In the medical environment, oxygen is not only a basic gas, but also an indispensable “basic medicine” to maintain the stability of patients’ vital signs and support the operation of the respiratory system. From ICU critical care, surgical anesthesia, to oxygen therapy in general wards, the purity, safety and continuous supply of medical-grade oxygen are directly related to the effectiveness of treatment and the quality of patients’ survival. Therefore, an in-depth understanding of the definition and purity requirements of medical oxygen is the first step in the scientific selection of an oxygen supply system.

So, what is “medical oxygen”? What is the fundamental difference between it and industrial and experimental oxygen? Essentially, medical oxygen must meet specific national and international standards (e.g., China YY/T 0298, Europe Pharm. Eur., U.S. USP, etc.), and its purity is required to be stabilized at 93%±3% or ≥99% (according to the different uses), and it needs to be equipped with safety functions such as on-line monitoring, automatic switching of standby gas source, and pressure alarms, etc., to ensure that the patients’ continuous inhalation of oxygen is uninterrupted and free from contamination in the different stages of treatment, and the patients can receive oxygen continuously without interruption and contamination. Continuous oxygen intake without interruption and pollution.

If you are selecting oxygen supply equipment for hospital ICU wards, anesthesia systems, mobile negative pressure trucks, community respiratory rehabilitation stations and other scenarios, or if you have questions about whether 93% purity is safe enough or whether liquid oxygen is necessary, this article will combine the standard specifications, In this article, we will provide you with answers to the questions of standardization, purity control, typical misunderstandings and configuration suggestions, which will help you scientifically identify the standard and authenticity of medical oxygen, and choose the right oxygen system that is truly suitable for you.

1. Standard Oxygen Purity Requirements

In medical and industrial scenarios, oxygen purity is clearly defined in different countries and industry standards. An accurate understanding of these standards helps users to choose the right oxygen supply equipment for their specific applications.

1.1 Comparison of Major International Standards

| Standard Organization/System | Required purity | Application Notes |

| China Medical Industry Standard YY/T 0298 | 93% ±3% | Mainstream PSA medical oxygen equipment, widely used in hospital wards, ICUs, respiratory therapy |

| European Pharmacopoeia Ph. Eur. | ≥93% | Basically in line with Chinese standards, supporting medical grade PSA oxygen system |

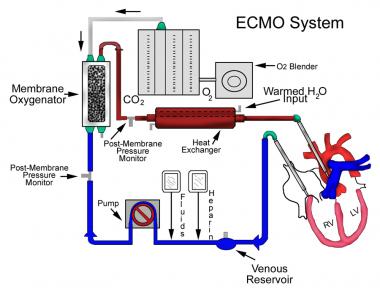

| United States Pharmacopoeia USP | ≥99% (for specified applications) | Mostly used in high end medical equipment (e.g., ECMO), certain ventilators or drug infusion scenarios |

| ISO 7396 Series | Different grades define oxygen concentration | International common specifications for medical building gas systems, guiding the design of centralized oxygen supply engineering |

✅ Tip: Not all medical scenarios require ≥99% high purity oxygen, 93% ±3% already meets the needs of most oxygen therapy, the key lies in the stability of the system and the ability to continue to supply oxygen.

1.2 Purity Differences Between Oxygen Types

| Oxygen Types | Purity range | Typical application scenarios |

| Medical Oxygen (PSA) | 93% ±3% | Hospital oxygen supply system, negative pressure ambulance, home oxygen therapy, etc. |

| Industrial High Purity Oxygen | 95%~99.5% | Welding, laser cutting, glass combustion, ozone generator, etc. |

| Liquid Oxygen Oxygen | ≥99.6% (but from complex sources) | Medical high-flow, industrial high-temperature oxidizing furnace, bottled gas supply station, etc. |

Upgrade of core knowledge:

The key index of medical oxygen is not “the purer the better”, but whether the output is stable, whether there is redundant switching, and whether there is a concentration alarm and fault protection mechanism;

The purity requirement of industrial oxygen is strongly related to specific processes, for example, laser cutting requires oxygen purity ≥99.5%, while ozone systems place more importance on the efficiency of coupling oxygen concentration and flow rate; liquid oxygen can provide high purity, but its transportation and storage have high pressure and low temperature risks, and have been gradually replaced by onsite oxygen systems (such as PSA/VPSA). Ozone system is more important to the efficiency of the coupling of oxygen concentration and flow rate;

Although liquid oxygen can provide high purity oxygen, but its transportation and storage of high-pressure, low-temperature risk, has been gradually replaced by onsite oxygen system (such as PSA / VPSA).

