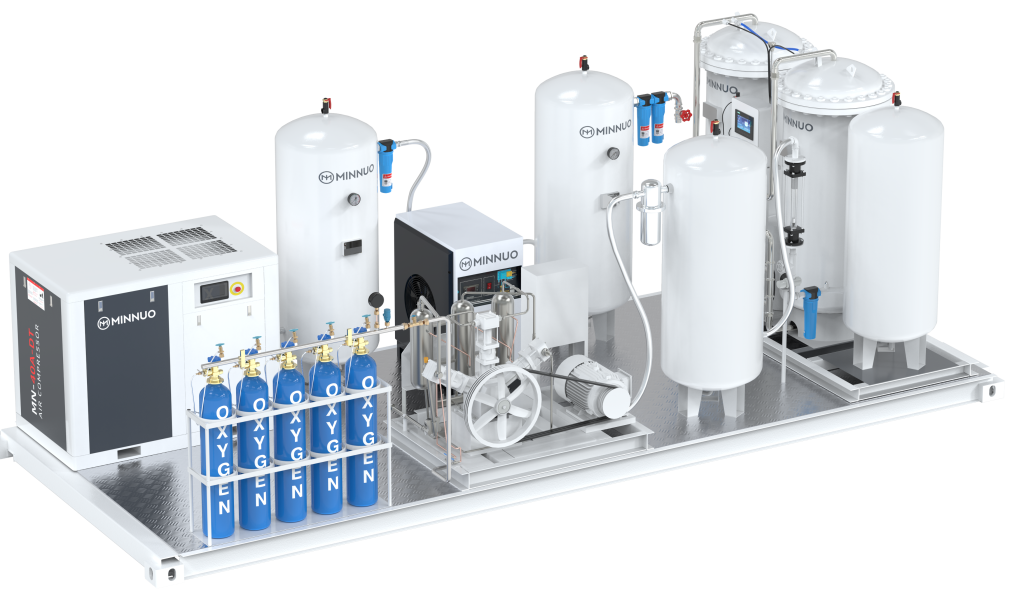

In modern industrial operations, especially in wastewater treatment plants and heavy manufacturing, the demand for a reliable, continuous oxygen supply is non-negotiable. PSA (Pressure Swing Adsorption) oxygen generators have emerged as the gold standard for on-site gas generation, offering unmatched durability in the most challenging conditions.

oxygen plays a crucial role in ensuring the efficiency of various processes, from metal cutting and welding to wastewater treatment and chemical production. Pressure Swing Adsorption (PSA) technology has emerged as a key method for oxygen generation in such environments, thanks to its long-term, cost-effective, and scalable capabilities. PSA oxygen generators operate by selectively adsorbing nitrogen from compressed air, providing high-purity oxygen that meets the demands of diverse industrial applications. However, in harsh industrial environments, the stability and performance of these systems are critical, as operations often take place under conditions that test the limits of machinery and systems.

Industries such as steel manufacturing, metal cutting, welding, and wastewater treatment require stable and consistent oxygen supplies to ensure the smooth running of their operations. The environmental challenges in these sectors are considerable, with fluctuations in temperature, exposure to high dust levels, moisture, and harsh chemicals being commonplace. These factors can lead to equipment wear, operational downtime, and inefficiencies if not addressed properly. Therefore, the choice of oxygen generator—especially in these extreme environments—becomes crucial for operational efficiency and cost-effectiveness.

If you’re operating in demanding conditions, you may be wondering: how do PSA oxygen generators handle these extreme factors? Are there specific features that ensure their stability and reliability in such environments? What sets PSA technology apart from other oxygen generation methods, and why is it the preferred solution in industries requiring high-performance, long-term use? This article will provide valuable insights into the importance of stability in harsh industrial settings and why PSA oxygen generators are engineered to meet the toughest challenges.

