As the global healthcare system improves and expands and the demand for industrial gases continues to grow (e.g. hospital ICUs, home oxygen therapy, welding and cutting, ozone generating systems, etc.), there is a growing reliance on a stable, intelligent and sustainable way to produce oxygen. The role of oxygen concentrator equipment systems becomes crucial, especially in situations such as responding to public emergencies, aging societies and highland hypoxic environments.

However, the traditional distribution model of bottled oxygen or liquid oxygen has significant limitations: not only is it inconvenient and costly to transport, but it also carries the risk of explosion and does not allow for continuous oxygen supply. Because of this, a new generation of Oxygen Concentrator, which can realize on-site oxygen production, on-demand oxygen supply, and intelligent control, is rapidly emerging and gradually replacing the traditional oxygen supply method.

This article will systematically analyze the core working principle of Oxygen Concentrator (e.g. PSA/VPSA), the main structural composition, the meaning of common oxygen purity level and flow rate unit from a technical point of view, and at the same time combine with typical application scenarios such as medical and industrial, to help readers to deeply understand: “How does the Oxygen Concentrator extract the oxygen from the air with high concentration? ” And “how to select the model according to the actual needs”.

1.What Is an Oxygen Concentrator?

Definition:

An oxygen concentrator is a device that concentrates the oxygen from a gas supply (typically ambient air) by selectively removing nitrogen to supply an oxygen-enriched product gas stream. They are used industrially, to provide supplemental oxygen at high altitudes, and as medical devices for oxygen therapy.

Oxygen concentrators are used widely for oxygen provision in healthcare applications, especially where liquid or pressurized oxygen is too dangerous or inconvenient, such as in homes or portable clinics, and can also provide an economical source of oxygen in industrial processes, where they are also known as oxygen gas generators or oxygen generation plants. Two methods in common use are pressure swing adsorption and membrane gas separation.

Overview of technology paths:

| Technology Route | Brief description of the principle | Application strengths |

| PSA (Pressurized Pressure Adsorption) | Atmospheric pressure / low pressure operation, the use of molecular sieve adsorption of nitrogen | Medical, industrial small and medium-sized on-site oxygen generation |

| VPSA (Vacuum Pressurization) | Vacuum desorption + low-pressure adsorption, more energy-saving | Oxygen supply for large-scale industries and gas companies |

| Membrane Separation | Difference in the rate of gas diffusion, suitable for the production of nitrogen / low-concentration of oxygen occasions | Simple and portable, low-concentration applications |

