In the world of modern gas separation technology, PSA (Pressure Swing Adsorption) has emerged as a widely adopted and reliable method for producing high-purity oxygen and nitrogen. This technique leverages the principle of selective adsorption, where different gases are captured or released based on pressure fluctuations and molecular properties. PSA systems are known for their energy efficiency, modularity, and continuous operation, making them essential in industrial, medical, and emergency response applications.

As the global demand for clean oxygen and nitrogen increases—driven by healthcare needs, green energy development, and advanced manufacturing—understanding how PSA works becomes more important than ever. Why is PSA often preferred over traditional cryogenic or membrane separation? How does it achieve precise gas purity and stable output? What role do adsorbent materials play? These are questions that engineers, procurement specialists, and energy managers are actively seeking to answer when selecting gas generation solutions.

This article takes you on a technical deep dive into how PSA technology separates oxygen and nitrogen. We’ll cover the physical basis of selective adsorption, step-by-step flow of the separation cycle, critical factors affecting efficiency, and how different materials and system configurations influence performance. Whether you’re an engineer designing an on-site oxygen generator, or a facility manager evaluating upgrades, this guide will equip you with the insights to make better-informed decisions and optimize your PSA gas separation system.

I. Fundamentals of Gas Separation

Gas separation is a core scientific principle underlying PSA (Pressure Swing Adsorption) technology. It relies on the differing physical and chemical properties of gases to enable selective adsorption. Understanding these fundamental differences is the first step in optimizing PSA systems for oxygen and nitrogen separation.

1. Physical Properties of Gases

Each gas has distinct characteristics—such as molecular size, polarity, and adsorption affinity—that determine how easily it can be separated from a mixture. For instance:

Oxygen molecules (O₂) are smaller and more linear than nitrogen (N₂) molecules.

Nitrogen is more readily adsorbed by certain molecular sieves (e.g., Zeolite 13X) due to its higher quadrupole moment, which increases interaction with the adsorbent’s surface.

These differences are what enable selective separation in PSA systems.

2. Principles of Adsorption and Desorption

The PSA process exploits a simple but powerful concept: under high pressure, certain gases (like nitrogen) are preferentially adsorbed onto solid surfaces (such as molecular sieves), while other gases (like oxygen) pass through. When pressure is released, the adsorbed gases are desorbed and expelled from the system.

This cyclic process involves two key stages:

Adsorption: Gases are pushed through an adsorption bed under high pressure. Nitrogen adheres to the adsorbent; oxygen passes through.

Desorption: The pressure is dropped, releasing the trapped nitrogen, which is then vented out.

3. What Is Selective Adsorption?

Selective adsorption refers to the ability of an adsorbent material to attract one gas more than another based on molecular properties. This selectivity is critical for gas separation, as it defines the purity, recovery rate, and efficiency of the process. The better the selectivity of the material, the more efficient the PSA system becomes.

For example:

In oxygen generators, zeolite molecular sieves preferentially adsorb nitrogen over oxygen.

In nitrogen generators, carbon molecular sieves (CMS) are used to trap oxygen, allowing nitrogen to pass.

II. How PSA Separates Oxygen from Nitrogen

PSA (Pressure Swing Adsorption) utilizes the difference in adsorption capacity of molecular sieve between oxygen and nitrogen under different pressures to achieve efficient gas separation. Below we explain the whole process of extracting oxygen and discharging nitrogen from air in PSA system in a step-by-step manner:

Step-by-step separation process:

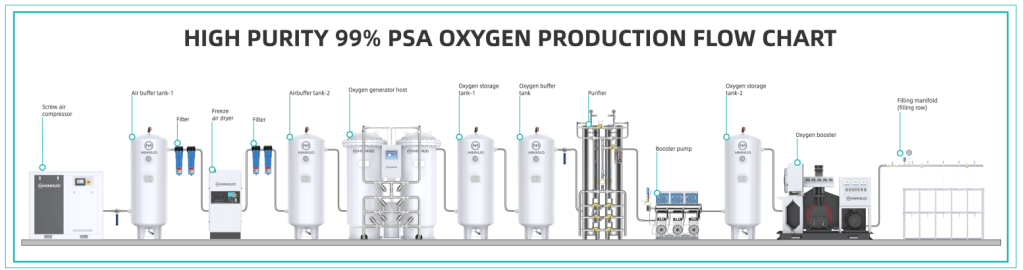

1. Air compression and pretreatment

The compressed air passes through a three-stage pretreatment unit to remove moisture, oil and solid particles, so as to avoid contaminating or clogging the molecular sieve. Commonly used pre-treatment units include:

Air filter

Refrigerated dryer or adsorption dryer

De-oiler and buffer tank

2. Pressurized adsorption stage

The compressed air is fed into an adsorption column filled with molecular sieves (e.g., 13X or LiX):

The molecular sieves preferentially adsorb nitrogen, while the oxygen passes through the bed and is “cleaned” out.

The oxygen that passes through the top of the column is the high-purity product gas, which can be 90-93%. 3. Decompression and desorption phase

3. Decompression desorption stage

Once the molecular sieve is saturated, the system automatically switches to desorption mode:

The pressure of the adsorption tower is rapidly reduced to atmospheric pressure or even to vacuum, releasing the adsorbed nitrogen.

The adsorbed nitrogen is then released. The nitrogen is usually discharged or partially used for regeneration by blowback to improve energy efficiency.

4. Cycle switching and stabilized output

Adopting the principle of alternating two towers:

When one tower adsorbs, the other tower desorbs and regenerates to ensure the continuous supply of oxygen to the system.

The PLC control system accurately controls the valve action and cycle beat to ensure stable pressure and purity output.

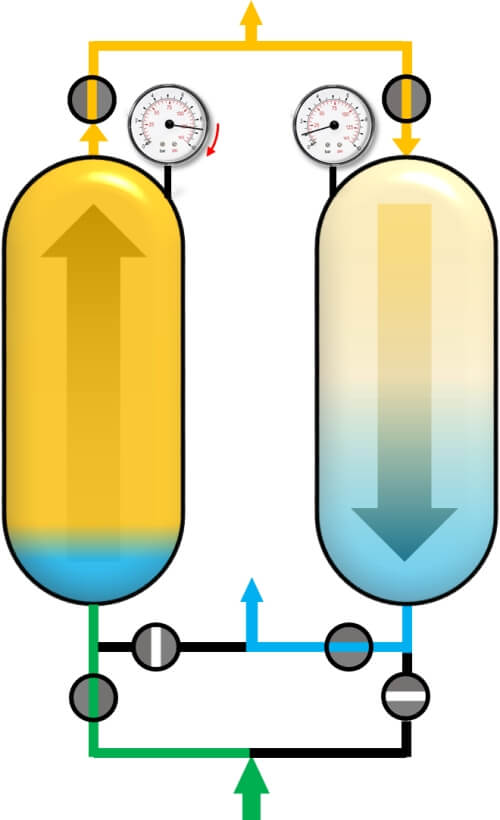

Two-tower cycle

The key to the operation of the PSA system lies in the alternate switching structure of the two towers:

Adsorption tower A works → tower B desorbs

Time reaches the switching threshold → A and B swap roles

The cycle repeats itself, realizing a stable 24/7 supply of oxygen

The cycle usually lasts from a few tens of seconds to a few minutes, depending on the performance of the adsorbent selected, the operating pressure, and the required gas flow.

Technical Advantages

No need for high temperatures or deep cooling: more energy efficient than deep cooling, suitable for small to medium sized oxygen supply needs

Fast start-up and flexible response: commissioning within minutes

Adjustable purity: adjustable oxygen concentration by adjusting adsorption time according to time/flow rate (commonly used for industrial oxygen)

III. Role of Adsorbent Materials

In PSA oxygen-nitrogen separation system, adsorbent is the core component that determines the separation efficiency and stable operation. The choice of adsorbent material directly affects the selective separation of oxygen and nitrogen, system energy consumption, equipment life and maintenance frequency.

1. Common adsorbents and their characteristics

Molecular sieve (Zeolite 13X): with regular pore size structure, it has strong selective adsorption of nitrogen and is widely used in oxygen PSA system.

Activated carbon: It is suitable for the adsorption of large molecule gases or used in the pretreatment process, and has no obvious effect on the separation of oxygen and nitrogen.