What is PSA? Meaning and Working Principle in Oxygen Plants

PSA (Pressure Swing Adsorption) is a sophisticated gas separation technology used to extract high-purity oxygen from ambient compressed air. By using specialized Molecular Sieves (ZMS), the system adsorbs nitrogen under high pressure and releases it under low pressure, delivering a constant stream of 93%±3% pure oxygen.

This technology is the preferred choice for industrial gas plants because it eliminates the need for liquid oxygen deliveries, significantly reducing operational costs and logistics complexity.

What is the meaning of PSA in an oxygen gas plant? PSA stands for Pressure Swing Adsorption. It is a cost-effective technology that separates oxygen from compressed air by using Molecular Sieves (ZMS) to adsorb nitrogen under high pressure, providing a continuous flow of high-purity oxygen.

Why PSA Oxygen Systems are Essential for Modern Wastewater Treatment

The wastewater treatment industry is one of the highest consumers of industrial oxygen. Traditional aeration methods often fall short when dealing with high-capacity biological loads.

- Enhanced Aeration Efficiency: High-purity oxygen from a PSA generator accelerates the breakdown of organic pollutants, significantly improving COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) removal rates.

- Odour Control: By maintaining optimal dissolved oxygen levels, PSA systems prevent anaerobic conditions, effectively neutralizing H2S and other foul-smelling gases.

- Cost-Effective Scalability: Unlike liquid oxygen tanks that require constant refilling, an on-site PSA oxygen generator for wastewater provides a “set and forget” solution with a lower carbon footprint.

- Footprint Optimization: Our compact PSA units allow treatment plants to expand their capacity without requiring massive infrastructure changes.

Engineered for Reliability in Harsh Environments

Industrial sites are rarely “clean” environments. Dust, high humidity, and extreme temperatures can degrade standard machinery. Minnuo’s PSA oxygen generators are specifically engineered to thrive where others fail.

Corrosion Resistance & Heavy-Duty Performance

In wastewater treatment plants, the air is often laden with moisture and corrosive gases like Hydrogen Sulfide. To combat this, our systems feature:

- Specialized Protective Coatings: All critical components are treated with industrial-grade anti-corrosion paint.

- Stainless Steel Piping: We use high-grade stainless steel for internal gas paths to prevent rust and ensure gas purity over decades of use.

- Advanced Filtration: Multi-stage filtration systems protect the Zeolite Molecular Sieve from oil, moisture, and particulates, extending the machine’s life to over 10 years.

Technical Specifications & Performance Data

For industrial buyers, performance metrics are the key to decision-making. Below is the typical specification for our Heavy-Duty PSA series:

| Feature | Technical Detail |

|---|---|

| Oxygen Purity | 93% ± 3% (Up to 99% upon request) |

| Oxygen Capacity | 3 – 200 Nm³/h |

| Outlet Pressure | 0.1 – 0.6 MPa (Customizable) |

| Operating Environment | -20°C to +45°C |

| Control System | Siemens PLC with Remote Monitoring |

| Application | Wastewater, Biogas, Medical, Metallurgy |

Robust Design: How PSA Oxygen Generators Are Built for Long-Term Use

PSA oxygen generators are designed to operate efficiently in the harshest industrial environments. Their robustness ensures long-term stability and reliable oxygen supply, even in extreme conditions such as high humidity, corrosive environments, and temperature fluctuations.

Durable Materials for Harsh Conditions

In industries such as mining, steel manufacturing, and chemical production, PSA oxygen generators must withstand a variety of challenging conditions. The materials used in the construction of these systems are carefully selected to ensure durability and minimize maintenance.

Corrosion-Resistant Metals: PSA oxygen generators often use corrosion-resistant materials such as stainless steel and specialized alloys. These metals are critical for ensuring the system’s longevity, especially in environments with high levels of moisture or chemicals that can lead to rust or corrosion over time.

Special Coatings: The components that are exposed to oxygen or harsh environmental conditions are often coated with protective layers. These coatings prevent rust, deterioration, and wear, ensuring that the generator can continue to function without breakdowns for extended periods.