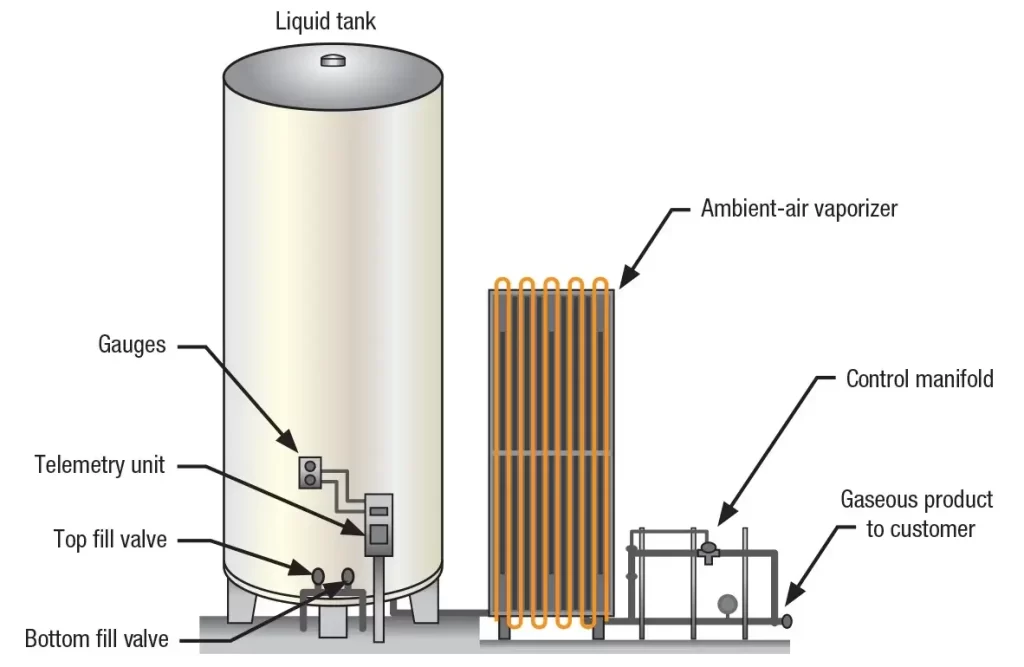

| Deep Cooling Air Separation | Fractionation after the liquefaction of air, the highest purity of oxygen | Large-scale centralized oxygen supply, gas sales |

2.Core Working Principle

The core principle of the oxygen generation equipment is to extract oxygen from air efficiently, and its main technology route is mainly based on Pressure Swing Adsorption (PSA), and at the same time, according to the different demand scenarios, it will also adopt the technologies of VPSA, Membrane Separation, and Deep Cooling Air Separation. The following is a disassembly of the workflow and technical principles:

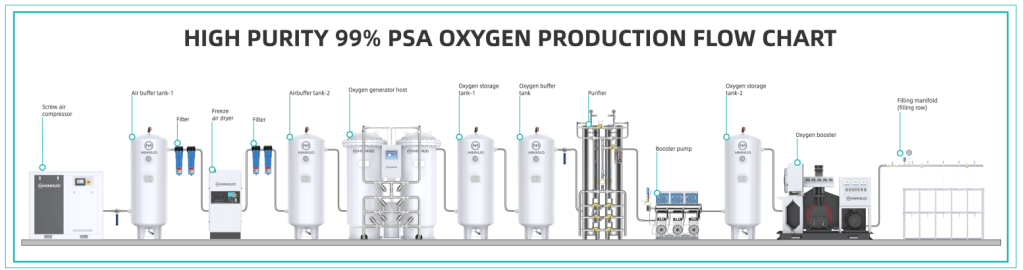

Air source treatment (pretreatment system)

The first step in any oxygen production process is to compress and purify ordinary air to ensure that the air source sent to the adsorption system is pure, dry and oil-free.

The main steps include:

Air compression: use oil-free air compressor to provide stable air pressure

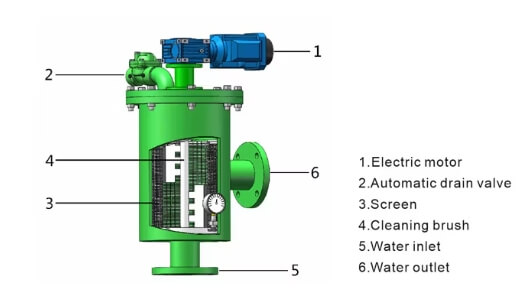

Dust removal and filtration: multi-stage precision filter to remove particles and impurities

Cold-dryer or suction-dryer: to reduce the humidity of the air and prevent the molecular sieve from failing to absorb moisture

✅ Suggested Configurations: The standard pre-treatment kit with “cold-drying + three-stage filtration + automatic drainage” can significantly extend the life of the core components.

PSA Technology Core Working Mechanism (Mainstream)

PSA: Pressure Swing Adsorption

Brief description of the principle:

Key adsorption material: molecular sieve (Zeolite 13X / LiX)

Using molecular sieve adsorption capacity difference between nitrogen and oxygen, to realize the separation of oxygen and nitrogen under different pressures.

One adsorption tower adsorbs nitrogen and releases oxygen. One adsorption tower adsorbs nitrogen and releases oxygen; the other tower desorbs and regenerates.

The two towers run alternately, constituting a closed loop of “continuous oxygen supply”.

