tower, vacuum section | 4~20mA |

| Vacuum sensor | Negative pumping pressure | Vacuum pump connection | 0~1V or Modbus |

| Control linkage | UPS / power switching / annunciator | Control box | Switching inputs and outputs |

It is recommended that the system support SCADA or cloud platform remote diagnostic interface to facilitate the implementation of equipment status trend analysis, early warning alerts, annual operating data report export and other functions.

5. Common VPSA Oxygen Generation System Layout Diagram

As an energy-saving large-scale oxygen generation technology, the system layout of VPSA (Vacuum Pressure Swing Adsorption) system not only affects the operating efficiency of the equipment, but also directly relates to the maintenance convenience and safety protection level. Reasonable system layout can help users avoid installation and operation bottlenecks at the early stage of design.

5.1 Ground layout

Core layout principles:

≥ 1.0 meter maintenance spacing should be left between the equipment to facilitate the operation of maintenance personnel;

air compressor, blower, vacuum pump should be arranged close to the outer wall or ventilation surface to reduce the hot gas backflow;

≥ 0.5 meter distance between adsorption tower and PLC control box is recommended to avoid the heat of the electronic control;

Oxygen buffer tanks are close to the outlet gas pipeline to reduce the pressure drop loss. Oxygen buffer tank is close to the outlet gas pipeline to reduce pressure drop loss.

Typical layout sequence (from left to right or front to back):

blower → air filter group → adsorption tower group (double or triple tower) → vacuum pump → oxygen buffer tank → oxygen piping → outlet control valve → air-using area

The direction of air inlet should be the same as the direction of convection of ventilation of the equipment, so as to ensure that heat dissipation effect is maximized.

5.2 Logic diagram of pipeline connection (including airflow direction and zone control)

In order to ensure a clear fluid path in the adsorption and resolution stage of the system and avoid gas mixing and backflow, the internal pipelines of the VPSA system should conform to the following structure:

| Pipe section name | Direction of gas | Recommended pipe size (typical system) | Control Elements |

| Raw material gas inlet pipe | Blower → adsorption tower inlet | DN80~DN150 | Check Valve + Air Flow Control Valve |

| Resolution gas discharge pipe | Bottom of adsorption tower → vacuum pump → exhaust cylinder | DN80~DN100 | Negative Pressure Shutoff Valve + Buffer Tank |

| Oxygen output main | Adsorption tower outlet → buffer tank → gas network | DN80~DN100 | Oxygen Manifold + Check Valve |

| Area switching branch | Contains two partitions (e.g., ICU and rehabilitation area) | DN40~DN65 | Zone Pneumatic Switching Valve |

Pipes should be made of oil-free carbon steel + epoxy anti-corrosion treatment or stainless steel to avoid reaction with oxygen.

5.3 Control system communication structure (support SCADA / 485 interface)

Intelligent control is the standard of modern VPSA system. A complete automation control communication system should meet the following structural distribution:

Recommended structural hierarchy diagram:

PLC master controller (Schneider/Siemens)

│

├── Oxygen Concentrator Module (Modbus RTU)

├── Vacuum Sensor (4~20mA)

├── Adsorption Tower Switching Solenoid Valve Controlling Terminal

├── HMI screen (local 7-inch touch screen)

└── Communication Interface:

├── RS485 (Remote Adjustment)

├── SCADA (Centralized Monitoring of Plant and Station)

└── TCP/IP (Cloud Data Upload/SMS Alarm Module)

Key Linkage Logic Suggestions:

Oxygen Concentration Below 90% → Issuing Alarm → Switching Alternate Gas Source → Recording Alarm Time;

System Supports Access to the Cloud Platform for Remote Viewing of Operational Status and Trend Analysis by Operation and Maintenance Engineers. The system supports cloud platform access for operation and maintenance engineers to remotely check the operation status and trend analysis.

Conclusion

VPSA (Vacuum Pressure Switching Adsorption) oxygen generation process realizes a solution of on-site oxygen generation with lower energy consumption and higher purity output than the traditional PSA by the core mechanism of “low-pressure intake + vacuum resolution”. Whether in hospital oxygen supply, industrial oxygen, or remote unattended sites, VPSA system has become the mainstream choice for medium and large-scale oxygen generation projects due to its good continuity and high performance.

MINNUO provides integrated VPSA oxygen solutions from 10Nm³/h to 300Nm³/h, covering engineering design, modular integration, SCADA intelligent control, and support for complex environments such as plateau, humidity, high temperature and other customized, helping users to build a stable, safe and compliant oxygen supply system.

Welcome to visit MINNUO Group Official Website for technical drawings, selection and quotation support, we will customize the most suitable VPSA oxygen system for you.

sales2:+86 17506119168

sales2:+86 17506119168