Long-Term Stability: The robust materials used in PSA oxygen generators are designed to endure years of continuous operation. Their ability to resist corrosion and damage ensures that the system remains stable even under intense industrial conditions.

Energy-Efficient Technology

One of the significant advantages of PSA oxygen generators is their energy efficiency, especially for long-term operation.

Minimized Energy Consumption: PSA systems are designed to consume the least amount of energy while providing a continuous supply of oxygen. They operate using a process of adsorption and desorption, which uses minimal energy compared to other oxygen generation methods, such as cryogenic systems.

Low Maintenance Costs: By minimizing energy consumption and reducing the need for intensive maintenance, PSA generators lower overall operating costs over their lifespan. The low operational costs make them a preferred choice for industries with high and constant oxygen demand.

Energy Savings Over Time: Compared to traditional methods, PSA systems provide significant energy savings. Over time, the reduction in energy costs can justify the initial investment, especially in industries requiring a long-term, stable oxygen supply.

Stability: Key Features That Ensure Continuous Operation

PSA oxygen generators are designed to operate continuously and reliably in industrial and medical environments. Their stability is not only a testament to their engineering but also to the advanced features integrated into their systems to maintain high performance. Below, we examine the three key elements that ensure PSA generators function seamlessly without interruptions.

Advanced Control Systems

Automated Control for Stable Oxygen Output: One of the most vital features of a PSA oxygen generator is its automated control system, which ensures the stability of the oxygen output. These systems monitor critical parameters, such as pressure levels, oxygen flow rates, and purity, in real-time.

The role of pressure sensors is to continuously monitor the pressure levels within the generator, adjusting the process when deviations occur, ensuring the system maintains steady operation.

Flow meters help regulate the volume of oxygen produced and delivered, ensuring that the demand is met without fluctuations. In case of pressure drops or abnormal readings, the system automatically adjusts, preventing any shortages.

Real-time monitoring allows for quick identification of any anomalies in the oxygen generation process. This advanced feedback loop minimizes the risk of downtime and ensures that the oxygen supply is continuous, even during peak demand periods.

Preventing Fluctuations in Oxygen Supply: The control systems are integrated with alarm systems that alert operators if any operational parameter exceeds or falls below predefined thresholds. These alerts prompt operators to take corrective action before the system is impacted, allowing for minimal intervention and preventing costly disruptions.

Temperature Control and Cooling Mechanisms

Preventing Overheating in High-Temperature Environments: Oxygen generators, particularly in industrial settings, can be exposed to extreme temperatures that may affect performance and longevity. PSA oxygen generators are equipped with advanced cooling systems to mitigate this issue.

Cooling fans circulate air around the unit, ensuring that components do not overheat. In environments where high heat is inevitable (e.g., steel plants or glass production), these systems are crucial for maintaining consistent performance without risking thermal damage.

Heat exchangers are employed to dissipate excess heat from the system. They are essential in keeping the system within its optimal operating temperature range.

Regular airflow checks are crucial, especially in industrial settings where dust, oil mist, and other particulate matter can obstruct the cooling system, potentially causing overheating.

Temperature Regulation for Consistent Performance: Stable operation depends heavily on regulating the temperature. An overly high temperature can lead to the degradation of sensitive components, reduced efficiency, and potential breakdowns.

PSA systems are designed with built-in temperature regulation features that ensure the system remains within the recommended temperature range, typically between 15°C to 40°C for optimal performance.

Intelligent algorithms in modern PSA systems can predict when temperature conditions might affect the system and adjust the cooling accordingly to avoid any adverse impacts.

Suitability for Challenging Conditions

PSA oxygen generators are designed to perform in a wide range of environments, including those with extreme conditions, fluctuating pressures, and continuous operation demands. Below is a detailed breakdown of how these systems excel in these challenging scenarios, ensuring reliable, consistent oxygen supply without compromising on safety or performance.