Range of oxygen concentration in the discharge gas: 93%~99.5% (adjustable depending on the configuration).

✅ Advantages:

Room temperature operation, no liquefaction required.

High degree of automation, easy maintenance.

Highly adaptable, applicable to medical, industrial and small and medium-sized gas consumption scenarios.

Brief overview of other technology comparisons:

| Technology Path | Principle features | Applicable scenes |

| VPSA (Vacuum Pressure Swing Adsorption) | Complementary vacuum desorption, lower energy consumption, more complex system | ≥100Nm³/h industrial centralized oxygen supply |

| Membrane Separation Membrane | Separation of oxygen according to the difference in the diffusion rate of gas molecules, lightweight structure | Small portable equipment, nitrogen system |

| Deep Cooling Air Separation (Cryogenic Liquefaction) | Fractionation of air liquefaction to obtain oxygen, high purity (≥99.9%) | Large industrial gas station, bottled oxygen plant |

Configuration recommendation:

Medical grade places recommend PSA + purity online monitoring + PLC control

Glass, chemical industry can prefer VPSA or deep cooling system to achieve ≥99.5% stable oxygen supply

Portable/distributed gas consumption scenarios recommend membrane separation or small PSA solutions

3. Main Components Overview

In the PSA oxygen system, the core components are synergistic with each other to achieve the goal of high purity, stable and continuous oxygen production. The core components in a PSA oxygen system work together to achieve high purity, stable and continuous oxygen production. Mastering their composition helps users to make more accurate judgment in selection, operation and troubleshooting. The following is an analysis of the five core modules:

Air Compressor: System Power Source

Function: Provide stable compressed air for the PSA system, which is the “heart” of the whole system.

Recommended Configuration: Adopt an oil-free air compressor to avoid oil contamination of adsorbent

Typical Parameters: Power Range 2.2kW 1.0MPa Note: The power range is 2.2kW, 1.0MPa. 1.0MPa

Note: Need to be used with a cold dryer and precision filter to ensure that the gas entering the adsorption tower is clean, dry and at constant pressure

✅ Suitable for: hospitals, laboratories, glass factories, welding shops and other scenarios requiring cleanliness

Adsorption tower + molecular sieve material: the core separating component

Dual-tower structure is common with internal filling of Zeolite 13X / LiX Molecular sieve

Principle of operation: oxygen-nitrogen separation + adsorption regeneration through alternating pressurization/depressurization

Molecular sieve life: generally 8000~12000 hours, regular replacement is recommended to maintain efficiency

✅ Triple-tower or “Variable Temperature + Variable Pressure” Hybrid System for high purity requirement

Automatic Valve Stack + PLC Intelligent control system

Realize full-cycle automatic operation of adsorption/resolution/switching without human intervention

Control includes: solenoid valve rhythm, differential pressure adjustment, purity alarm, etc.

Support remote monitoring / HMI touch screen / one key start/stop

✅ Suitable for intelligent plant scenarios that require unattended operation or want to realize MES / SCADA interface

Oxygen Buffer Tank + Purity Analyzer + Safety Valve

Buffer tank: balance pressure fluctuation, ensure stable flow output

On-line analyzer: real-time monitoring of oxygen purity (±0.5% accuracy), if lower than the set value automatically triggers an alarm/shutdown

Safety valve/check valve: to prevent backpressure shocks, to improve the safety of the system

✅ Medical applications recommend the configuration of a multi-stage alarm + standby supply switching valve group

4. Oxygen Purity and Flow Explained

When choosing the PSA or VPSA oxygen system, the purity grade of oxygen is the most important factor to be taken into account. When choosing PSA or VPSA oxygen generation system, the purity level and flow unit of oxygen are the two key technical parameters that users are most concerned about. This part will be combined with the standard specification and the actual application requirements to analyze one by one, to help users scientifically match the equipment specifications.