2. Why 93% Oxygen Is Medically Acceptable

Although many users believe that “the higher the purity, the better”, in fact, 93% ± 3% purity oxygen has been widely proven to be clinically safe and effective enough to meet the medical standard for oxygen supply. The following is an explanation from three dimensions:

2.1 Practical Impact on SpO2₂

The core goal of oxygen therapy is to improve hypoxemia and increase SpO₂ (blood oxygen saturation).

Medical studies have shown that when inhaling 93%~96% pure oxygen, the SpO₂ of healthy people or most patients can be maintained in the range of 95%~99%, which is similar to the clinical improvement when compared with the use of 99% pure oxygen.

Excessive concentration may cause oxygen toxicity or aggravate CO₂ retention, especially in patients with chronic obstructive pulmonary disease (COPD), so medical oxygen concentration needs to be kept within a controllable range.

Conclusion: 93% medical oxygen can meet most of the clinical oxygen needs, and is both effective and safe.

2.2 International medical standards have been fully validated

| Certification Body / Standard System | Approved medical oxygen concentration | Description of application |

| Chinese Standard YY/T 0298 | 93% ±3% | Compulsory standard for medical oxygen equipment, applicable to centralized oxygen supply system and oxygen equipment |

| European Pharmacopoeia Ph. Eur. | ≥93% | Consistent with the Chinese standard, has been widely used in major hospitals in the European Union |

| World Health Organization WHO | ≥90% Qualified | For primary hospitals and mobile clinics, it has been clarified that 90%~96% of them are acceptable for medical oxygen. |

Description: 93%±3% of medical oxygen is supplied by PSA oxygen system, eliminating the need for cryogenic liquefaction and high-pressure cylinders, reducing transportation risks and enhancing system safety.

2.3 Safety and stability have been fully controlled

Modern PSA medical oxygen equipment not only provides stable oxygen concentration, but also has multiple safeguard functions:

| Safety Control Module | Function Description |

| Online Oxygen Concentration Analyzer | Real-time monitoring of the output oxygen concentration, below the set value of the automatic alarm |

| PLC Linkage System | Linkage of the backup gas source switching, automatic drainage, timed detection |

| Redundant Oxygen Source Mechanism | Failure to switch the bottle oxygen, liquid oxygen or the second host oxygen supply |

| Medical Grade Purity Fluctuation Range Control | Ensure that the long-term output oxygen concentration stabilized at 93% ±3% within the |

Summary: the stability of oxygen concentration is more important than “absolute purity”. 93% ± 3% medical oxygen in terms of safety, response time and system integration has been mature and reliable.

✅ Medical Selection Suggestions:

Centralized Oxygen Supply for Ward/ICU/Operating Room: Prefer 93%±3% PSA System + Dual Tower Switching + Concentration Alarm System;

Primary Hospitals/Mobile Medical Stations: Portable PSA Medical Models + UPS Power Supplies;

Specific Departments that are Extremely Sensitive to Oxygen Concentration (e.g., ECMO/Hyperbaric Oxygen Chambers): ≥ 99.5% Liquid Oxygen or Deep Cooled Oxygen System, Combined with a Dual Concentration Monitoring Mechanism.

3. Purity Monitoring and Quality Control in Oxygen Systems

In order to ensure the safety and consistency of oxygen used in medical and industrial fields, modern oxygen generation systems need to be equipped with complete purity monitoring and linkage control mechanisms. Oxygen purity not only affects the therapeutic effect or process reaction efficiency, but also directly related to personnel safety and system stability.

