In modern industrial production, nitrogen has become an indispensable industrial gas, widely used in critical sectors such as food preservation, electronics manufacturing, chemical production, and metal processing. As an internationally leading provider of nitrogen generation solutions, MINNUO understands the varying demands of different industries for nitrogen purity, flow rate, reliability, and cost. This article will provide a comprehensive comparison across multiple dimensions including technological principles, performance parameters, application scenarios, and economic benefits, offering scientific guidance to help you choose the most suitable nitrogen generation technology for your production needs.

PSA nitrogen generation and membrane separation nitrogen generation each have their own advantages and disadvantages, making them suitable for different needs. PSA technology is ideal for industrial applications requiring high purity (95%-99.999%) and large flow rates, such as in the electronics, pharmaceuticals, and chemical industries. Although PSA has higher energy consumption and slower startup, it offers strong long-term stability, making it suitable for large-scale continuous operations. On the other hand, membrane separation technology is more suitable for medium to low purity (95%-99.5%) and small flow rate applications, such as food packaging, tire nitrogen inflation, and laboratory use. It has high energy efficiency and quick startup, but is limited in purity and flow rate capabilities. The choice should be based on purity requirements, flow rate needs, cost, and application scenarios.

1. Technical Principles Analysis

1.1 PSA Pressure Swing Adsorption Nitrogen Generation Technology

PSA (Pressure Swing Adsorption) nitrogen generation technology is based on the selective adsorption characteristics of molecular sieves. The system uses specially designed carbon molecular sieves (zeolite molecular sieves) as the adsorption medium, which have a stronger affinity for oxygen, water vapor, and carbon dioxide in the air. The working process is based on pressure cycle changes:

- Adsorption Phase: Compressed air (typically 0.4-1.6MPa) enters an adsorption tower filled with molecular sieves. Under high pressure, oxygen molecules (kinetic diameter 2.8Å) are preferentially adsorbed in the molecular sieve pores, while nitrogen molecules (3.6Å), being larger in size, are not easily adsorbed and exit as product gas.

- Desorption Phase: When the adsorption tower approaches saturation, the system automatically switches to a depressurization state, reducing pressure to atmospheric or vacuum conditions. At this point, the adsorbed oxygen is released from the molecular sieve and expelled through the exhaust.

- Dual Tower Coordination: A typical PSA system uses a dual-adsorption tower design. While one tower is in the adsorption and nitrogen production phase, the other tower is undergoing desorption and regeneration. The two towers alternate in cycles, controlled by a precise PLC control system, ensuring continuous nitrogen output.

This cycle can repeat several times per minute, ensuring a continuous nitrogen supply. The stability of the molecular sieve’s performance is key to the PSA system, and high-quality carbon molecular sieves can last more than 10 years under normal maintenance without significant degradation.

1.2 Membrane Separation Nitrogen Generation Technology

Membrane separation nitrogen generation technology uses a completely different physical separation principle – gas selective permeation. The core of the system is a separation module made up of thousands of hollow fiber membranes. These polymer materials (such as polysulfone, polyimide) form fibers as fine as hair, with special permeation channels inside:

- Permeation Rate Difference: When compressed air (typically 0.8-1.2MPa) enters the membrane module, different gas components permeate at different rates due to differences in molecular size and solubility. Oxygen (O₂), water vapor (H₂O), and carbon dioxide (CO₂) are considered “fast gases” and rapidly dissolve and permeate the membrane wall, while nitrogen (N₂) and argon (Ar) are “slow gases” and continue to flow through the membrane tubes and accumulate.

- Pressure Drive: The separation process is entirely driven by pressure difference, requiring no electricity or heat source. The permeation pressure difference causes fast gas molecules to pass through the membrane wall into the intermembrane chamber, from which they are expelled, while the enriched nitrogen is output from the end of the membrane tube.

- Continuous Separation: Unlike PSA’s cyclical process, membrane separation is a continuous steady-state process with no moving parts or switching valves. As air enters the membrane module, nitrogen is immediately produced, providing “instant response.”