Performance in Extreme Environments

PSA oxygen generators are engineered to handle the toughest industrial environments, where conditions such as high heat, humidity, dust, and chemical exposure can pose significant operational challenges. These systems are built with durable components that can withstand harsh conditions, ensuring that oxygen production remains stable even in difficult settings.

High Heat & Humidity: Many industries operate in areas where ambient temperatures exceed typical operational limits, such as steel mills, foundries, or high-temperature chemical plants. PSA generators are designed with cooling systems to manage excess heat and ensure that internal components remain within safe operating temperatures. Furthermore, the system’s temperature regulation mechanisms help avoid overheating, which can lead to inefficiency or system failure.

Case Study: A manufacturing plant in the Middle East faced extremely high ambient temperatures, often exceeding 45°C. The PSA oxygen generator was fitted with an industrial-grade cooling system, allowing it to function effectively in these high-heat conditions without compromising oxygen output or operational stability.

Dust & Chemical Exposure: Environments such as cement plants or mining operations often deal with airborne dust, which can clog filters or corrode metal components. To combat this, PSA oxygen generators are equipped with advanced filtration systems designed to protect the core components from dust and particulate matter. Chemical exposure, especially in industries like pharmaceuticals and chemicals, requires oxygen systems to resist corrosion. PSA generators use stainless steel components and chemical-resistant coatings to prevent damage and ensure long-term functionality.

Case Study: A large-scale cement production facility reported improved reliability after switching to PSA systems equipped with high-efficiency air filters and corrosion-resistant materials, ensuring the equipment remained operational in their dust-heavy environment.

Resistance to Pressure Fluctuations

Industries operating in remote or volatile conditions often face inconsistent or fluctuating pressures, which can affect the performance of standard oxygen generators. PSA oxygen generators are specifically designed to handle these fluctuations, providing a stable output despite variations in supply pressure.

Stable Oxygen Production Despite Fluctuations: PSA systems can automatically adjust to pressure fluctuations, ensuring a steady supply of oxygen even when the source pressure varies. This is crucial in remote locations or industries where external conditions, such as pipeline pressure or fluctuating demands, cannot always be controlled.

For instance, in offshore oil rigs or mining operations, pressure instability can occur frequently. PSA systems can accommodate these changes without compromising oxygen purity or production rates.

Resilience in Remote Locations: PSA oxygen generators are ideal for use in areas with limited infrastructure, such as remote oil and gas operations, or in locations where energy supply is unstable. These systems are designed to function autonomously, requiring minimal intervention and allowing for continuous operation without frequent adjustments or downtime.

Economic Benefits: Long-Term Cost Efficiency

PSA (Pressure Swing Adsorption) oxygen generators are designed with a focus on long-term operational efficiency, making them a cost-effective solution for industries requiring continuous oxygen supply. By considering their low maintenance, energy optimization, and return on investment (ROI), companies can experience significant savings while improving their overall operations. Below is an in-depth exploration of the key economic benefits these systems provide over time.

Low Maintenance Costs Over Time

One of the primary reasons PSA oxygen generators are considered a cost-effective solution is their low maintenance requirements. Unlike conventional systems, PSA systems are engineered to require minimal servicing, thus significantly reducing the overall cost of ownership.

Fewer Parts Replacements: PSA systems have fewer moving parts compared to alternatives, such as cryogenic oxygen systems or liquid oxygen storage, which leads to lower replacement costs over time. Components like the valves, filters, and adsorbent beds in PSA generators are designed for longevity, and regular maintenance focuses on simple tasks such as filter changes and system inspections rather than major component replacements.

Longer Intervals Between Servicing: The design of PSA systems minimizes wear and tear. By incorporating advanced automation and monitoring features, these generators require less frequent intervention, meaning that users experience fewer downtimes and reduced repair costs. This is particularly important in industries where unplanned downtime can result in significant losses.

Case Example: A mining company in a remote location shifted from using liquid oxygen tanks to a PSA generator. The switch reduced maintenance costs by 25% annually, as fewer parts needed replacing and servicing intervals were extended, leading to substantial cost savings in terms of labor and spare parts.