3.1 Online Oxygen Concentration Analyzer (±0.5% accuracy)

One of the core functions of the system is to install a high-precision online oxygen concentration sensor with the following features:

| Indicator parameters | Typical values |

| Measurement accuracy | ±0.5% |

| Detection range | 0% ~ 100% O₂ |

| Output method | Analog signal/digital signal (4~20mA or RS485) |

| Mounting position | Oxygen outlet mains, back end of storage tanks, branch junction of main oxygen tubing |

| Calibration period | Recommended yearly calibration |

This module can be used for real-time feedback of oxygen purity, for triggering alarm linkage, recording oxygen trend curve, and generating compliance reports.

3.2 Low Purity Automatic Alarm and Standby Gas Source Switching

In medical grade system, insufficient oxygen concentration will directly affect the safety of patients’ oxygen intake, so the system should be set up with multiple safeguard mechanisms:

Built-in Purity Threshold: Automatically triggers audible and visual alarm when the concentration is lower than the set value (e.g., 90%)

System Response: Automatically switches to the standby bottled oxygen or liquid oxygen gas supply system to avoid the interruption of oxygen

Example of Medical Gas Station: Oxygen Concentration <90% → alarm → main system maintenance This function is used to trigger alarm linkage in real time. → Turn on spare cylinder oxygen → Main system maintenance

This function is mandatory for critical areas such as ICU, operating room, intensive care area, etc.

3.3 Linkage Control System Docking PLC / SCADA / HIS

The modern oxygen generating system is no longer a “stand-alone device”, but is integrated into the automation centralized control network of hospitals or factories:

| Interface type | Application Notes |

| PLC control module | Control valve switching, concentration adjustment, fault reporting and other linkage operations |

| SCADA platform | Data acquisition and monitoring system for centralized visual management and historical traceability of the gas station |

| HIS interfacing | Medical information system for recording the oxygen consumption of wards and alarm information |

System data can be uploaded to the cloud to realize remote diagnosis, SMS alarm, WeChat alarm, fault automatic work order and other functions.

✅ Practical suggestions:

Medical PSA system should be equipped with ≥93% online oxygen concentration analyzer + PLC alarm linkage + automatic switching of gas source

Industrial VPSA system is recommended to set up three levels of monitoring points: main outlet + branch circuit + tail gas, to meet the dual requirements of process and safety

It is recommended to back up purity fluctuation logs on a quarterly basis for auditing and quality tracing.

4. PSA Oxygen Generators and Medical Oxygen Supply

Application of PSA Oxygen Concentrator in Medical Oxygen

With the rising global concern for medical oxygen safety, continuity and regional adaptability, PSA (Pressure Swing Adsorption) Variable Pressure Adsorption (PSA) oxygen generation technology, is becoming the preferred oxygen source solution for all kinds of medical institutions. The system is widely used in hospital ICU, wards, emergency vehicle stations, regional oxygen supply platforms and other scenarios due to its controllability, flexible deployment and low cost of use.

4.1 Brief description of the technical principle: Why can PSA output 93%±3% of oxygen stably?

PSA system utilizes the different adsorption properties of molecular sieve (e.g. Zeolite 13X) on nitrogen and oxygen, and operates alternately with two towers:

one tower adsorbs nitrogen to produce oxygen, and the other tower desorbs and regenerates at the same time, realizing a 24-hour continuous cycle of oxygen production.

The output concentration is stably controlled at 93%±3%, which fully meets the medical oxygen standard of China YY/T 0298 and the European Union Pharmacopoeia specification.

Room temperature operation, without deep cooling equipment, reduces energy consumption and failure risk.