4.1 Oxygen purity level classification

The requirements for oxygen purity in different scenarios vary greatly, and can be divided into the following two categories:

Medical-grade oxygen:

Purity standard: 93%±3%, in line with YY/T 0298 or EU Pharmacopoeia standards;

Applicable scenarios: ICU wards in hospitals, operating rooms, negative-pressure ambulances, community oxygen therapy stations, etc.;

High safety and stability requirements, with on-line oxygen concentration monitoring module and alarm system. High safety and stability requirements, with online oxygen concentration monitoring module and alarm system.

Industrial-grade high-purity oxygen:

Purity standard: 95% ~ 99.5% (can be customized)

Application scenarios: glass kiln combustion, laser/plasma cutting, ozone generator oxygen supply, environmental protection water treatment, etc.;

The higher the purity, the higher the efficiency of the reaction, but the configuration of the equipment requirements are also more complex.

✅ Suggestions for selection:

For export or to meet higher standards, multi-stage refining system can be selected to support the output of ≥99.5% high purity oxygen, and configured with precision flow meter and oxygen concentration automatic control module.

4.2 Analysis of Oxygen Flow Units

There are two common flow units, which are applicable to oxygen supply systems of different sizes:

| Units | Description | Applicable Scenarios |

| L/min (liters per minute) | Commonly used for medical single-bed or single-unit oxygen supply, small quantities | Portable machines, ICU oxygen therapy devices, emergency vehicles, etc. |

| Nm³/h (standard cubic meters per hour) | Commonly used unit in industry for medium to large oxygen pipeline delivery or centralized oxygen supply | Factory oxygen stations, hospital central oxygen supply stations, oxygen manifold systems, etc. |

Conversion reference:

1 Nm³/h ≈ 16.67 L/min

Example: A 30Nm³/h system ≈ provides a total flow rate of about 500 L/min, which meets the oxygen demand of about 30 beds at the same time.

5. Energy Consumption and Maintenance

When selecting and deploying a PSA/VPSA oxygen generation system, energy performance and O&M costs are the core factors affecting the long-term experience and return on investment. This section will analyze the operating economics of this type of equipment from the perspectives of operating energy consumption, routine maintenance cycles and long-term cost advantages.

5.1 Normal Temperature and Pressure Operation, Energy Saving and High Efficiency

Compared with the traditional cryogenic separation method (liquid oxygen extraction requires -180°C deep-cooling liquefaction), both PSA and VPSA systems adopt the normal temperature and normal pressure/normal temperature and low pressure process route, which eliminates the need for an additional cooling system and significantly reduces the overall energy consumption.

Energy source:

air compressor (PSA) or variable frequency fan + vacuum pump (VPSA);

low power consumption of control system (PLC, solenoid valve, electric valve, etc.);

does not rely on liquid nitrogen/liquid oxygen storage tanks, saving the cold chain distribution and secondary evaporation loss.

5.2 Common Maintenance Items and Replacement Cycle

Although the PSA/VPSA system is highly automated, there is still a life cycle for its core components, and a regular maintenance plan should be formulated:

| Maintenance Items | Recommended cycle | Description |

| Molecular Sieve Replacement | 3~5 years | Oxygen and nitrogen separation of core materials, adsorption performance decreases year by year, timely replacement can maintain the purity of the output stability |

| Air Filter / Oil Separator Cartridge | Every 4000~8000 hours | Air compressor front protection, it is recommended to regularly check to prevent particles / oil mist pollution system |

| On-Line Oxygen Concentration Tester | Calibration once a year | used to ensure that the oxygen concentration is stable, to meet the requirements of the standard for medical/industrial oxygen |

| Drain Valve / Solenoid Valve | Periodic inspection depending on site conditions | Moist areas are recommended to be equipped with an automatic water drainage system to reduce the probability of failure of water accumulation |

Suggestion: The above maintenance can be included in the annual inspection form, or entrusted to the manufacturer to provide operation and maintenance hosting services, to realize remote diagnosis + early warning, to reduce the risk of human misuse.

❓ FAQ:

Q1: How do I determine whether I need medical or industrial oxygen generators?

