Liquid nitrogen has long been a key cold source infrastructure in many fields, such as medical care, life sciences, industrial cutting, and food preservation, due to its cryogenic properties and wide adaptability. However, in recent years, the Brazilian market has been faced with a headache: the continuous rise in the price of liquid nitrogen, unstable supply and high transportation costs have become a heavy burden in the daily operations of many enterprises and research institutions.

So why is liquid nitrogen so expensive in Brazil? Is it due to market speculation, or are there other structural factors? For those who have been relying on imported liquid nitrogen for a long time, is there a more economical and controllable alternative path? In this article, we will analyze these core issues and put forward a proposal to solve them in light of the industry trend: build your own liquid nitrogen system, get rid of the dependence on high-priced purchased liquid nitrogen, and build a stable, low-cost and sustainable nitrogen supply system.

If you are a scientific researcher, hospital equipment buyer, or food factory operation manager, and you are suffering from the problem of high-priced liquid nitrogen procurement, please read on. In this article, we will not only analyze the underlying logic of the cost structure, but also introduce a solution that can really take the initiative – localized liquid nitrogen system deployment advice from MINNUO.

1. Liquid Nitrogen Price in Brazil: Regional Monopoly, Cold Chain Gap and International Inversion

In Brazil, the market retail price of liquid nitrogen has been maintained at 25-35 USD/liter all year round, and even up to 40 USD/liter or more in some areas (e.g., remote areas of the northern states of Amazonas and Maranhão, etc.). This phenomenon is much higher than the average of the United States (8-12 USD/liter), the European Union (10-14 USD/liter) and China (6-10 USD/liter), creating a serious international price inversion.

1.1 Cost Components in Detail

Let’s take the example of an agricultural frozen embryo laboratory in Southeast Brazil that uses about 1,000 liters of liquid nitrogen per month. The following are typical cost components:

| Cost items | Unit Price Estimate (USD/L) | Percentage |

| Liquid Nitrogen ex-factory (factory price) | $10 | 28.6% |

| Long-distance transportation cost (200-800km) | $8-$12 | 25-34% |

| Dispensing and transshipment (bottle rental, etc.) | $4 | 11.4% |

| Cold chain insurance and losses | $2-$4 | 5-10% |

| Service markup (local agent) | $5-$8 | 14-22 |

End-user price: $29-$38/liter. Even if the liquid nitrogen itself is not expensive, the complexity of the transportation chain, the lack of cold chain infrastructure, and the markup mechanism of regional suppliers all combine to raise the final selling price.

1.2 Why does the price of liquid nitrogen remain high in Brazil?

Weak cold chain transportation system

Brazil is a vast country with different road conditions, and the logistics time in many regions (such as Northeast and North) often exceeds 48 hours. The low temperature (-196°C) of liquid nitrogen leads to the necessity of using professional Dewar’s tanks and cold chain vehicles, which is expensive, and the natural evaporation of liquid nitrogen during transportation often results in a loss rate of about 5-10%. The cost of transportation is high, and about 5-10% of liquid nitrogen is lost during transportation due to natural evaporation.

Monopolization of suppliers

The Brazilian liquid nitrogen supply market is highly concentrated, with oligopolies such as Air Liquide and White Martins (Praxair Brazil) controlling more than 95% of liquid nitrogen production capacity, leaving small and medium-sized enterprises (SMEs) with no choice but to passively accept their pricing. Coupled with the high barriers to equipment imports, there is no local liquid nitrogen equipment manufacturer that has formed a large-scale, medium- to long-term supply and demand imbalance trend has not changed.

⏳ Liquid nitrogen supply cycle is long and poorly planned

Most customers need to make an appointment for liquid nitrogen delivery 7-14 days in advance, which is poorly planned and inflexible. For organizations with sudden needs (such as frozen embryos, vaccine transportation, medical emergencies, etc.), there are high risks and business bottlenecks.

1.3 Is it more cost-effective to build your own liquid nitrogen production system? Comparison of In-depth Cost Recovery Models

Assuming that a cold chain enterprise uses 1,200 liters of liquid nitrogen per month, and the purchase price is $30/liter, the annual purchase cost will be:

1,200 L × $30 × 12 months = $432,000/year

The total investment cost of purchasing a 50-liter-per-day production capacity of liquid nitrogen (including liquid nitrogen generator + air compressor + cold dryer + storage tank) is:

$90,000-$120,000 (MINNUO model for example)

Calculation of payback cycle

Based on the electricity cost of $0.15/kWh, the average energy consumption is 1 liter of liquid nitrogen ≈ 2.5 kWh, then the electricity consumption for producing 1,200 liters of liquid nitrogen is as follows:

1,200 × 2.5 = 3,000 kWh × $0.15 = $450/month

Annual operating cost ≈ $5,400

Comparison Purchase price $432,000/year, payback only 3-5 months, subsequent annual cost savings over $400,000. If the remaining capacity can be used to sell liquid nitrogen to the outside world, it will form a stable side business profit model.