✅ Flexible configuration: Oxygen production can be increased through modularization (3L/min to more than 200Nm³/h)

4.2 Conventional System Configurations for Medical Scenarios

In order to guarantee the purity, flow rate and safety of oxygen, the standard configuration of PSA system in hospitals is recommended as follows:

| Module Name | Function Description |

| Dual Tower Structure + Molecular Sieve | Main body adsorption device, to ensure continuous and stable oxygen |

| Online Oxygen Concentration Monitor | Real-time detection of purity (± 0.5% accuracy), such as below the threshold automatically alarm or switch |

| UPS Uninterruptible Power Supply | Ensure that the power outage is still supplying oxygen for critical care, emergency wards, and other high-priority places |

| Spare Bottle Oxygen Switching Valve Stack | Rapid manual switching in the event of a failure of the main system to protect the redundancy of the system |

| PLC Linkage Control System | Automatically adjust the adsorption tempo, networked with the SCADA system of hospitals, to support the reporting of data and remote diagnostic |

Recommended for use in high altitude/high temperature/dusty environments with dehumidification + vibration isolation + filtration redundancy

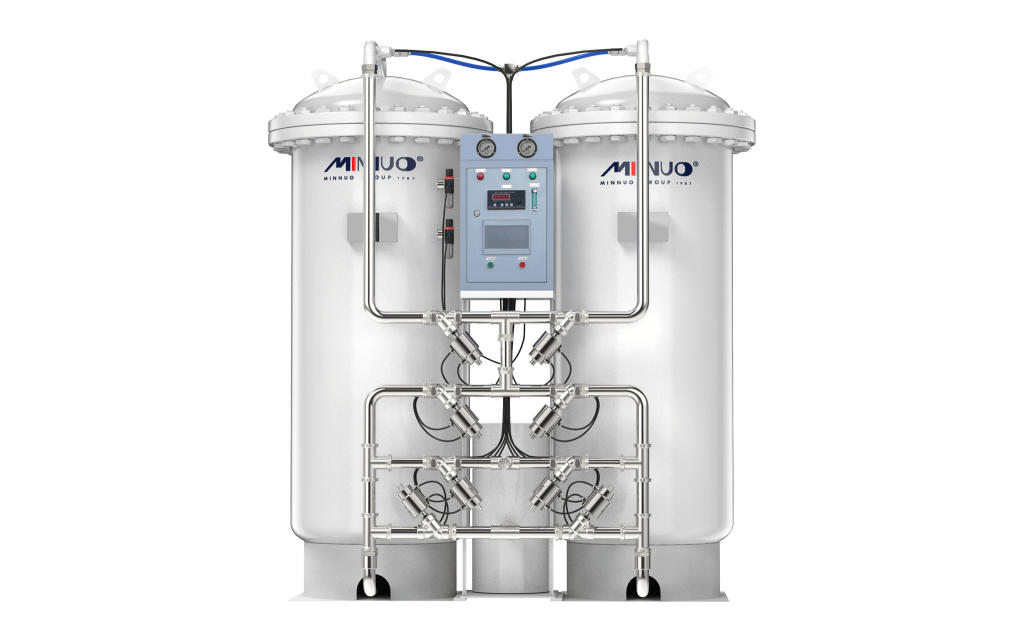

4.3 Selected Typical Cases of MINNUO Medical Oxygen Systems

MINNUO provides customized medical grade PSA oxygen systems with high altitude adaptability, high temperature resistance, and flexible deployment for customers around the world. Some of the scenarios include:

Tibetan county hospital: deploying twin-tower + UPS structure, with purity stability ≥93%, meeting the demand for constant oxygen supply at an altitude of 3,800m.

Southeast subtropical first aid station: configured with a forced ventilation system and automatic drainage function to ensure no downtime in hot and humid environments.

Mobile clinic in Africa: using a mobile trailer-type all-in-one unit + solar power supply, realizing remote oxygen supply in areas with no power supply.

Urban level Hospital central oxygen station: centralized oxygen supply capacity ≥150Nm³/h, networked HIS system, automatic data archiving

✅ Practical recommendations:

For regular ICU/ward, PSA medical oxygen generator is recommended, equipped with on-line purity monitoring and standby gas switching module

For critical isolation areas, negative pressure wards, or plateau hospitals, dual-redundant air source + plateau air compressor module is recommended.

If the system is for mobile rescue system, integrated mobile trailer + UV power supply + UV power supply should be considered. For mobile rescue system, the combination of integrated mobile trailer + UPS + battery pack should be considered.