The performance of the membrane module depends on material selection and structural design. High-quality membrane modules can last 5-10 years under appropriate operating conditions, but high temperatures or oil contamination can significantly shorten their lifespan.

2. Key Performance Comparison

Table: Key Performance Comparison Between PSA and Membrane Separation Nitrogen Generation Systems

| Performance Parameter | PSA Nitrogen Generation System | Membrane Separation Nitrogen Generation System | Technical Impact |

| Nitrogen Purity Range | 95% ~ 99.999%+ | 95% ~ 99.5% | PSA can achieve ultra-high purity, while membrane separation is suitable for medium to low purity |

| Flow Rate Capacity | 1 ~ 5000 Nm³/h | <1000 Nm³/h | PSA is suitable for large flow needs, while membrane separation is suited for medium to small flow |

| Startup Response Time | Approx. 20 minutes | Instant startup (but requires preheating in low temperatures) | Membrane separation responds faster, suitable for intermittent operation |

| Energy Consumption Index | Relatively high (0.3-0.5 kWh/Nm³) | Relatively low (0.25-0.4 kWh/Nm³) | Membrane separation saves about 15-30% in energy |

| Noise Level | 65-75 dB (during adsorption tower switching) | <60 dB | Membrane separation is more suitable for working environments |

| Maintenance Requirement | Molecular sieve replacement every 5-10 years, valve maintenance | Membrane module replacement every 5-10 years, pre-filter maintenance | PSA maintenance is more complex but has a longer cycle |

| Equipment Size and Weight | Larger and heavier (requires dual adsorption towers) | Compact and lightweight (modular design) | Membrane separation saves 40-60% of space |

| Environmental Sensitivity | Sensitive to oil/water (requires strict pre-treatment) | Sensitive to oil/water (requires strict pre-treatment) | Both require high-quality compressed air sources |

| Purity Adjustment Flexibility | Small flow variation (93%-99% purity) | Large flow variation (same purity range) | PSA is more stable in purity adjustment |

| Long-term Stability | Molecular sieve performance stable for 10+ years | Membrane material may degrade after 3-5 years | PSA offers better long-term stability |

2.1 Purity and Flow Rate Capacity

Nitrogen purity is the most critical performance indicator for nitrogen generation systems, directly determining their application field:

- PSA systems have a significant advantage in purity, capable of providing stable nitrogen with a purity of 99%-99.999%. This feature makes PSA technology the preferred choice for industries such as electronics semiconductors, pharmaceuticals, and high-end chemicals that require very high gas purity. Purity is enhanced by optimizing adsorption time, improving molecular sieve performance, and adding multi-stage purification.

- Membrane separation systems typically offer 95%-99.5% nitrogen purity, and while it is possible to achieve over 99.9% by connecting multiple membrane modules, this significantly increases the size and cost of the equipment, reducing its economic efficiency. Therefore, membrane systems are more suited for medium to low purity applications such as food packaging and tire nitrogen inflation.

Flow rate capacity is another critical consideration:

- PSA systems offer a wide flow rate range, from small systems (1 Nm³/h) to large installations (5000 Nm³/h), making them particularly suitable for industries such as steel, chemicals, etc., which require large-scale continuous nitrogen supply.

- Membrane separation systems are more advantageous in medium and small flow scenarios (<1000 Nm³/h), and their modular design allows for increased production by adding more membrane modules. However, beyond a certain scale, PSA systems offer better economic efficiency.

2.2 Operating Characteristics and Energy Efficiency

Startup response time affects operational flexibility:

- PSA systems have a relatively slow startup, typically taking about 20 minutes to produce qualified nitrogen. This is because the adsorption tower needs to reach working pressure and temperature balance, and establish a stable adsorption-desorption cycle.

- Membrane separation systems have an instant response ability, producing nitrogen almost immediately after startup (though low-temperature environments may require air heating, potentially delaying startup). This feature makes membrane separation particularly suitable for applications requiring frequent startups and shutdowns.

