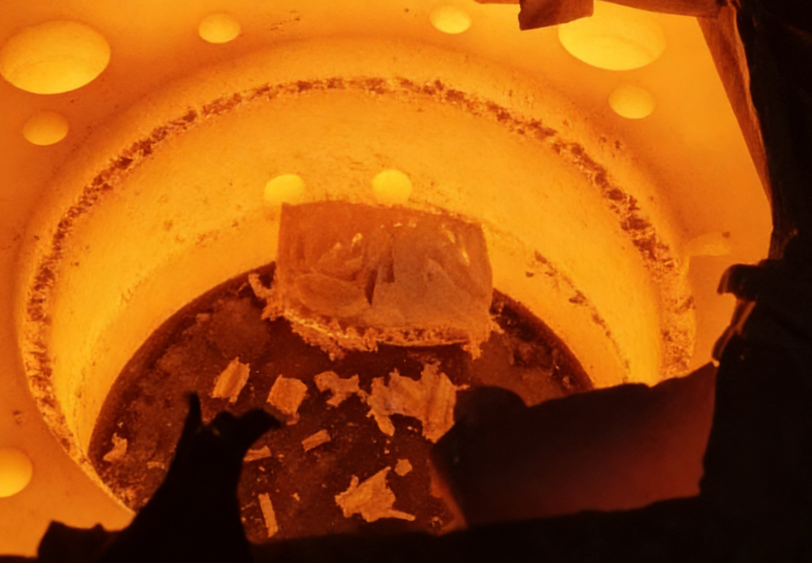

In precision heat treating, the furnace atmosphere is as critical as time and temperature. An uncontrolled atmosphere leads to scaling (oxidation), discoloration, and decarburization, ruining part surfaces, dimensions, and mechanical properties. For processes like bright annealing, clean hardening, and brazing, an inert nitrogen-based atmosphere is the industry-standard solution to protect metal surfaces at high temperatures.

However, simply introducing nitrogen is not enough. The purity, dryness, and precise control of the atmosphere determine success or failure. This guide explains how nitrogen works in a heat-treating furnace and provides the key parameters you must control to achieve perfect, scale-free results.

The Problem: What Happens Without a Protective Atmosphere?

When steel is heated in the presence of oxygen or water vapor, three damaging reactions occur:

- Scaling (Oxidation): Iron (Fe) reacts with oxygen (O₂) to form iron oxide (Fe₂O₃, Fe₃O₄)—a brittle, flaky layer on the surface.

- Discoloration: A thin oxide layer forms, creating yellow, blue, or rainbow tints, indicating surface contamination.

- Decarburization: At high temperatures, carbon (C) in the steel diffuses to the surface and reacts with oxygen or hydrogen, leaving a soft, carbon-depleted layer. This drastically reduces hardness and fatigue strength.

The Role of Nitrogen: It acts as an inert diluent and purging gas, displacing oxygen and water vapor to create a non-reactive environment. For some processes, nitrogen is used as a carrier gas for small, precise additions of reactive gases (like hydrogen or carbon-based gases) to achieve specific surface chemistry.

The 3 Critical Parameters for Your Nitrogen Atmosphere

1. Oxygen Purity: The Primary Shield

The residual oxygen level in your nitrogen is the first line of defense.

- Minimum Requirement: For most bright annealing of stainless steel or copper, you need < 10 ppm (parts per million) oxygen in the furnace atmosphere. This often requires nitrogen with 99.999% (Grade 5.0) purity or better.

- Reality Check: A standard PSA generator (95-99.5% purity) delivers gas with 500 – 50,000 ppm O₂—this is insufficient for bright work and will cause discoloration. It may only be suitable for rough purging or low-temperature processes.

- Solution: For critical applications, you need a high-purity PSA system with an integrated catalytic deoxygenizer or a membrane + deoxo system to reach <10 ppm O₂. Bulk liquid nitrogen (LN₂) is another common source of ultra-high purity.

2. Dew Point: Eliminating Water-Based Oxidation

Water vapor (H₂O) is as destructive as oxygen. It dissociates at high heat into H₂ and O₂, leading to oxidation and hydrogen embrittlement risk.

- Minimum Requirement: A furnace atmosphere dew point of -40°C or lower is standard for bright annealing. For ultra-sensitive alloys (like titanium or some electrical steels), -60°C or lower may be required.

- The Challenge: Even if your nitrogen source is dry, water can be introduced from leaky water-jacketed furnaces, humid loads, or ambient air ingress.

- Solution: Ensure your nitrogen supply has an integrated desiccant dryer capable of reaching your target dew point. Continuously monitor the furnace atmosphere dew point with an in-situ probe.