Carbon molecular sieve (CMS): used in nitrogen production system, with high adsorption rate of oxygen and strong selective adsorption ability.

2. Adsorption selectivity and gas preference

Different adsorption materials have different affinity for O₂ and N₂:

molecular sieve tends to adsorb nitrogen, letting oxygen penetrate and output

CMS tends to adsorb oxygen, letting nitrogen stay and output

This Selective Adsorption is the core of PSA separation principle.

3. Key Performance Indicators and Selection Criteria

During the selection process, the following indicators should be paid attention to:

Adsorption rate: determines the system response speed and cycle frequency

Regeneration capacity: affects the adsorbent life and the system’s long-term operating costs

Anti-pollution capacity: resists dust, moisture and oil mist pollution and determines the maintenance frequency

Thermal stability: ensures that the performance of the adsorbent is stable under temperature fluctuations

4. Adsorbent Life and Maintenance Strategy

High-quality molecular sieve (e.g. Zeolite 13X) is the core of PSA separation principle. High quality molecular sieves (e.g. Zeolite 13X) have a lifetime of 3-5 years under standard operating conditions. Periodic replacement or regeneration is recommended to avoid the loss of adsorption efficiency.

It is recommended to choose appropriate pre-filtration and drying system to protect the adsorbent and prolong its service life in accordance with the operating environment of PSA system (e.g. temperature and humidity, oil and water content).

IV. Factors Affecting PSA Separation Performance

In PSA oxygen-nitrogen separation systems, system performance is influenced by a variety of operating parameters and structural factors. Proper regulation of these variables is the key to achieving high purity, high recovery and high energy efficiency.

1. Pressure level (adsorption/desorption pressure ratio)

The higher the adsorption pressure, the higher the density of gas molecules in contact with the adsorbent, which is favorable to the target gas adsorption; however, too high a pressure will lead to a surge in energy consumption.

The lower the desorption pressure, the easier it is for the adsorbent to release the adsorbed gas.

Optimized ratio: It is generally recommended that the adsorption/desorption pressure ratio be controlled at 4:1 to 6:1, depending on the gas source conditions and application.

Technical suggestion: Configure variable frequency compressor and vacuum pump linkage control system, which can dynamically adjust the pressure in real time to adapt to the load change.

2. Adsorption time and switching frequency

Insufficient adsorption time will lead to incomplete separation and affect the purity of oxygen; too long time will reduce the unit output.

Switching frequency is too high, which may lead to the increase of pressure loss and energy consumption of the tower, and too low, which affects the response speed.

Recommended way: Adopt PLC intelligent control system to realize load-based “adaptive adsorption cycle”. 3.

3. Influence of temperature

High temperature will reduce the selectivity and capacity of the adsorbent, resulting in a decrease in the recovery rate.

Low temperature is good for adsorption, but may increase the compression load and the risk of condensation.

The system should be equipped with reasonable temperature control and cooling devices (such as pre-cooler, water-cooled/air-cooled heat exchanger) to balance the operating temperature.

4. Raw gas composition and impurity content

Oily, water vapor, particles and other impurities will cause molecular sieve clogging and failure, affecting the adsorption performance and system stability.

Oxygen and nitrogen ratio in the air is abnormal (such as altitude plateau or special industrial gas source) also need to adjust the design parameters to match.

It is recommended to configure a five-stage filtration system (coarse filter + fine filter + water + oil + bacteria removal) to ensure the cleanliness of the intake air. 5.

5. Adsorption bed structure and molecular sieve loading density

Excessive loading density will result in short gas penetration path and increased pressure loss; too little loading density will reduce the adsorption capacity.

Uneven bed structure, gaps or lumps will form “gas channel effect”, which will seriously reduce the adsorption efficiency.

Practical optimization measures: use vibration filling process to ensure filling uniformity; introduce zonal flow distributor to improve penetration depth.

V. Limitations and Challenges of PSA Systems

Although PSA (Pressure Swing Adsorption) technology has the advantages of high efficiency, low consumption and ready-to-use in the separation of oxygen and nitrogen, it still faces some technical and application challenges in practical application, which need to be paid great attention in design and operation.