Energy and Resource Optimization

PSA oxygen generators are built with energy efficiency in mind, offering cost-saving advantages for industries that require continuous operation. Their operational design reduces energy consumption and ensures more sustainable use of resources.

Energy-Efficient Design: Unlike traditional systems that consume excessive power due to constant refrigeration and cryogenic processes, PSA systems use a pressure swing process, which requires less energy to operate. This results in lower electricity bills, especially for industries that need large volumes of oxygen consistently.

Cost Savings on Utility Bills: The low energy consumption of PSA oxygen generators helps businesses optimize their overall utility costs. This is particularly significant in industries where the demand for oxygen is high, such as in welding, metal fabrication, and chemical processing. Over time, these savings add up, allowing companies to allocate resources more effectively.

Example: An industrial gas supplier switched to a PSA oxygen generator and noted a reduction in electricity usage by 15-18% annually. The reduction was attributed to the system’s efficient use of air compression and lower power consumption compared to conventional methods.

Sustainable Resource Use: PSA systems do not rely on the transportation of oxygen or the use of bulky gas cylinders, reducing the environmental impact and resources spent on logistics. This reduces the carbon footprint of businesses and ensures a more sustainable oxygen supply chain.

Case Studies: PSA Oxygen Generators in Action

The following case studies illustrate how PSA oxygen generators are being successfully used across a variety of industries, showcasing their role in stabilizing oxygen supply, reducing operational costs, and improving production efficiency. These examples demonstrate the versatility and reliability of PSA systems in different environments, emphasizing their critical role in industries requiring a continuous and stable oxygen supply.

Case Study 1: Steel Manufacturing

In steel manufacturing, oxygen plays a pivotal role in the combustion process, especially in blast furnaces and steel production furnaces. The need for stable and high-quality oxygen is paramount, as any fluctuation in oxygen supply can lead to inefficiencies, reduced production capacity, and increased costs.

Problem:

A steel mill was experiencing inconsistent oxygen supply, which was negatively affecting the combustion process in the furnaces. This resulted in fluctuations in production rates, increased energy consumption, and a rise in operational costs. The plant relied on external liquid oxygen delivery, which led to supply chain challenges and variable oxygen quality.

Solution:

The mill opted to implement a PSA oxygen generator to produce on-site oxygen. This system allowed for continuous, reliable oxygen supply, directly addressing fluctuations caused by external suppliers. The PSA system was designed to meet the mill’s high-volume oxygen requirements while offering the flexibility to adjust oxygen purity levels as needed.

Outcome:

The implementation of the PSA oxygen generator helped the steel mill stabilize its oxygen supply, leading to a 20% reduction in energy costs and a 15% increase in production efficiency. The mill also saved significant costs by eliminating reliance on liquid oxygen suppliers, leading to a higher ROI in the long term.

Case Study 2: Mining and Oil Extraction

In mining and oil extraction, oxygen is essential for a variety of processes, including combustion for mining operations and enhancing oil recovery through oxygen injection techniques. The stability and purity of the oxygen supplied can significantly impact the success of these operations.

Problem:

An oil extraction facility in a remote area faced issues with inconsistent oxygen supply, which affected their ability to maintain optimal combustion for oil recovery. The location’s harsh environmental conditions also posed a challenge, as extreme temperatures and dust were affecting the performance of the oxygen equipment.

Solution:

The facility decided to replace their liquid oxygen supply with a PSA oxygen generator. This system was able to operate continuously without interruption and was equipped with specialized cooling and dust-filtering mechanisms to function reliably in the challenging conditions of the oil field.

Outcome:

The PSA oxygen generator provided consistent oxygen flow, which improved the efficiency of combustion processes and oil extraction operations. The stability of the system reduced downtime caused by oxygen supply interruptions, and the long-term cost savings allowed the facility to improve its overall operational efficiency. Furthermore, the system’s durability in harsh conditions reduced maintenance needs and extended the lifespan of the equipment.