2.Analysis of the core factors contributing to the high price of liquid nitrogen

2.1 Production monopoly: scarce number of suppliers and strong bargaining power

In Brazil, the production market for liquid nitrogen is highly concentrated and is mainly controlled by multinational groups such as Air Liquide and White Martins. These companies have well-established LNG infrastructures and transportation networks, making the market entry barrier high. As it is difficult for new entrants to obtain construction permits, purchase air separation equipment, and complete the cold chain layout, the market is in a structural state of oversupply, resulting in a loss of competitive regulation of the price of liquid nitrogen.

Solution Suggestion:

The government can consider guiding local small and medium-sized enterprises to introduce small-scale liquid nitrogen equipment and promote the localized in-situ production mode of liquid nitrogen.

Factories can decouple the supply chain by building their own nitrogen systems or purchasing domestic liquid nitrogen equipment.

2.2 High refrigeration and energy costs: soaring electricity prices and energy inefficiency

The core cost of liquid nitrogen production is the deep-freeze refrigeration process, which consumes large amounts of industrial electricity. Although Brazil has a high proportion of hydroelectric power, the price of electricity is affected by inflation, taxes and local power supply policies, showing a regional fluctuation and upward trend. At the same time, old or outdated equipment means that electricity consumption per unit of liquid nitrogen remains high.

In-depth analysis:

The price of electricity in some industrial areas in Brazil is as high as 0.15~0.20 USD/kWh.

In contrast, domestic equipment (such as MINNUO) using advanced energy-saving inverter compressors and high-efficiency cooling systems has an advantage in terms of energy consumption per unit.

2.3 Cold chain transportation dilemma: high long-distance distribution costs and serious price stratification

Liquid nitrogen must be kept at ultra-low temperatures (-196°C) during transportation, and relies on special Dewar’s tanks or tanker trucks for low-temperature cold chain distribution. Brazil is a vast country, and the transportation distance from central factories to remote industrial parks or hospitals can be hundreds of kilometers, with significant costs for transportation fuel, manpower, and refrigeration losses.

Practical Impact:

The price of liquid nitrogen in urban areas is around $20-25/liter, and even up to $30 or more in remote areas.

Medical distribution channels increase the price layer by layer, and the most end-users have the highest cost.

Suggested Path:

End-users with stable demand (e.g. refrigeration factories, hospitals) can build their own liquid nitrogen machines for local production, avoiding the price exploitation brought by cold chain distribution.

2.4 Regulatory Barriers: Cumbersome Approval Processes and Spillover of Compliance Costs

In Brazil, the storage, transportation and sale of hazardous chemicals such as liquid nitrogen are subject to multiple regulatory standards, such as ANVISA (National Sanitary Surveillance Agency) and IBAMA (Brazilian Environmental Agency), resulting in an average cycle of more than 12 months for liquid nitrogen projects from inception to operation. Some state governments require specialized permit reviews and environmental filings, and companies also need to bear the cost of third-party safety audits.

Extended reflection:

Policy barriers are for safety, but they also make project expansion difficult and push up market access thresholds.

Potential Ways Out:

Partnering with overseas manufacturers with export certifications and experience, such as MINNUO, allows for advance planning of compliance paths and avoidance of trial-and-error costs.

Adopting an integrated liquid nitrogen system that meets international standard certifications (e.g., CE, ISO) can speed up the project approval process.

3. Cracking the dilemma: why is it recommended to build the liquid nitrogen system independently?

The price of local liquid nitrogen in Brazil is persistently high, with a large transportation radius and strong dependence, which, together with the exchange rate fluctuations and other factors, makes the cost of nitrogen for enterprises uncontrollable. In contrast, self-built liquid nitrogen system has become an active choice for more and more enterprises, and the logic behind it is much more than saving.

3.1 Cost pressure dominates and return on investment is controllable

Although the initial purchase cost of liquid nitrogen equipment is high, long-term operation can significantly dilute the unit cost. Take medium-sized liquid nitrogen demand enterprises as an example, according to the average daily nitrogen consumption of 5 tons of calculation, if the current purchase price of R $ 5-6/kg, self-built system unit cost can be controlled at R $ 2.5/kg or less, and can be paid back within 3 years.