1. Oxygen purity limitation

Overview of the problem:

Oxygen purity from PSA system is usually between 90-95%, which can meet the demand of industrial and some medical applications, but it is difficult to reach the high purity of 99.5% or above (e.g., electronic grade or rocket propellant oxygen requirements).

Compared with the deep cooling separation method, the PSA technology has limited selectivity, and the molecular sieve has a lower selectivity ratio of oxygen to nitrogen (α ≈ 6), so there is an upper limit of purity.

Implications and Responses:

High purity oxygen applications require additional refining: for applications requiring more than 95%, this can be enhanced by tail gas reflux, membrane separation, or deep-cooled refining.

Two-stage PSA system design: By connecting two PSA systems in series, the oxygen can be further purified after the first stage separation, increasing the upper purity limit to 96-97%. 2.

2. Sensitivity to Humidity and Contaminated Gases

Problem Overview:

PSA systems require high levels of cleanliness of incoming gases. Impurities such as high humidity, water vapor, oil, CO₂ or fine dust can:

Reduce molecular sieve adsorption performance

Accelerate adsorbent toxicity or failure

Lead to pressure control system clogging, which affects operational stability

Solution:

Configure a multi-stage air pre-treatment system:

Precision filters (≤0.01 μm) to remove oil and dust

Chiller/dryer to control the dew point (≤-20°C)

Activated carbon de-oiling device or pre-completion CO₂ absorber tower

Regular replacement of filter element and adsorbent, and establishment of a system to ensure purification up to 9697%. Filter element and adsorbent, establish maintenance cycle management system

Note: Once the molecular sieve is “poisoned” by water vapor, it is irreversible, and the loss cannot be recovered, so the input of pretreatment system should not be omitted.

3. Footprint and System Integration Challenges

Overview of the Problem:

Compared with liquid oxygen storage tanks or high-pressure oxygen cylinders, PSA systems are process equipment and require components such as compressors, storage tanks, adsorption towers, and cold dryers, which are large and heavy.

For space-constrained locations (e.g., on-board, on-board, mobile emergency stations), conventional PSA systems are not easy to deploy.

Response:

Adopt compact and modular structure: through integrating skid system, reducing the size of adsorption tower, and increasing the bed filling ratio, it can be adapted to the deployment needs in small space.

Development of integrated PSA units: for example, the medical equipment integrating cold-drying, adsorption and oxygen buffer tanks occupies an area of only 0.8 square meters, which is suitable for bedside or mobile trolley use.

| Limitations | Technical Remediation Solutions | Application Recommendations |

| Insufficient purity | Dual Stage PSA / Membrane Separation and Refining | Not for high purity oxygen scenarios (>99.5%) |

| Weak resistance to contamination | Front End Precision Filtration and Drying System | Strictly control the cleanliness of the inlet air, with inlet air monitoring and alarms |

| Large/bulky footprint | Modular Construction / Compact Integrated Design | Suitable for places with a fixed oxygen supply room or plenty of space |

VI. Optimization and Future Development

Although PSA (Pressure Swing Adsorption) technology has been maturely applied in the industrial and medical fields, in the pursuit of higher efficiency, greater stability, lower energy consumption and wider applicability, the future PSA system will continue to be optimized and developed in terms of the control mode, structural layout, adsorption materials and integration of multiple processes.

1. Intelligent control system: realizing adaptive pressure regulation and energy saving

Problem: Traditional PSA system mostly relies on PLC fixed value control, with limited regulation flexibility, making it difficult to dynamically adapt to fluctuations in oxygen consumption, changes in the environment or differences in the cost of electricity.

Optimization direction:

Introduce AI+IoT control system to realize multi-dimensional sensing and feedback on temperature, flow, pressure, and purity, and intelligently switch adsorption/desorption parameters on demand.

Implement load-on-demand operation strategy: the system can automatically operate at variable frequency according to the actual gas dosage or tank pressure, reducing standby energy consumption.

Use historical data modeling to predict the energy consumption and the decline of the adsorption performance, and realize forward-looking operation and maintenance.

Example: By deploying an intelligent control platform, a medical PSA system is able to achieve the same level of energy efficiency and energy saving. Example: By deploying an intelligent control platform, a medical PSA oxygen system can automatically switch to the “low-consumption and pressure preservation” mode at night, with an average annual energy saving of more than 18%. 2.