3. Atmosphere Control & Flow Dynamics

Introducing nitrogen correctly is vital.

- Positive Pressure: Maintain a slight positive pressure inside the furnace (a few inches of water column) to prevent ambient air from being sucked in through leaks.

- Proper Purging: Before heating, purge the cold furnace with 5-10 volume changes of nitrogen to displace air. Calculate volume changes based on furnace cubic meters and your nitrogen flow rate.

- Continuous Flow vs. Blanketing: Some processes use a continuous nitrogen flow, others a static blanket. Flow rates must be calculated to compensate for leaks and thermal convection.

Process-Specific Nitrogen Guidelines

| Heat Treat Process | Typical Material | Key Nitrogen Function | Critical Parameter Targets |

| Bright Annealing | Stainless Steel, Copper, Nickel Alloys | Prevent all oxidation to maintain reflective, clean surface. | O₂ < 10 ppm, Dew Point < -40°C. Often uses 5-10% H₂ in N₂ for reducing residual oxides. |

| Clean Hardening/Tempering | Tool Steels, Alloy Steels | Prevent scaling & decarburization to avoid post-machining. | O₂ < 100 ppm, Dew Point < -40°C. May use endothermic gas (EndoGas) generated from N₂ + natural gas. |

| Brazing | Various Steels, Copper | Create oxide-free surfaces for filler metal flow. | O₂ < 50-100 ppm, Dew Point < -40°C. Atmosphere must be dry to prevent filler metal oxidation. |

| Powder Metal Sintering | Ferrous & Stainless Powders | Control carbon potential and prevent oxidation during bonding. | O₂ < 100 ppm, Dew Point < -40°C. Precise blends with H₂ and CH₄/CO common. |

Common Pitfalls & How to Avoid Them

- “My parts are still discolored with 99.9% nitrogen.”

Cause: 99.9% N₂ = 1000 ppm O₂, which is 100 times too high for bright annealing.

Fix: Upgrade to a true high-purity supply (<10 ppm O₂).

- “Scaling occurs during cooling.”

Cause: Stopping the nitrogen flow too early. Oxidation can occur above ~300°C.

Fix: Continue nitrogen flow until parts cool below 250°C. Use furnace cooling jackets if possible.

- “Inconsistent results from one load to the next.”

Cause: Air leaks (door seals, thermocouple ports) or variable moisture from the workload.

Fix: Perform a furnace leak rate test with positive pressure and soapy water. Pre-dry loaded parts if they are washed or stored in humid conditions.

FAQ: Nitrogen in Heat Treating

Q1: Can I use a standard industrial nitrogen generator for heat treating?

A1: For non-critical, scaled work where surface finish is unimportant—possibly. For any process requiring a “bright” or “clean” finish, a standard generator (95-99.5% purity) will not suffice. You need a system designed for <100 ppm, and often <10 ppm, oxygen residual.

Q2: What‘s the difference between using pure nitrogen and a nitrogen-hydrogen mix?

A2: Pure nitrogen is inert—it prevents further oxidation. A 2-10% hydrogen blend is reducing—it can chemically remove thin, existing oxide layers already on the metal surface during heating, resulting in a brighter finish. Hydrogen requires careful safety procedures.

Q3: How do I calculate the nitrogen flow rate needed for my furnace?

A3: Base rate = (Furnace Volume in m³ × Number of Purges per Hour) + (Leakage Compensation).

Example: A 5 m³ furnace needing 6 purges/hour with a 2 m³/hr estimated leak rate: (5 × 6) + 2 = 32 m³/h. Always consult your furnace manufacturer.

Q4: Is it more economical to use bulk liquid nitrogen or an on-site generator?

A4: For high and continuous consumption, an on-site high-purity generator typically has a lower cost per cubic meter after the payback period (2-5 years). Liquid nitrogen is simpler (no equipment maintenance) and better for lower, intermittent usage or as a peak/backup supply. A lifecycle cost analysis is essential.

Conclusion: Precision Atmosphere for Precision Results

In heat treating, nitrogen is not a commodity gas but a precision-process parameter. Achieving scale-free, bright results demands an investment in high-purity gas, ultra-dry conditions, and controlled furnace dynamics. The upfront cost of a proper atmosphere system is quickly offset by the elimination of post-treatment cleaning, grinding, scrap, and consistent delivery of high-value parts.

Planning a heat-treat line or upgrading your atmosphere system? Contact the MINNUO engineering team. We specialize in high-purity gas solutions for metallurgy and can help you specify the right nitrogen generation, purification, and monitoring system to meet the stringent requirements of bright annealing, hardening, and brazing.

sales2:+86 17506119168

sales2:+86 17506119168