✅ Lower unit cost, payback in 2-3 years can be expected

Although the initial construction cost of liquid nitrogen equipment is higher than that of direct purchasing, according to the market practice, enterprises can realize cost recovery in 2-3 years, mainly thanks to the following three points:

Avoiding fluctuating price: Dodge the soaring of purchasing price caused by seasonality, emergencies, rising energy cost, and so on.

Low daily running cost: For example, for a laboratory that consumes 300L of liquid nitrogen per day, self-production can save 40~60% compared with procurement.

Application of automated energy-saving technology: new refrigeration technology (such as magnetic refrigeration and nitrogen recovery system) further compresses long-term running costs.

✅ Avoid drastic price fluctuations and long-term dependence on imported gas source

✅ It can be used as a long-term mechanism for enterprises to fight inflation and control costs

3.2 Avoid transportation risks and improve gas source security

Local liquid nitrogen in Brazil is mainly concentrated in the southeast cities, while enterprises in the west and north regions are often faced with the problems of excessive transportation radius, untimely delivery, and evaporation and loss in the middle of the journey. Especially in seasonal agricultural nitrogen use and vaccine cold chain and other time-sensitive scenarios, outsourcing is extremely unstable.

Liquid nitrogen transportation faces multiple uncertainties, and a self-built system can solve these pain points at the source:

Transportation is uncontrollable: traffic control, bad weather, and driver shortages can all affect supply.

Frequent safety problems: Leakage of transportation tanks, abnormal pressure and other events are unpredictable.

High depletion: Evaporation of liquid nitrogen during transportation is unavoidable, resulting in hidden losses.

✅ Build localized nitrogen system to effectively realize “freedom of nitrogen”

✅ Enhance the risk-resistant ability of key industries such as biopharmaceutical, scientific research, food preservation, etc.

3.3 Enhance the extensibility of the production line, and realize the value-addedness of “Nitrogen+Business” integration.

Liquid nitrogen is not only a cooling/freezing medium, but also part of the process chain. Once an enterprise grasps the right to control the gas source, it can flexibly increase the capacity according to the business growth, and expand the business by combining with new types of business such as cold chain processing, liquid nitrogen welding, cryopreservation, AI+ inspection, etc., thus forming the “Nitrogen+Business” linkage.

Investing in liquid nitrogen system is not only a tool to reduce cost and increase efficiency, but also a lever to promote enterprise value reconstruction:

Formation of fixed assets: the equipment can be depreciated, and the value of tax deduction can be reflected in the long term.

Open up value-added service space: some enterprises build their own systems and then carry out “liquid nitrogen supply” service, forming regional cold chain micro-center.

Enhance bargaining power: suppliers have more initiative to avoid passive acceptance of price increase notices.

✅ Promote the realization of joint production and control of equipment in the industrial field

✅ Provide underlying support capacity for business innovation

3.4 Helping Corporate Sustainability and Compliance Governance

Driven by the global ESG trend, more and more multinational customers are requesting supply chain companies to provide compliance reports such as “Carbon Emission Tracking” and “Energy Efficiency”. Compared with purchasing gas sources, it is easier to obtain complete energy data and carbon footprint records from self-built liquid nitrogen systems, which supports enterprises’ environmental protection and compliance reporting.

Carbon reduction: The system integrates energy-saving compressors and intelligent coolers, which significantly reduces power consumption.

Respond to policy guidance: In countries such as Brazil, self-built systems can be included in clean energy subsidies or tax incentives.

Enhance brand reputation: green cooling capability becomes the embodiment of corporate social responsibility and winning customers’ trust.

✅ Can be docked into environmental protection and carbon reduction projects (e.g. REDD+, carbon trading)

✅ Reduce the dependence on traditional energy high-pollution enterprises

4.Recommended Choice: Cost-Effective Advantages of Made-in-China — MINNUO Liquid Nitrogen Equipment

One of the biggest obstacles to the current self-built liquid nitrogen system in Brazil is: the high price of imported equipments, slow delivery, and weak after-sales service. However, made in China, especially liquid nitrogen equipment manufacturers with international export qualification, has become a cost-effective solution recognized by the global market.