Case Study 3: Chemical Processing

In chemical plants, oxygen is often required for oxidation reactions, which are essential in processes such as the production of chemicals, polymers, and other industrial products. Oxygen purity and availability are crucial for maintaining reaction efficiency and safety standards.

Problem:

A chemical processing plant faced challenges in maintaining stable oxygen supply for its oxidation processes. The plant had been using a traditional oxygen cylinder system, but the frequent delivery delays, fluctuation in supply pressure, and high operational costs led to inefficiencies and safety concerns.

Solution:

The plant switched to a PSA oxygen generator, which allowed for the on-site generation of high-purity oxygen, tailored to their specific requirements. The system was designed to maintain consistent oxygen purity and was integrated with real-time monitoring tools to ensure the stable operation of the chemical reactions.

Outcome:

With the PSA system in place, the chemical plant was able to achieve a consistent supply of oxygen for its oxidation reactions, reducing safety risks and minimizing downtime. The system’s energy-efficient design also led to a reduction in operating costs, while the improved purity of the oxygen resulted in better reaction outcomes and increased production efficiency.

Frequently Asked Questions (FAQ)

Q: Why is a PSA oxygen generator better than liquid oxygen for wastewater?

A: On-site PSA generators eliminate delivery costs, rental fees for tanks, and the risk of supply chain disruptions. For 24/7 operations like wastewater treatment, the ROI is typically achieved within 12-18 months.

Q: Can these systems operate in high-humidity tropical climates?

A: Yes. Our “Harsh Environment” series includes integrated refrigerated dryers and high-efficiency water separators specifically designed for high-humidity industrial zones.

Q: What maintenance is required for a PSA oxygen plant?

A: Maintenance is minimal, primarily involving the periodic replacement of filter elements and monitoring the air compressor. The Zeolite Molecular Sieve (ZMS) can last over 10 years with proper air pretreatment.

Q: How does a PSA oxygen generator benefit wastewater treatment

A: It provides a continuous, on-site oxygen supply for aeration, reducing chemical costs and improving COD/BOD removal efficiency.

Comparative Analysis: Standard vs. Minnuo Heavy-Duty PSA Systems

| Feature | Standard Industrial Generator | Minnuo Heavy-Duty PSA Generator |

|---|---|---|

| Purity Range | 90% – 93% | 93% ± 3% (Customizable to 99%) |

| Environment Adaptability | General Indoor | Corrosive & High Humidity (Wastewater) |

| Control System | Basic PLC | Smart Remote Monitoring & Auto-Adjust |

| Service Life | 5-8 Years | 10+ Years with Robust Design |

Conclusion

PSA oxygen generators offer a robust and reliable solution for industries that require a consistent and stable oxygen supply, particularly in harsh and challenging environments. These systems excel in providing stability, energy efficiency, and long operational life, all while keeping maintenance costs low. Their energy-efficient design ensures that oxygen production is optimized to meet industrial demands without incurring excessive operational expenses. The ability to operate in extreme conditions, whether it’s extreme heat, dust, humidity, or chemical exposure, makes PSA oxygen generators indispensable in many industrial applications.

Industries operating in harsh environments or those that demand continuous oxygen supply should consider PSA oxygen generators for long-term benefits. These systems are tailored to meet the rigorous demands of heavy-duty applications, offering a reliable, low-maintenance solution that reduces downtime and operational costs. By choosing PSA technology, industries can ensure their oxygen production systems remain operational without the need for frequent repairs, thereby maximizing efficiency and cost-effectiveness over time. MINNUO’s PSA oxygen generators are designed to offer just these benefits, providing industrial sectors with a trusted, efficient, and economical solution for years to come.

By integrating MINNUO’s advanced PSA technology, industries gain not only a system designed for continuous operation but also a partner committed to optimizing the performance of their oxygen generators, ensuring reliable and stable oxygen supply wherever it’s needed.

sales2:+86 17506119168

sales2:+86 17506119168