❓FAQ

Q1: Is it that medical oxygen must be ≥99% to be qualified?

A: No.

According to China’s “YY/T 0298” national industry standard and the European Union Pharmacopoeia standard, 93% ±3% oxygen purity (i.e. 90%~96%) has been widely recognized as a safe and effective medical oxygen concentration, which can fully meet the clinical needs of patients’ blood oxygen saturation (SpO₂) maintenance.

Q2: Is there any difference between 93% PSA medical oxygen and 99% liquid oxygen in actual use?

A: For most patients, there is no significant difference.

93% PSA medical oxygen has been widely used in intensive care and ward oxygen therapy, with online concentration monitoring system, it has good stability and controllability;

99% liquid oxygen is suitable for special occasions requiring high concentration or ultra-long storage, such as oxygen storage bottling and long-distance transportation; however, it is more costly, requires deep-cooling liquefaction, and there is a risk of transportation explosion.

✅ In medical scenarios, continuous oxygen supply + concentration compliance + alarm system are more important than the oxygen purity value itself.

Q3: What is the essential difference between home oxygen concentrator and hospital PSA oxygen system?

A: The main difference lies in continuity, stability and the availability of alarm redundancy:

| Comparison dimension | Home Portable Oxygen Concentrator | PSA system for hospitals |

| Oxygen concentration | Mostly 30% to 90% fluctuation | 93%±3%, stabilized output |

| Operating hours | Suitable for intermittent use | Supports 24h continuous operation |

| Alarm function | Few with low oxygen alerts | Multiple automatic alarms + switching |

| Oxygen flow units | L/min (3 to 10L) | Nm³/h (≥20Nm³) |

| Scene adaptation | Home Care/Highland Relief | ICU/operating room/community hospitals, etc. |

Home use machines are suitable for “personal oxygen supplementation” and cannot replace “central oxygen system”.

Q4: Under what circumstances must I use ≥99% high purity oxygen?

A: High purity oxygen (≥99.5%) is recommended for the following special situations:

Neonatal intensive oxygen therapy or hyperbaric chamber

Specific surgical procedures (e.g., ophthalmology, cardiac bypass)

Industrial high-reaction-rate processes (e.g., ozone reaction, metal cutting)

In a general hospitalization or oxygen therapy ward, 93% of the medical oxygen is sufficient to satisfy the demand and is more cost-effective.

Q5: What purity levels are supported by the medical oxygen systems offered by MINNUO? Is it compliant?

A: The output purity of PSA medical oxygen system provided by MINNUO is 93%±3%, which is fully compliant with China YY/T 0298 and EU Pharmacopoeia standards.

Equipped with:

Real-time concentration online monitor (±0.5% accuracy)

Automatic switching of back-up gas system (if main gas <90%)

SCADA/PLC linkage with hospital HIS system

Support medical registration + CE/ISO13485 certification Export Compliance

Conclusion

The core of medical oxygen is not “the higher the purity, the better”, but to realize the balance of continuous oxygen supply, reasonable purity and real-time monitoring. Clinical research and standard verification have confirmed that the oxygen concentration of 93%±3% can fully meet the human body’s oxygen demand, especially with the high-precision on-line detector, standby gas source switching system and other safety mechanisms, which can guarantee the continuous and stable supply of oxygen in hospitals, ICUs, anesthesia systems and other high-intensity scenarios.

Users are recommended to make scientific judgments based on the three elements of “usage scenario × oxygen demand × deployment cycle” when selecting a model, and give priority to professional manufacturers that have passed regulatory certifications and have engineering experience.MINNUO provides medical/industrial oxygen generation solutions that cover 93%~99.5% of the total oxygen demand, and supports remote monitoring, module expansion, and customization for plateau/high-temperature special scenarios. MINNUO provides medical/industrial oxygen solutions covering 93%~99.5%, supporting remote monitoring, module expansion, and customization for special high-temperature/plateau scenarios, helping hospitals and enterprises to build a more efficient, safer, and economical oxygen supply system.

sales2:+86 17506119168

sales2:+86 17506119168