Energy efficiency directly impacts operational costs:

- Membrane separation systems are generally more energy-efficient than PSA systems, with energy consumption about 15-30% lower. This is mainly due to its lack of moving parts and the absence of frequent pressure switching. Membrane systems achieve optimal efficiency at 80-90% load.

- PSA systems consume most of their energy in compressing air and the pressure cycle of the adsorption tower, especially in high-purity applications (>99.9%), where efficiency is higher. Advanced PSA systems can reduce energy consumption by more than 15% through energy recovery technologies.

2.3 Physical Characteristics and Environmental Adaptability

Equipment size and weight are crucial for applications with limited installation space:

- Membrane separation systems use a compact modular design, which is typically 40-60% lighter and occupies less space compared to PSA systems producing the same output. This advantage makes them ideal for space-constrained environments such as offshore platforms and mobile vehicles.

- PSA systems, due to their dual adsorption towers, buffer tanks, and complex valve systems, are larger and require dedicated equipment rooms.

Environmental adaptability affects system reliability under harsh conditions:

- Both technologies are sensitive to oil contamination and water vapor and require strict compressed air pre-treatment (three-stage filtration + drying). Oil vapor can permanently damage molecular sieves and membrane materials.

- Temperature Impact: Membrane system performance is highly affected by environmental temperature (permeation rate increases with temperature), usually requiring heaters to maintain optimal working temperature. PSA systems are relatively insensitive to temperature changes.

3. Application Scenario Selection

Table: Recommended Application Scenarios for PSA and Membrane Separation Nitrogen Generation

| Industry/Application Scenario | Recommended Technology | Ideal Purity Range | Key Considerations |

| Electronics Semiconductor Manufacturing | PSA | 99.999%-99.9999% | Ultra-high purity requirements |

| Pharmaceuticals & Biotech Products | PSA | 99.99%-99.999% | Sterile environment, GMP compliance |

| Laser Cutting (Metals) | PSA | 99.5%-99.9% | High purity for oxidation prevention |

| Chemicals & Petrochemicals | PSA | 99.9%-99.999% | Large flow, continuous operation |

| Food & Beverage Packaging | Membrane Separation | 97%-99.5% | Medium purity, cost-sensitive |

| Tire Inflation | Membrane Separation | 95%-98% | Mobile equipment, quick response |

| Oilfield Nitrogen Injection & Pipeline Purging | Membrane Separation | 95%-99% | Mobile deployment, harsh environment |

| Laboratory Gas | Either | Based on experiment needs | Small flow flexibility |

| Combustion Support | Membrane Separation | 95%-98% | Low-cost, large flow |

3.1 Recommended PSA Nitrogen Generation Application Scenarios

When application scenarios have strict requirements for nitrogen purity, system stability, and large-scale production capacity, PSA technology is usually the best choice:

- Electronics & Semiconductor Manufacturing: Chip production and packaging require nitrogen with purity above 99.999% to prevent oxidation and contamination. PSA systems can stably provide Class 1 electronic-grade nitrogen to meet cleanroom standards.

- Pharmaceuticals & Biotechnology: In drug production, inert gas protection and sterile nitrogen filling require purity above 99.99% and compliance with GMP standards. PSA systems can integrate online monitoring and validation functions to ensure drug safety.

- High-end Metal Processing: Stainless steel bright annealing, aluminum processing, and laser cutting require 99.5%-99.9% high-purity nitrogen for oxidation-free surfaces. PSA systems provide stable high-purity gases, improving processing quality.

- Chemical Synthesis & Protection: The petrochemical industry requires large amounts of high-purity nitrogen for reactor protection, pipeline purging, and product transfer. PSA systems can achieve flow rates above 5000 Nm³/h by paralleling multiple towers.

In these applications, PSA technology, while having a higher initial investment, offers superior economic benefits due to the high purity guarantees and production stability.

3.2 Recommended Membrane Separation Nitrogen Generation Application Scenarios

When application scenarios are more sensitive to equipment portability, response speed, and operational costs, membrane separation technology shows significant advantages:

- Food & Beverage Packaging: Nitrogen for food preservation (e.g., chips, coffee packaging) typically requires 97%-99.5% purity. Membrane systems provide an economical and efficient solution, with a compact design easily integrated into packaging production lines.