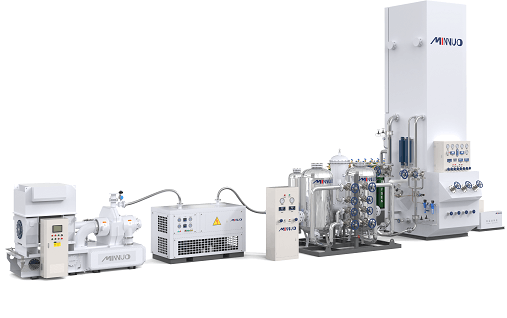

4.1 Full-coverage capacity design to meet different customers’ needs

MINNUO liquid nitrogen units cover various types of production capacity from 20L to 2,000L, which is suitable for the nitrogen needs of small laboratories, animal husbandry farms, and large-scale metal manufacturing enterprises.

Compared with European, American and Japanese brands, Chinese manufacturers provide more models to choose from and more targeted technical advice.

Agricultural Nitrogen Filling and Preservation: Suitable for 100L~500L daily consumption

Scientific Research Laboratory: Silent type, high precision flow control

Industrial Cooling Application: Supporting 7×24 continuous operation, including remote monitoring module.

4.2 Significant price advantage, quickly lower the threshold of building the system

Taking MINNUO liquid nitrogen unit as an example, the equipment procurement cost is only 50-60% of the equipment in Europe and the United States, and under the premise of guaranteeing the use of imported brands of key components (such as Siemens, Hanzhong, Huichuan), it effectively realizes the uncompromising core performance, and the pressure on the overall investment is reduced significantly.

The price is more advantageous, about 30%-50% cheaper

Maintenance is simple, parts do not rely on foreign original

4.3 Shorter delivery cycle and engineering response

MINNUO supports mass production + sea delivery + local assembly services, compared with the European and American customized equipment in general to save 2-3 months delivery cycle. Meanwhile, MINNUO is equipped with multi-language installation manuals, online remote guidance, and key point delivery instructions to ensure a controllable building cycle and short commissioning period.

4.4 Localization of after-sales service and reduction of technical barriers

MINNUO has a team of Spanish/Portuguese engineers in the Latin American market to support regular inspections, remote troubleshooting, spare parts replacement suggestions and other services, assisting customers in establishing a long-term self-maintenance system and reducing later dependence.

Provide full-process support from “station construction→operation and maintenance→upgrade”

Export experience covers more than 40 countries in Asia, Africa, South America and Eastern Europe

As a professional manufacturer of liquid nitrogen equipment, MINNUO has been deeply engaged in the global market for more than 10 years, and its equipment has a large number of landing cases in South America, the Middle East, Southeast Asia and other places.

Advantageous Dimension Features of MINNUO Liquid Nitrogen System

Cost Control The overall price is only 40-60% of European and American brands, which saves a lot of initial investment.

Technical Configuration All-in-one integrated design supports intelligent control, remote monitoring and unattended operation.

Maintenance and Accessories We provide a full set of compression, cooling and liquefaction accessories and spare parts, and our after-sales logistics are directly delivered to South America.

Cooling Efficiency Liquid Nitrogen purity 99.999%, daily production capacity 99.999% and 99.999% liquid nitrogen purity, with daily output ranging from 10L to 200L, meeting the needs of various industries.

Sustainable Development No longer rely on external high-priced liquid nitrogen market, avoiding the risk of unstable supply and temporary price hike, and building a long-term competitive barrier for the enterprise.

Conclusion

It is no coincidence that the underlying reasons behind the persistently high price of liquid nitrogen in Brazil are not coincidental. From the structural capacity gap to the long and complicated inland logistics system, the supply chain costs of liquid nitrogen products from factory to user have been accumulating, making the end price much higher than the global average. Especially in remote areas or small and medium-sized medical and scientific research scenarios, the high price of liquid nitrogen has become a long-term pain point for many users.

Against this background, self-built liquid nitrogen systems have become a direction that more and more users are exploring. Compared with relying on external procurement, self-built liquid nitrogen units are more controllable, with clearer costs and higher stability. Especially for scenarios with stable dosage and continuous cycles, such as medical institutions, food factories, biological laboratories, etc., the self-built solution will significantly reduce the cost of liquid nitrogen per unit, and solve the uncertainty risk brought by fluctuations in supply and demand.

MINNUO, as an expert in liquid nitrogen equipment manufacturing, provides one-stop service from selection and design, costing to remote guidance for installation. We support all sizes from 20L to 2000L, covering a wide range of applications from basic scientific research to bulk industry, providing you with a sustainable, cost-effective and reliable way out in the region of high liquid nitrogen prices.

sales2:+86 17506119168

sales2:+86 17506119168