A:Please make a comprehensive judgment according to “usage scenario + oxygen purity requirement”:

Medical use: need to comply with YY/T 0298 or European standard, purity ≥93%±3%, it is recommended to choose PSA medical type equipped with alarm and standby system;

Industrial use: such as welding, glass, ozone, aquatic, etc., it is recommended to choose industrial type with purity of 95%~99.5%, it is recommended to choose industrial type with purity of 95%~99.5%, it is recommended to choose industrial type with purity of 95%~99.5%. 99.5% purity of industrial oxygen system, can be customized flow and pressure.

Q2: How to determine the oxygen flow unit I need, what is the difference between L/min and Nm³/h?

A:Medical equipment mostly use L/min, such as respiratory machine or ward single bed oxygen supply commonly 3~10L/min;

Industrial equipment to Nm³/h (standard cubic meter per hour) as a unit, such as welding station, glass furnace often need to be ≥10Nm³/h;

Conversion reference: 1 Nm³/h ≈ 16.67 L/min

✅ Suggestion: reserve 10~20% redundant space when calculating the demand to ensure stable gas supply. Stability.

Q3: I am temporarily deploying or using in disaster areas, should I only use mobile devices?

A: It is not mandatory, but it is recommended to use portable all-in-one or vehicle-mounted oxygen system. The features include:

does not depend on large infrastructure, and can be used immediately after power is turned on;

supports “quick deployment” in tents, field stations, ICU wards, etc.;

can be configured with battery or diesel power supply, which is suitable for the environment of power outage.

Q4:Does the fixed equipment support remote monitoring? Can it be docked with factory/hospital system?

A: Yes. It is recommended to choose the system with the following functions:

PLC automatic controller: support remote start/stop and automatic adjustment;

Oxygen concentration analyzer + early warning module: guarantee gas safety;

can be docked with SCADA / MES / hospital central control platform to realize intelligent integrated management.

Q5:What basic conditions do I need to prepare before installing the equipment?

A: It is recommended to confirm the following items:

Power supply: whether it is 220V/380V, whether the power to meet the total power consumption of the equipment (ranging from 1 to 15kW);

Site: whether there is a dry and flat area can be arranged for the equipment (>2 square meters);

Water/Drainage: such as the inclusion of a cooler needs to be arranged for the cooling water and drainage piping;

Ventilation: in particular, the VPSA system needs a good design of the exhaust air.

Q6:I don’t know how to select the type, is there a professional manufacturer can give the configuration plan?

A: Of course, MINNUO can recommend the best solution for you according to the following parameters:

Daily oxygen consumption (L/min / Nm³/h);

Usage scenarios (medical/industrial/emergency/food);

Whether fixed deployment/mobile deployment; remote monitoring and SCADA connection is required;there are supporting conditions such as power, water, and site.

Conclusion

Oxygen generator can efficiently separate oxygen from air by PSA or VPSA technology, and output 93%~99.5% high purity oxygen. Compared with the traditional bottled/liquid oxygen mode, it has the advantages of high automation, low energy consumption, stable continuous oxygen supply and high safety, and is widely used in medical rescue, industrial production, environmental protection, experimental analysis and other fields.

To meet the oxygen requirements of different scenarios, we suggest users to consider oxygen purity, unit flow rate, deployment mode (fixed/mobile), budget cycle and intelligent joint control requirements, and choose the right model scientifically.MINNUO provides PSA/VPSA all-in-one solutions ranging from 10L/min to 3000Nm³/h, and supports remote monitoring, modular expansion, and industry-standard certifications, which help users build a safer, more efficient, and more effective oxygen supply system. MINNUO provides an integrated PSA/VPSA solution from 10L/min to 3000Nm³/h, supporting remote monitoring, module expansion and industry standard certifications, helping users to build a safer, more efficient and economical oxygen supply system.

Visit https://minnuogas.com for exclusive configuration recommendations and quote support.

sales2:+86 17506119168

sales2:+86 17506119168