- Mobile & Offshore Applications: Oilfield nitrogen injection, ship protection, and other scenarios require compact and lightweight equipment. Membrane separation systems can be installed on mobile trailers or offshore platforms, resistant to vibration and easy to maintain.

- Tire Nitrogen Inflation Service: Car tire nitrogen inflation requires 95%-98% purity and fast startup with multi-point service capabilities. Membrane systems can be moved with service vehicles and used immediately.

- Laboratory & Small-Scale Research: Research institutions with small gas needs (<50 Nm³/h) are suited for modular membrane systems, which can be flexibly expanded based on demand, avoiding overinvestment in equipment.

In these scenarios, membrane separation technology, with its low energy consumption, compact design, and easy operation, becomes the more cost-effective choice.

4. Cost and Maintenance Analysis: Full Lifecycle Economic Evaluation

4.1 Initial Investment and Operating Costs

The equipment purchase cost is a key consideration for businesses making initial investment decisions:

- Membrane separation systems typically have a cost advantage for small to medium-sized equipment (<200 Nm³/h), with equipment prices 20%-30% lower than comparable PSA systems. This is mainly due to their simpler structure.

- PSA systems perform better in large equipment (>500 Nm³/h) and high-purity applications (>99.9%), with better economies of scale. When purity exceeds 99%, PSA offers significantly lower unit production costs than membrane separation.

Operating costs include energy consumption, maintenance, and consumables replacement:

- Energy Costs: Membrane systems consume 15%-30% less energy than PSA systems, with a clear advantage in regions with high energy prices. For a 100 Nm³/h unit, a membrane system can save 50,000-80,000 kWh annually.

- Consumables Replacement: The main consumable for PSA is the molecular sieve (replaced every 5-10 years at a cost of several tens of thousands of dollars) and valves. For membrane systems, the core consumable is the membrane module (replaced every 5-10 years, with higher cost) and precision filters.

- Labor for Maintenance: PSA systems typically require 30%-50% more maintenance labor due to their more complex valves and control systems.

4.2 Maintenance Requirements and System Lifetime

The focus of PSA system maintenance is:

- Valve Systems: Pneumatic/electronic switching valves need to be checked every 1-2 years for seal and actuator conditions, with failures being a major cause of PSA downtime.

- Molecular Sieve Monitoring: The strength and wear rate of molecular sieves should be tested annually, with replacement needed every 5-10 years (high-quality carbon molecular sieves can last 10+ years).

- Control Systems: PLC and sensors need to be regularly calibrated to ensure accurate adsorption timing.

The focus of membrane separation system maintenance is:

- Membrane Module Protection: Core maintenance involves pre-filtration systems (three-stage filtration) to prevent oil and particulate contamination of the membrane fibers.

- Heating System: Pre-heaters for the membrane should be regularly checked to ensure stable intake temperature.

- Membrane Performance Testing: Membrane separation efficiency should be tested annually, and when performance declines by more than 15%, replacement should be considered (normal lifespan 5-10 years).

In terms of system lifetime, PSA systems have a main structure that can last over 20 years with periodic consumable replacements, while membrane systems may experience gradual performance degradation after 5 years, with membrane module replacement costs being high (approximately 40%-60% of initial investment).

4.3 Full Lifecycle Cost Analysis

Considering a 10-year usage cycle, the cost structure of the two technologies differs:

- PSA systems: Higher initial investment (especially for high-purity systems), but operating costs increase gradually. Under high-purity (>99.9%) applications, PSA offers significant overall cost advantages, with large flow systems benefiting from economies of scale.

- Membrane separation systems: Lower initial investment, but high membrane module replacement costs. Economic efficiency is better for low-purity (<99%) and medium-small flow scenarios.

MINNUO provides a professional nitrogen generation lifecycle cost analysis tool to help customers accurately calculate based on specific parameters (purity, flow rate, energy prices, etc.) and make the optimal investment decision.