2. Multi-tower Parallel Program and Modularized Design

Background: Traditional PSA system is mainly based on twin towers, which has the problems of slow response, poor expandability, and large land occupation under the application scenario of large flow.

Optimization and development direction:

Multi-tower cooperative operation mechanism: 4-tower and 6-tower parallel design, staggered rotation of adsorption towers to shorten cycle time and improve oxygen stability.

Modular assembly system: each module contains compression, drying and adsorption towers, which can be flexibly combined to meet different capacity requirements and site constraints.

Plug-and-play design: support for independent operation of the module and remote monitoring to achieve rapid deployment and convenient maintenance.

3. High performance Development of adsorption materials (e.g. nanoporous materials)

Material is the core bottleneck: Currently, PSA mostly uses Zeolite 5A/13X molecular sieves, which have limited adsorption rate and insufficient pollution resistance.

Development trend:

Nanoscale porous materials (e.g. MOFs, COFs) can realize stronger selectivity and higher adsorption efficiency by virtue of their high specific surface area and adjustable pore size.

Hybridized composite adsorbent: improve water resistance and thermal stability by composite of metal oxides/graphene/organic skeleton, etc.

High-regeneration adsorbent: develop materials with faster desorption rate and low heat demand, reduce cycle intervals, and improve oxygen production efficiency per unit. Efficiency

Experiments have shown a 35% increase in adsorption efficiency in a pilot plant using the MOF-ZIF series of materials compared to a conventional 13X molecular sieve system. 4. Trends in integration with other processes

4. Integration Trends with Other Processes (e.g., TSA / Membrane Separation)

A single PSA process has limitations in extreme demand scenarios, such as high purity oxygen preparation, extreme temperature and humidity conditions, and complex gas separations.

Integration trends include:

TSA (Temperature Swing Adsorption) + PSA: temperature adsorption coarse separation, then pressure fluctuation purification, to achieve both stability and energy saving

Membrane Separation + PSA Combined System: membrane section of the primary separation, to increase the concentration of the PSA intake gas, reduce the energy consumption and load of the system

Deep cooling pretreatment + PSA purification: for high-end electronics / aerospace, etc., which require 99% high purity oxygen. Deep cooling pre-treatment + PSA fine stripping: suitable for high-end electronics/aeronautics and other scenarios requiring 99.99% high purity oxygen.

| Optimization Direction | Technical Highlights | Practical value |

| Intelligent control system | AI feedback, self-adaptive voltage regulation, energy-saving loads | Reduce energy consumption, extend life, stabilize gas production |

| Multi-tower modular design | Flexible combinations, rapid expansion, easy maintenance | Reduce footprint, improve scalability |

| Nanoscale adsorbent materials | High specific surface, strong selectivity, high-temperature resistance | Improve efficiency, reduce cycle energy consumption |

| Process integration (TSA/membrane) | Complementary strengths, complementary advantages | Adapt to more scenarios, break through purity limits |

Conclusion

PSA with its excellent ability to separate oxygen and nitrogen, the technology has become an important technical route for gas preparation in today’s industrial and medical fields. It is based on selective adsorption as the core, through the molecular sieve on the different gases in the pressure change of selective capture and release, to achieve high efficiency separation, with low operating costs, a high degree of automation, continuous production of gas stability and other advantages.

With higher requirements on gas purity, energy consumption and system response speed, PSA system is developing in the direction of being more intelligent, energy-saving and compact, and in the future, it will form a complementary fusion with membrane separation, TSA, deep-cooling and other processes, and will be expanded to more fields such as high-end manufacturing, green energy and disaster relief.

As a professional manufacturer in the gas equipment industry, MINNUO is committed to providing advanced PSA oxygen and nitrogen solutions, covering a wide range of scenarios from hospital emergency, ICU to industrial welding and food preservation. Relying on high-performance molecular sieve technology, intelligent control system and modular design capability, MINNUO can provide customers with customized, high-efficiency, low-energy consumption complete sets of equipment, which can help users to improve the gas separation efficiency, reduce operating costs, and achieve higher safety and sustainable development goals.

sales2:+86 17506119168

sales2:+86 17506119168