5. FAQ

Question 1: I need nitrogen with 99.9% purity, which technology should I choose?

- PSA technology is the preferred choice for applications requiring purity above 99.9%. While membrane separation systems can theoretically reach this purity, they require more membrane modules and higher air pressure, which increases equipment size and cost.

Question 2: Is there a significant difference in investment costs between the two technologies?

- Cost differences depend on system scale and purity requirements:

- For small to medium-sized equipment (<100Nm³/h, 95%-99% purity): Membrane systems typically have a 20%-30% lower initial cost.

- For large high-purity equipment (>200Nm³/h, >99.9% purity): PSA systems are more cost-effective, as membrane systems require more investment to reach the same purity. MINNUO recommends evaluating total cost of ownership (TCO) over a 10-year period, including energy and maintenance expenses.

Question 3: Which type of equipment is more energy-efficient?

- Membrane separation systems are typically 15%-30% more energy-efficient at the same gas production volume due to the absence of pressure cycle energy consumption. However, note that:

- Membrane systems have energy advantages primarily in the 95%-99% purity range.

- PSA systems perform better in terms of energy efficiency in high-purity (>99.5%) applications.

- Specific energy savings depend on intake conditions and system design.

Question 4: How often do the membrane modules of a membrane separation nitrogen generator need to be replaced?

- The lifespan of membrane modules is typically 5-10 years, depending on:

- Air quality: Oil vapor is the biggest threat, requiring strict filtration (oil content < 0.01ppm).

- Operating conditions: High temperatures accelerate aging, avoid exceeding 50°C.

- Usage patterns: Continuous operation results in a longer lifespan than intermittent use. Membrane modules should be replaced when performance drops by 30% or cannot be restored by cleaning.

Question 5: Is PSA nitrogen generation more prone to failure?

- PSA systems have a slightly higher failure rate due to moving parts (valves) and a complex control system compared to the fully static membrane system. However, modern PSA technology has greatly improved reliability:

- High-quality valves can last up to one million cycles.

- PLC control systems have self-diagnostic functions.

- The dual-tower redundancy design ensures continuous supply. MINNUO PSA systems have an average Mean Time Between Failures (MTBF) of over 30,000 hours.

Question 6: How does startup speed affect production?

- Membrane separation systems start almost instantly (<1 minute), making them suitable for intermittent operations (such as shift production). PSA systems typically require 15-30 minutes to reach stable purity, making them more suited for continuous operations in factories. MINNUO offers a quick startup PSA option (<5 minutes), but with additional investment.

Question 7: What type of air pre-treatment is required for both technologies?

- Both technologies require strict pre-treatment:

- Three-stage filtration: Particles (1μm), oil mist (0.01ppm), and activated carbon for oil gas removal.

- Drying system: Pressure dew point of 3-7°C (to prevent moisture from affecting the separation medium).

- Membrane systems are more sensitive to oil and require extra protection. MINNUO recommends using a “1+1” redundant filtration configuration for safety.

Question 8: How should I choose the technology based on flow rate needs?

- <100 Nm³/h: Membrane systems are more economical for medium to small flows.

- 100-1000 Nm³/h: Choose based on purity requirements; PSA for high purity, membrane for medium-low purity.

1000 Nm³/h: PSA systems are better for large flows.

Question 9: Does space limitation affect the choice of technology?

- Yes:

- Membrane systems are compact modular designs, occupying 40%-60% less space and being more than 50% lighter than PSA systems, making them ideal for space-constrained environments.

- PSA systems require dual adsorption towers and buffer tanks, taking up more space. MINNUO offers containerized PSA solutions to optimize space utilization.

Question 10: How can I assess the feasibility of technology upgrades?

- MINNUO offers professional evaluation services:

- Gas audit: Analyze current nitrogen usage, purity, and pressure requirements.

- On-site survey: Assess space, power, and gas source conditions.

- TCO simulation: Compare 10-year costs for different technologies.

- Pilot testing: Provide rental equipment for on-site testing. Upgrades should consider pipeline modifications, control system integration, and other engineering factors.

5. MINNUO Solutions

As an internationally leading nitrogen generation solutions provider with over 30 years of professional experience, MINNUO offers a full range of nitrogen generation equipment and customized services for global customers:

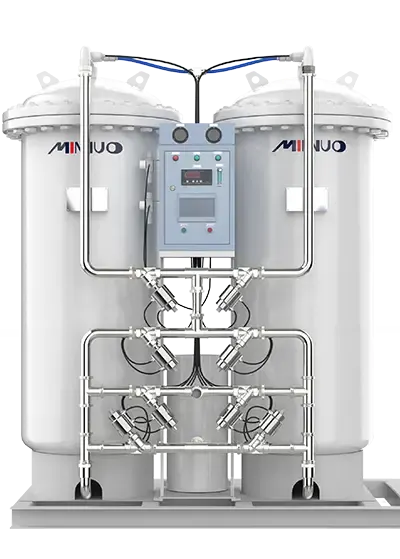

6.1 PSA Nitrogen Generation System Product Advantages

- Intelligent control: Equipped with an AI optimization system to adjust adsorption cycles in real time, saving more than 15% in energy.

- Modular design: Supports a flow range of 20-5000 Nm³/h, with parallel expansion.

- High purity guarantee: 99.9995% ultra-high purity models meet electronic-grade standards.

- Reliable components: Uses international brand molecular sieves (Clariant, Zeochem) and high-lifetime valves (SMC, Burkert).

- Remote management: Integrated IoT module for global remote monitoring and warnings.

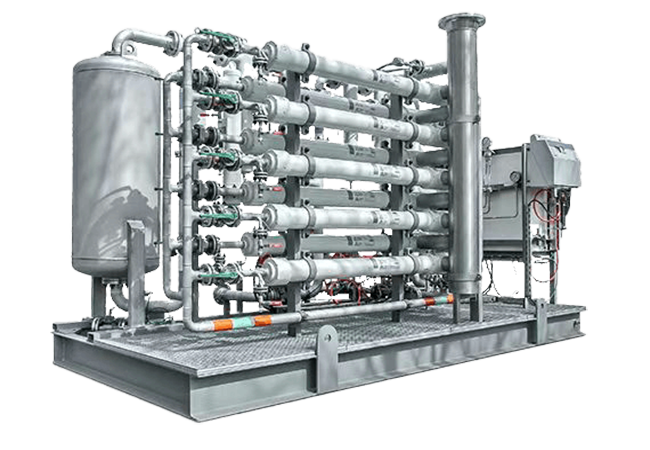

6.2 Membrane Separation Nitrogen Generation System Core Features

- High-efficiency membrane components: Uses Hollow Fiber series membranes, improving anti-pollution performance by 30%.

- Lightweight and compact: M-SKID series with flow rates up to 1000 Nm³/h, suitable for container integration.

- Energy-saving design: Energy consumption is 10% lower than industry standards, with patented flow path design reducing pressure loss.

- Plug and play: Pre-assembled system, saving 70% installation time on-site.

- Wide temperature adaptability: Stable operation in temperatures ranging from -20℃ to 50℃, suitable for extreme climates.

6.3 Full Lifecycle Service System

MINNUO provides professional services covering the full lifecycle of equipment:

- Design stage: Free gas audit and solution optimization to ensure system matches actual needs.

- Installation and commissioning: Certified global engineers on-site, with operator training.

- Operations and maintenance support: Predictive maintenance systems, consumable replacement reminders, and remote fault diagnosis.

- Upgrades and retrofits: System performance enhancement services, including control system updates and component replacements.

- Nitrogen guarantee: Backup equipment rentals and emergency on-site support.

7. Conclusion

Whether you need a high-purity PSA system or a compact membrane separation unit, MINNUO provides reliable, efficient, and economical solutions. Visit MINNUO’s official website for a free nitrogen generation solution consultation or schedule a factory gas audit service to explore your energy-saving potential!

sales2:+86 17506119168

sales2:+86 17506119168